Patents

Literature

53results about How to "Save R&D costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

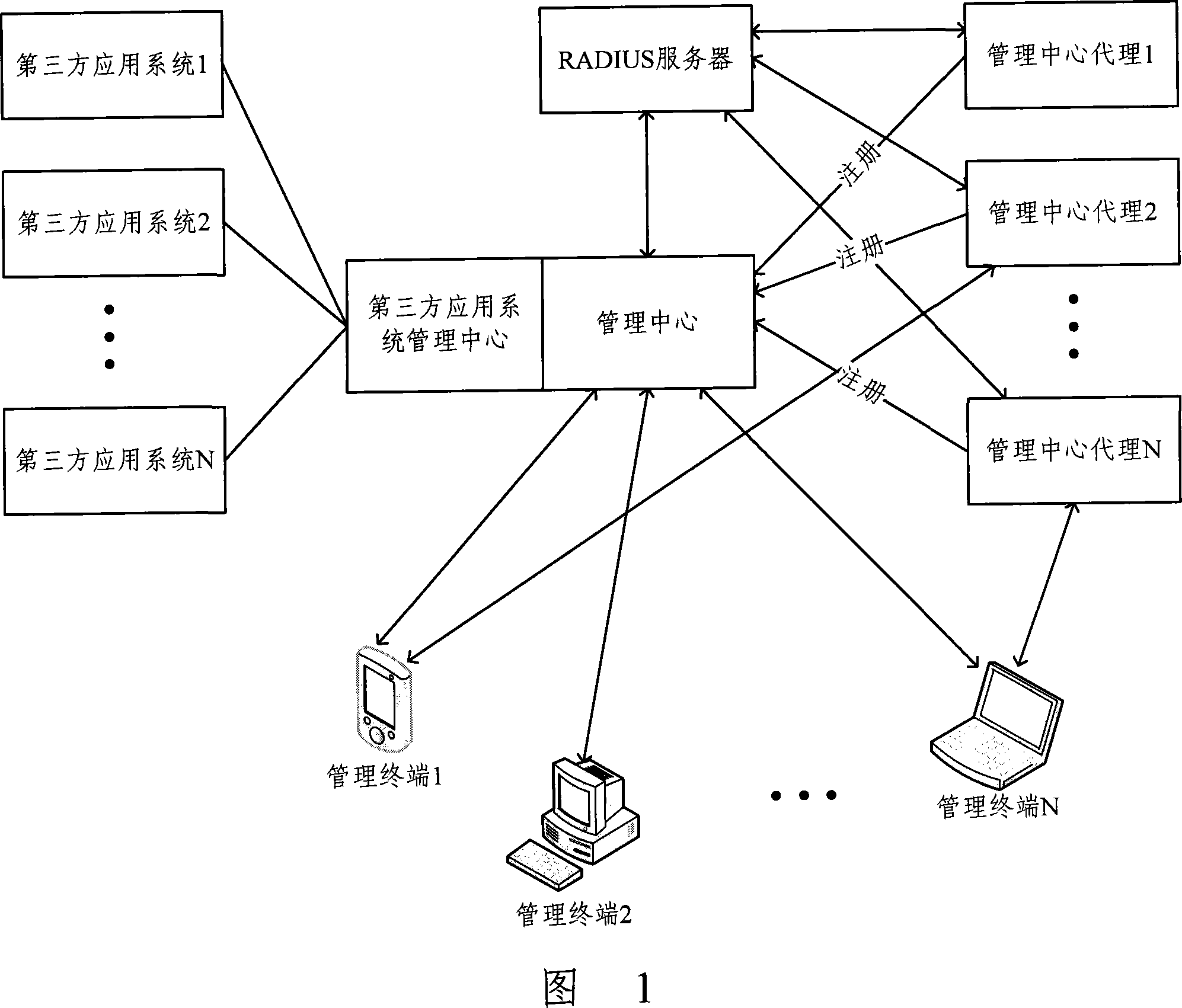

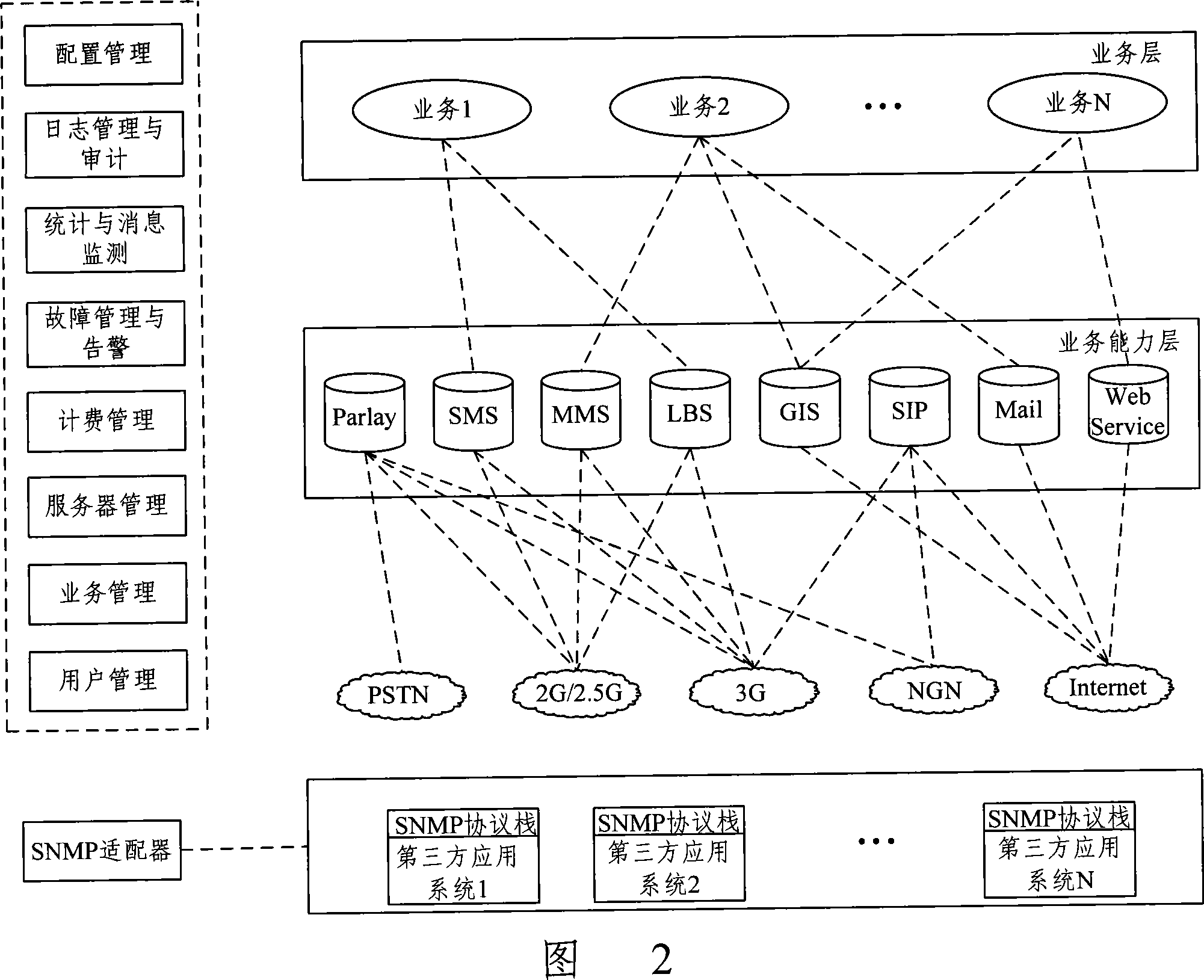

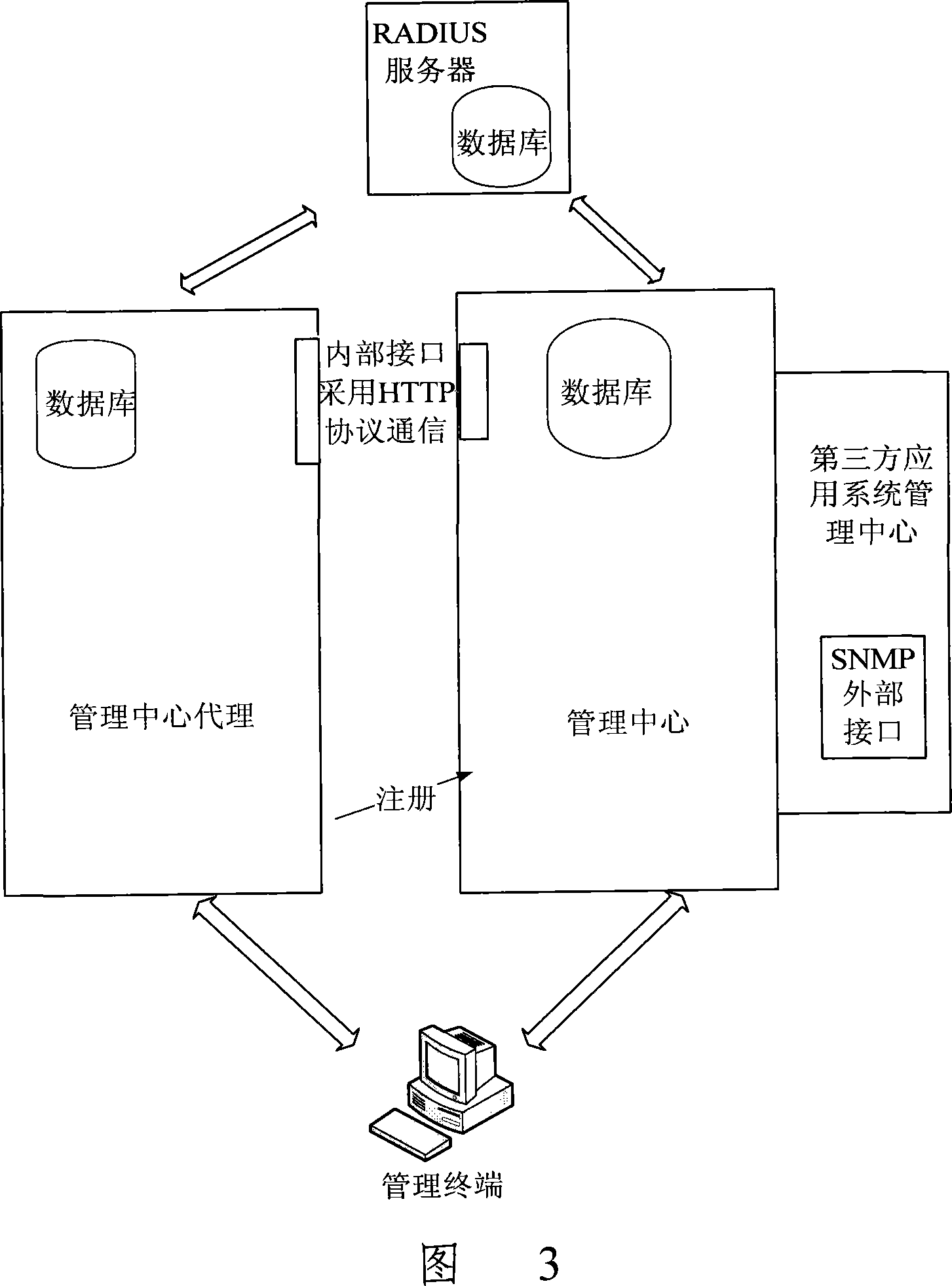

JMX based network service management method and its application system

InactiveCN101072129AAvoid complicated settingsAchieve intelligenceData switching networksSelection arrangementsThird partySystems management

Using administrator - agent mode, the system can carries out distribution type management for multiple telecom services and service capabilities across platforms. Logging on management center (MC) in the method, management terminal (MT) configures global basic settings of system. Being registered on MC, agent of MC is managed by MC. Based on command of MT, MC carries out managing one or more functions of resources of each server in system by calling each agent of MC. Based on call from MC, each agent of MC executes managing operations, and feeds back accomplishing situation to MT. MC is possible to be integrated to application system in third party. Application system includes MC, MC of application system in third party, at least one agent of MC, and at least one MT. Advantages are: supporting multiple kinds of user interface, and unified charging for services.

Owner:BEIJING UNIV OF POSTS & TELECOMM

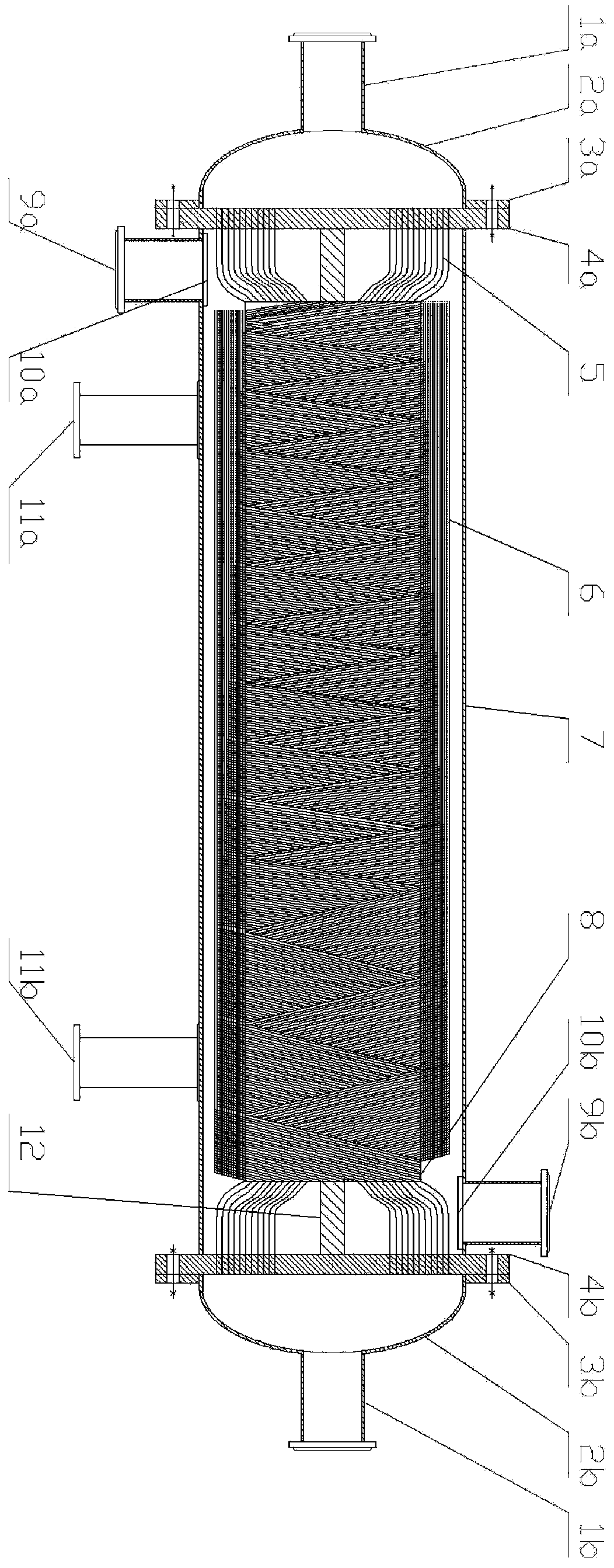

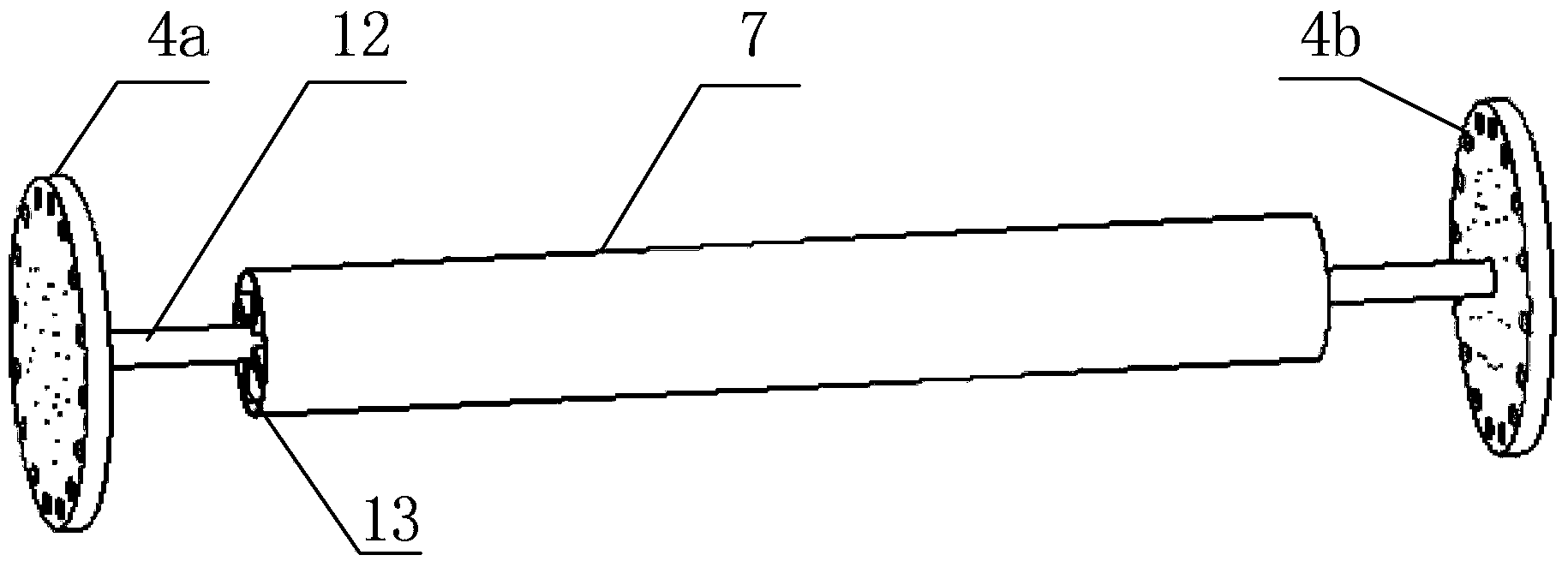

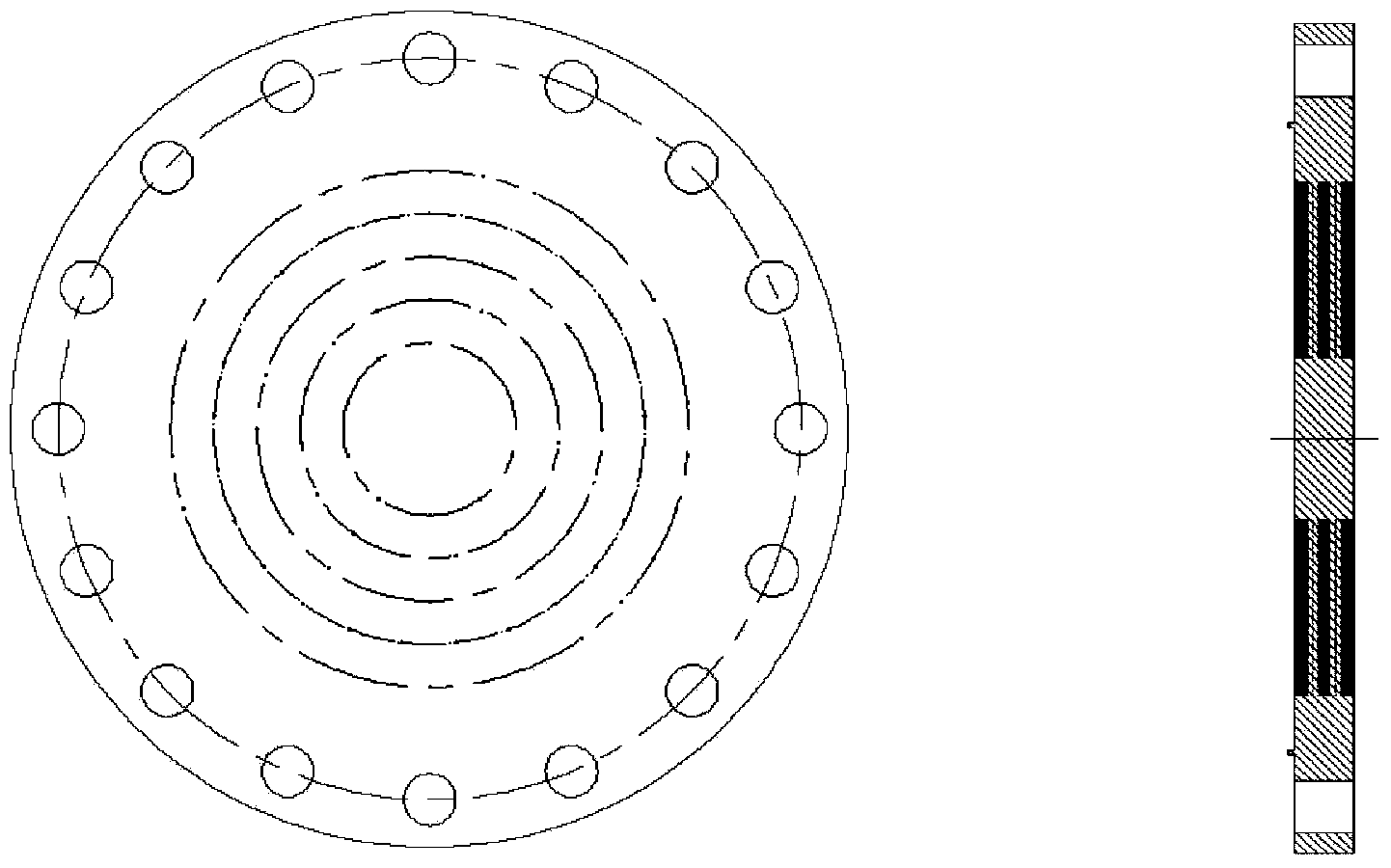

Novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes

ActiveCN104258796APrecisely control the feeding ratioPrevent "overheating"Chemical/physical/physico-chemical processesCapillary TubingEngineering

The invention relates to the technical field of the design of chemical reactors and discloses a novel high-throughput micro-channel reactor provided with multiple layers of spirally winding tubes. The reactor mainly comprises reactant inlet and outlet sections, inlet and outlet glands, flanges, inlet and outlet tube plates, stainless steel capillary tubes, a fixed pad strip, a drum, a winding drum, constant-temperature medium inlet and outlet sections, baffles, left and right supports, a central support tube and a support piece, wherein two ends of the central support tube are connected with the inlet and outlet tube plates, and the winding drum and the central support tube are located on a same axis and welded and connected through the support piece; the stainless steel capillary tubes spirally wind around the winding drum in a multi-layer manner, spiral directions of adjacent winding layers are opposite, multiple reaction tube bundles which take the winding drum as the circle center and have different circle diameters are formed, and two ends of each stainless steel capillary tube are connected onto the inlet and outlet tube plates respectively; the inlet and outlet glands are connected with the inlet and outlet tube plates respectively through the flanges. The reactor has the advantages of high throughput, high heat transfer capacity, high synthetic rate, safety, high efficiency, low machining cost, capability of realizing continuous production, easiness in parallel enlargement and the like.

