Modular electromagnetic pump

An electromagnetic pump, modular technology, applied in the field of nuclear reactors, can solve the problems of great difficulty in the design, manufacture and installation of large-flow electromagnetic pumps, and achieve design and research and development costs savings, more coil turns, and greater electromagnetic thrust Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to illustrate the technical solutions of the present disclosure more clearly, a brief introduction will be made below in conjunction with specific implementation methods, and the specific circumstances are as follows:

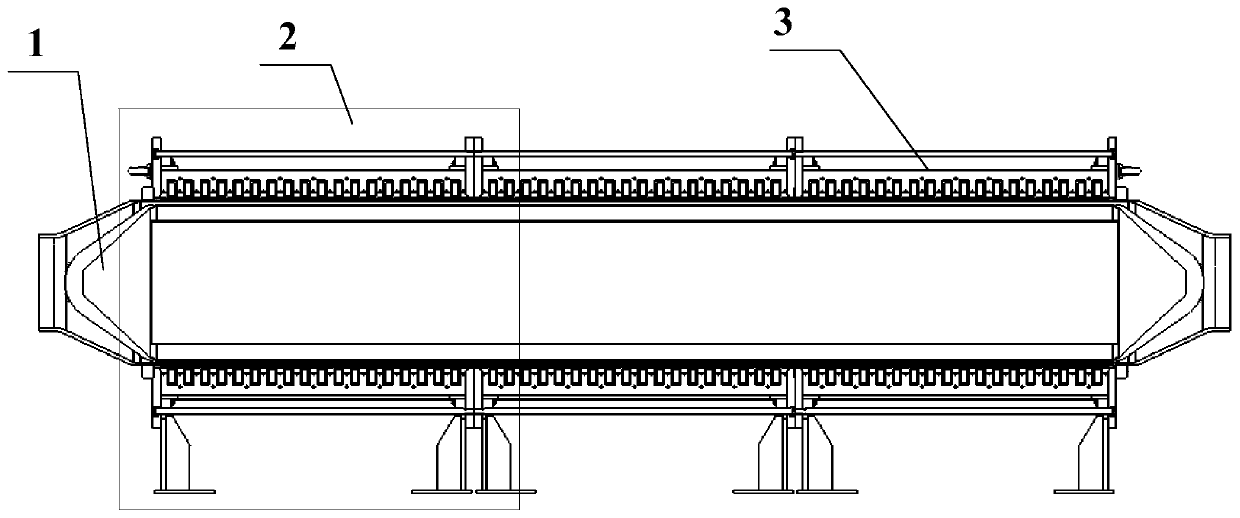

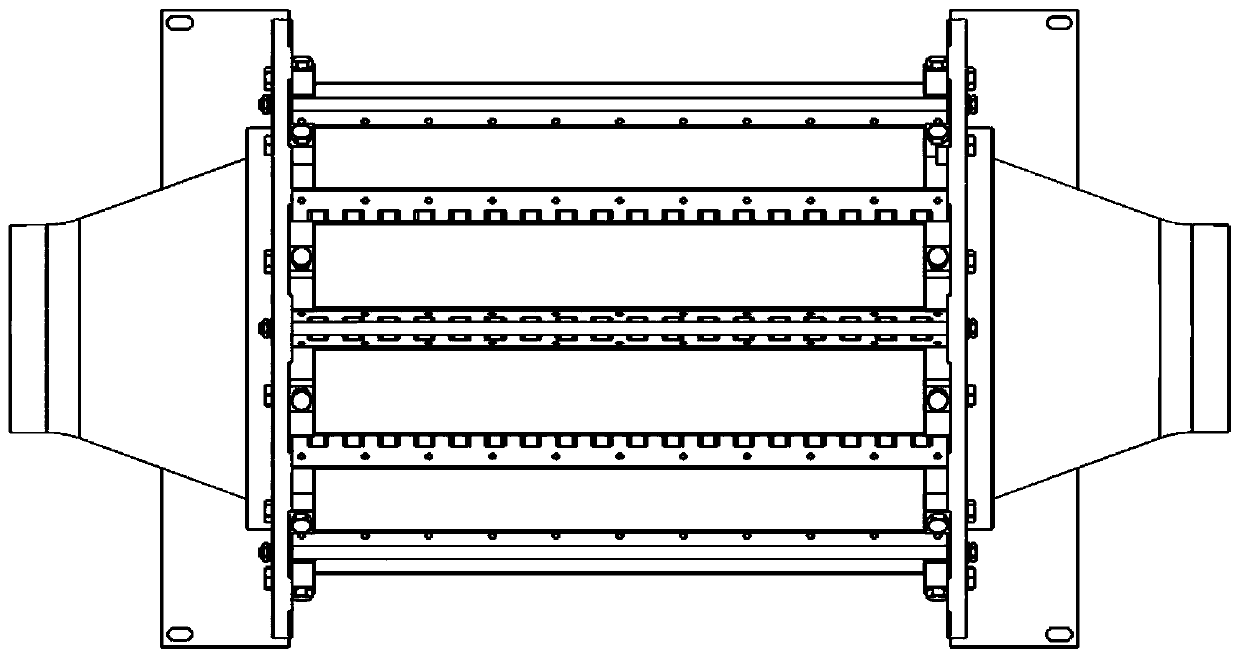

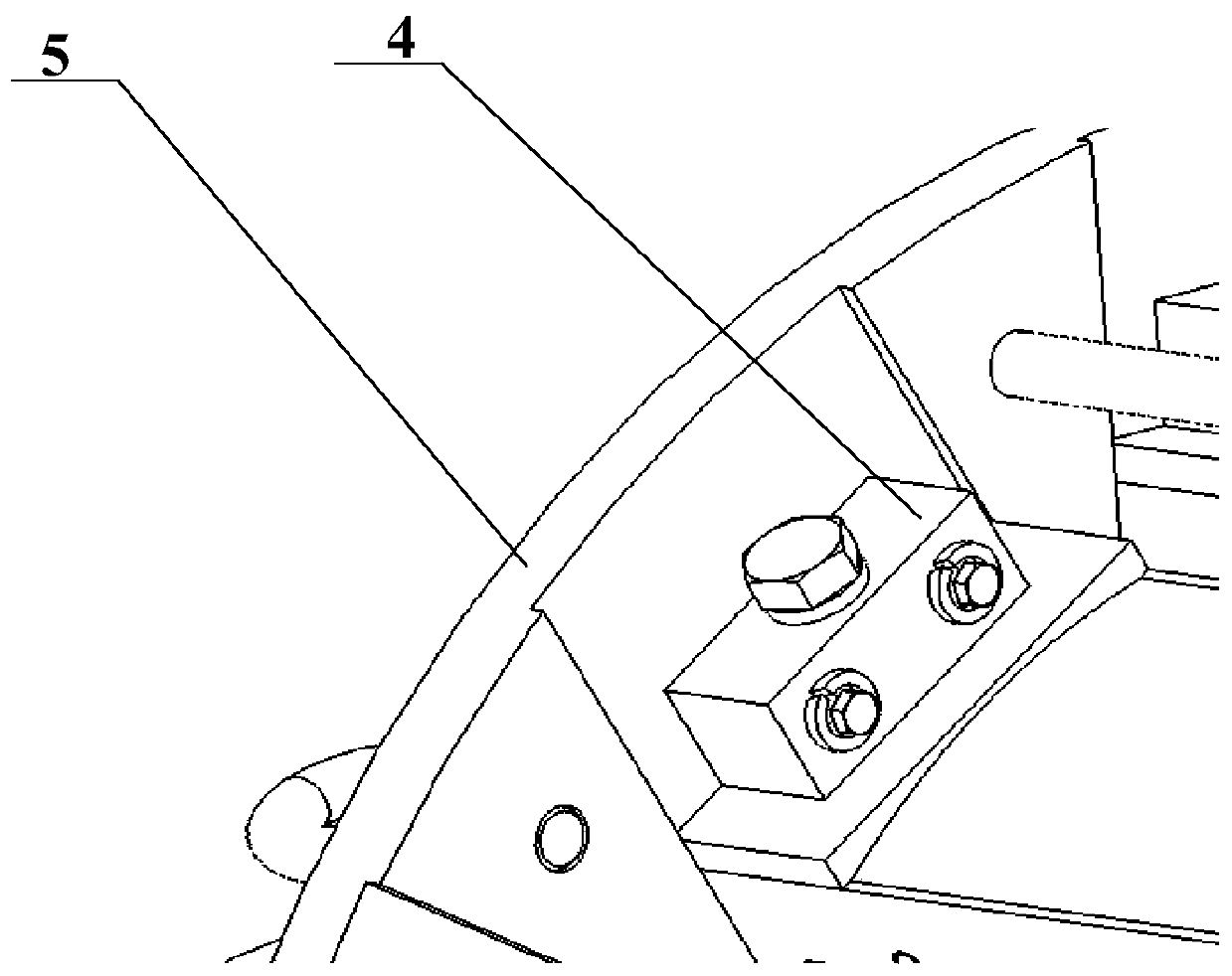

[0024] The present disclosure discloses a modular electromagnetic pump, which comprises: a pump channel assembly 1 and an electromagnetic module 2; wherein the electromagnetic module 2 is used to provide electromagnetic force; the pump channel assembly 1 runs through the center of the electromagnetic module 2; the two ends of the electromagnetic module 2 are arranged There is a flange 5, and a fixing block 4 is arranged at the joint between the flange 5 and the electromagnetic module 2. The modular electromagnetic pump also includes a stator assembly 3 , and the fixing block 4 is provided with studs for adjusting the air gap between the stator assembly 3 and the pump channel assembly 1 . The number of fixed blocks 4 is greater than or equal to 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com