Dynamic stiffness and dynamic damping test bench for foil dynamic-pressure air radial bearing

A radial bearing, dynamic stiffness technology, used in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as gaps, rotor system failures, large differences, etc., to improve accuracy, reduce The difficulty of designing the whole machine, the effect of saving R&D costs and the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

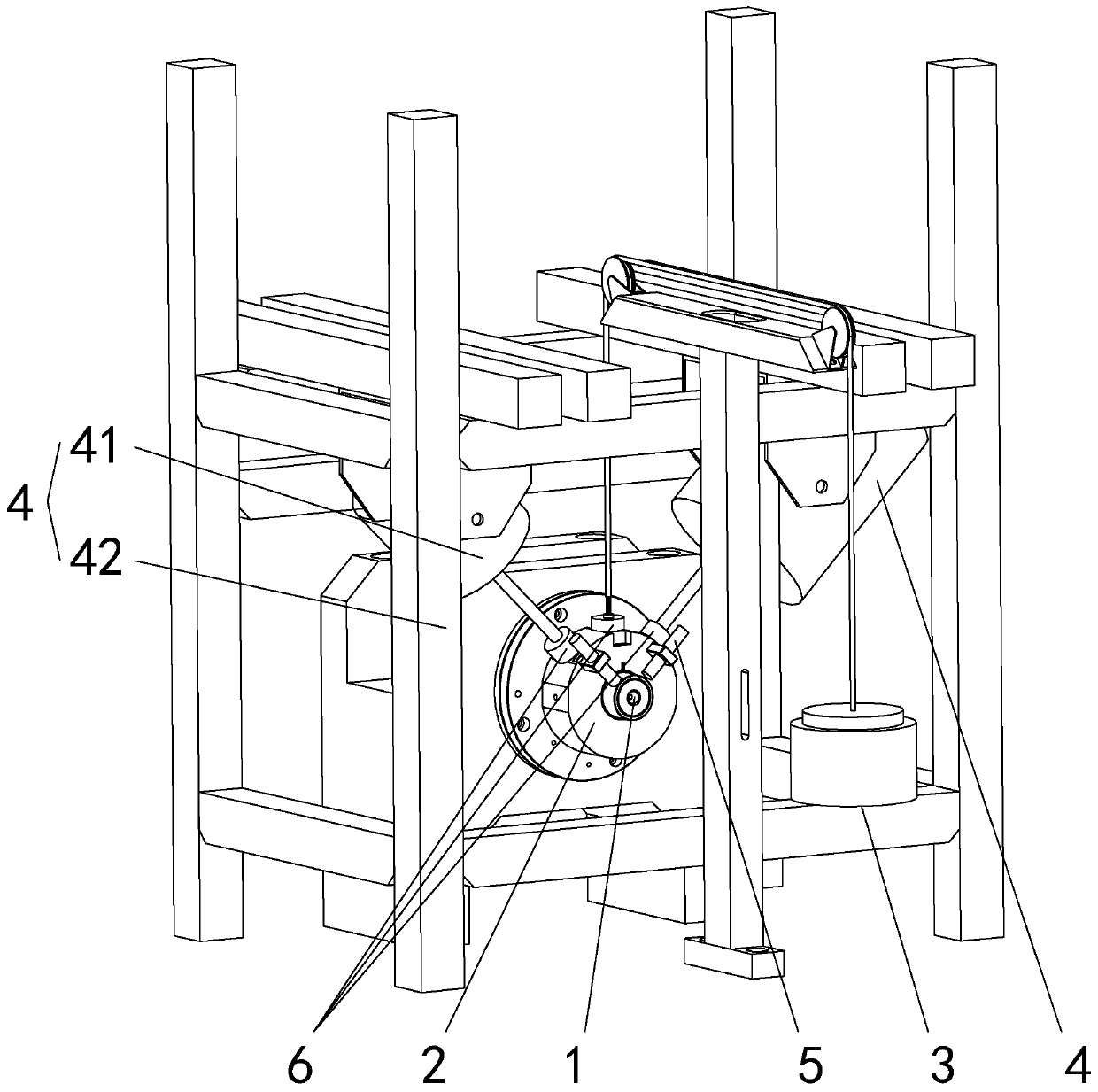

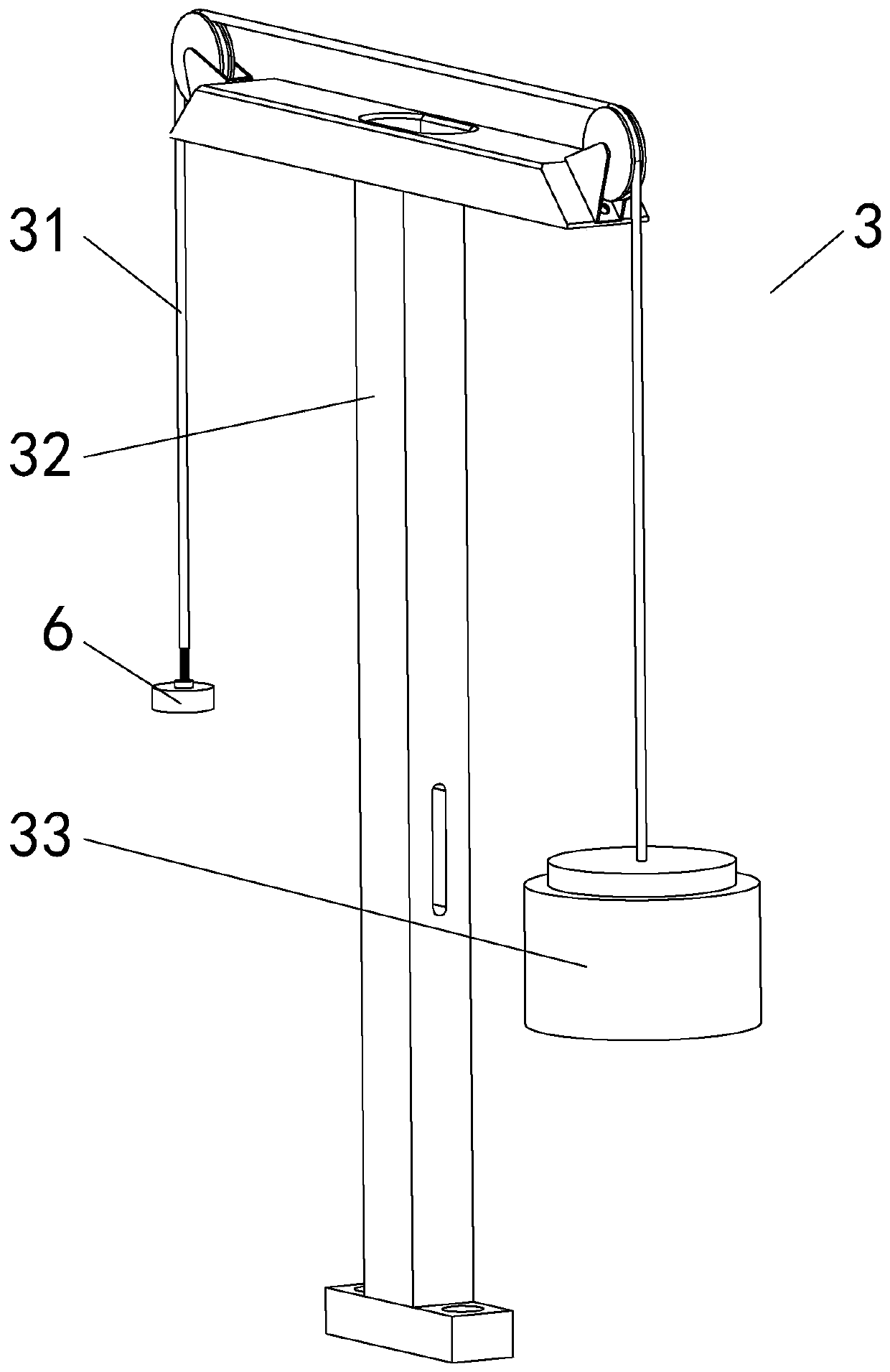

