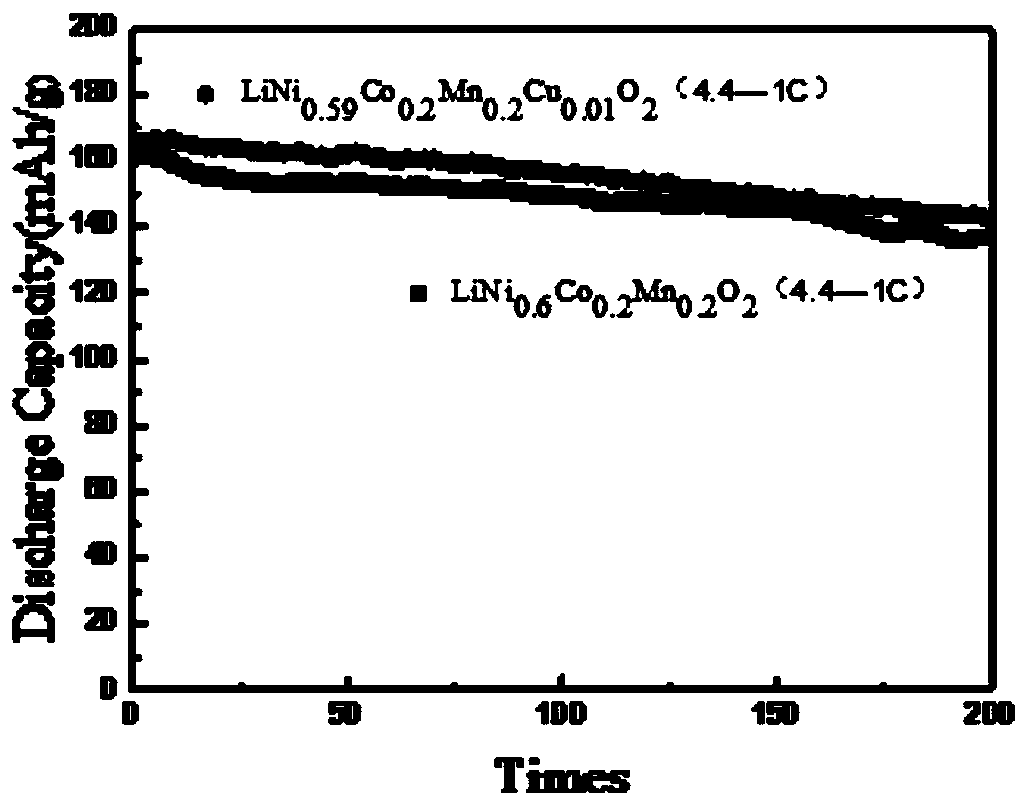

Preparation method of copper-doped ternary positive electrode material

A positive electrode material, copper doping technology, applied in positive electrodes, electrical components, battery electrodes, etc., can solve the problems of unstable electrochemical performance of products, long calcination time, difficult diffusion process, etc., to save research and development time and cost, The effect of improving electrochemical performance and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

