Preparation method of microspheres capable of increasing entrapment efficiency of hydrophilic medicines

A technology of hydrophilic drugs and encapsulation efficiency, applied in drug delivery, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve problems such as incomplete solid-liquid separation, sacrifice of yield, and irregular shape. Achieve the effects of saving R&D and production costs, improving competitiveness, and reducing pain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

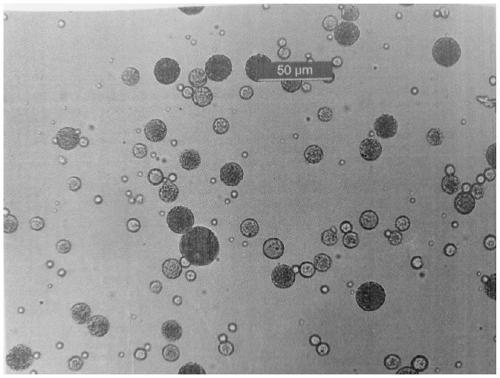

Image

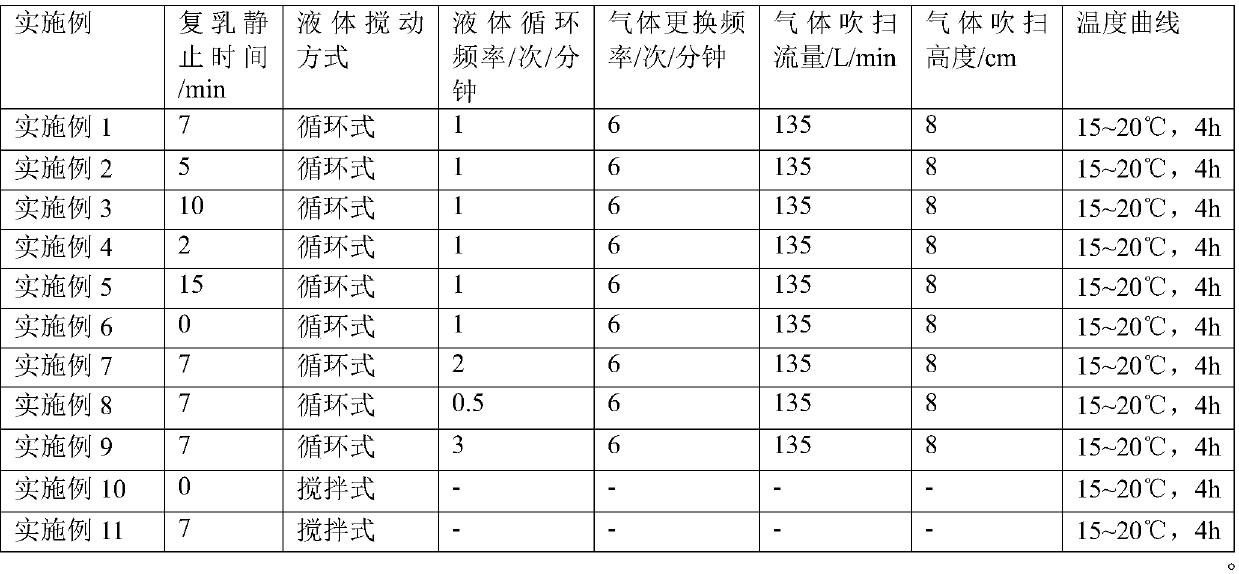

Examples

Embodiment 1

[0054] Weigh 0.78 g of leuprolide acetate and dissolve it in 1.0 g of distilled water, shake and dissolve under heating at 55° C., so as to obtain an inner aqueous phase solution. Weigh 6.0 g of poly(lactic-co-glycolic acid) copolymer and dissolve it in 10.0 g of dichloromethane, vortex and oscillate to dissolve, so as to obtain an oil phase solution. The above internal aqueous phase solution was added to the oil phase solution, emulsified by a homogenizer (IKA, T25) to obtain a colostrum, and then rapidly cooled to 15°C to increase the viscosity of the colostrum.

[0055] The aqueous solution (outer water phase) that contains 0.25% (w / w) polyvinyl alcohol is prepared in advance, and constant temperature is to 15 ℃, and the above-mentioned first emulsion that is kept at the same temperature and the outer water are passed through an online shearing machine (IKA, Magic Lab) uniformly disperse the primary emulsion to obtain a double emulsion with a target particle size.

[0056]...

Embodiment 2

[0061] Weigh 0.78 g of leuprolide acetate and dissolve it in 1.0 g of distilled water, shake and dissolve under heating at 55° C., so as to obtain an inner aqueous phase solution. Weigh 6.0 g of poly(lactic-co-glycolic acid) copolymer and dissolve it in 10.0 g of dichloromethane, vortex and oscillate to dissolve, so as to obtain an oil phase solution. The above internal aqueous phase solution was added to the oil phase solution, emulsified by a homogenizer (IKA, T25) to obtain a colostrum, and then rapidly cooled to 15°C to increase the viscosity of the colostrum.

[0062] The aqueous solution (outer water phase) that contains 0.25% (w / w) polyvinyl alcohol is prepared in advance, and constant temperature is to 15 ℃, and the above-mentioned first emulsion that is kept at the same temperature and the outer water are passed through an online shearing machine (IKA, Magic Lab) uniformly disperse the primary emulsion to obtain a double emulsion with a target particle size.

[0063]...

Embodiment 3

[0068] Weigh 0.78 g of leuprolide acetate and dissolve it in 1.0 g of distilled water, shake and dissolve under heating at 55° C., so as to obtain an inner aqueous phase solution. Weigh 6.0 g of poly(lactic-co-glycolic acid) copolymer and dissolve it in 10.0 g of dichloromethane, vortex and oscillate to dissolve, so as to obtain an oil phase solution. The above internal aqueous phase solution was added to the oil phase solution, emulsified by a homogenizer (IKA, T25) to obtain a colostrum, and then rapidly cooled to 15°C to increase the viscosity of the colostrum.

[0069] The aqueous solution (outer water phase) that contains 0.25% (w / w) polyvinyl alcohol is prepared in advance, and constant temperature is to 15 ℃, and the above-mentioned first emulsion that is kept at the same temperature and the outer water are passed through an online shearing machine (IKA, Magic Lab) uniformly disperse the primary emulsion to obtain a double emulsion with a target particle size.

[0070]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com