Owner:NANJING UNIV OF TECH

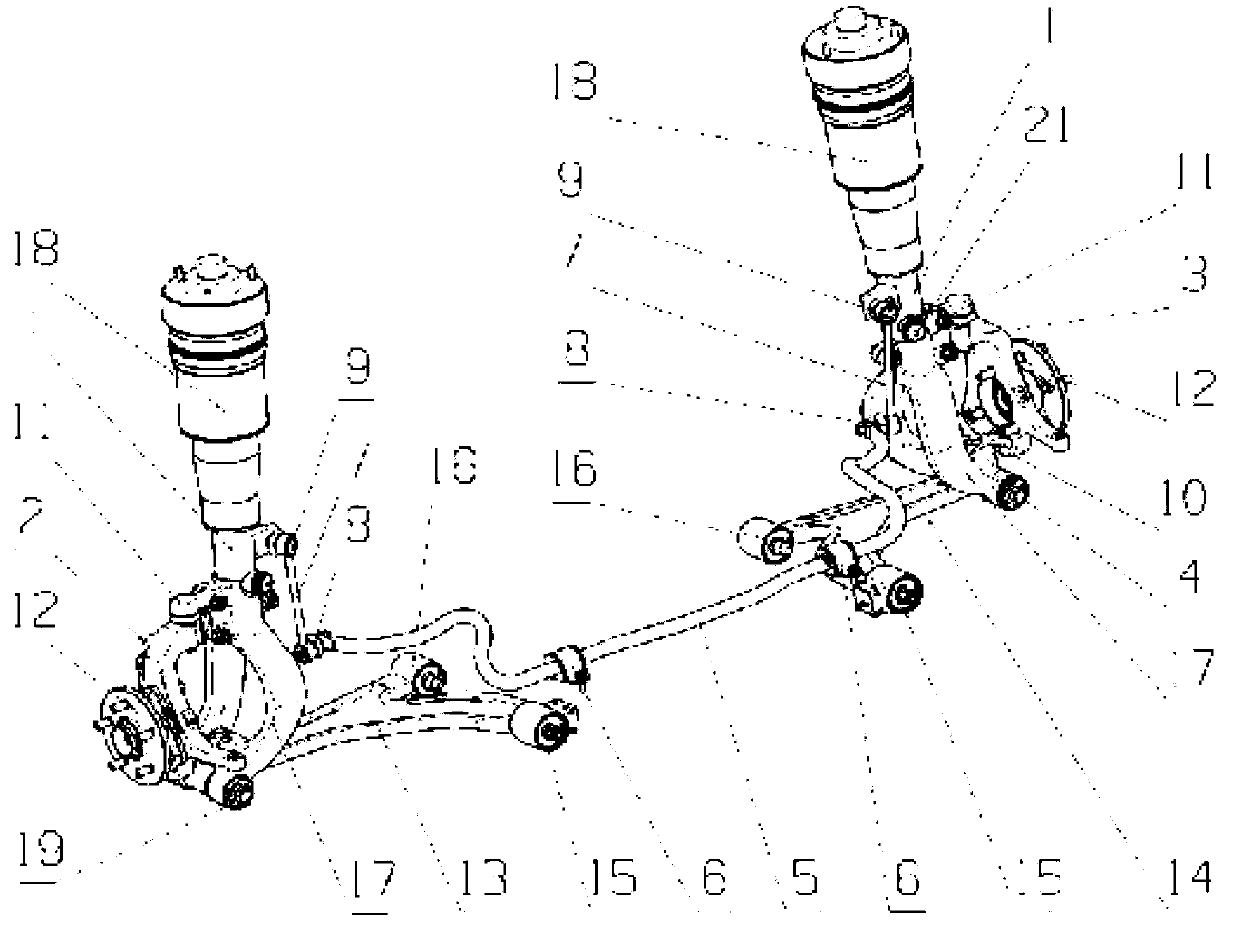

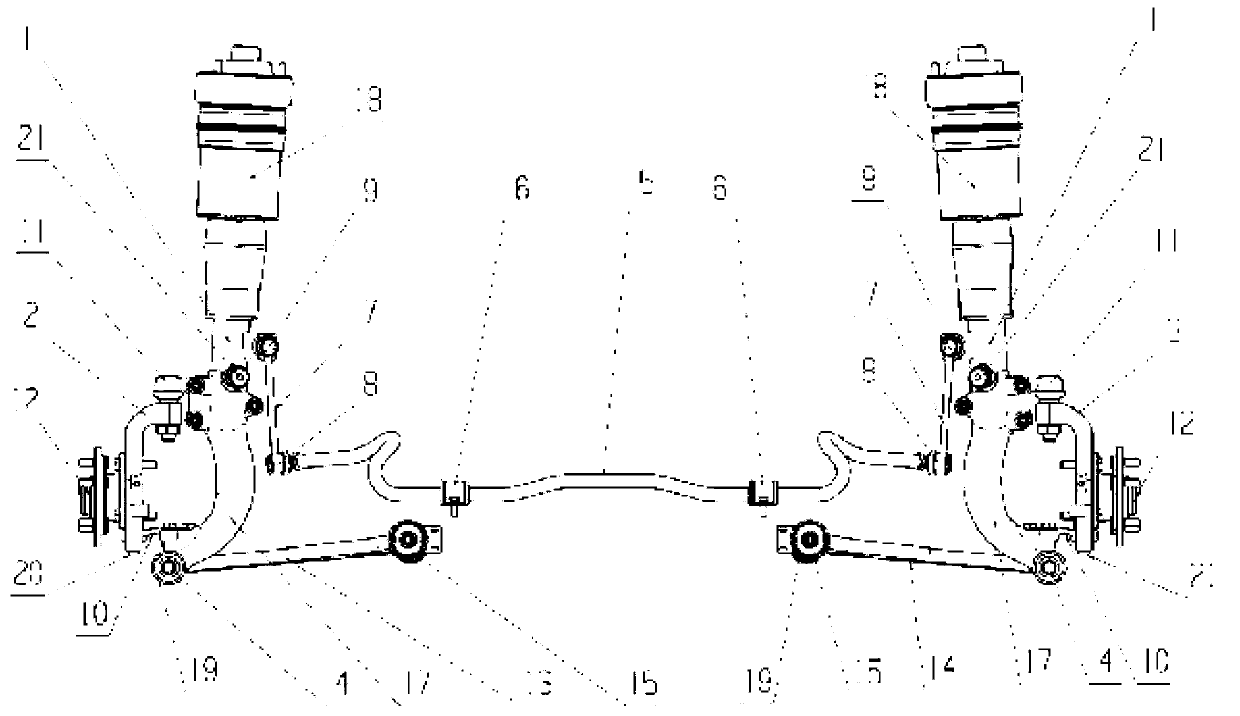

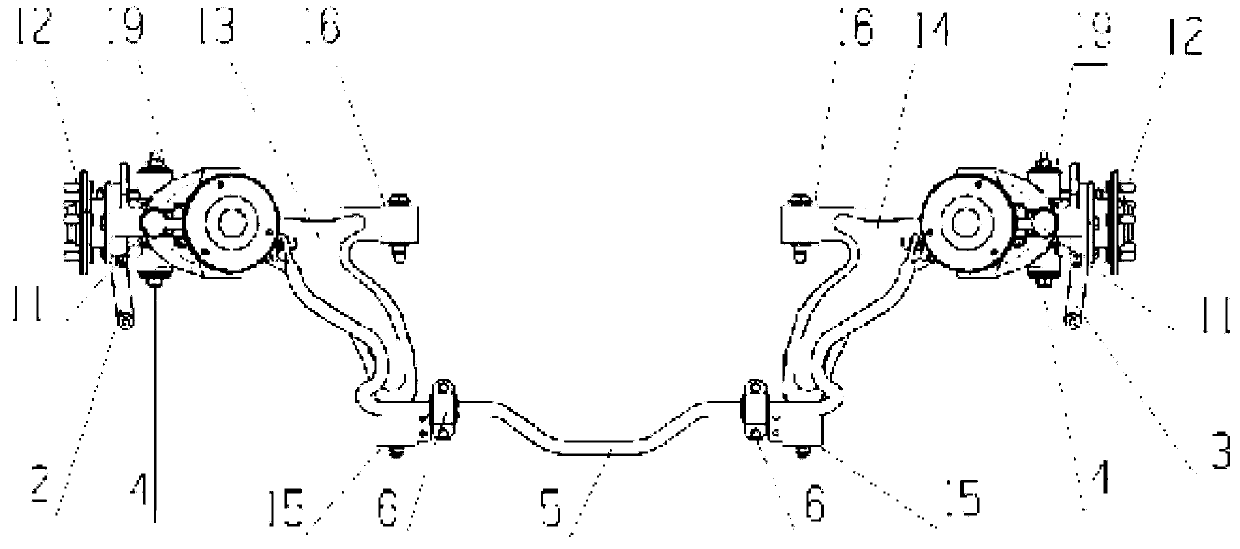

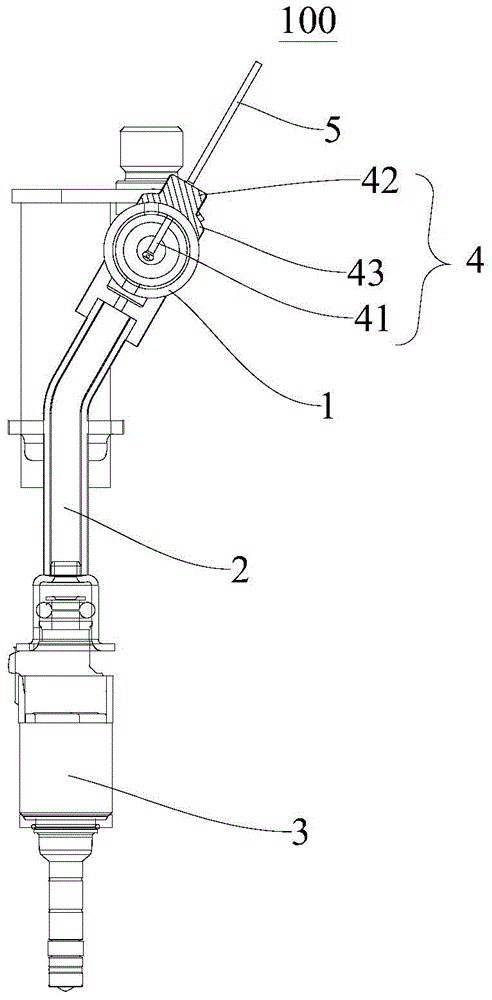

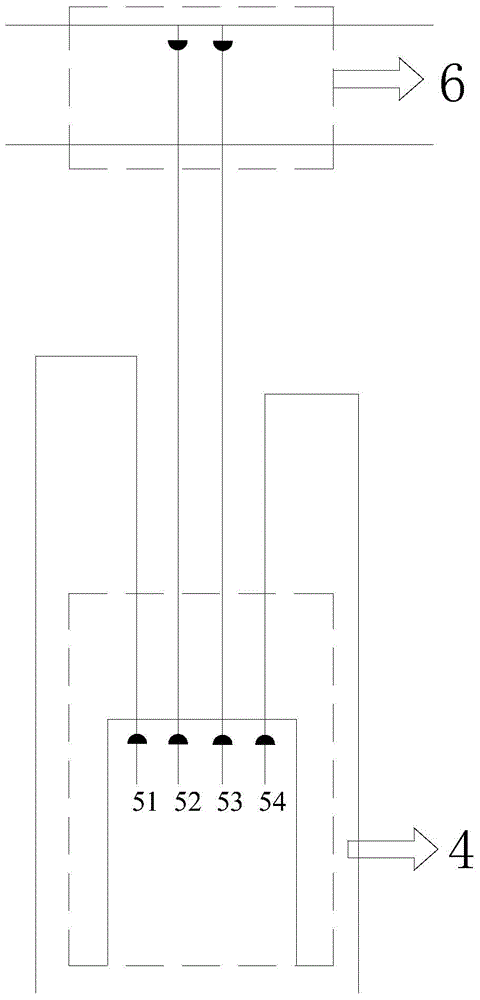

MacPherson air suspension and assembly method thereof

InactiveCN103121387ACompact structureSmall footprintSteering linkagesResilient suspensionsAir springClassical mechanics

A MacPherson air suspension comprises a cross stabilizer bar, two strut assemblies arranged on the left side and the right side of the cross stabilizer bar, a left steering knuckle, a right steering knuckle, a left lower suspension arm, a right lower suspension arm and a left-right stabilizer bar connection push rod connecting the cross stabilizer bar and the strut assemblies. Each strut assembly comprises a front shock absorber and an air spring assembly integrated on the front shock absorber, and the front shock absorber is fastened with the lower support of the front shock absorber through bolts. The upper ends of the left steering knuckle and right steering knuckle are respectively connected with the upper portion of the lower support of the front shock absorber through ball pin fittings, the lower portions of the left steering knuckle and right steering knuckle are connected with shaft sleeve connection plates of the steering knuckles through shaft pins and are connected with the lower portion of the lower support of the front shock absorber through the shaft sleeve connection plates, and the left steering knuckle and right steering knuckle respectively form an integrated frame structure with the lower support of the front shock absorber. The central connection line of the ball joints of the ball pin fittings and the shaft sleeves of the shaft sleeve connection plates of the steering knuckles is a main pin axis a. The MacPherson air suspension can meet the requirements of an automobile under various loading conditions, and ideal comfortable ride comfort can be obtained.

Owner:柳州孔辉汽车科技有限公司

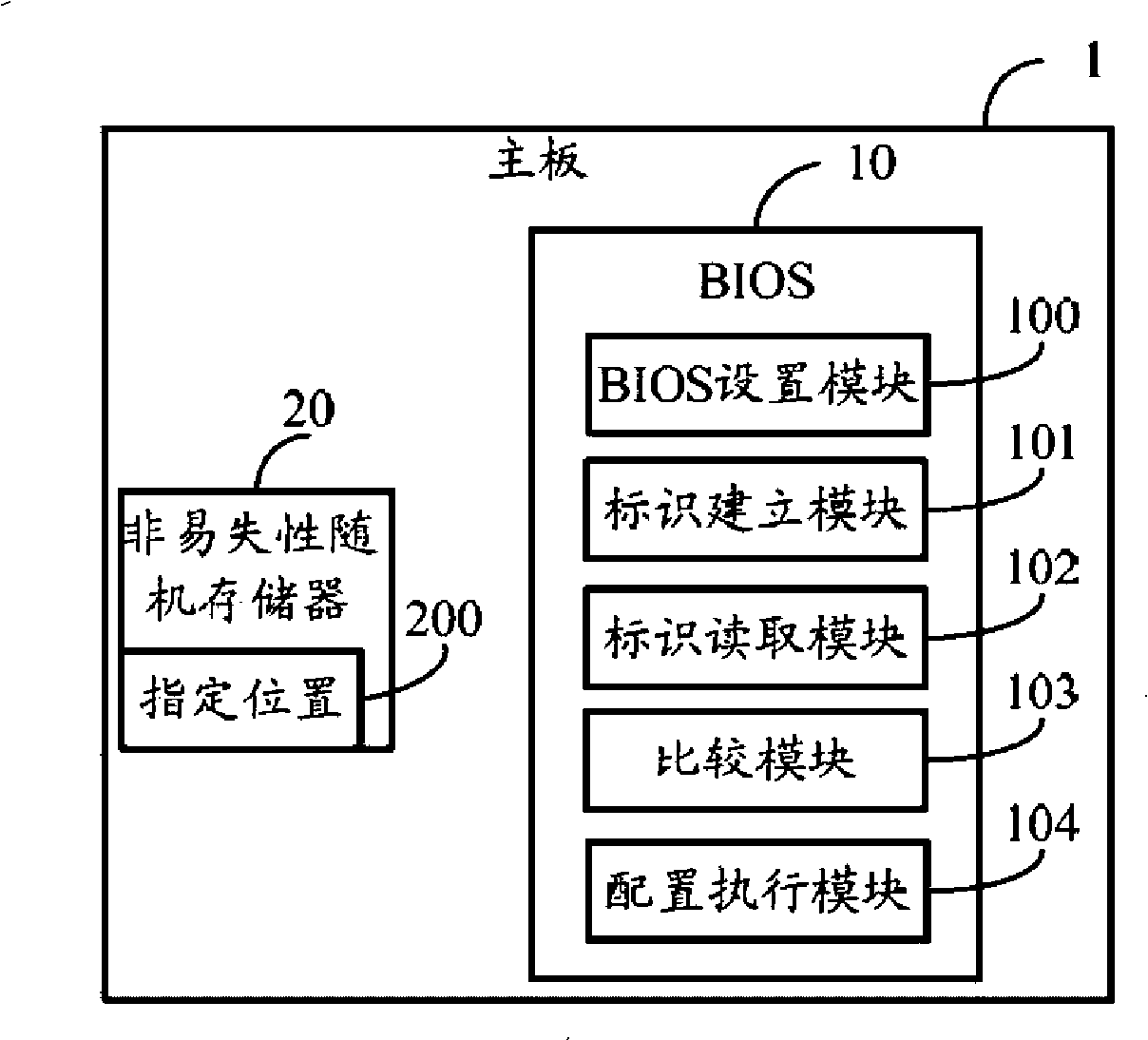

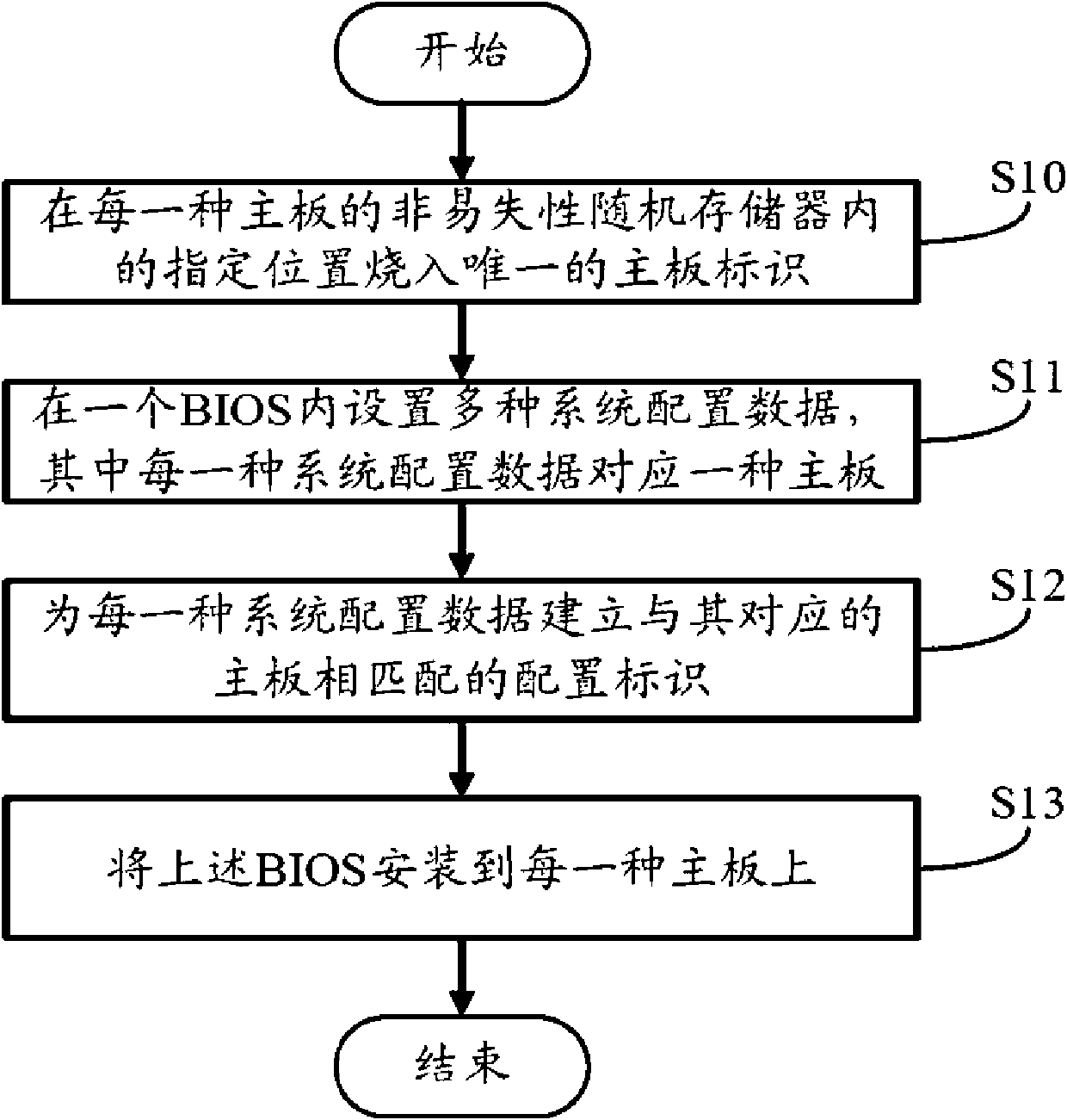

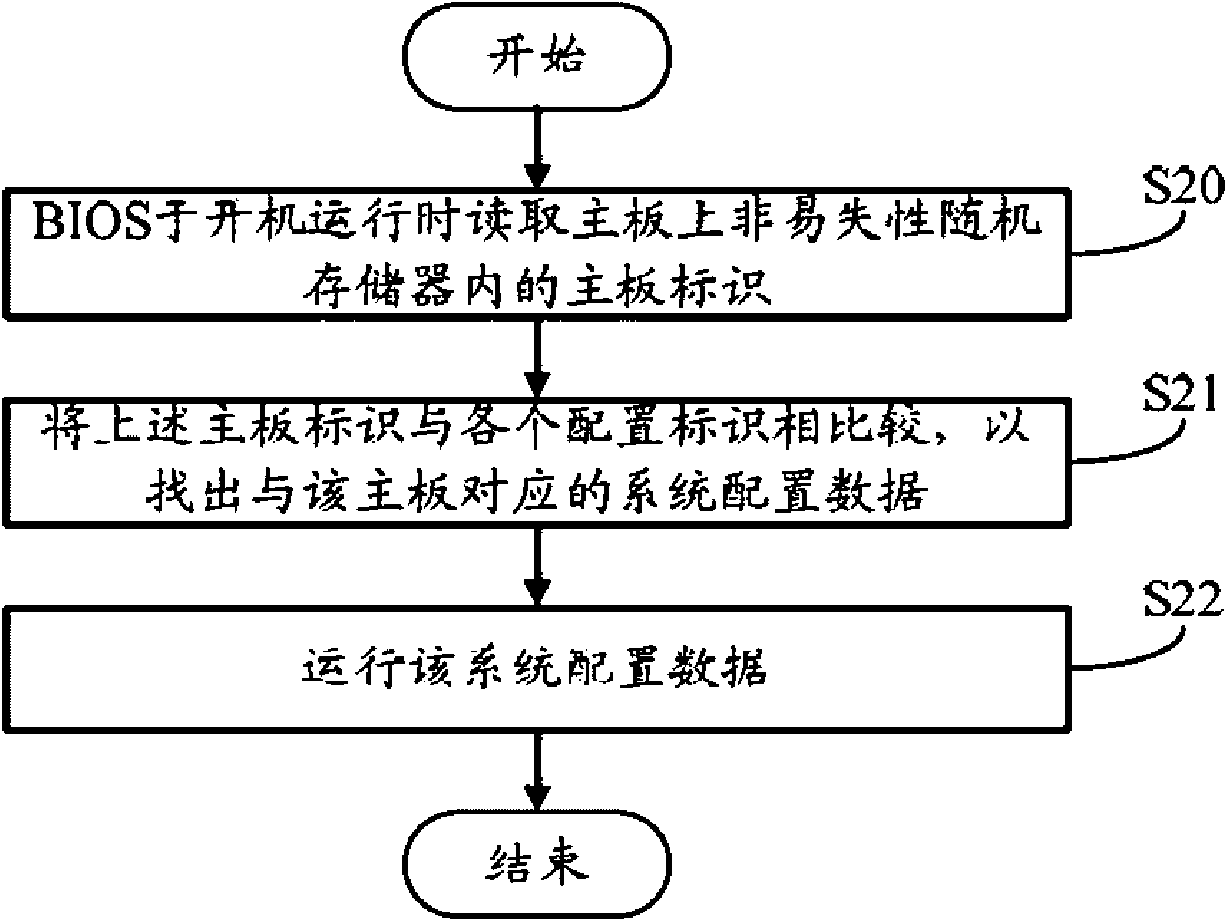

System and method for sharing same BIOS (Basic Input Output System) for different mainboards

InactiveCN102023875ASave R&D cycleSave R&D costsProgram loading/initiatingSystem configurationNon-volatile random-access memory

The invention discloses a system and a method for sharing the same BIOS (Basic Input Output System) for different mainboards. Each mainboard is respectively provided with a NVRAM (Non Volatile Random Access Memory) and BIOS, wherein the NVRAM internally stores the mainboard mark of the mainboard, and various types of system configuration data is arranged in the BIOS. Each type of system configuration data corresponds to one mainboard and needs one configuration mark to be built; the configuration mark of each type of system configuration data is matched with the mainboard mark of the corresponding mainboard. When the BIOS operates, the mainboard mark is read from the NVRAM, and the read mainboard mark is compared with the configuration mark of each type of system configuration data to obtain the system configuration data corresponding to the mainboard so as to perform the obtained system configuration data. The invention also provides a relevant method. The same BIOS can be applied for different mainboards by setting the mark.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

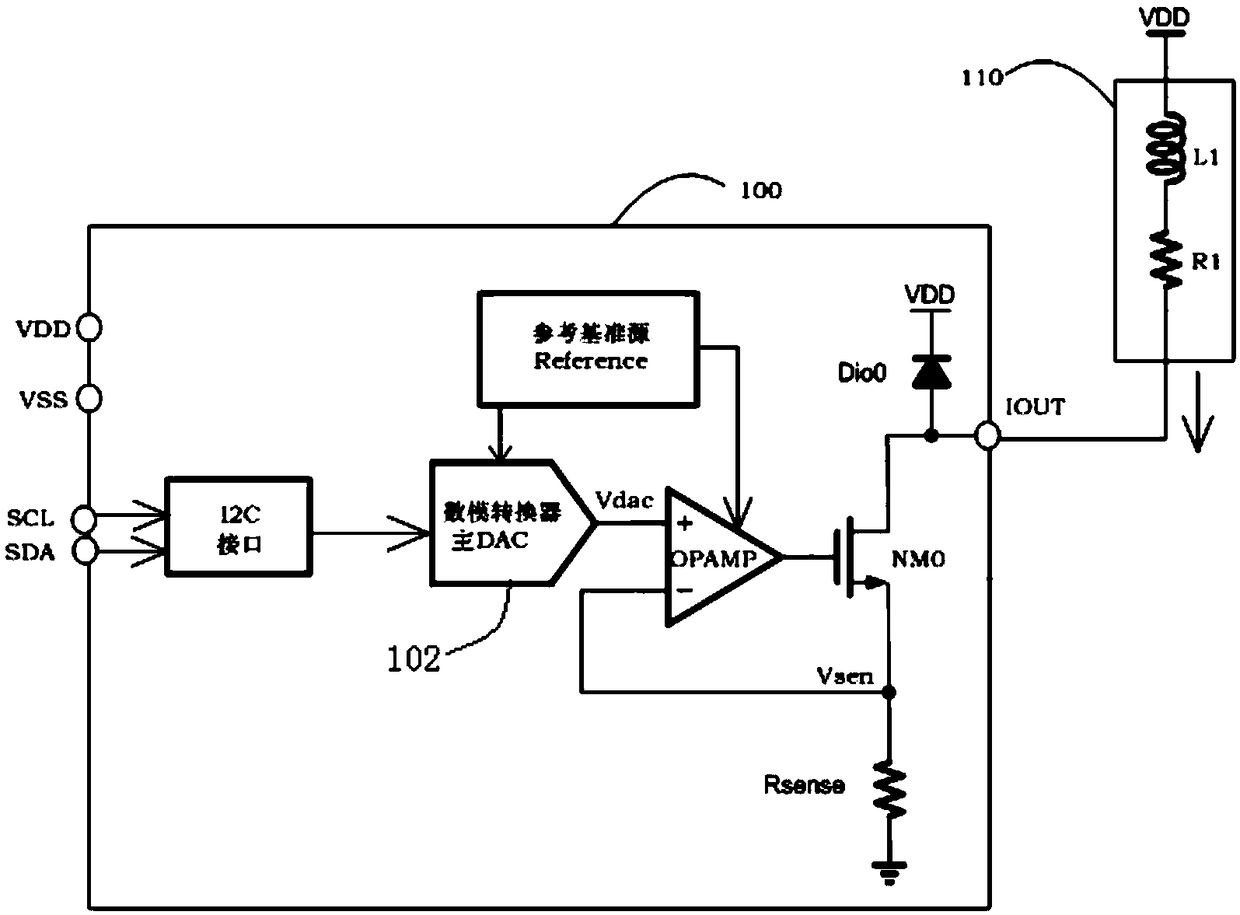

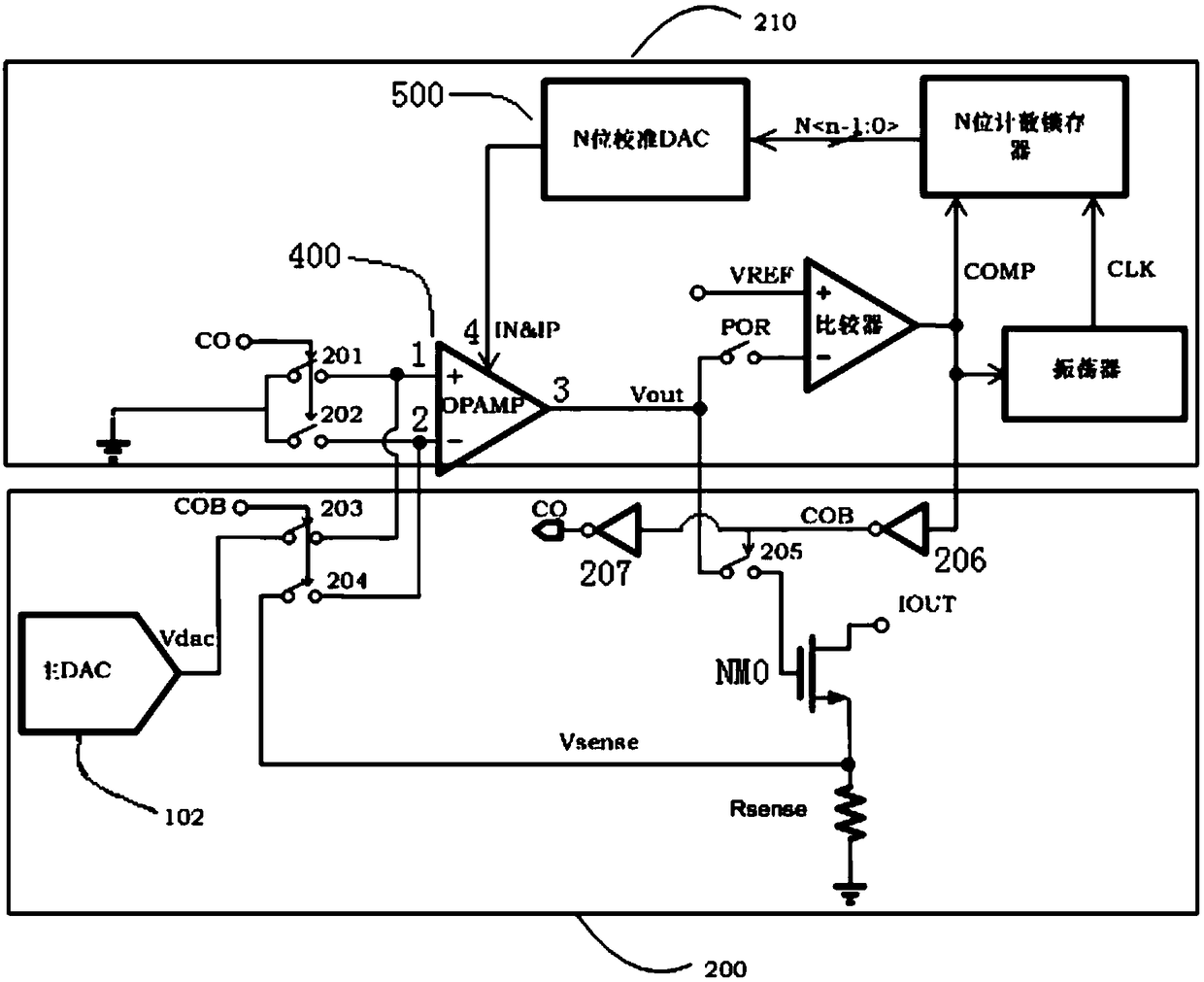

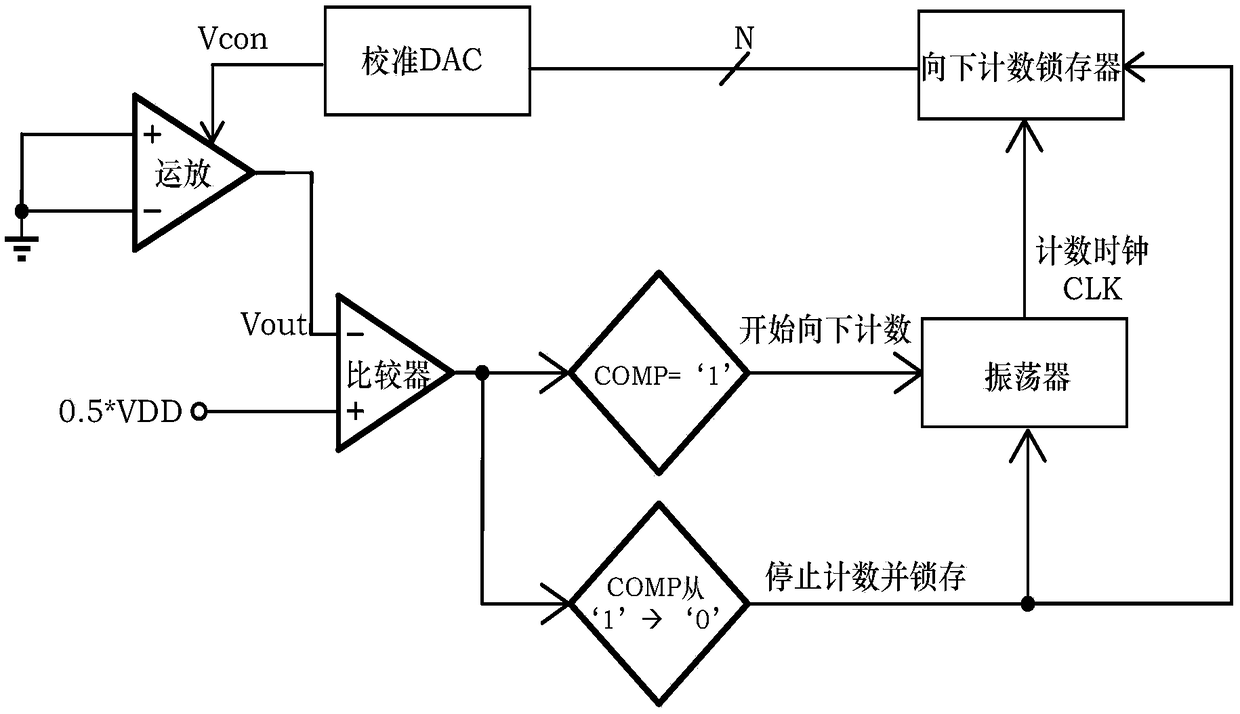

Operational amplifier offset self-calibration circuit applied to voice coil motor driver chip

ActiveCN108718196AIncrease development costsIncreased cost of testingPower saving provisionsElectric signal transmission systemsDigital analog converterOffset calibration

The invention discloses an operational amplifier offset self-calibration circuit applied to a voice coil motor driver chip. The operational amplifier offset self-calibration circuit comprises an operational amplifier (OPAMP), a counting latch, a comparator, an oscillator and a digital analog converter for calibration (DAC), wherein the output end of the OPAMP is connected with the negative pole input end of the comparator; the output end of the comparator is connected with the input end of the oscillator and one input end of the counting latch; the output end of the oscillator is connected with another input end of the counting latch; the output end of the counting latch is connected with the input end of the DAC for calibration; the output end of the DAC for calibration is connected witha signal feedback end of the OPAMP; and the input end and the output end of the OPAMP are further respectively connected with the voice coil motor driver chip. The offset of the OPAMP can be eliminated or greatly decreased, the accuracy of output current of the motor driver chip is improved, the service time of the system battery is prolonged, and the condition that the chip development and test cost is increased due to offset calibration by using a fuse wire is avoided.