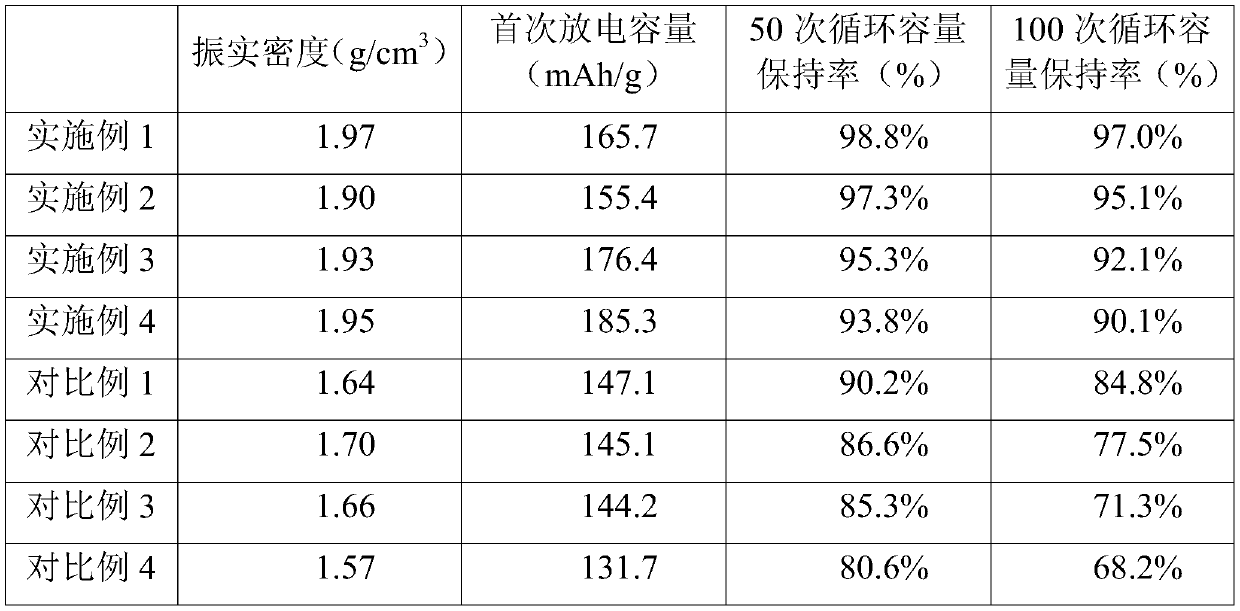

Examples

Embodiment 1

[0033] A method for preparing a copper-doped ternary positive electrode material, comprising the following steps:

[0034] (1) Weigh NiSO with an electronic balance 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, CuSO 4 ·5H 2 O, make the molar ratio n(Ni:Co:Mn:Cu)=0.59:0.2:0.2:0.01, add deionized water to be mixed with 1.5L, 2.5mol / L mixed metal solution;

[0035] Take ammonia water as a complexing agent, dissolve it in deionized water, and prepare 0.5 L of solution B with a concentration of 3 mol / L;

[0036] Take sodium hydroxide as a precipitant, dissolve it in deionized water, and prepare a solution C with a concentration of 10mol / L;

[0037] (2) Add 2L, 0.9mol / L ammonia solution to the 5L reaction kettle as the bottom liquid; Add solution A, solution B and solution C to the reaction kettle at a constant speed under the control of the peristaltic pump to control the feed flow rate of solution A ≤3mL / min, the feed flow rate of solution B is ≤1.2mL / min, the feed flow rate ...

Embodiment 2

[0042] A method for preparing a copper-doped ternary positive electrode material, comprising the following steps:

[0043] (1) Weigh NiSO with an electronic balance 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, CuSO 4 ·5H 2 O, to make the molar ratio n(Ni:Co:Mn:Cu)=0.6:0.17:0.2:0.03, add deionized water to prepare a mixed metal solution of 1.5L, 2mol / L;

[0044] Take ammonia water as a complexing agent, dissolve it in deionized water, and prepare a solution B with a concentration of 0.5 L and 2 mol / L;

[0045] Take sodium hydroxide as a precipitating agent, dissolve it in deionized water, and prepare a solution C whose concentration is 8mol / L;

[0046] (2) Add 2L, 1mol / L ammonia solution to the 5L reaction kettle as the bottom liquid; add solution A, solution B and solution C to the reaction kettle at a uniform speed under the control of the peristaltic pump, and control the feed flow rate of solution A≤ 3mL / min, the feed flow rate of solution B is ≤1.2mL / min, the feed fl...

Embodiment 3

[0049] A method for preparing a copper-doped ternary positive electrode material, comprising the following steps:

[0050] (1) Weigh NiSO with an electronic balance 4 ·6H 2 O. CoSO 4 ·7H 2 O, MnSO 4 ·H 2 O, CuSO 4 ·5H 2 O, make the molar ratio n(Ni:Co:Mn:Cu)=0.33:0.33:0.33:0.01, add deionized water to prepare 1L, 3mol / L mixed metal solution;

[0051] Take ammonia water as a complexing agent, dissolve it in deionized water, and prepare a solution B with a concentration of 0.5 L and 3 mol / L;

[0052] Take sodium hydroxide as a precipitating agent, dissolve it in deionized water, and prepare a solution C whose concentration is 5mol / L;

[0053] (2) Add 1.5L, 1mol / L ammonia solution to the 5L reaction kettle as the bottom liquid; add solution A, solution B and solution C to the reaction kettle at a constant speed under the control of the peristaltic pump, and control the feed flow rate of solution A ≤3mL / min, the feed flow rate of solution B is ≤1.2mL / min, the feed flow ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com