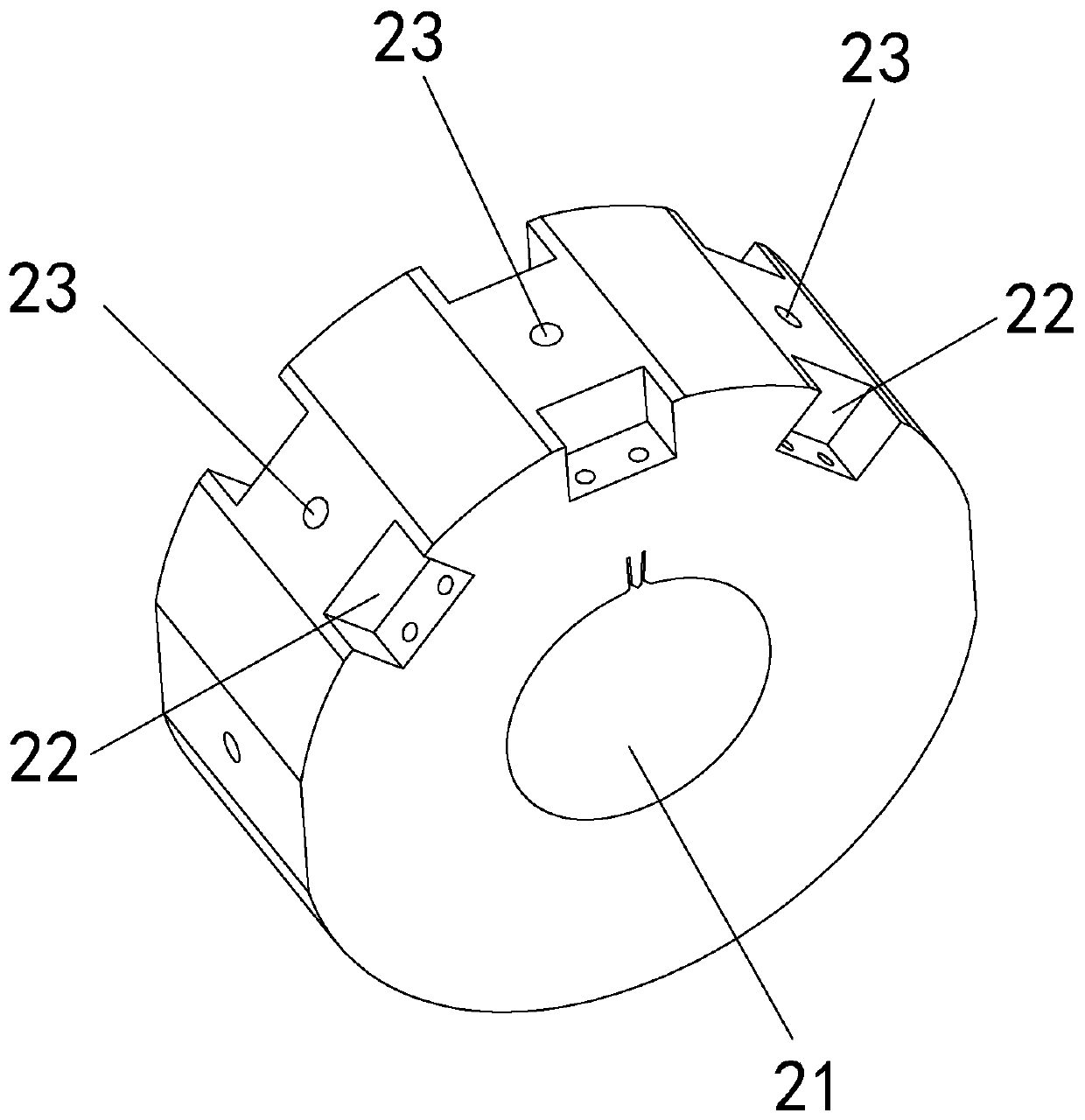

[0015] refer to Figure 1-Figure 3 , a dynamic stiffness and dynamic damping test bench for foil dynamic pressure air radial bearings, including a test bench electric spindle 1, a radial test bearing seat 2 set on the test bench electric spindle 1, and a radial test bearing seat 2 located in front of the test bench electric spindle 1 Static load loading device 3, dynamic load loading device 4 located on both sides of the radial test bearing seat 2, the electric spindle 1 of the test bench is supported by a static pressure air bearing, and is directly driven by a three-phase asynchronous motor. The three-phase asynchronous motor has high operating accuracy The characteristics of high stability and high stability greatly reduce the influence of the rotation of the shaft itself on the measurement of bearing performance parameters; the radial test bearing seat 2 is equipped with an eddy current displacement sensor 5, and the end of the static load loading device 3 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com