Owner:武汉韦尔半导体有限公司

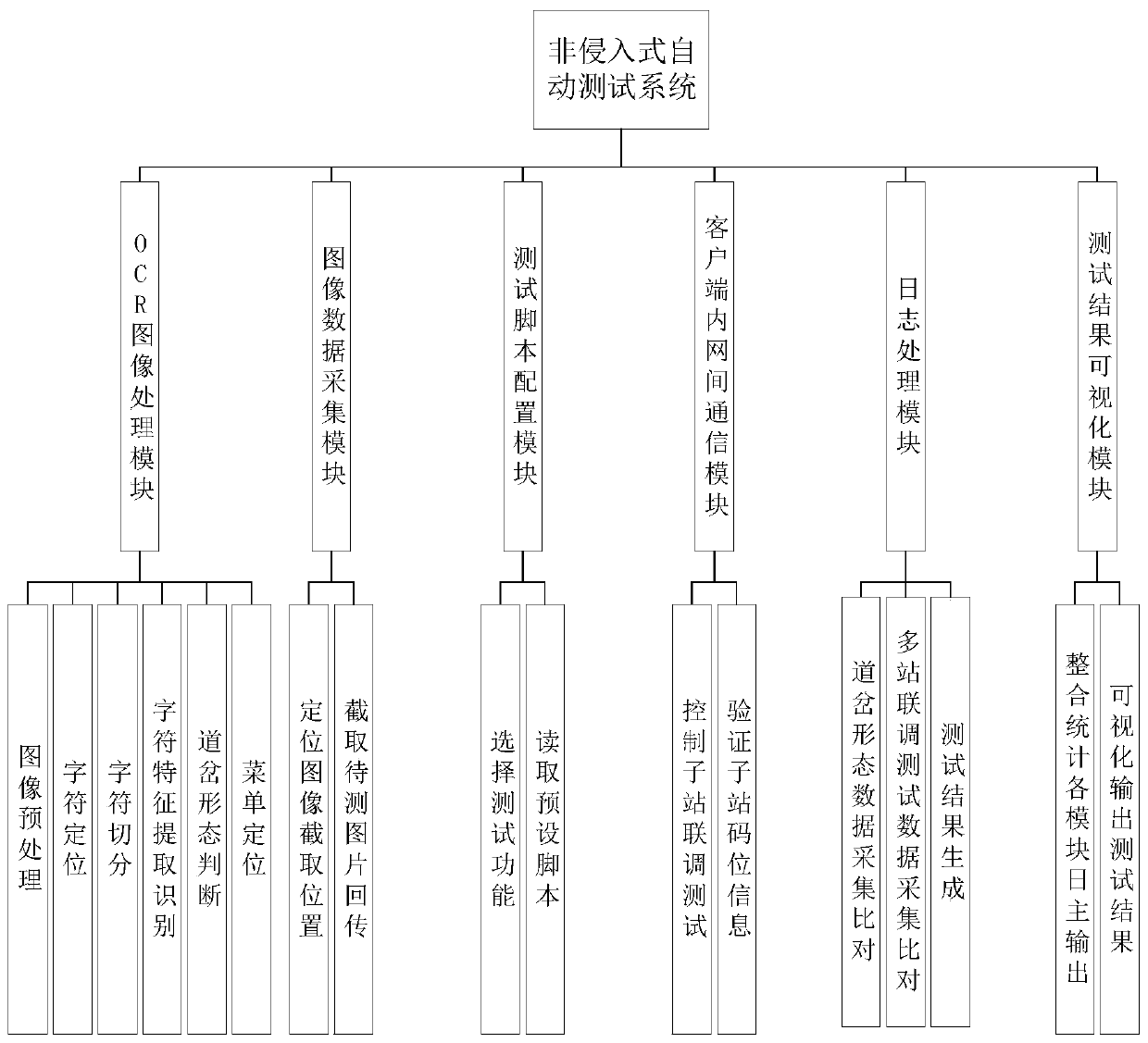

Non-invasive automatic test system for subway signal system test software

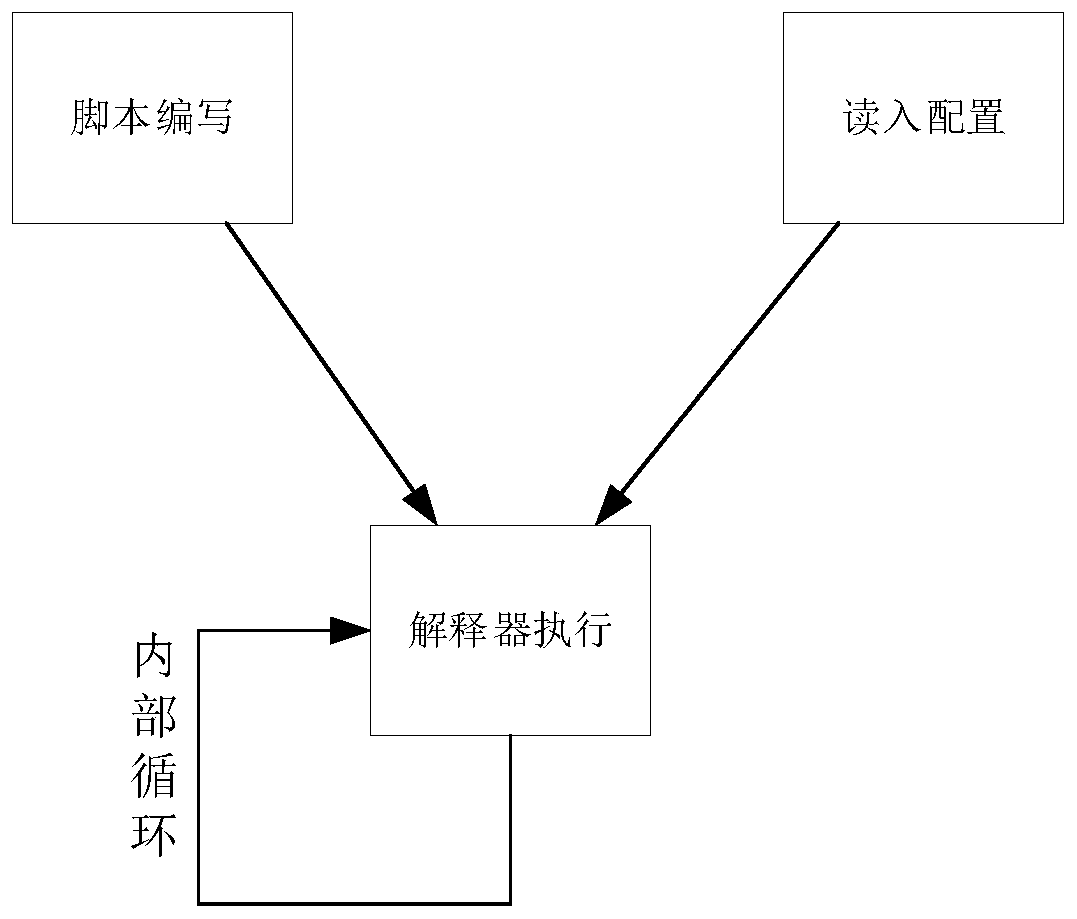

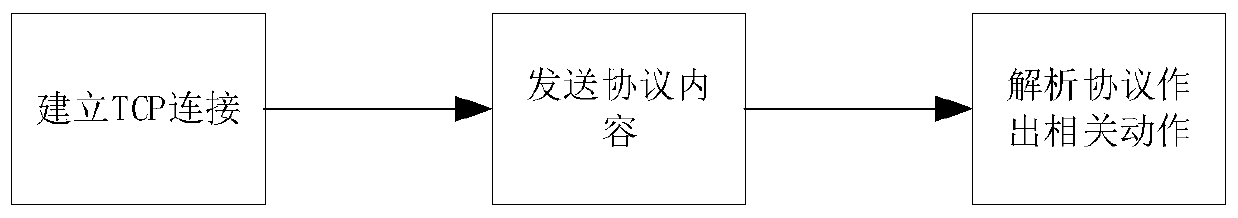

ActiveCN111290955AReduce in quantityThe testing process is simpleSoftware testing/debuggingCharacter recognitionTestwareTest script

The invention relates to a non-invasive automatic test system for subway signal system test software, and the system comprises an OCR image processing module which is used for recognizing and processing the information in a subway signal system test software interface; an image data acquisition module which is used for monitoring and acquiring a to-be-processed picture with test interested information in the graphical interface of the subway signal system test software in real time; a test script configuration module which is used for setting a test process; a client intranet inter-network communication module which is used for meeting the multi-machine linkage test requirement; a log processing module which is used for performing test logic comparison; and a test result visualization module which is used for visualizing the output result of the test logic. Compared with the prior art, the method has the advantages that the problems that subway signal system testing software depends too heavily on testing personnel and does not support automatic testing are solved, improvement of full automation of subway signal system testing is facilitated, promotion of the automation process ofa subway is facilitated, and the development and testing cost is reduced.

Owner:CASCO SIGNAL

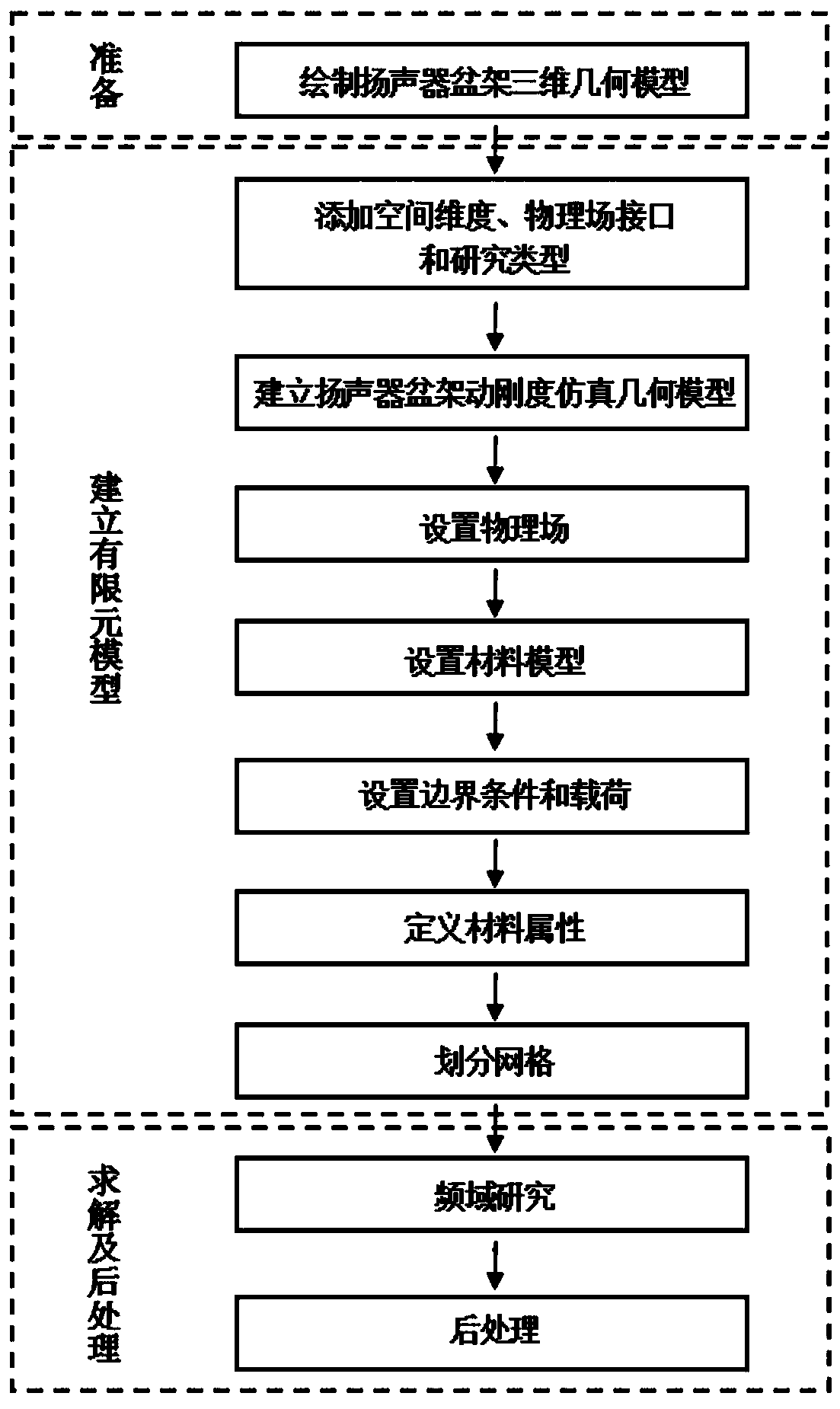

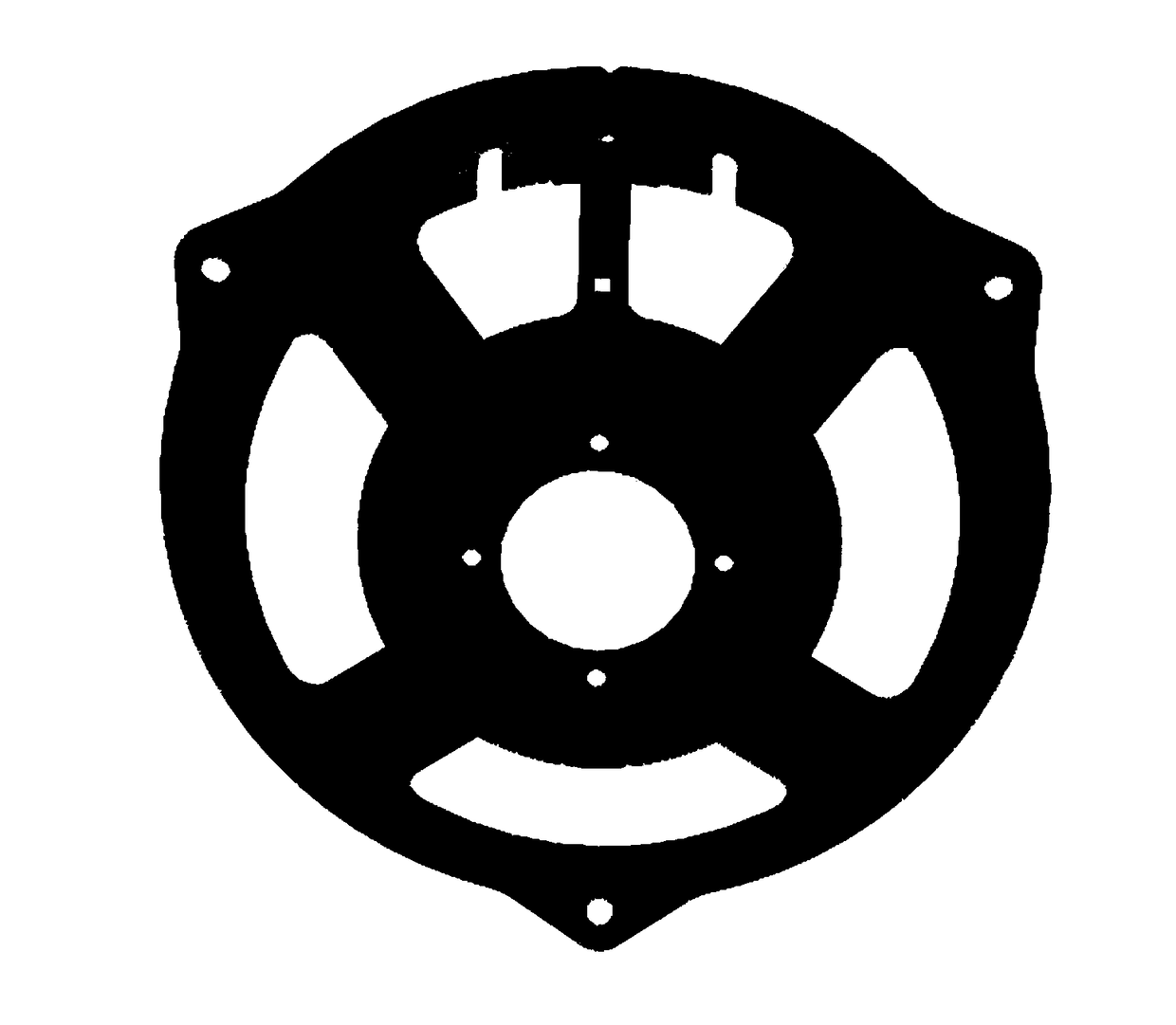

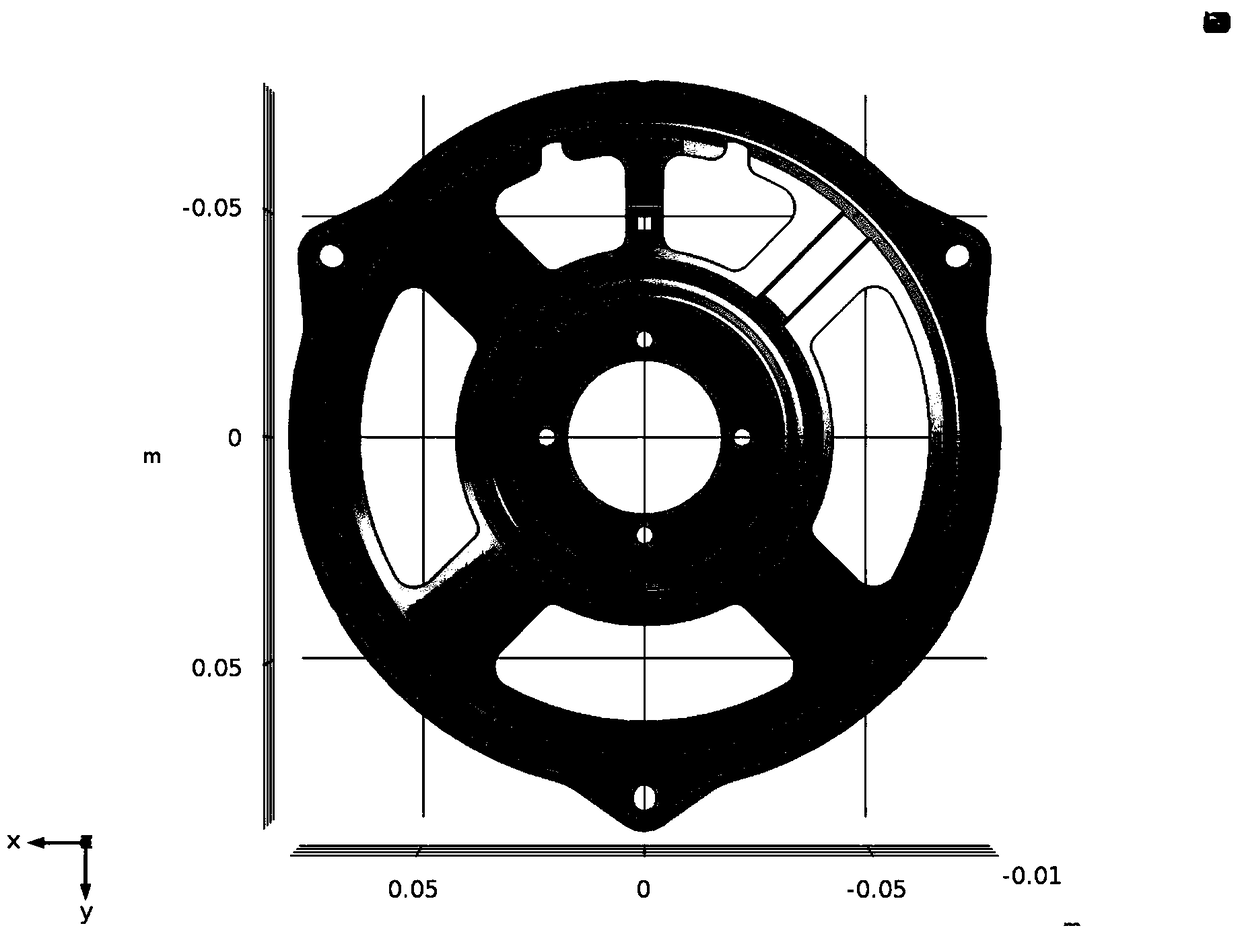

Numerical simulation analysis method for dynamic stiffness of loudspeaker basin stand

ActiveCN109362020AImprove design efficiencySave R&D costsDesign optimisation/simulationNon-planar diaphragms/conesElement modelPhysical field

The invention provides a numerical simulation analysis method for dynamic stiffness of a loudspeaker basin stand. The method comprises the steps of firstly building a finite element simulation model comprising the sub-steps of 1, adding a physical field and a research type; 2, building a geometrical model of the loudspeaker basin stand; and 3, setting the physical field; setting an elastic material model, damping, a constraint condition and a loading force in a solid mechanics physical field; 3, setting a material parameter; and 4, setting grid types and sizes, and dividing grids to generate afinite element model; then solving the finite element model by using a frequency domain analysis method; and at last, performing postprocessing to acquire a change relationship of the dynamic stiffness of the loudspeaker basin stand along with frequency. A distribution diagram of the stress, strain and displacement on the basin stand and frequency responses of the displacement amplitude, speed amplitude and acceleration amplitude of any point on the basin stand also can be acquired under the sinusoidal loading effect at any frequency.

Owner:ZHEJIANG ELECTRO ACOUSTIC R&D CENT CAS +1

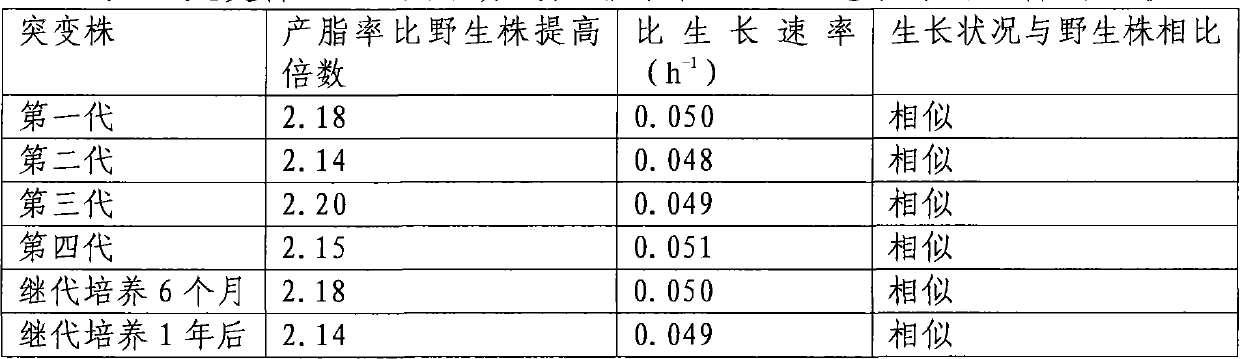

Chlorella mutant strain and application thereof

ActiveCN102888347AAvoid interferenceAvoid blindnessUnicellular algaeMutant preparationMicroorganismMicrobial oil

The invention relates to a chlorella mutant strain which is bred and used for producing single-cell grease and biodiesel and application thereof. The chlorella mutant strain is collected in CGMCC (China General Microbiological Culture Collection Center) on May 27, 2011, and the collection number is CGMCC No.4917. The chlorella mutant strain is a single-cell grease high-fat mutant strain and can be widely applied to the biodiesel production technology.

Owner:YANTAI INST OF COASTAL ZONE RES CHINESE ACAD OF SCI

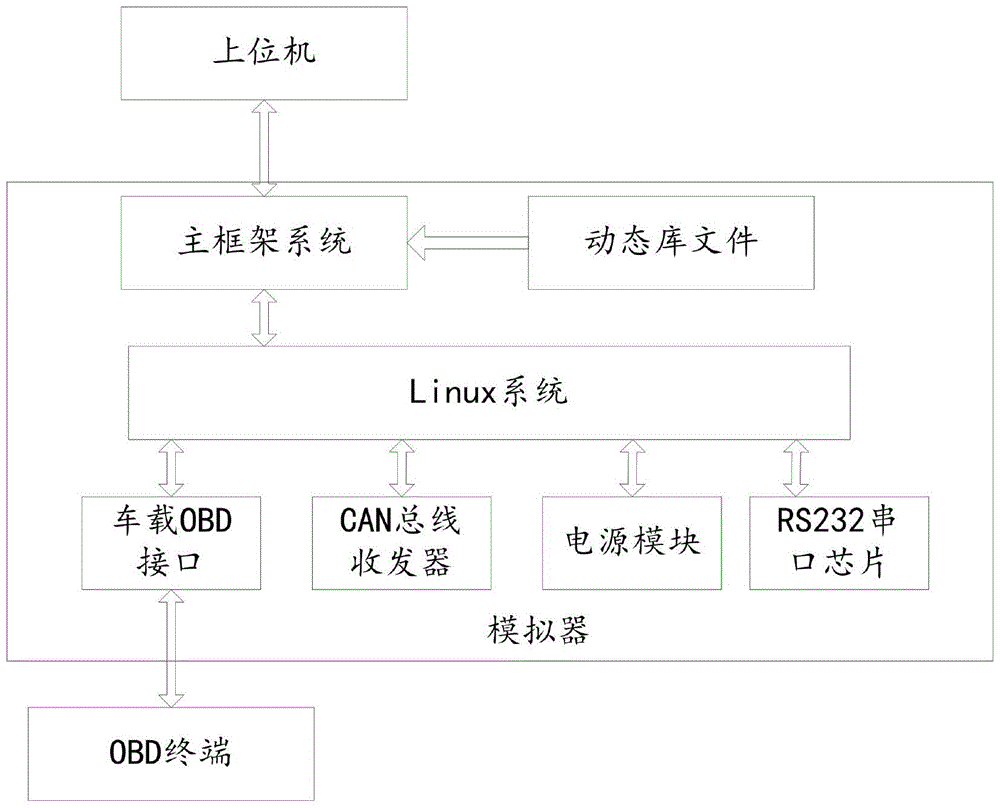

Multi-vehicle-model simulation system based on Linux dynamic link library and working method thereof

The invention provides a multi-vehicle-model simulation system based on a Linux dynamic link library and a working method thereof. The multi-vehicle-model simulation system comprises an upper computer, a simulator and an OBD terminal. The simulator is respectively connected with the upper computer and the OBD terminal. The simulator comprises a CAN bus transceiver, a vehicle-mounted OBD interface, a power supply module, an RS232 serial port chip, a Linux system, a main frame system and a dynamic library file. The Linux system is respectively connected with the CAN bus transceiver, the vehicle-mounted OBD interface, the power supply module, the RS232 serial port chip and the main frame system. The main frame system is also connected with the dynamic library file. Dependence of the OBD terminal product on a real vehicle in the test phase can be solved, and the requirement of testing multiple vehicle models in the office can be realized.

Owner:DALIAN ROILAND SCI & TECH CO LTD

Engine

ActiveCN104405549AReduced precision requirementsSave R&D costsFuel injection apparatusMachines/enginesFuel oilCarbon deposition

The invention discloses an engine. The engine comprises a fuel oil guide rail, a plurality of connecting pipes, a plurality of fuel oil sprayers, a plurality of fuel oil spraying detection devices, a plurality of fuel oil heating devices, and a controller; the fuel oil sprayers are connected to the fuel oil guide rail respectively through the connecting pipes; the fuel oil spraying detection devices are used for detecting working states of the fuel oil sprayers; the fuel oil heating devices are arranged corresponding to the connecting pipes respectively; each fuel oil heating device comprises a heater component and a driver; each heater component comprises a temperature detection module and a heater; and the controller is connected with the fuel oil spraying detection devices and the fuel oil heating devices of the engine. The engine can reduce the phenomena that fuel oil wets a wall, and engine oil is diluted; the combustion process of the engine is more sufficient, and the generation of carbon deposition and hydrocarbon emissions are reduced; and the heat efficiency of the engine is improved, and meanwhile oil consumption is reduced.

