Preparation method of ultrafine porous calcium carbonate microsphere

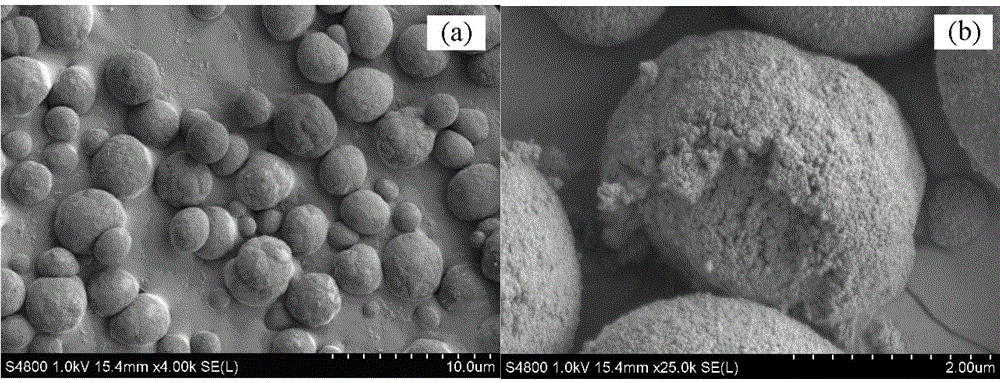

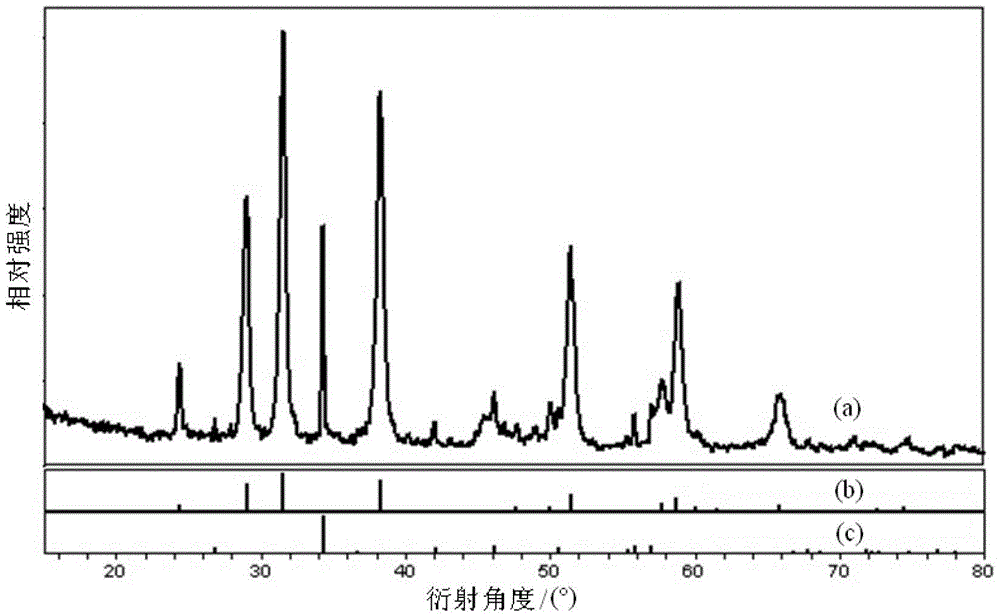

A technology of porous calcium carbonate and microspheres, which is applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of smooth surface of calcium carbonate microspheres and unsuitability for drug carriers, and achieve uniform size, spherical shape and wide application value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Dissolve the surfactant Tween-80 in the aqueous solution of n-hexane at a volume ratio of 4:100, and stir evenly with magnetic force at room temperature to obtain a mixed solution A; the volume fraction of n-hexane in the aqueous solution of n-hexane is 0.5% ;

[0033] 2) According to PVP and Na 2 CO 3 The molar ratio is 0.3:1, PVP is added to Na with a concentration of 1mol / L 2 CO 3 In the aqueous solution, stir magnetically at room temperature until the PVP is completely dissolved to obtain a mixed solution B;

[0034] 3) Add the mixed solution A to the mixed solution B, and ultrasonically emulsify with a power of 275W for 10 minutes to obtain an emulsion; the Na in the emulsion 2 CO 3 The concentration is 0.3mol / L;

[0035] 4) Under magnetic stirring, press Na 2 CO 3 with CaCl 2 The molar ratio is 2:3, and the emulsion that has just been ultrasonically emulsified is quickly poured into CaCl with a concentration of 0.15mol / L 2 In the aqueous solution, mag...

Embodiment 2

[0038] 1) Dissolve the surfactant Tween-80 in the aqueous solution of n-hexane at a volume ratio of 5:100, and stir evenly with magnetic force at room temperature to obtain a mixed solution A; the volume fraction of n-hexane in the aqueous solution of n-hexane is 0.8% ;

[0039] 2) According to PVP and Na 2 CO 3 The molar ratio of PVP is 0.15:1, and PVP is added to Na with a concentration of 0.5mol / L 2 CO 3 In the aqueous solution, stir magnetically at room temperature until the PVP is completely dissolved to obtain a mixed solution B;

[0040] 3) Add the mixed solution A to the mixed solution B, and ultrasonically emulsify with a power of 275W for 5 minutes to obtain an emulsion; the Na in the emulsion 2 CO 3 The concentration is 0.3mol / L;

[0041] 4) Under magnetic stirring, press Na 2 CO 3 with CaCl 2 The molar ratio is 2:3, and the emulsion that has just been ultrasonically emulsified is quickly poured into CaCl with a concentration of 0.2mol / L 2 In the aqueous s...

Embodiment 3

[0044] 1) Dissolve the surfactant Tween-80 in the aqueous solution of n-hexane at a volume ratio of 6:100, and stir evenly with magnetic force at room temperature to obtain a mixed solution A; the volume fraction of n-hexane in the aqueous solution of n-hexane is 1% ;

[0045] 2) According to PVP and Na 2 CO 3 The molar ratio of PVP is 0.75:1 and PVP is added to Na with a concentration of 1.5mol / L 2 CO 3 In the aqueous solution, stir magnetically at room temperature until the PVP is completely dissolved to obtain a mixed solution B;

[0046] 3) Add the mixed solution A to the mixed solution B, and ultrasonically emulsify for 20 minutes with a power of 275W to obtain an emulsion; the Na in the emulsion 2 CO 3 The concentration is 0.3mol / L;

[0047] 4) Under magnetic stirring, press Na 2 CO 3 with CaCl 2 The molar ratio is 2:3, and the emulsion that has just been ultrasonically emulsified is quickly poured into CaCl with a concentration of 0.1mol / L 2 In the aqueous sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com