Owner:GREAT WALL MOTOR CO LTD

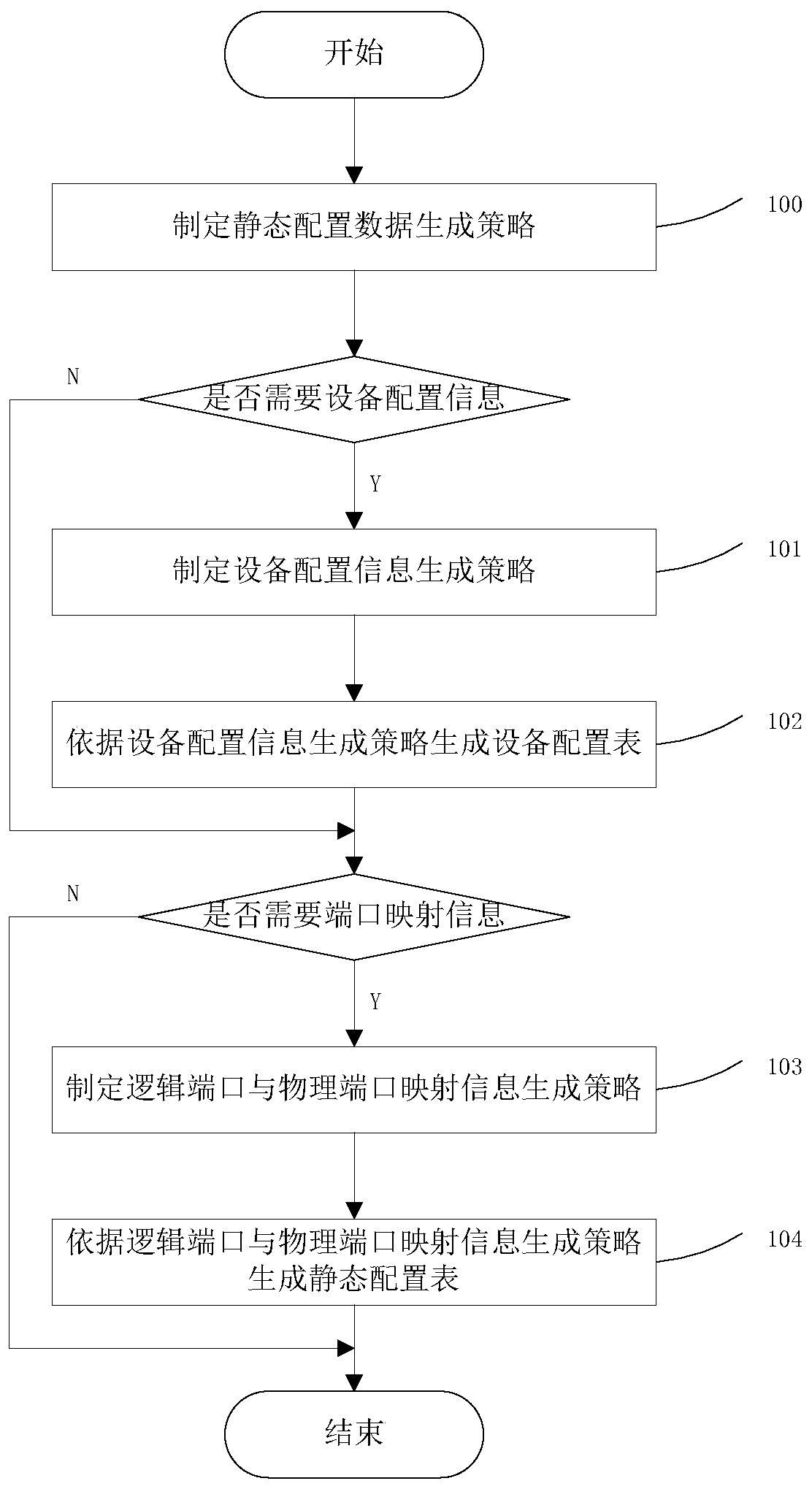

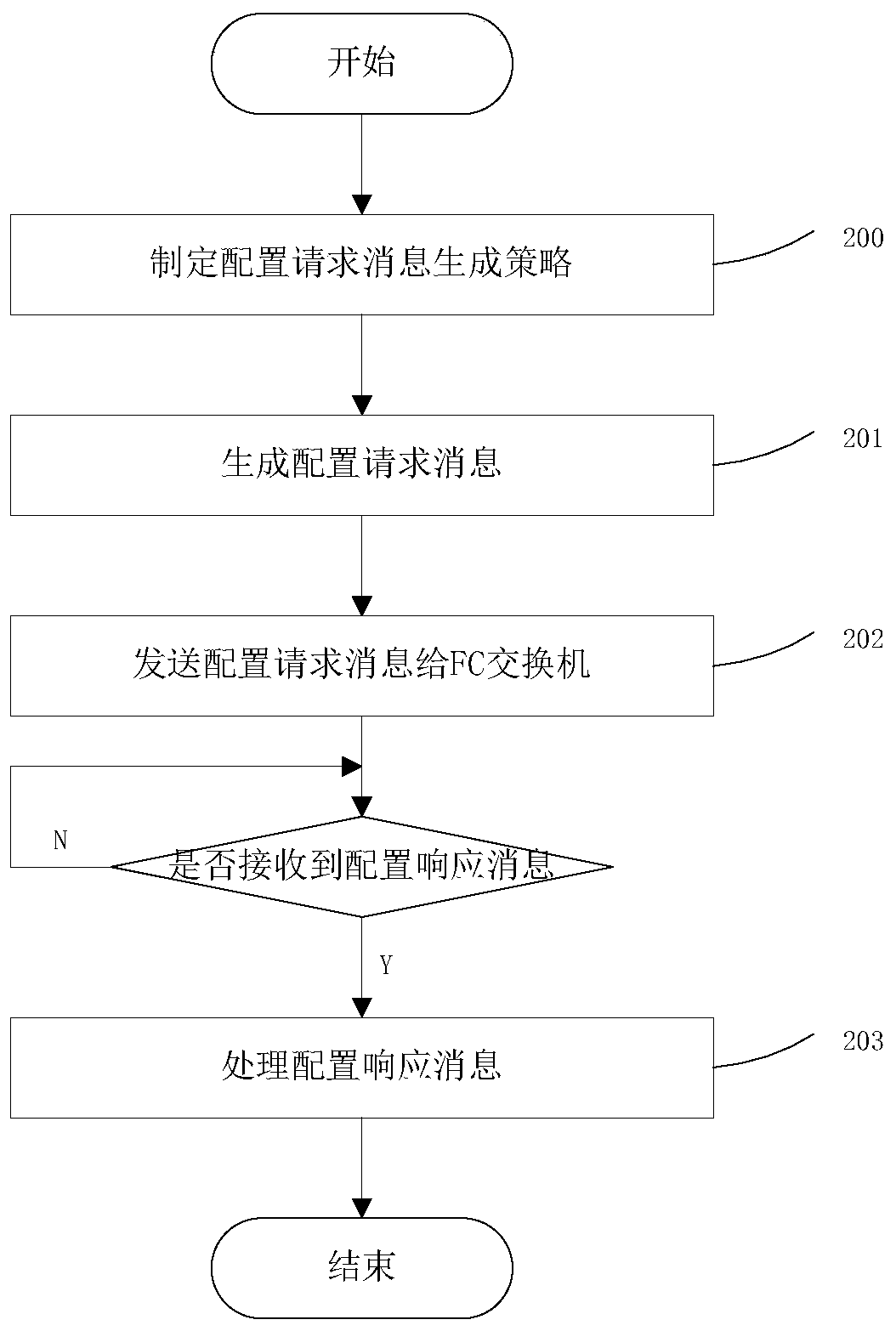

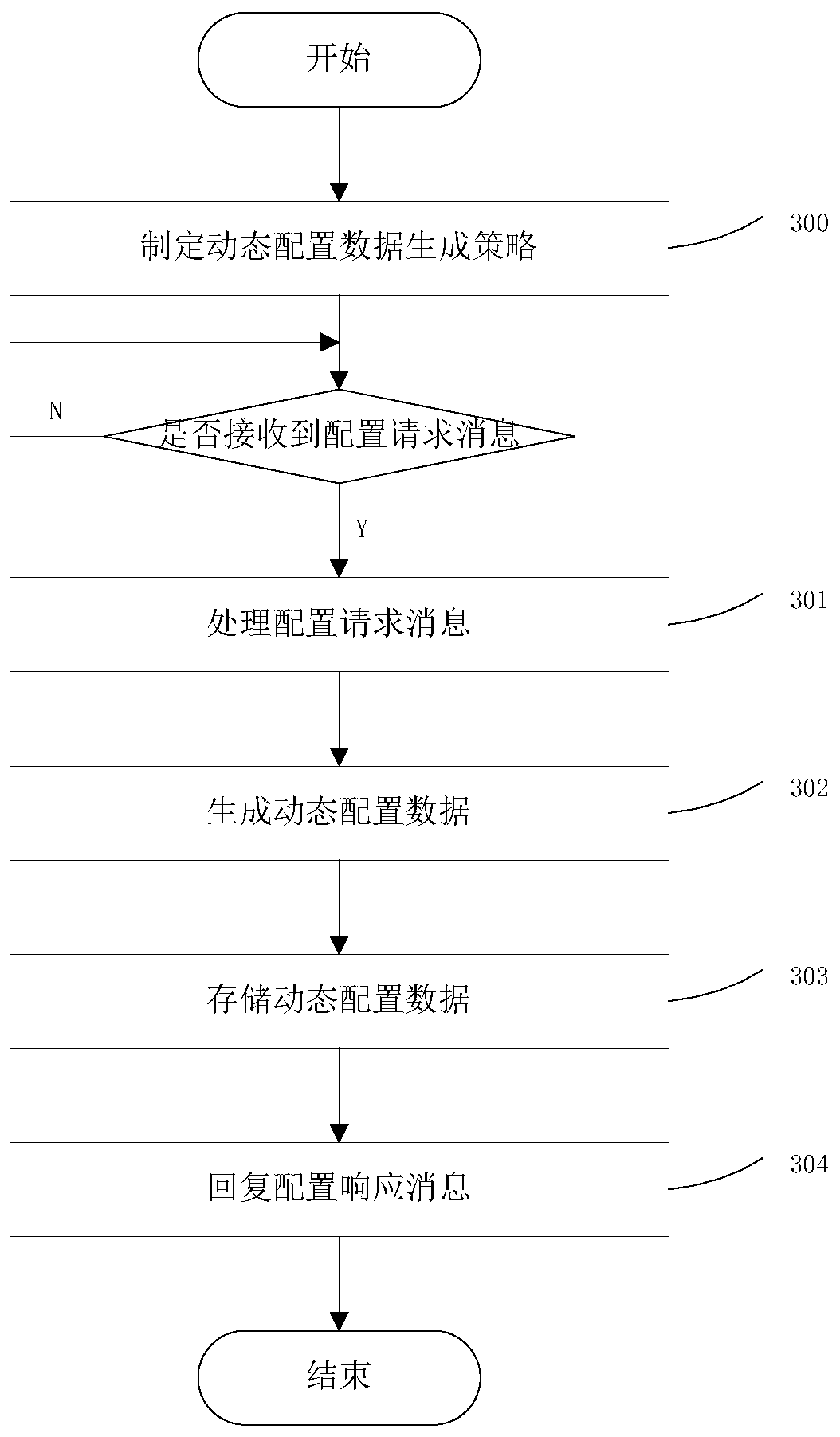

Implementation method for dynamic configuration of optical fiber channel switch

ActiveCN110166857ASave labor costSave R&D costsMultiplex system selection arrangementsData switching networksComputer scienceFibre Channel switch

The invention belongs to the field of airborne networks of avionics systems, and provides an implementation method for dynamic configuration of an optical fiber channel switch. The method comprises the steps of generating static configuration data of the optical fiber channel switch according to an automatic generation mechanism of the static configuration data of the optical fiber channel switch;and after the static configuration data of the optical fiber channel switch is generated, generating the dynamic configuration data of the optical fiber channel switch according to a dynamic generation mechanism of the dynamic configuration data of the optical fiber channel switch configured by the dynamic configuration data configuration mechanism of the optical fiber channel node.

Owner:XIAN AVIATION COMPUTING TECH RES INST OF AVIATION IND CORP OF CHINA

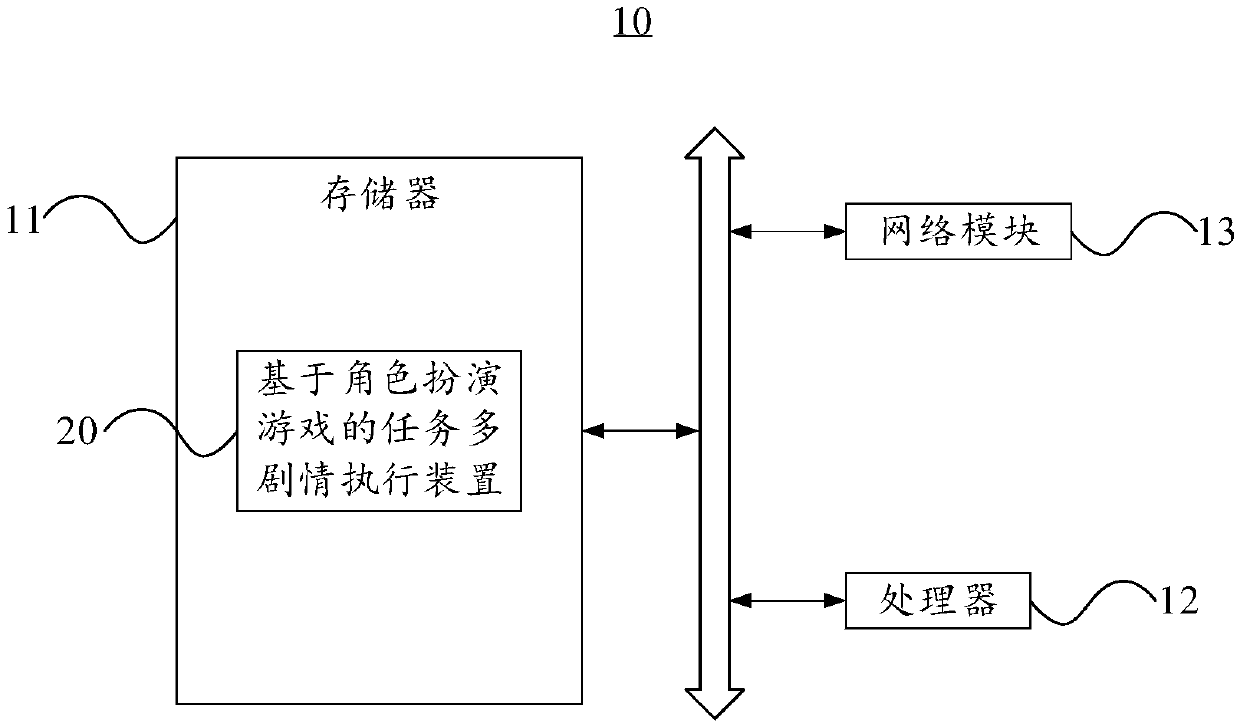

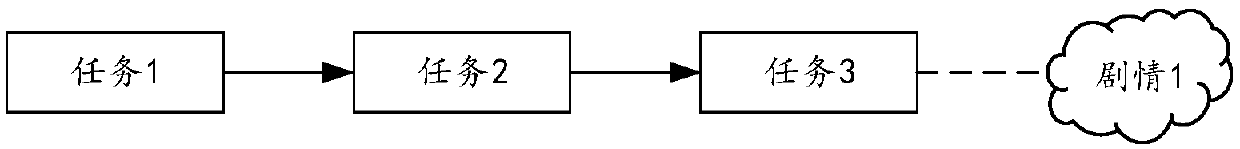

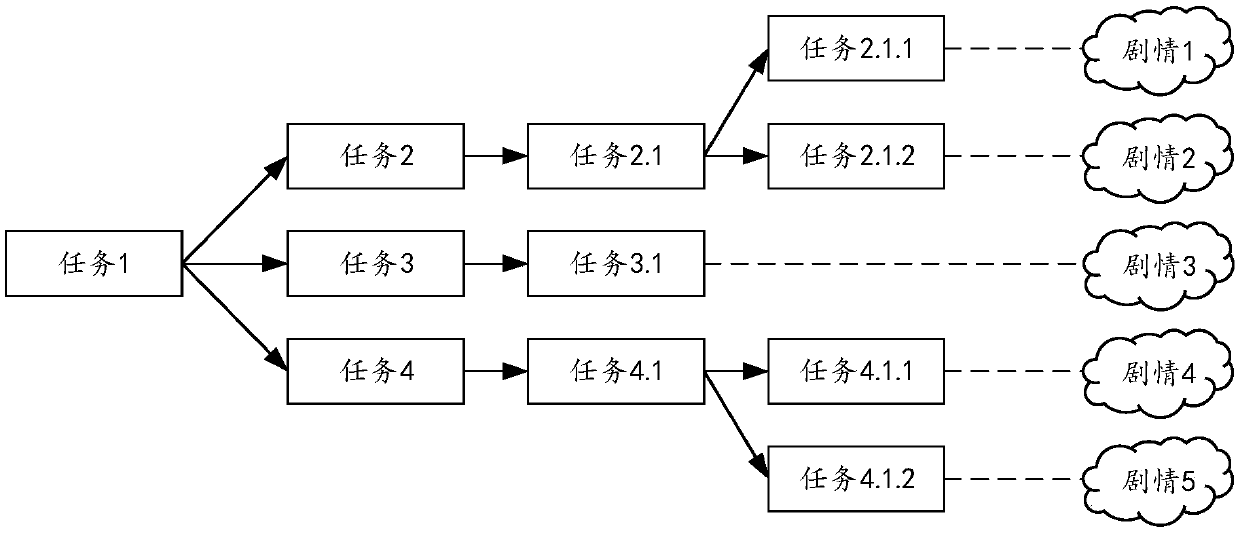

Task multi-plot execution method and device based on role-playing game

InactiveCN109529353AHigh playabilitySave R&D costsVideo gamesRole playing gameHuman–computer interaction

The embodiment of the invention relates to the technical field of game processing, in particular to a task multi-plot execution method and device based on a role-playing game. The method is applied toa game server in communication connection with a game client side. The method comprises the steps that multiple real-time task processes sent by the game client side in sequence are acquired, whereineach real-time task process comprises an initial task, an ending task and multiple middle tasks, and the initial tasks, the ending tasks and the middle tasks are selected from multiple preset tasks;a corresponding game plot is generated according to each real-time task process, and the generated game plots are sent to the game client side; in this way, the flexible and varied game plots can be provided based on the limited preset tasks, and the playability of a game is improved.

Owner:BEIJING PIXEL SOFTWARE TECH

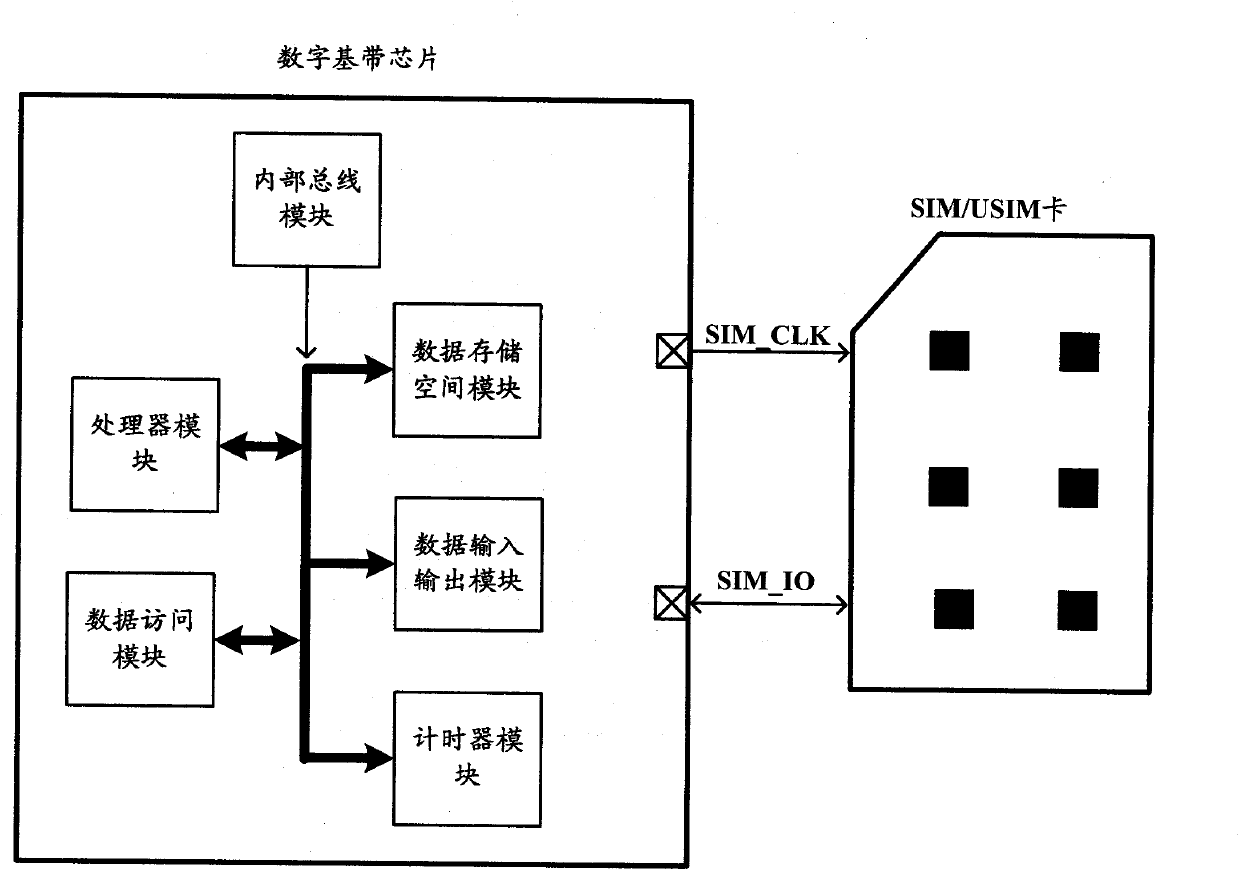

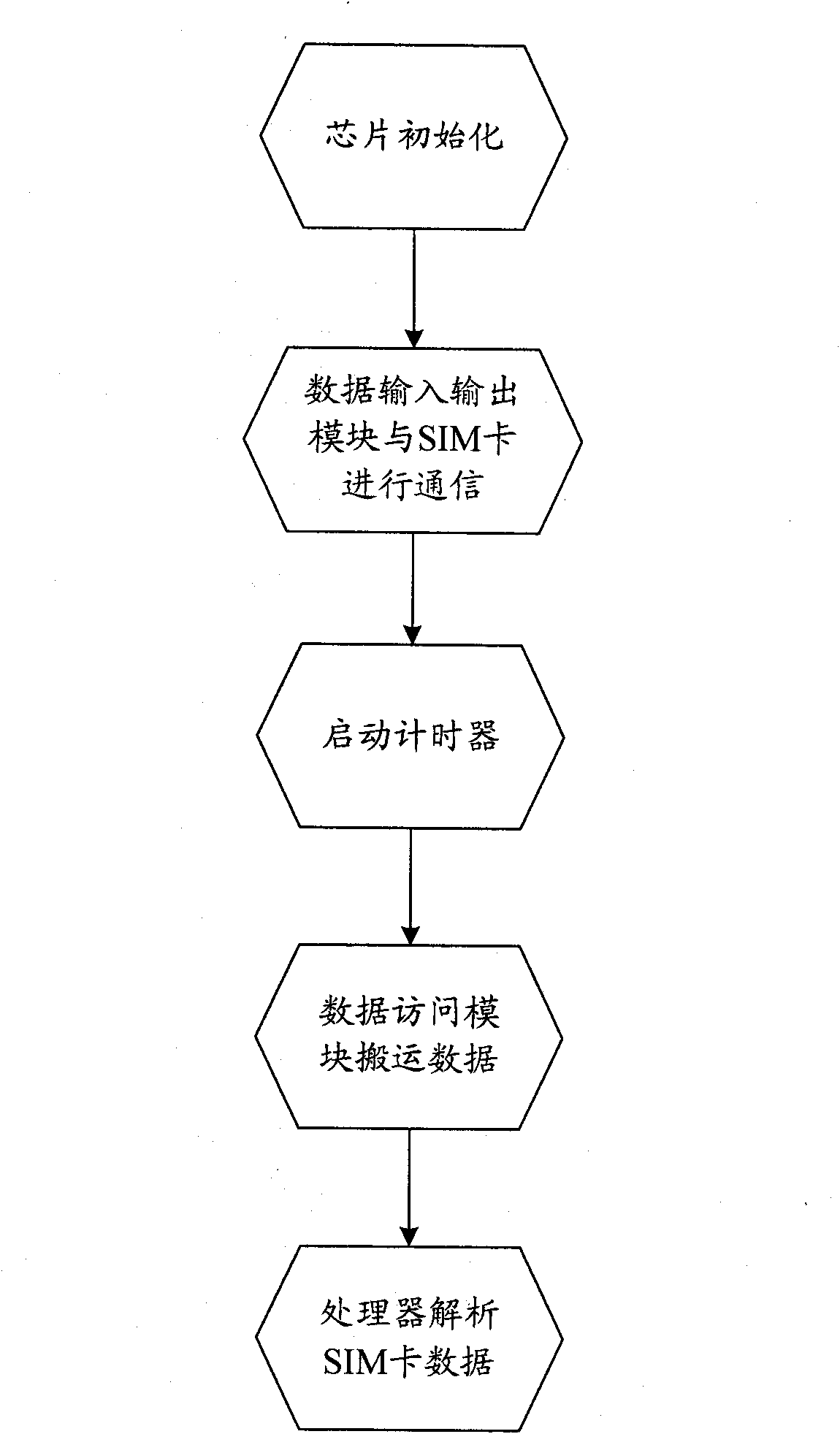

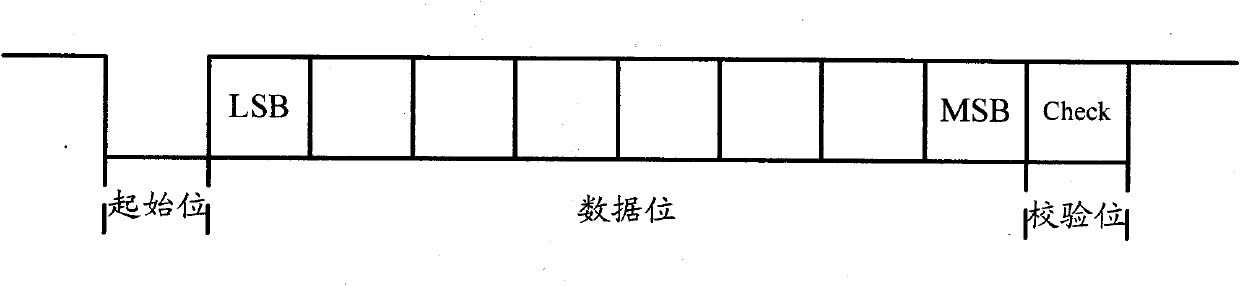

Circuit structure and method for realizing data parsing of SIM/USIM ((Subscriber Identity Module/Universal Subscriber Identity Module) card in digital baseband communication chip

ActiveCN102201829AReliable performanceSave R&D costsSubstation equipmentTransmissionWork performanceIdle time

The invention relates to a circuit structure for realizing data parsing of an SIM / USIM (Subscriber Identity Module / Universal Subscriber Identity Module) card in a digital baseband communication chip. The circuit structure comprises a processor module, a data access module, a data storage space module, a data input-output module and a timer module which are interactively connected with one another through an internal bus module. The invention further relates to a method for realizing the data parsing of the SIM / USIM card in the digital baseband communication chip based on the circuit structure. Due to the adoption of the circuit structure and the method for realizing the data parsing of the SIM / USIM card in the digital baseband communication chip, a small quantity of system resources are occupied, the processing procedure is finished by using idle time of the processor, the working performance is stable and reliable, the application range is wide, a large quantity of research and development cost and time are saved, and the parsing scheme of the conventional digital baseband chip for the data of the SIM / USIM card is expanded; and the circuit structure and the method have wide application prospect in the field of digital communication application.

Owner:SPREADTRUM COMM (SHANGHAI) CO LTD

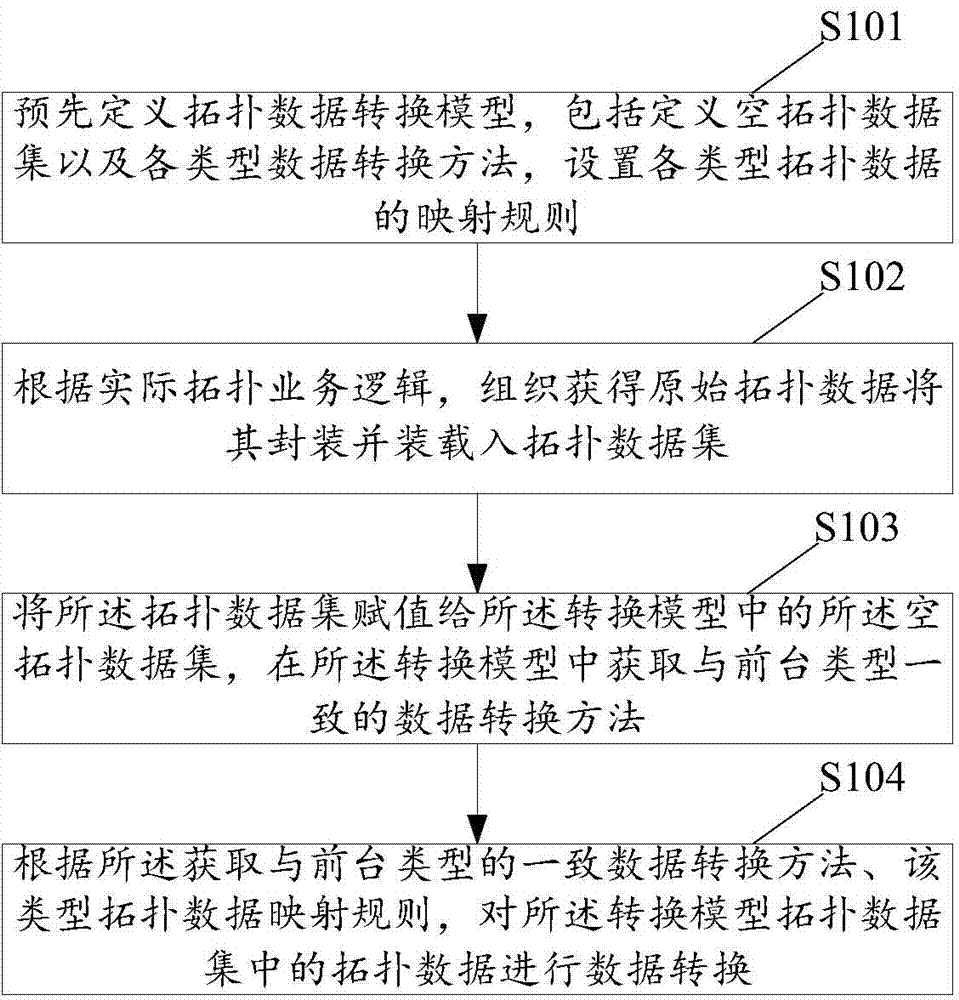

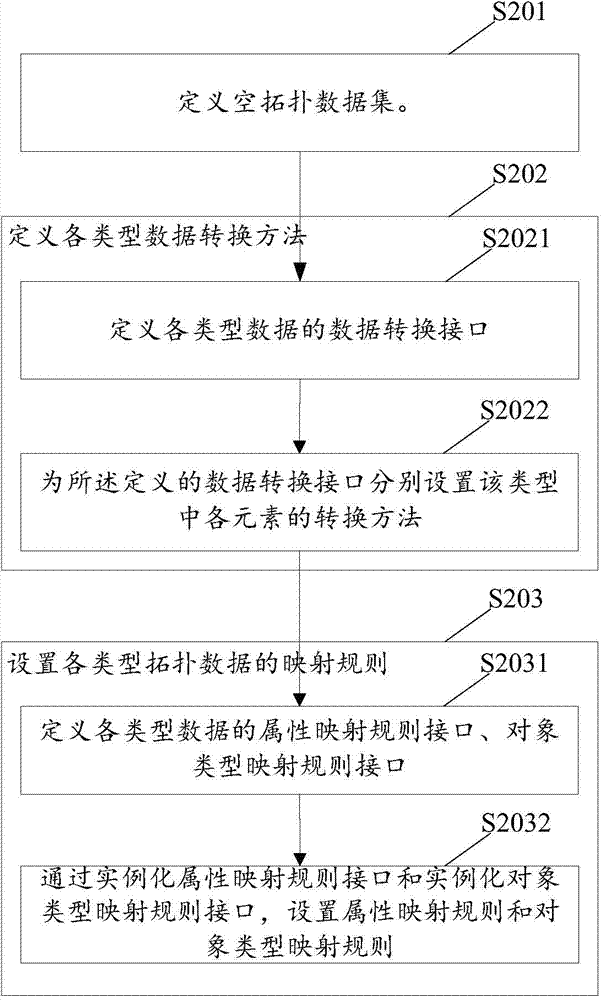

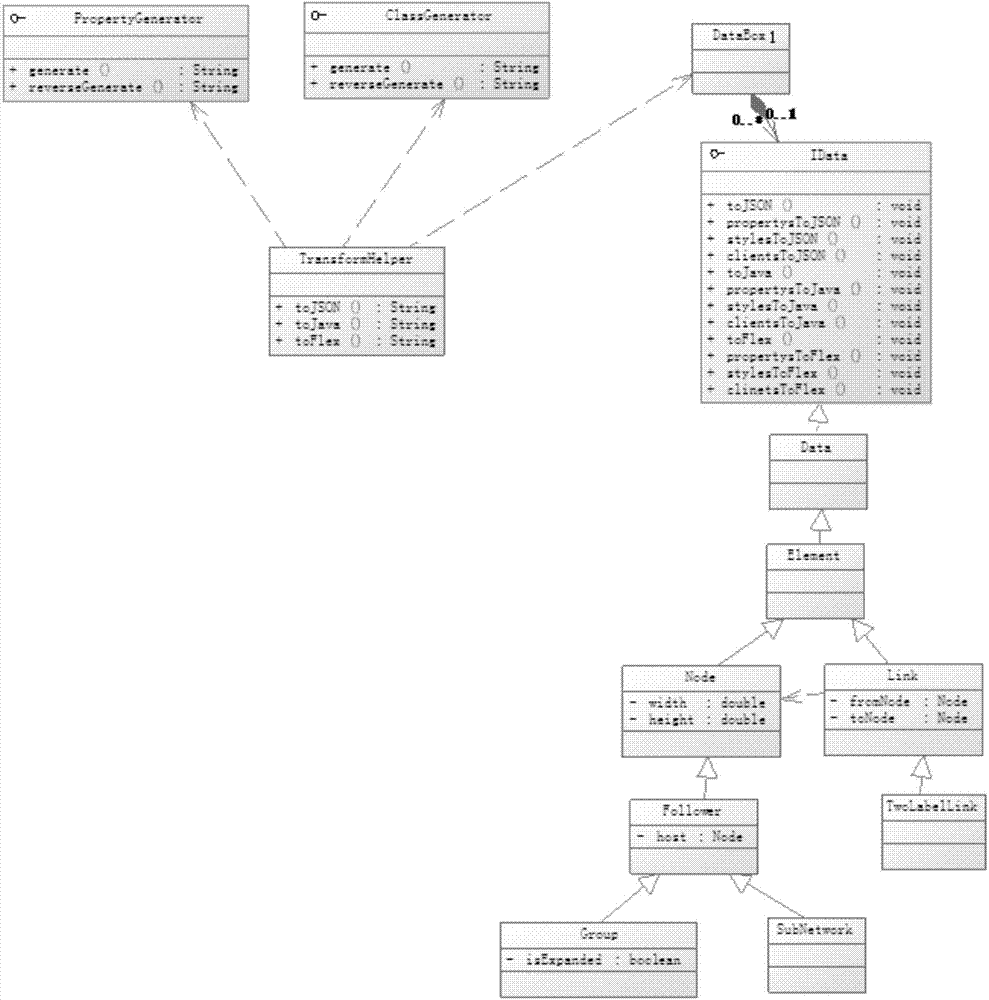

Server side topological data conversion method and device

ActiveCN104750468AImprove scalabilityGuaranteed singularitySpecific program execution arrangementsSpecial data processing applicationsData setServer-side

The invention discloses a server side topological data conversion method which includes preliminarily defining a topological data conversion model, including defining a null topological data set and various data conversion methods, and setting the mapping rule of the various topological data; acquiring the original topological data according to the practical topological service logic and packaging and loading the original topological data into a topological data set; assigning the topological data set to the empty topological data set in the conversion model and acquiring the data conversion method identical to the type of a foreground in the conversion model; conducting data conversion for topological data in the topological data set of the conversion model according to the acquired data conversion method identical to the type of the foreground and the topological data mapping rule of the type. The server side topological data conversion method is simple and convenient to operate and avoids repeated data conversion development aiming at different types of foregrounds. The invention further discloses a server side topological data conversion device.

Owner:BEIJING BOCO COMM TECH

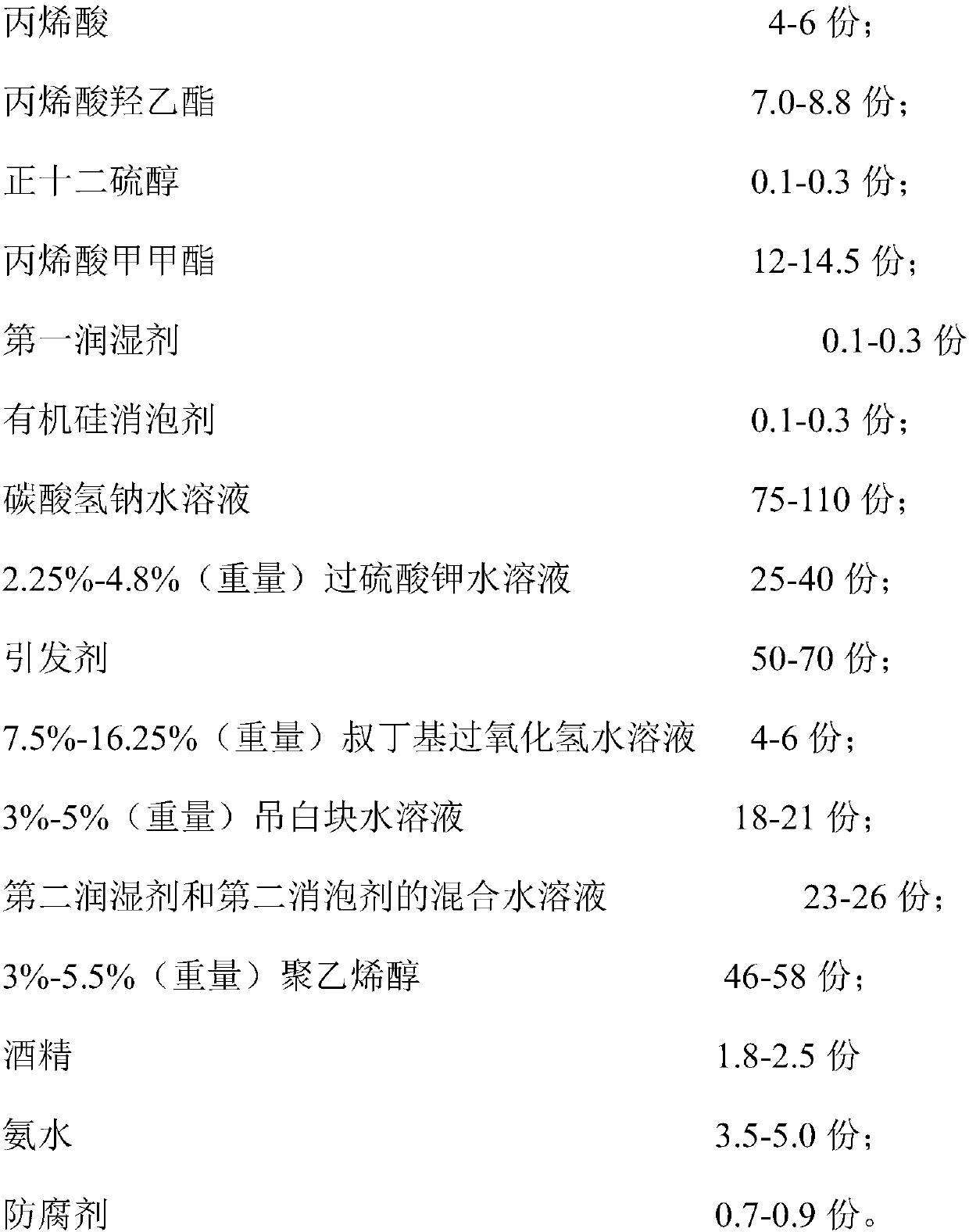

Adhesive for white and transparent OPP (Oriented Polypropylene) adhesive tape and processing technology thereof

InactiveCN107699169AThe synthesis process is simpleBeautify the appearanceFilm/foil adhesivesMacromolecular adhesive additivesIsooctyl acrylateFoaming agent

The invention discloses an adhesive for a white and transparent OPP (Oriented Polypropylene) adhesive tape and a processing technology thereof. The adhesive is mainly prepared from the following raw materials: butyl acrylate, isooctyl acrylate, acrylic acid, hydroxyethyl acrylate, dodecanethiol, methyl methacrylate, an emulsifier, a wetting agent, a de-foaming agent, an initiator and a preservative. According to the adhesive disclosed by the invention, other raw materials do not need to be added and the adhesive tape can have a white and transparent effect; the research and development cost isreduced; meanwhile, a synthesis technology is simplified.

Owner:福建友谊胶粘带集团有限公司

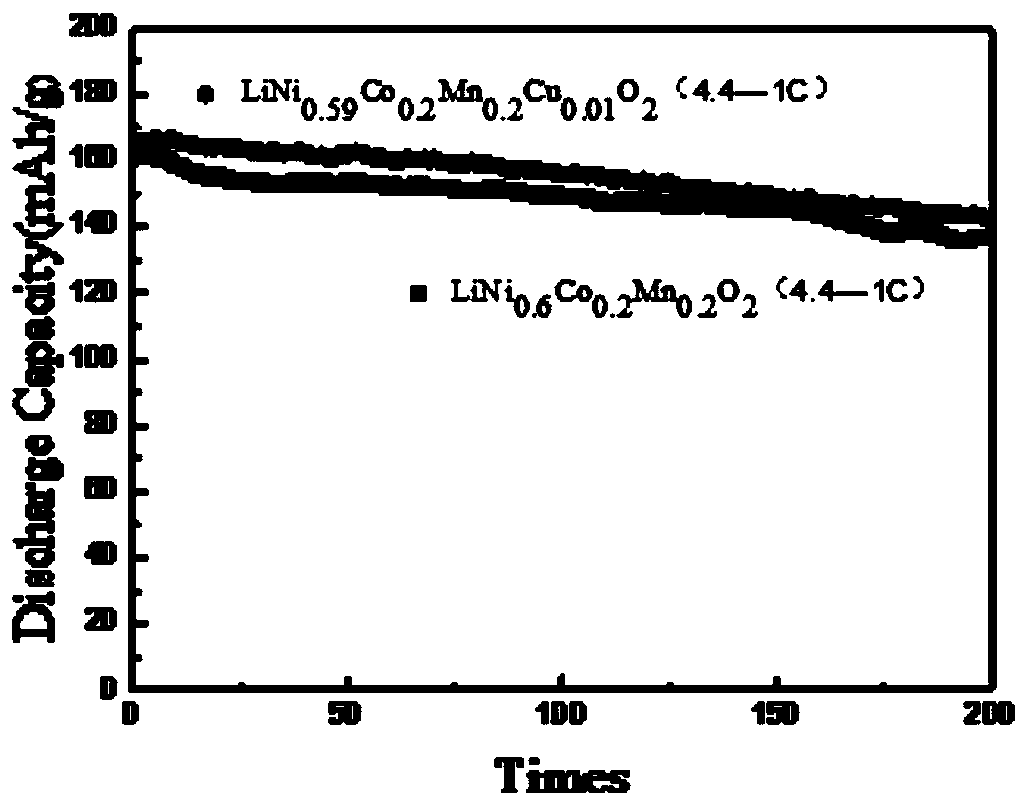

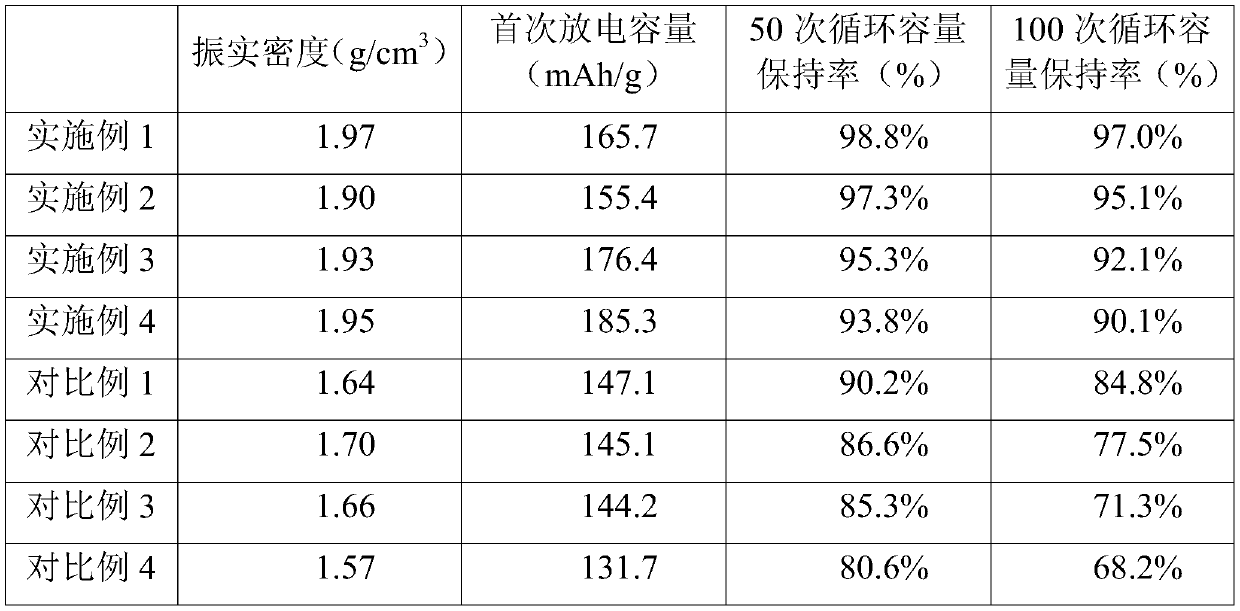

Preparation method of copper-doped ternary positive electrode material

InactiveCN110391410AImprove electrochemical performanceImprove stabilityPositive electrodesNickel saltReaction temperature

The invention provides a preparation method of a copper-doped ternary positive electrode material. The method comprises the steps that soluble nickel salt, cobalt salt, manganese salt and copper saltare taken and formulated into a solution A according to an element molar ratio Ni:Co:Mn:Cu=x:y:z:1-x-y-z, wherein x is between 1 / 3 and 0.9, y is between 0 and 1 / 3, z is between 0 and 1 / 3, 1-x-y-z is between 0 and 0.1; a complexing agent is taken to prepare a solution B; a precipitant is taken to prepare a solution C; a complexing agent aqueous solution is added into a reaction kettle and used as abottom liquid; the above solution is added into the reaction kettle; the pH is controlled to be 10 to 11. 6, and the reaction temperature is 50 to 55 DEG C; stirring is carried out; under the protection of inert gas, coprecipitation reaction is carried out, and then the product is filtered, washed to neutral and dried to acquire a precursor M; and the precursor M and lithium salt are mixed and sintered by oxygen, wherein the calcination temperature is 520 to 550 DEG C, the calcination time is 3 to 4.5 h, the sintering temperature is 820 to 849 DEG C, the sintering time is 10 to 14 h, the heating rate is 4 to 6 DEG C / min. The prepared copper-doped ternary positive electrode material is suitable for industrial mass production. The electrochemical performance of the product is stable.

Owner:HAINAN UNIVERSITY

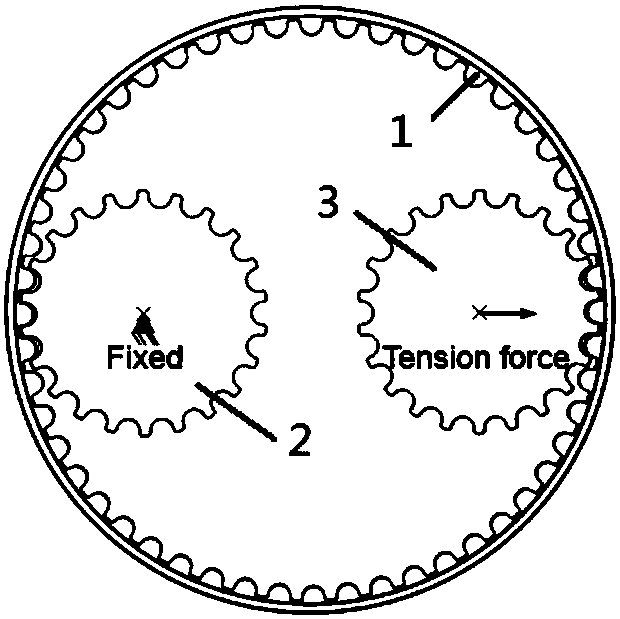

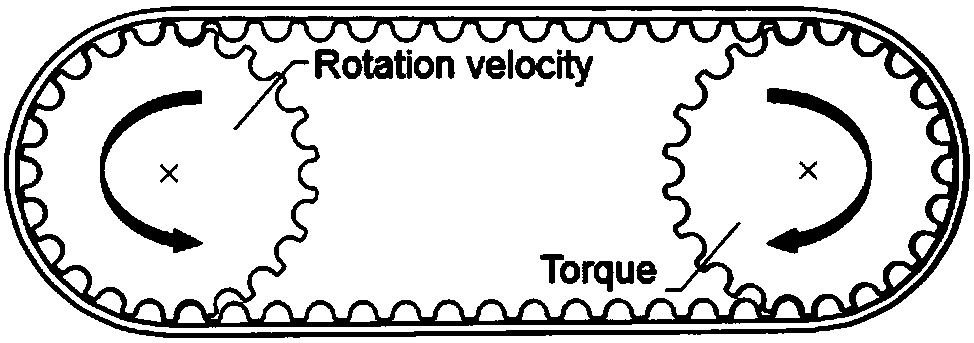

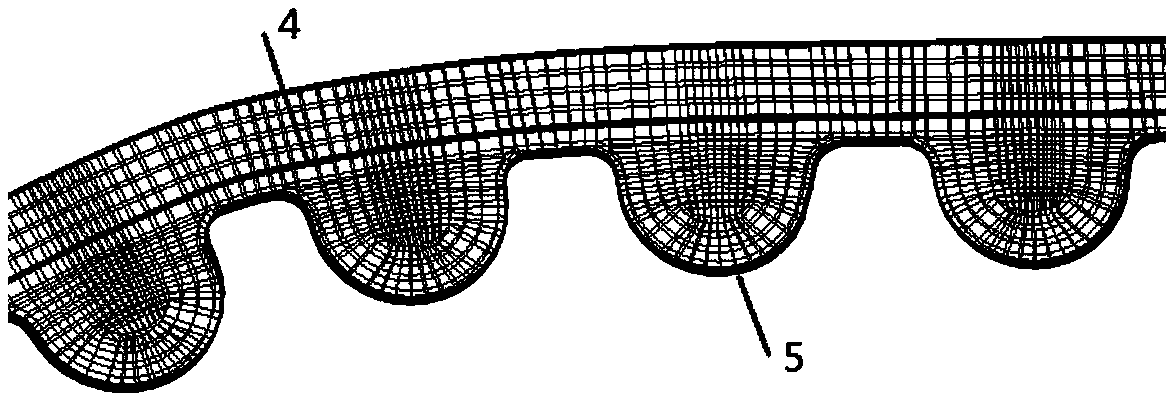

Finite element-based pitch and tooth profile optimization method for 8M arc tooth synchronous belt

InactiveCN107798191AExtended service lifeReduce lossGeometric CADDesign optimisation/simulationElement modelStress inversion

The invention relates to a finite element-based pitch and tooth profile optimization method for an 8M arc tooth synchronous belt. By building a standard 8M arc tooth synchronous belt transmission finite element model, an interference stress occurring in high-speed meshing transmission between belt teeth and gear teeth is accurately calculated; and synchronous belt parameters are optimized by adopting a stress inversion method through an orthogonal experimental design. According to the optimized parameters, a new 8M arc tooth synchronous belt transmission model is built; an interference stressgenerated in meshing transmission of the synchronous belt after optimization is calculated; multiple optimization schemes are compared; and optimal pitch and tooth profile parameters are determined. Therefore, the 8M arc tooth synchronous belt with longer service life, higher transmission stability and higher transmission efficiency is designed. According to the optimized 8M arc tooth synchronousbelt, the interference stress generated in meshing of the belt teeth and the gear teeth is greatly reduced; the synchronous belt is longer in service life and smaller in energy loss; and the researchand development cycle and cost are greatly shortened and reduced.

Owner:QINGDAO UNIV OF SCI & TECH +1

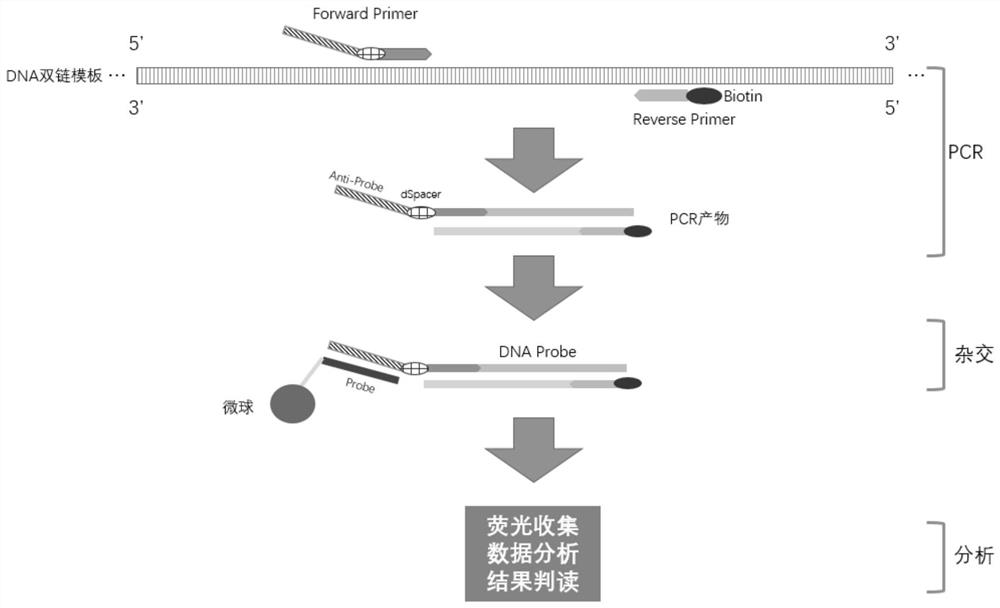

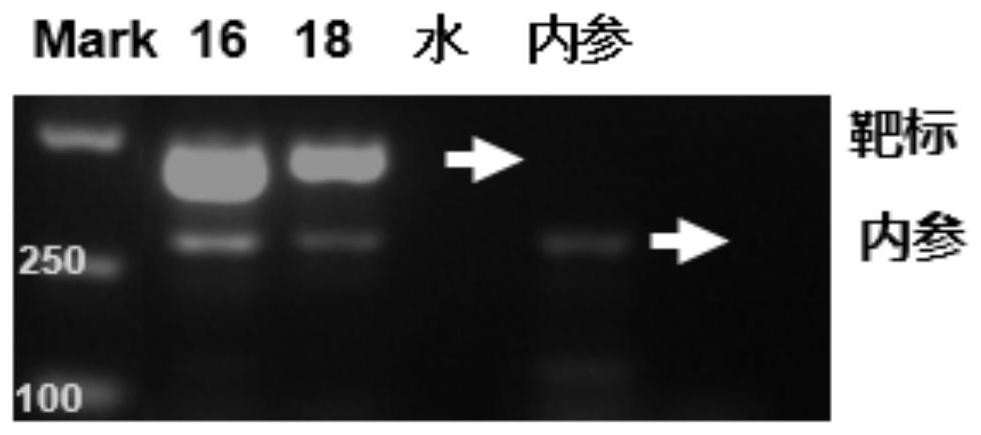

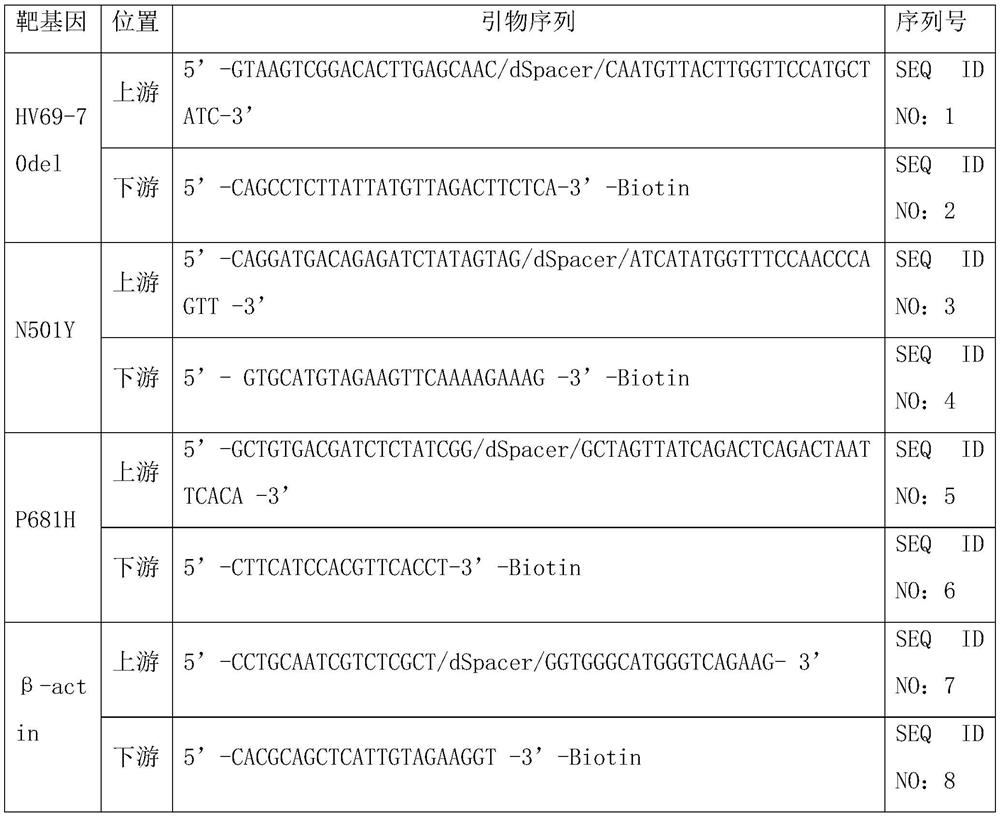

Nucleic acid detection method based on liquid chip technology

PendingCN113755558AImprove securityEliminate R&D proceduresMicrobiological testing/measurementForward primerMultiplex

Owner:上海万子健生物科技有限公司

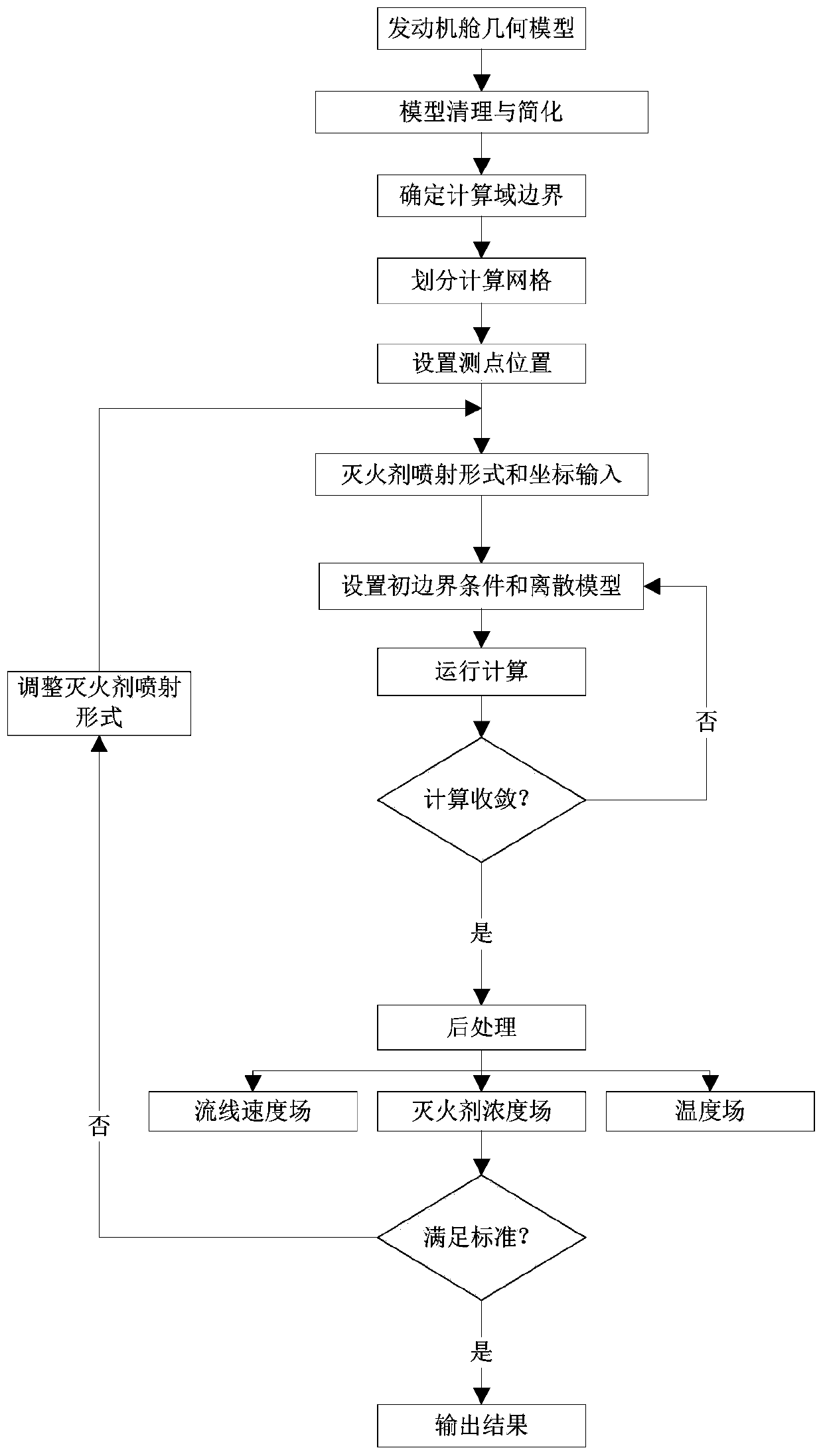

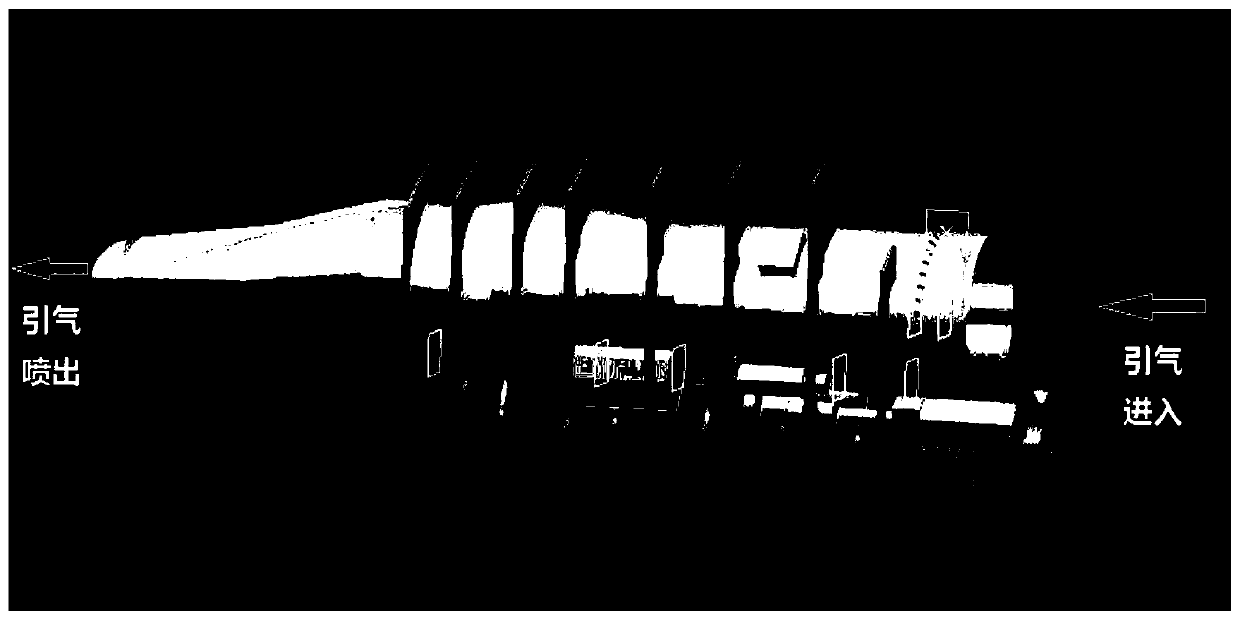

Method for simulating concentration of aircraft cabin fluid extinguishing agent

PendingCN110990942ASave R&D costsSave R&D timeGeometric CADDesign optimisation/simulationNacelleTypes of mesh

The invention belongs to the technical field of aircraft fire prevention and extinguishing, and particularly provides an aircraft cabin liquid fire extinguishing agent concentration simulation methodwhich comprises the following steps: 1) adding a physical field and a research type; 2) importing a geometric model of the cabin and simplifying; 3) carrying out simulation equivalence on a fire extinguishing spraying position; 4) setting a grid type and a grid size, and dividing grids; 5) setting a simulation model; 6) setting Haron fire extinguishing agent material parameters and initial boundary conditions; 7) initializing the system; according to the method, the fluid fire extinguishing agent spraying process is simulated through the finite volume principle, waste of manpower and materialresources in a traditional concentration test is effectively avoided, and cabin fire extinguishing agent distribution data obtained through the method have certain guiding significance in actual airplane cabin fire extinguishing system design.

Owner:天津航空机电有限公司

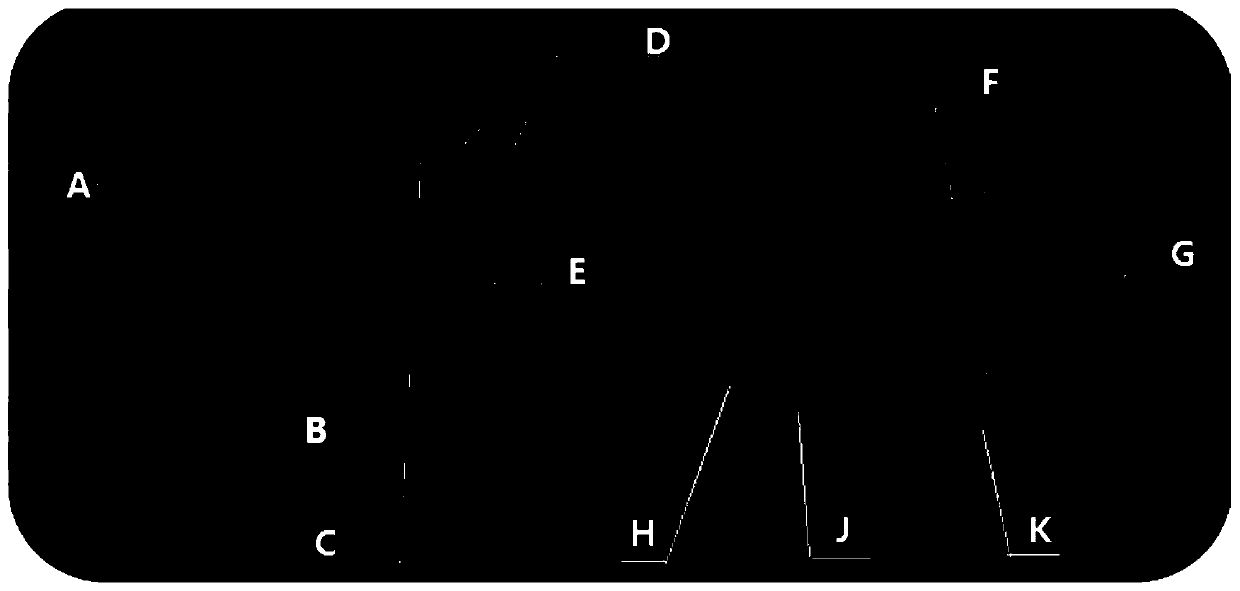

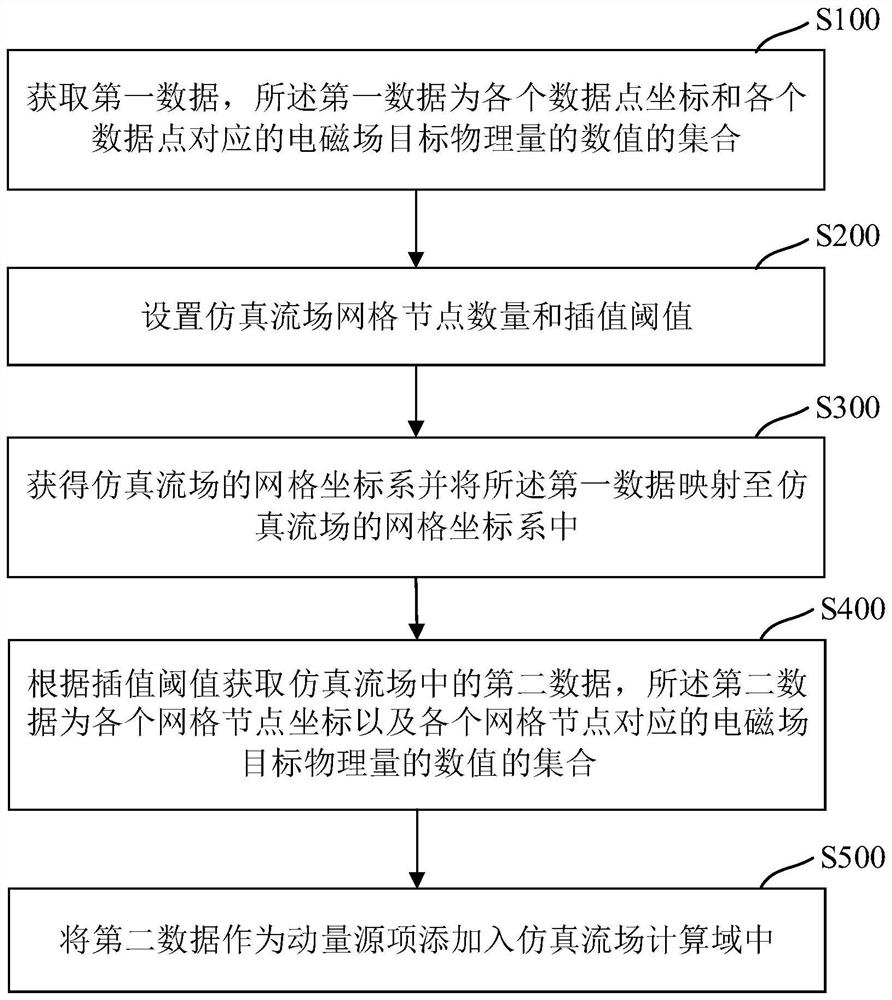

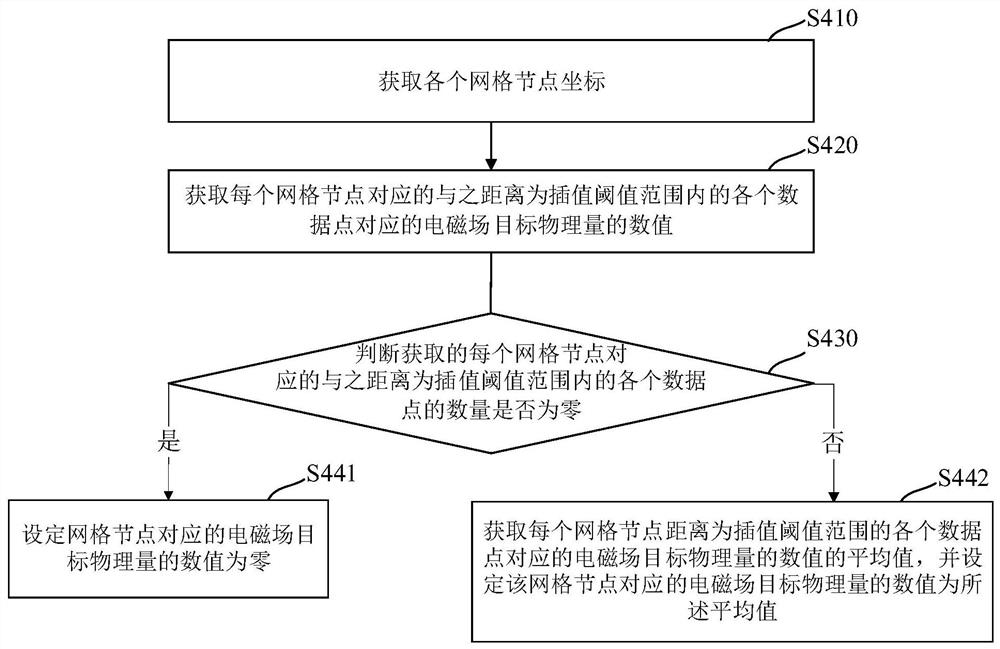

Coupling interface interaction method and system, simulation system, equipment and storage medium

PendingCN113792464AIncrease forceSave investment costDesign optimisation/simulationSpecial data processing applicationsEngineeringMechanical engineering

The invention provides a coupling interface interaction method and system, a simulation system, equipment and a storage medium, the method is suitable for coupling interaction of interfaces between electromagnetic field-flow field simulation software. The method comprises the following steps: obtaining first data, and setting the number of simulation flow field grid nodes and an interpolation threshold; obtaining a grid coordinate system of the simulation flow field and mapping the first data into the grid coordinate system of the simulation flow field; obtaining second data in the simulation flow field according to the interpolation threshold, wherein the second data is a set of the coordinates of the grid nodes and the numerical values of the target physical quantities of the electromagnetic field corresponding to the grid nodes; and adding the second data as a momentum source item into the simulation flow field computational domain. According to the coupling interface interaction method, coupling interaction of interfaces between the electromagnetic field simulation software and the flow field simulation software is achieved, an algorithm between the electromagnetic field simulation software and the flow field simulation software is more flexible, concise and rapid, calculation resources are optimized. Meanwhile, calculation results are more accurate, and hardware investment cost and research and development cost are saved.

Owner:CHINA ENFI ENGINEERING CORPORATION

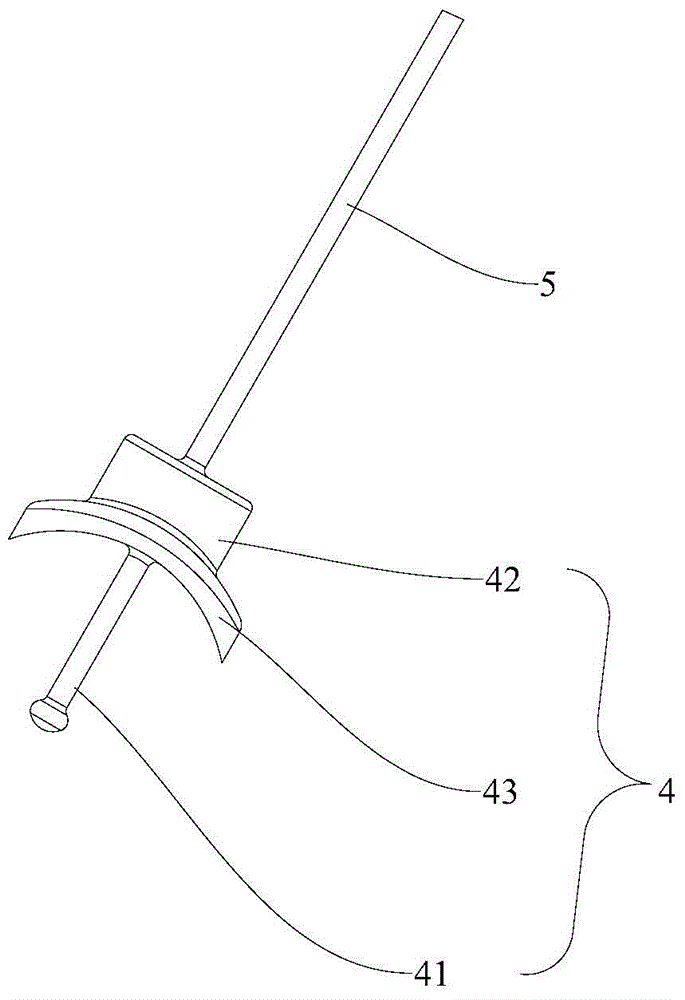

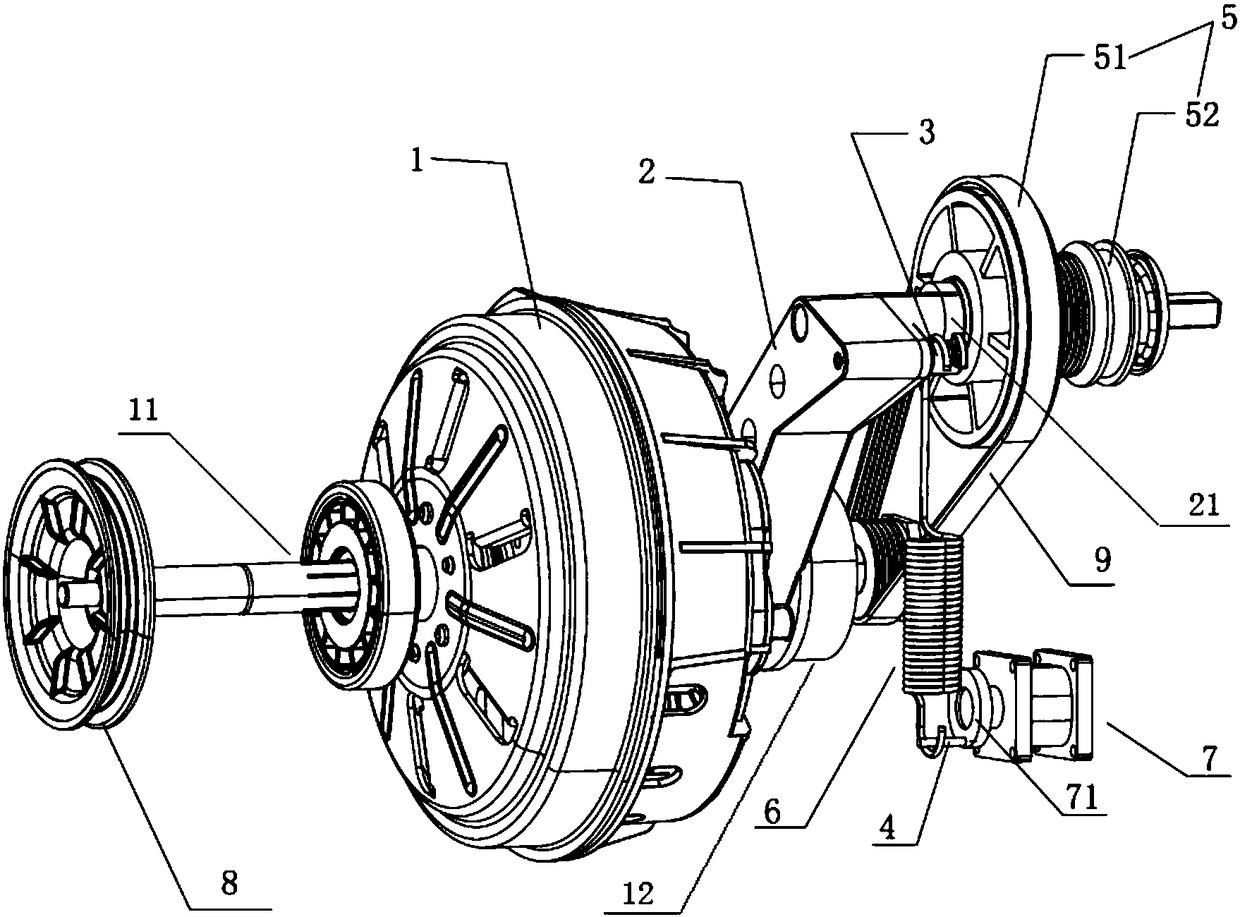

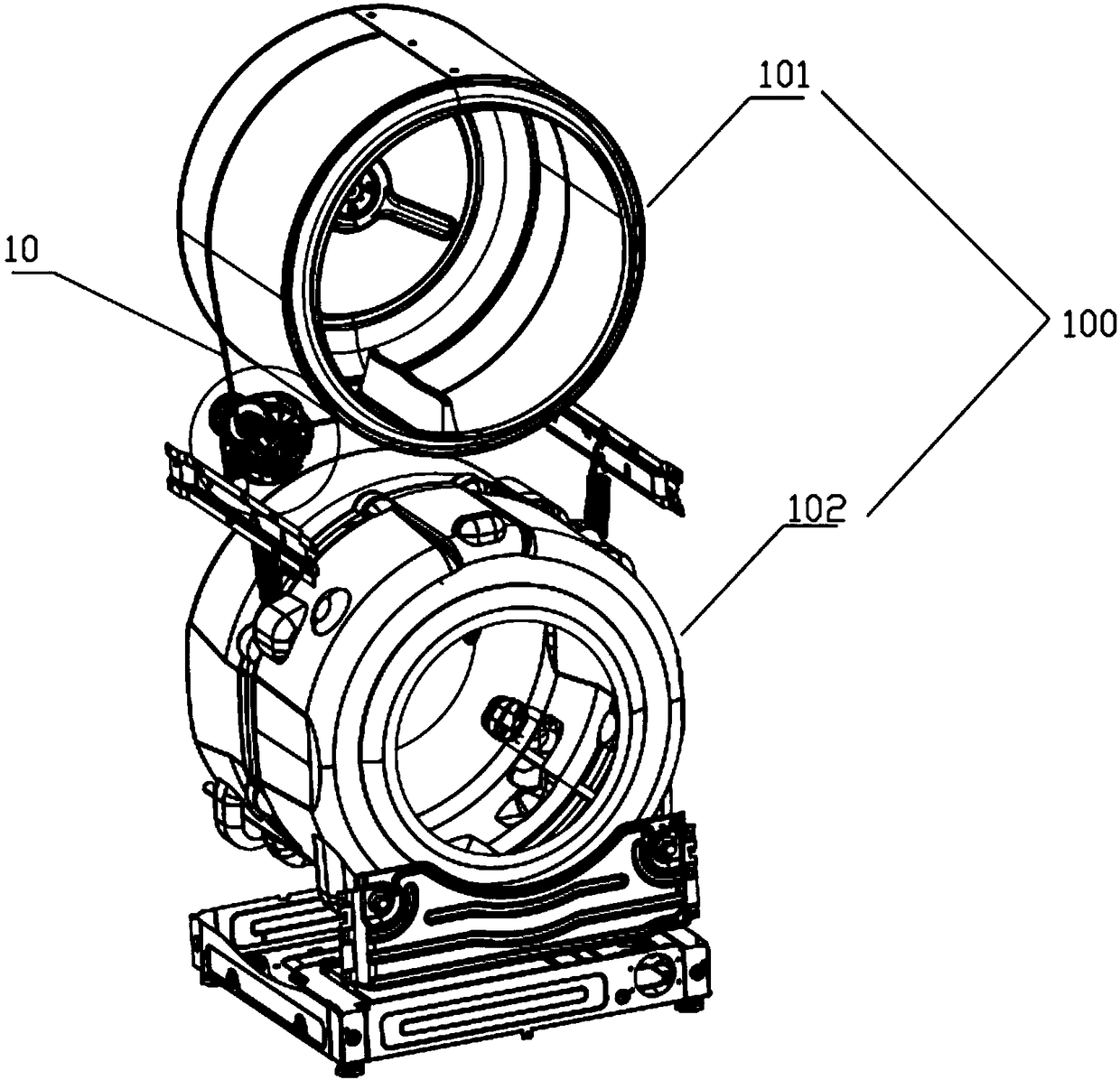

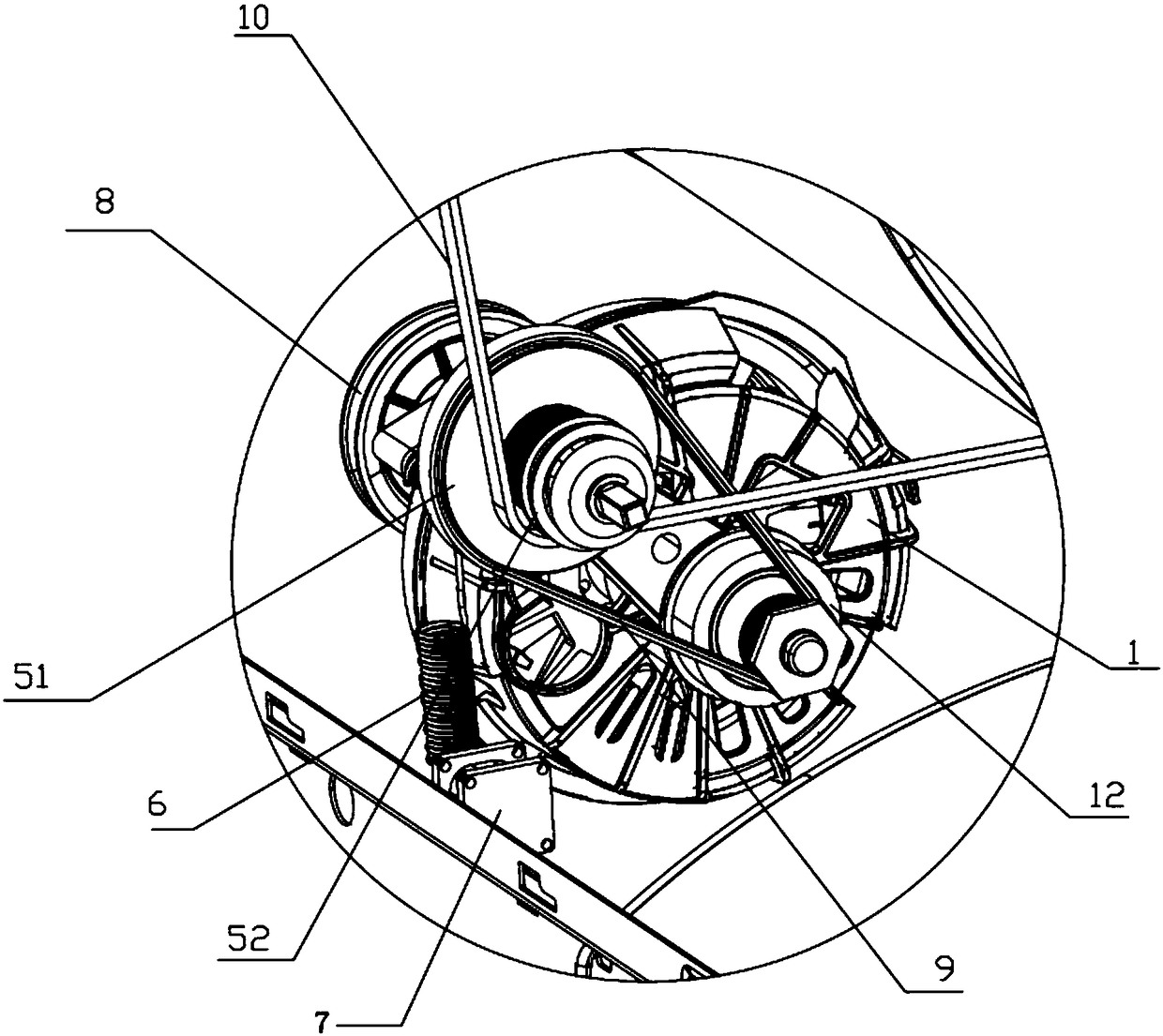

Clutch structure and clothes processing device

ActiveCN109468806AExtended service lifeEasy to set upOther washing machinesTextiles and paperDrive wheelDrive motor

The invention belongs to the technical field of clothes processing devices and particularly relates to a clutch structure and a clothes processing device. The clutch structure comprises a driving motor, wherein the first output end of the driving motor is connected with a drying fan through a belt wheel in a transmission way, the second output end drives a driven wheel to rotate, the driven wheelis connected with a clothes processing cylinder through a second belt so as to drive the clothes processing cylinder to rotate, the driven wheel can be oppositely installed on the driving motor through a rocker arm in a swinging way so that a control motor controllably pulls the rocker arm to act through a spring and then change the position of the driven wheel, and tensioning or looseness of thesecond belt is adjusted to achieve engagement and disengagement of the belt wheel and the belt. The clutch structure achieves independent execution of drying functions of clothes processing structuresof the clothes processing device including two clothes processing structures having drying functions, and separate arrangement of drying and condensing devices is not needed.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

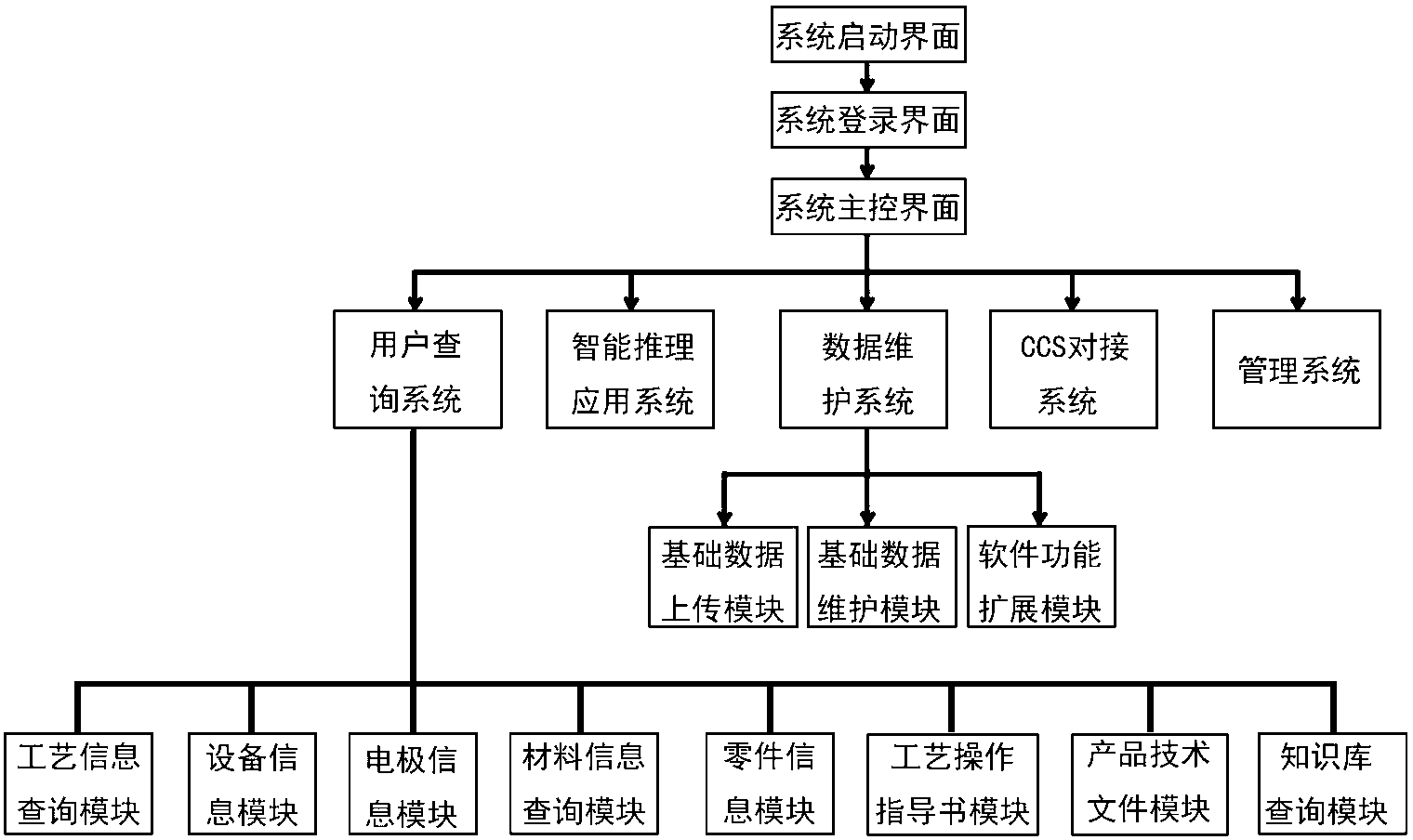

Automobile product welding database system

InactiveCN103226579AImprove efficiencyEasy to manageSpecial data processing applicationsAutomotive productMonitoring system

The invention discloses an automobile product welding database system. The system is characterized by comprising a data access layer, a business logic layer and a presentation layer, wherein the data access layer comprises a system startup interface, a system login interface and a system master-control interface; and the business logic layer comprises a user enquiry system, an intelligent reasoning and application system, a data maintenance system, a CCS (carbon capture and storage) docking real-time monitoring system and a management system. Compared with the prior art, the automobile product welding database system has the advantages as follows: a complicated automobile product and a welding processing technology are organically combined and effectively managed, all automobile types and various welding manners of point welding, projection welding, CO2 shielded welding, stud welding and the like can be covered, the efficiency is improved, the integrated management capability and the quality control capability are improved, and the costs for production and manufacture are reduced.

Owner:易明辉 +1

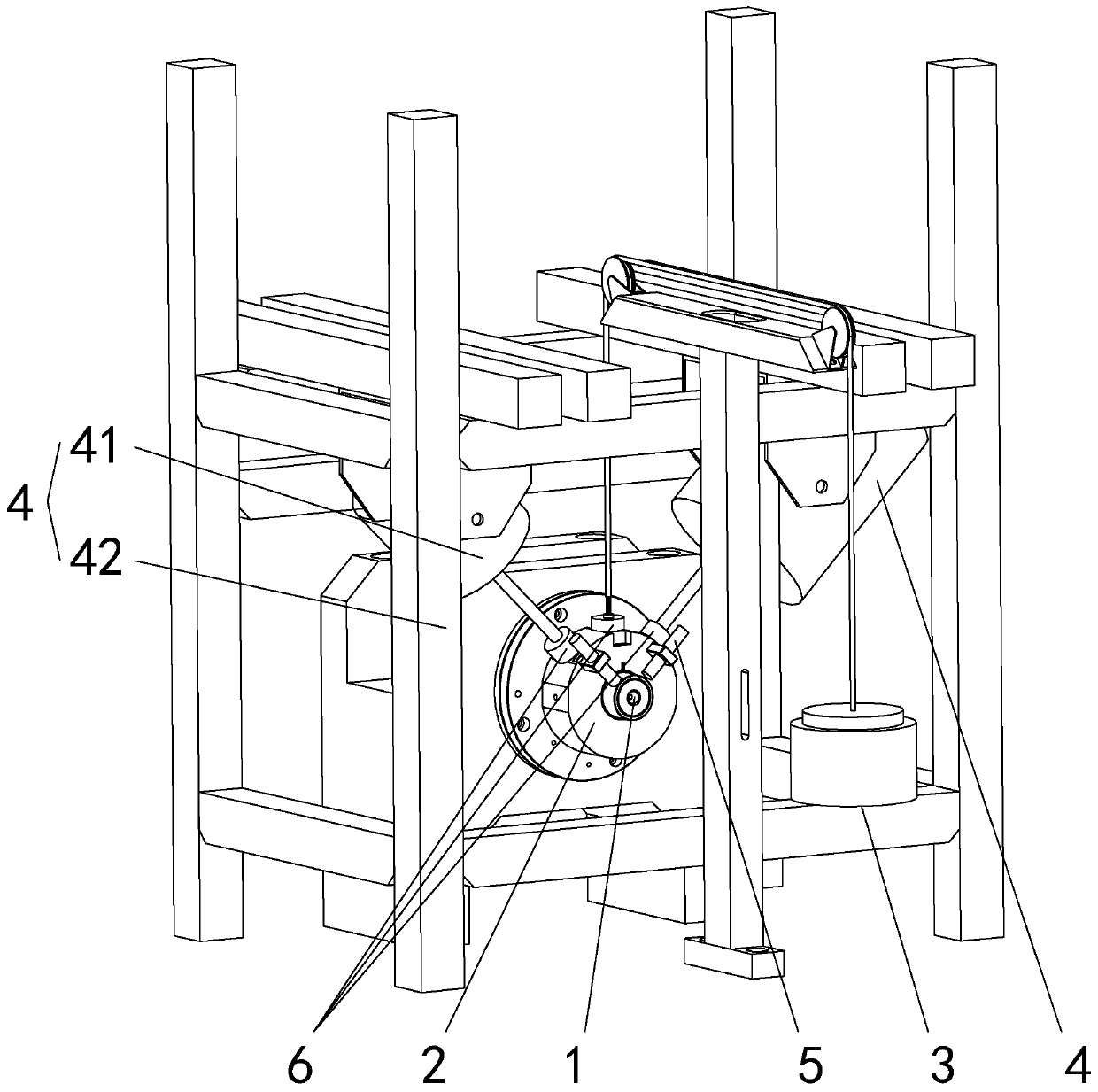

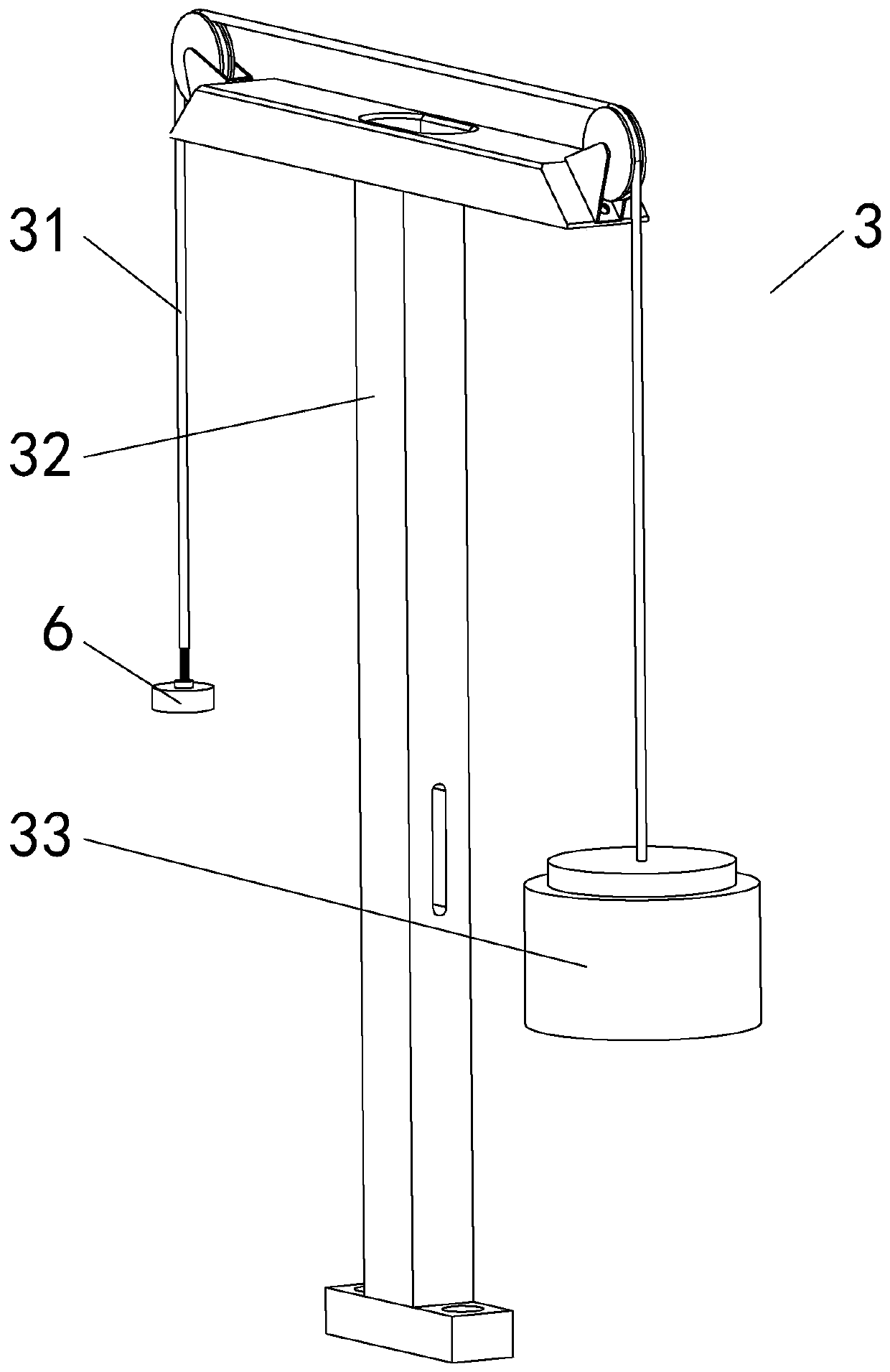

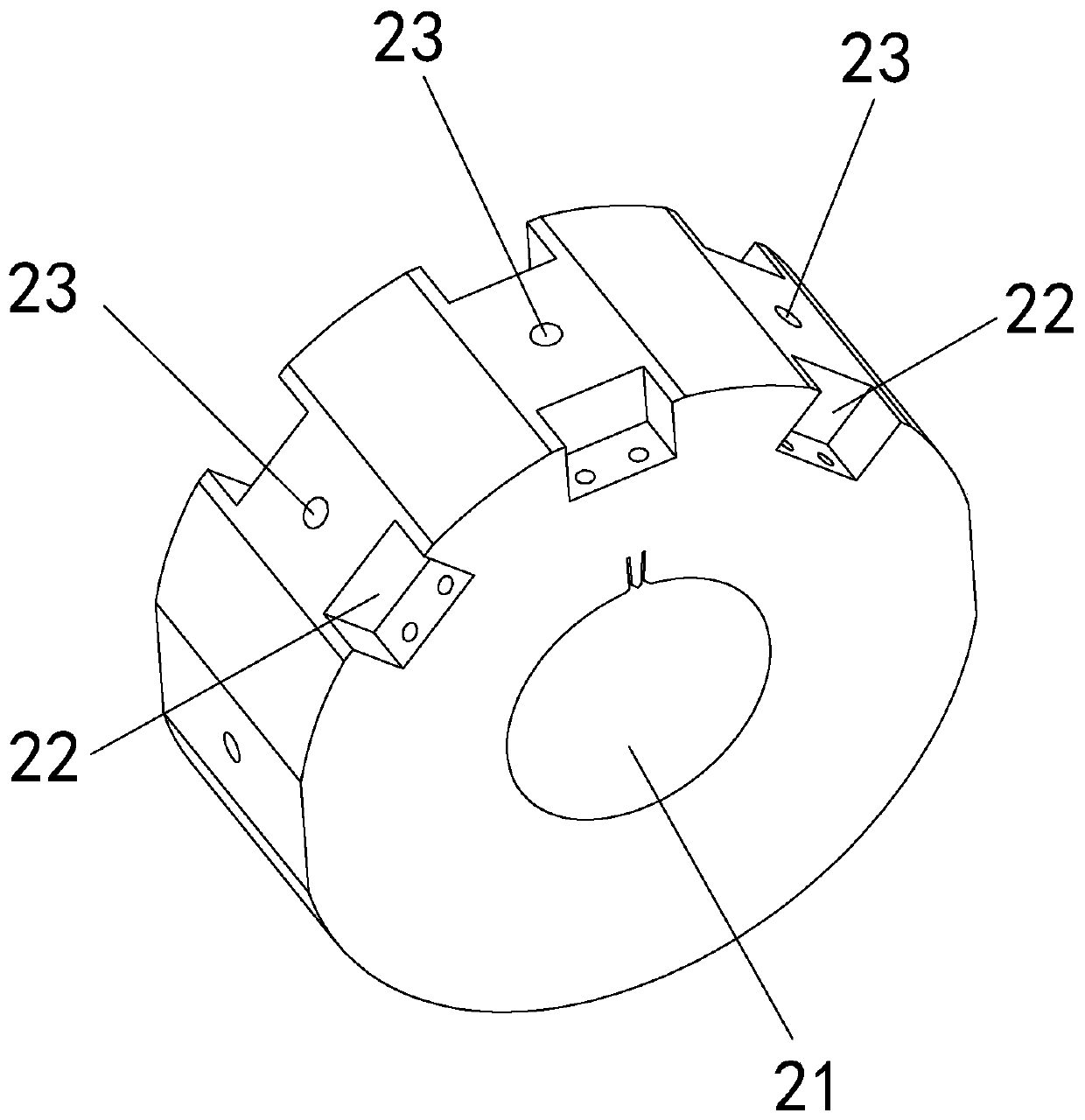

Dynamic stiffness and dynamic damping test bench for foil dynamic-pressure air radial bearing

PendingCN109708892ASolve the problem of only measuring the static stiffness of the bearingImprove accuracyMachine part testingDynamic stiffnessAir bearing

The invention discloses a dynamic stiffness and dynamic damping test bench for a foil dynamic-pressure air radial bearing. According to the test bench, displacement and loads, measured under conditions of different static loads, different exciting forces and different rotational speeds, of a bearing are analyzed to obtain the dynamic stiffness and dynamic damping of the bearing under the corresponding conditions. Therefore, a problem that the existing bearing performance test bench only measure the static stiffness of the bearing on the market is solved; the accuracy of the theoretical designof the rotor dynamics is improved; the overall design difficulty of the foil dynamic-pressure air bearing support is reduced; and the research and development cost and the development cycle are saved.

Owner:宁波云特博科技有限公司

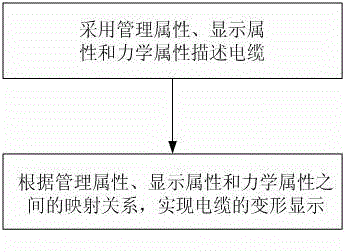

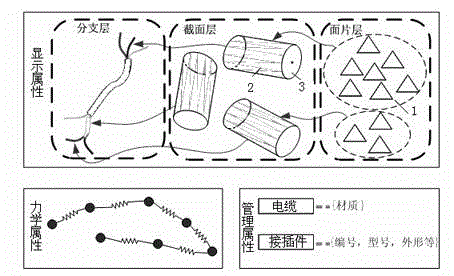

Deformation simulation method for flexible cable

InactiveCN105718613ARealize real-time dynamic adjustmentAvoid repeated installation attemptsSpecial data processing applicationsSimulationElectric cables

The invention provides a deformation simulation method for a flexible cable. The method comprises the following steps: (1) describing the cable by management attributes, display attributes and mechanical attributes; and (2) implementing deformation display of the cable according to the mapping relation among the management attributes, the display attributes and the mechanical attributes. By adopting the method, real-time interactive dynamic adjustment can be performed on the cable in a virtual assembly environment and repeated trial installation of an actual physical prototype in cable design is avoided, thereby reducing the product research and development cycle and cost.

Owner:SHANGHAI INST OF ELECTROMECHANICAL ENG

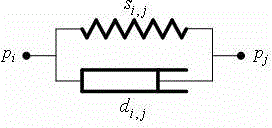

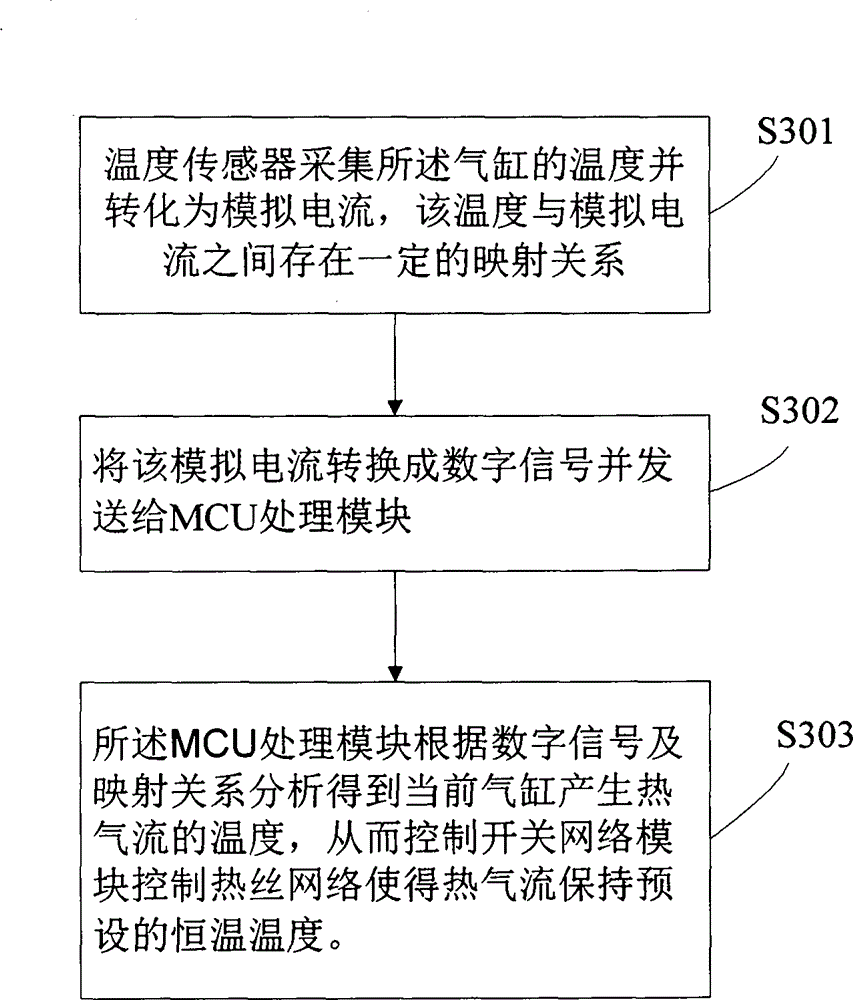

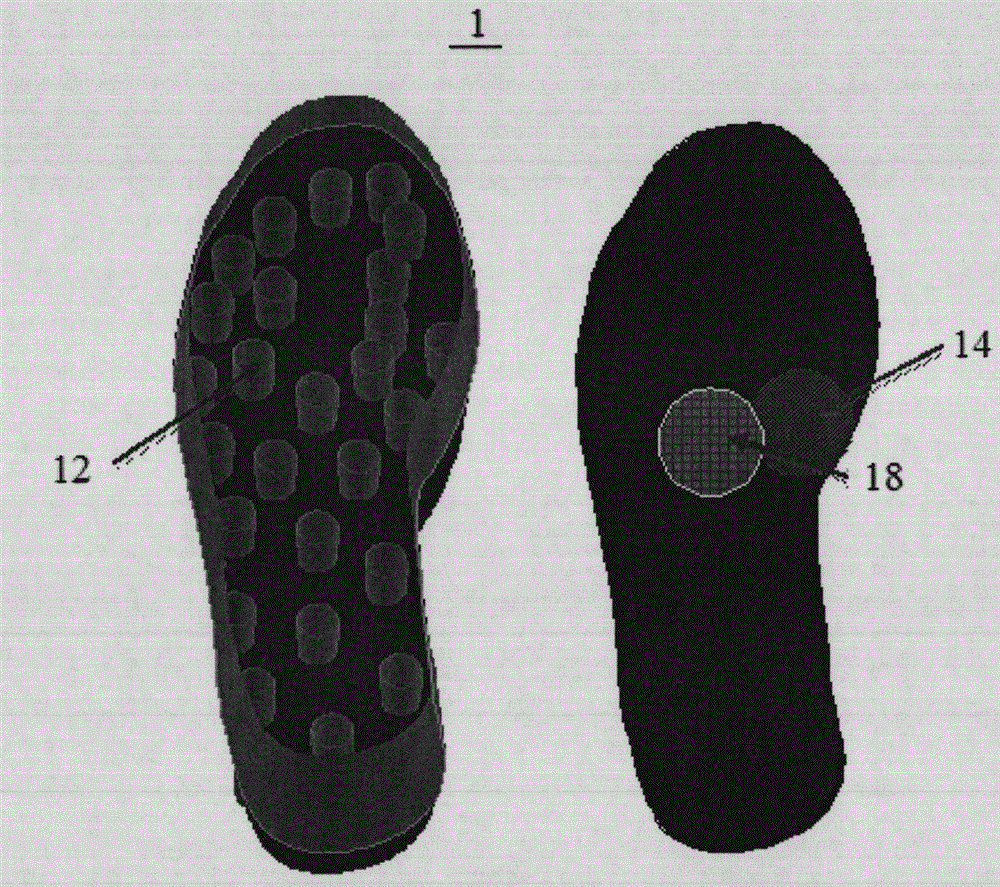

Digital thermostatic health-care shoe and control method thereof

InactiveCN105011461AImprove performanceExtended service lifeElectrotherapySolesEngineeringBlood circulation

The invention discloses a digital thermostatic health-care shoe and a control method thereof. The digital thermostatic health-care shoe comprises a sole device integrated to a sole and a shoe seat device correspondingly matched with the sole device, wherein the sole device comprises acupuncture point ducts distributed in the sole and corresponding to acupuncture points of a foot and air vents; the shoe seat device is provided with air outlets corresponding to the air vents; when the air vents of the sole device are aligned with the air outlets of the shoe seat device and inserted, the shoe seat device controls the shoe to produce constant temperature airflow, and the constant temperature airflow is introduced to the acupuncture point ducts of the sole from the air outlets and the air vents to massage the acupuncture points of the foot. According to the digital thermostatic health-care shoe and the control method thereof, warm and constant temperature can be kept, the acupuncture points of the foot can be massaged under control, double effects of promoting blood circulation and massaging are achieved, violent exercise is not intervened, and the design is relatively humanized.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

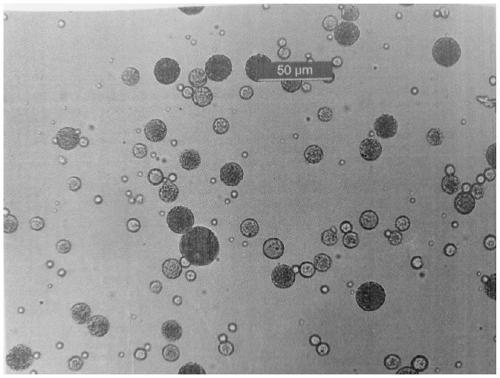

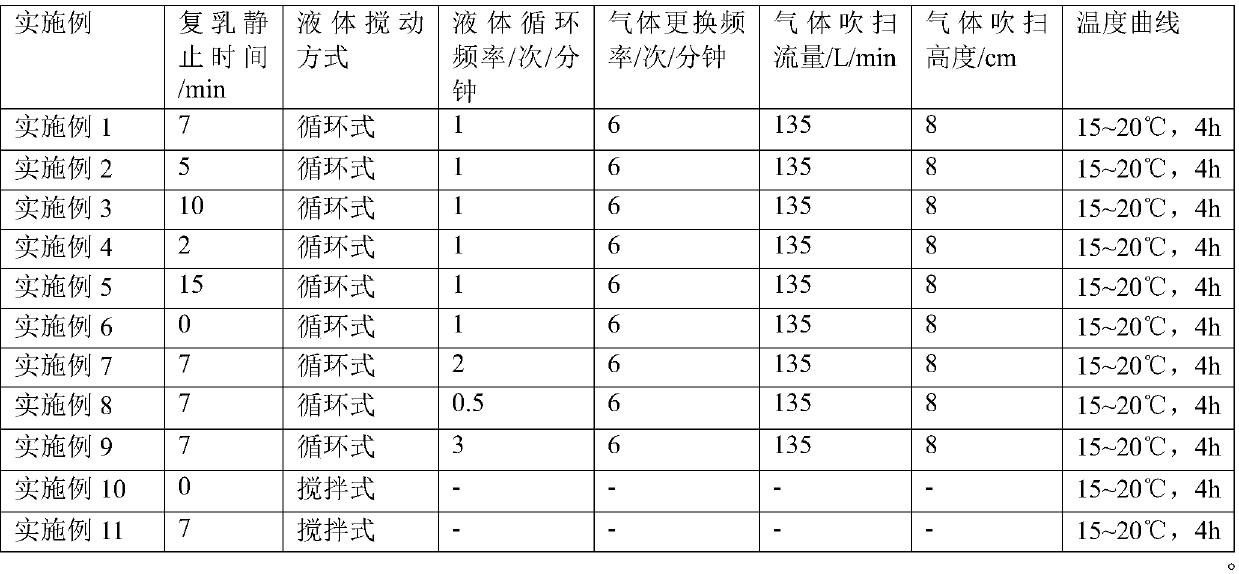

Preparation method of microspheres capable of increasing entrapment efficiency of hydrophilic medicines

ActiveCN111568877ASpherical roundingControlled releasePeptide/protein ingredientsPharmaceutical non-active ingredientsOrganic solventMicrosphere

The invention discloses a preparation method of microspheres capable of increasing entrapment efficiency of hydrophilic medicines. The preparation method comprises the following steps: step (a): preparing an inner water phase containing hydrophilic medicines, and an oil phase containing polymer carriers; step (b): mixing the inner water phase with the oil phase to obtain primary emulsion, and after formation of the primary emulsion, performing fast temperature reduction to increase stickiness of primary emulsion to 1000-2000cp; step (c): mixing and dispersing the primary emulsion after stickiness increase in the step (b) in a volume ratio being (1:100)-(1:200) in an outer water phase to obtain secondary emulsion, and immediately maintaining the formed secondary emulsion static for 5-10minso as to obtain primary products; and step (d): performing first-round drying on the primary products to obtain humid microspheres, wherein the residual quantity of organic solvents in the obtained humid microspheres is not higher than 0.5%, and then performing second-round drying to remove moisture and remaining solvents so as to obtain microsphere end products. Through the adoption of the preparation method, the polypeptide microspheres high in entrapment efficiency, high in medicine loading quantity and low in grain size can be obtained.

Owner:ZHEJIANG SUNDOC PHARMA SCI & TECH CO LTD

User login method and device, storage medium and electronic equipment

PendingCN112632516AImprove experienceSave R&D costsDigital data authenticationApplication serverSoftware engineering

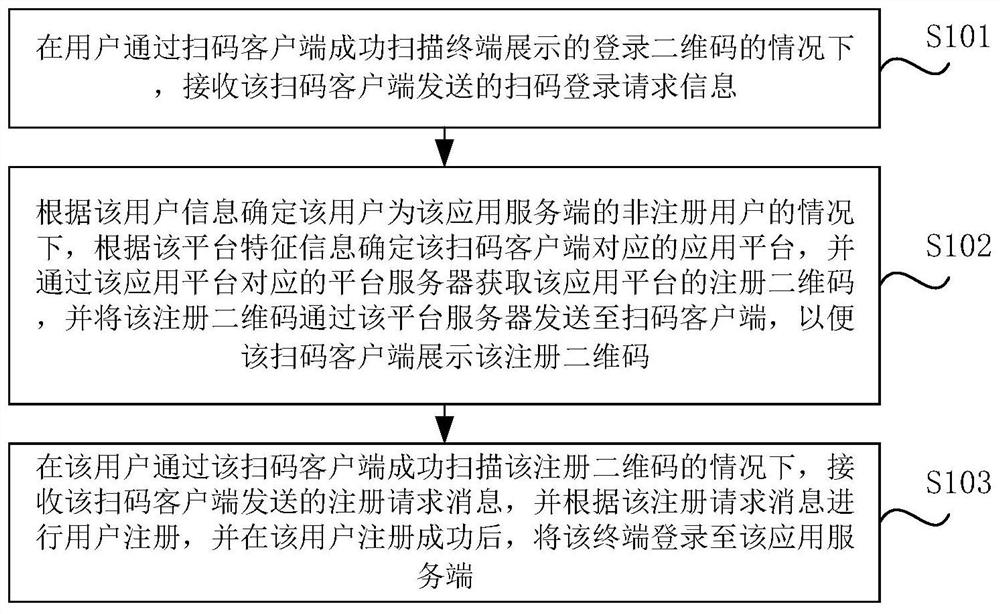

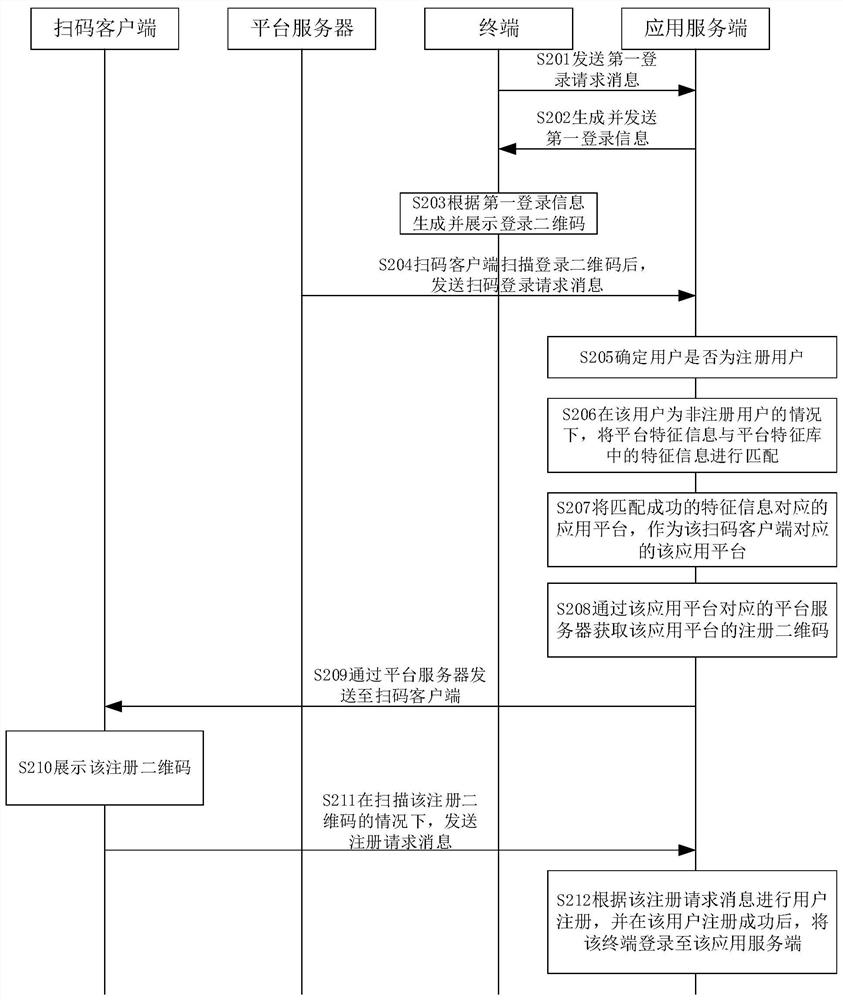

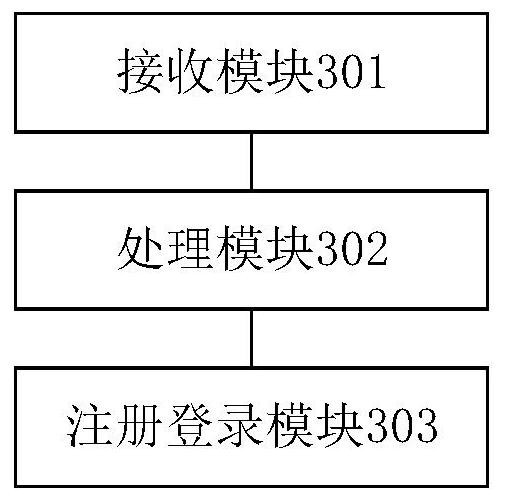

The invention relates to a user login method and device, a storage medium and electronic equipment, and the method comprises the steps: receiving code scanning login request information transmitted by a platform server corresponding to a code scanning client under the condition that a user successfully scans a login two-dimensional code displayed by a terminal through the code scanning client, wherein the code scanning login request information comprises platform feature information of an application platform corresponding to the code scanning client and user information registered by the user on the application platform, and under the condition that the user is determined to be a non-registered user according to the user information, the application platform corresponding to the code scanning client is determined according to the platform feature information, obtaining a registration two-dimensional code of the application platform through a platform server corresponding to the application platform, and displaying the registration two-dimensional code through a code scanning client; and under the condition that the user successfully scans the registered two-dimensional code through the code scanning client, receiving a registration request message sent by the code scanning client, and logging in the terminal to the application server after successful registration according to the registration request message.

Owner:AEROSPACE INFORMATION

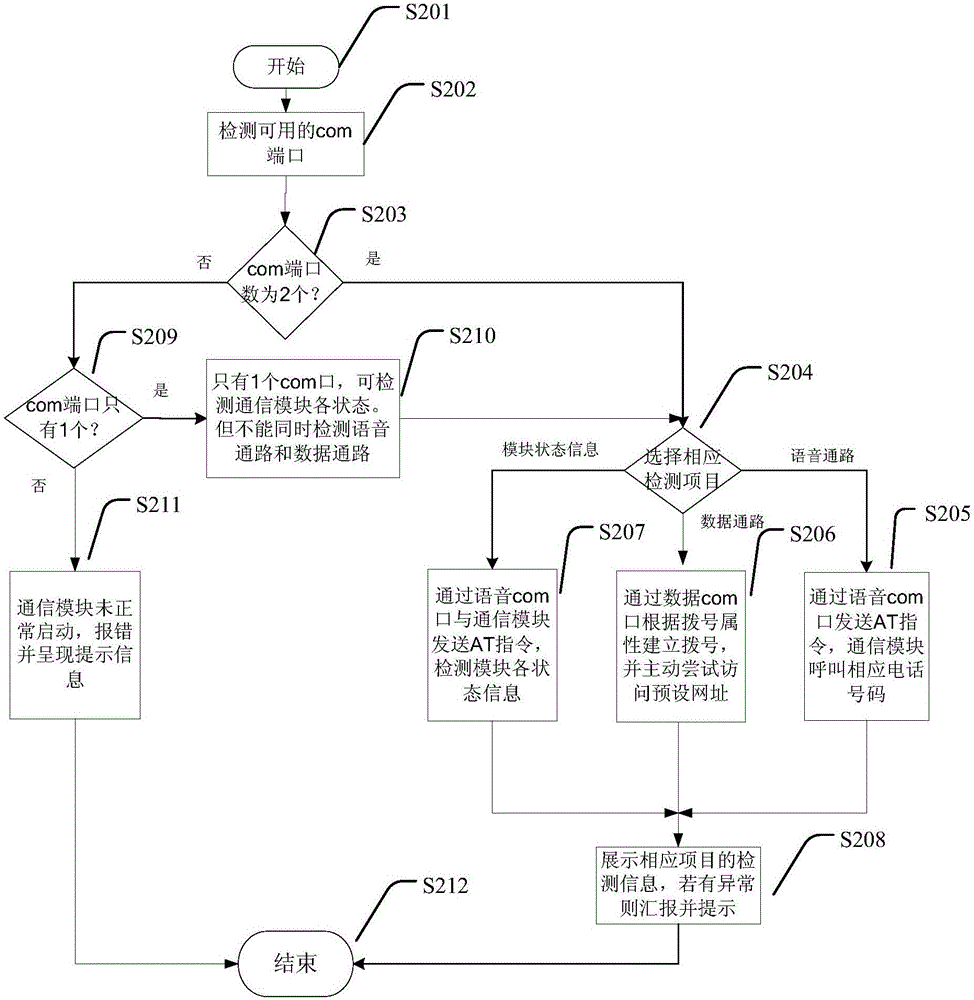

Detection tool and detection method for vehicle-mounted 3G/4G communication module

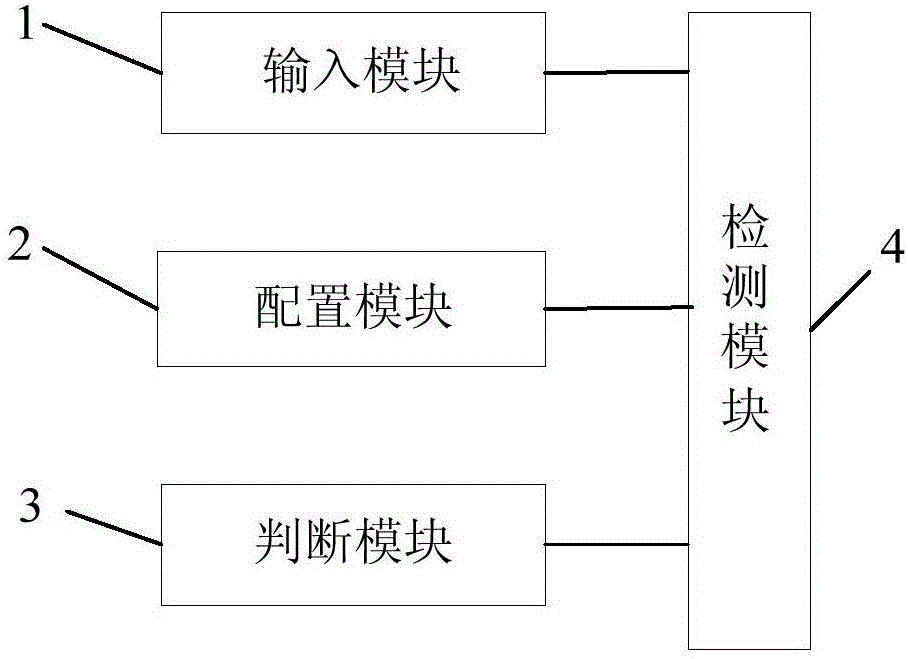

InactiveCN106850340ASave R&D costsSave after-sales costData switching networksTest efficiencyThird generation

The invention discloses a detection tool and a detection method for a vehicle-mounted 3G / 4G communication module. The tool and the method are used to detect the vehicle-mounted 3G / 4G communication module. The detection tool comprises an input module which is composed of a keypad used to enter manually the specified number and buttons used to choose detection items; a configuration module used to configure a default voice number, a default website, a dialing attribute and com ports; a judgment module used to detect the number of the com ports, which can be used to establish the communication with the vehicle-mounted 3G / 4G communication module, in a vehicle-mounted navigation system, wherein the judgment module is also used to determine whether the number of the available com ports is one or two, and if not, the vehicle-mounted 3G / 4G communication module is regarded as not being normally started, an error is reported and a prompt message is output, and if so, the vehicle-mounted 3G / 4G communication module is regarded as being normally started; and a detection module used to carry out the corresponding detection according to the chosen detection items after the vehicle-mounted 3G / 4G communication module is normally started and output the corresponding detection results. According to the invention, the detection efficiency is improved and the operation is convenient.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

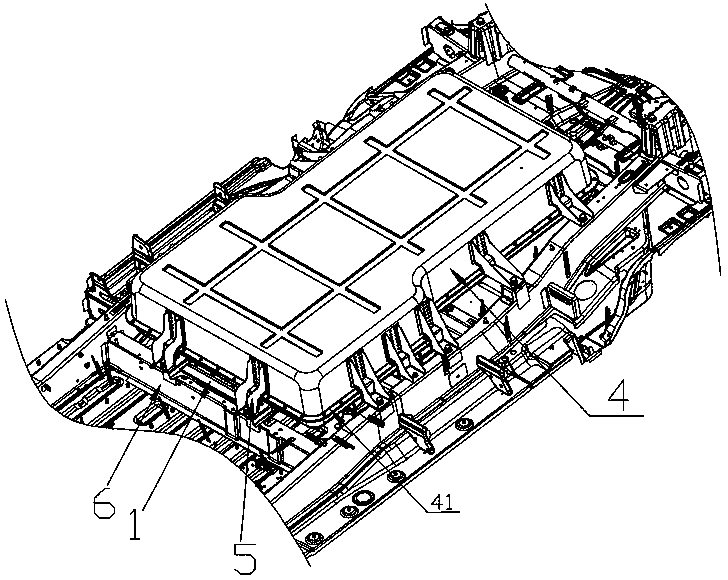

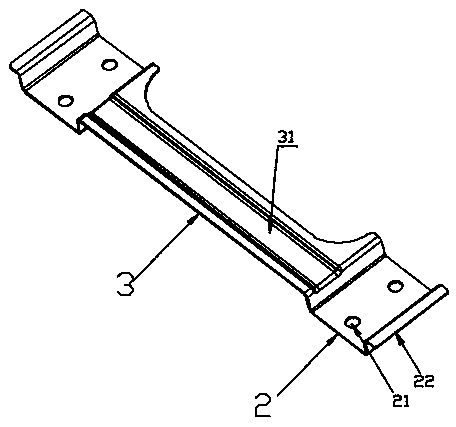

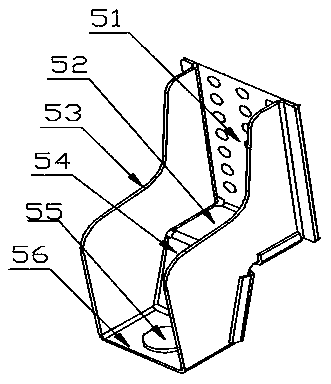

Power battery installing structure for novel electric vehicle

PendingCN109774446AImprove versatilityImprove stabilityElectric propulsion mountingUnderstructuresPower batteryElectrical battery

The invention discloses a power battery installing structure for a novel electric vehicle. The power battery installing structure comprises an expanded support body, a battery fixing support and a vehicle body beam. The power battery installing structure is characterized in that the expanded support body comprises reinforcing ribs, the two ends of each reinforcing rib are symmetrically provided with connecting tables respectively, the connecting tables are each of a groove structure, a plurality of through holes are formed in each connecting table, a turned edge is arranged on each connectingtable, the battery fixing support comprises a first connecting plate, a second connecting plate, a third connecting plate, a fourth connecting plate and a reinforcing plate, the first connecting plateand the end face of one side of a power battery are attached and fixedly connected through welding, first threaded holes are formed in the second connecting plate, corresponding second threaded holesare formed in the vehicle body beam, and the first threaded holes, the through holes and the second threaded holes are matched. Power batteries of different sizes can be assembled for the same vehicle type, the structure of a lower vehicle body does not need to be adjusted, the universality of the vehicle body is increased, and the research and development cost and manufacturing cost are saved.

Owner:JIANGXI CHANGHE AUTO

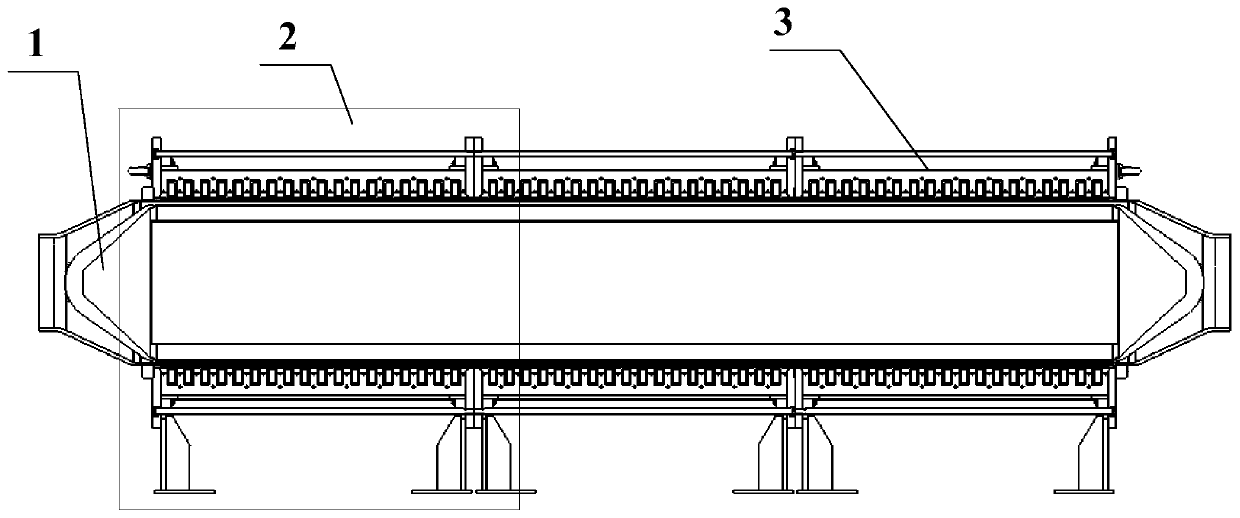

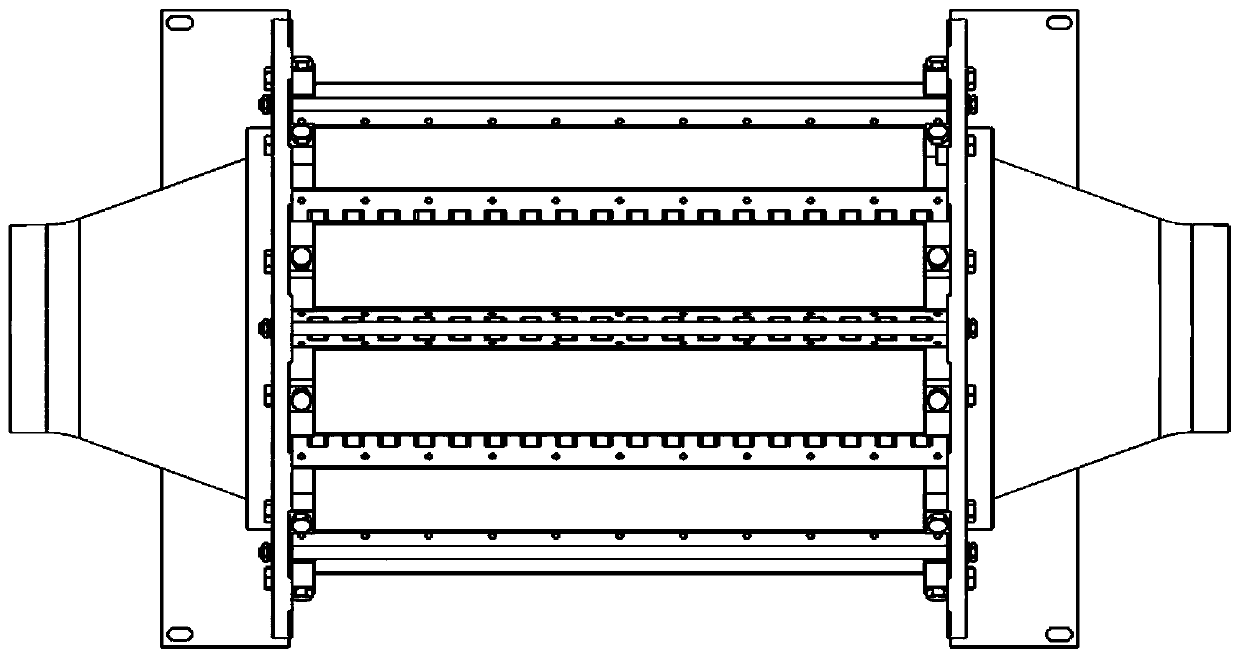

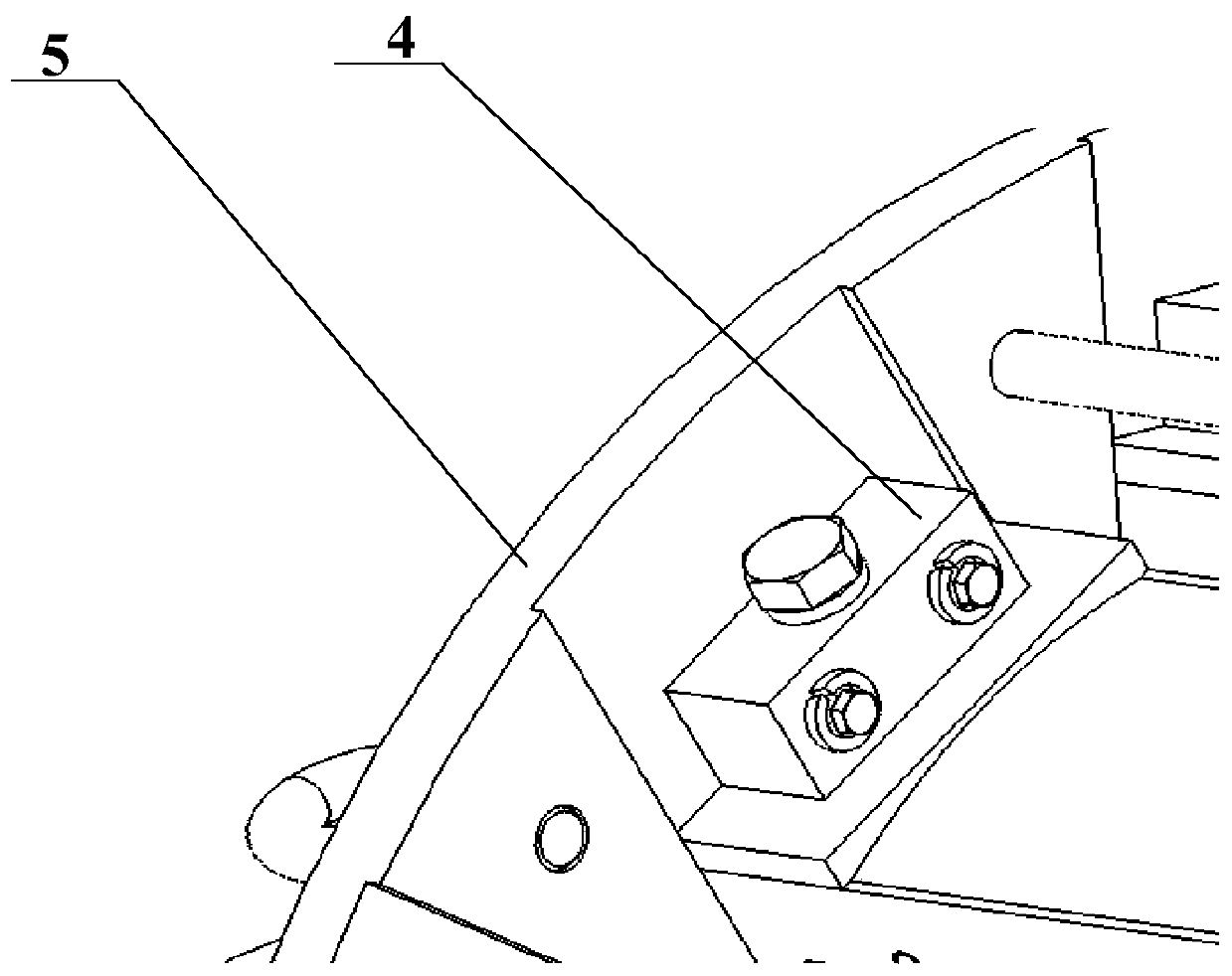

Modular electromagnetic pump

PendingCN110173406AImprove economySave design costPumpsPositive-displacement liquid enginesNuclear reactorElectromagnetic interference

The invention belongs to the field of nuclear reactors, and particularly relates to a modular electromagnetic pump for transporting liquid metal in the nuclear reactor. The pump comprises a pump gutter assembly and an electromagnetic module, wherein the electromagnetic module is used for providing electromagnetic force; the pump gutter assembly penetrates the center of the electromagnetic module;flanges are arranged at both ends of the electromagnetic module; fixed blocks are arranged at connecting parts of the flanges and the electromagnetic module; and thus, the modular electromagnetic pumpis provided.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com