Clutch structure and clothes processing device

A clothing processing and clutch technology, applied in washing devices, other washing machines, textiles and paper making, etc., can solve the problems of energy waste, inability to realize the drying work of washing machines and dryers, etc., so as to reduce the failure rate and save R&D and production. Cost, easy to set up effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

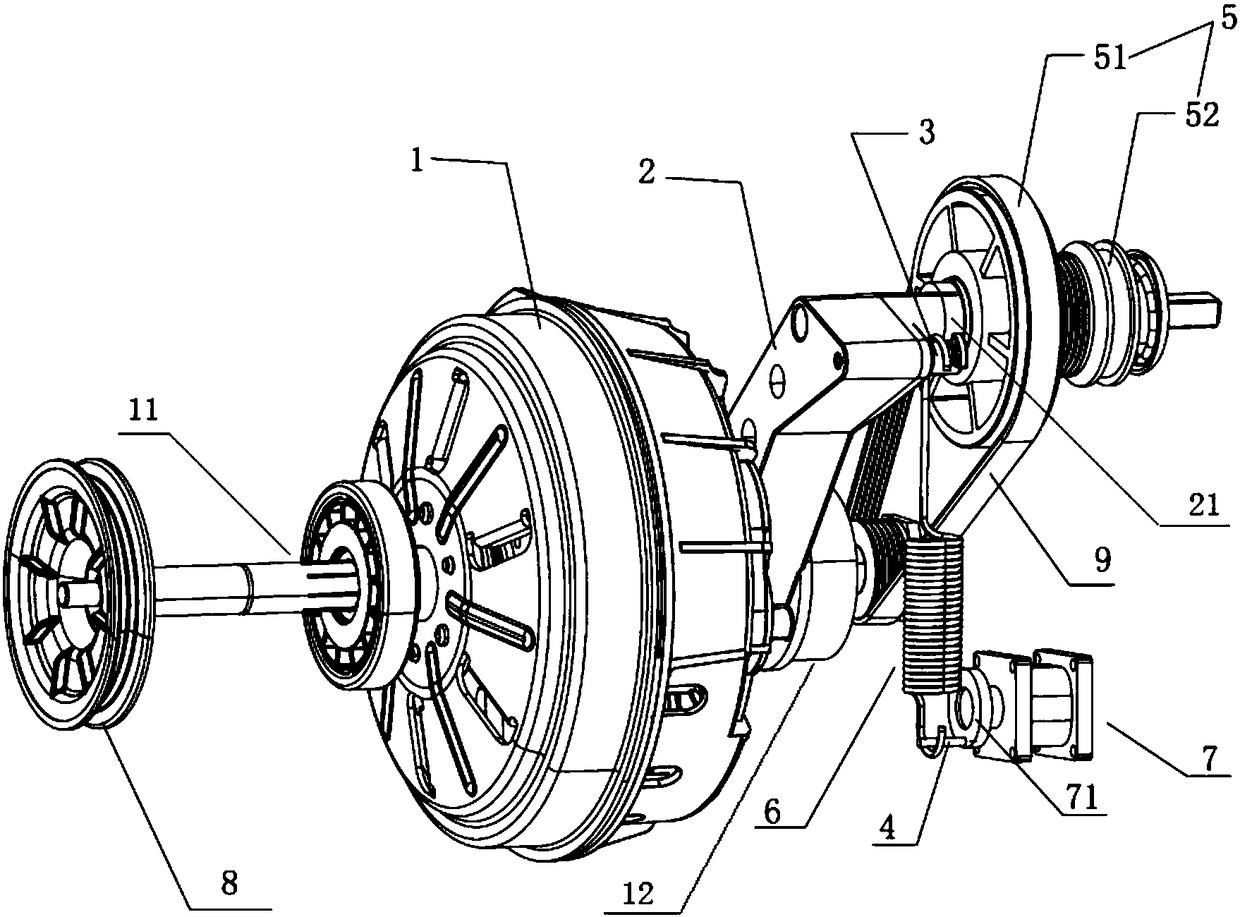

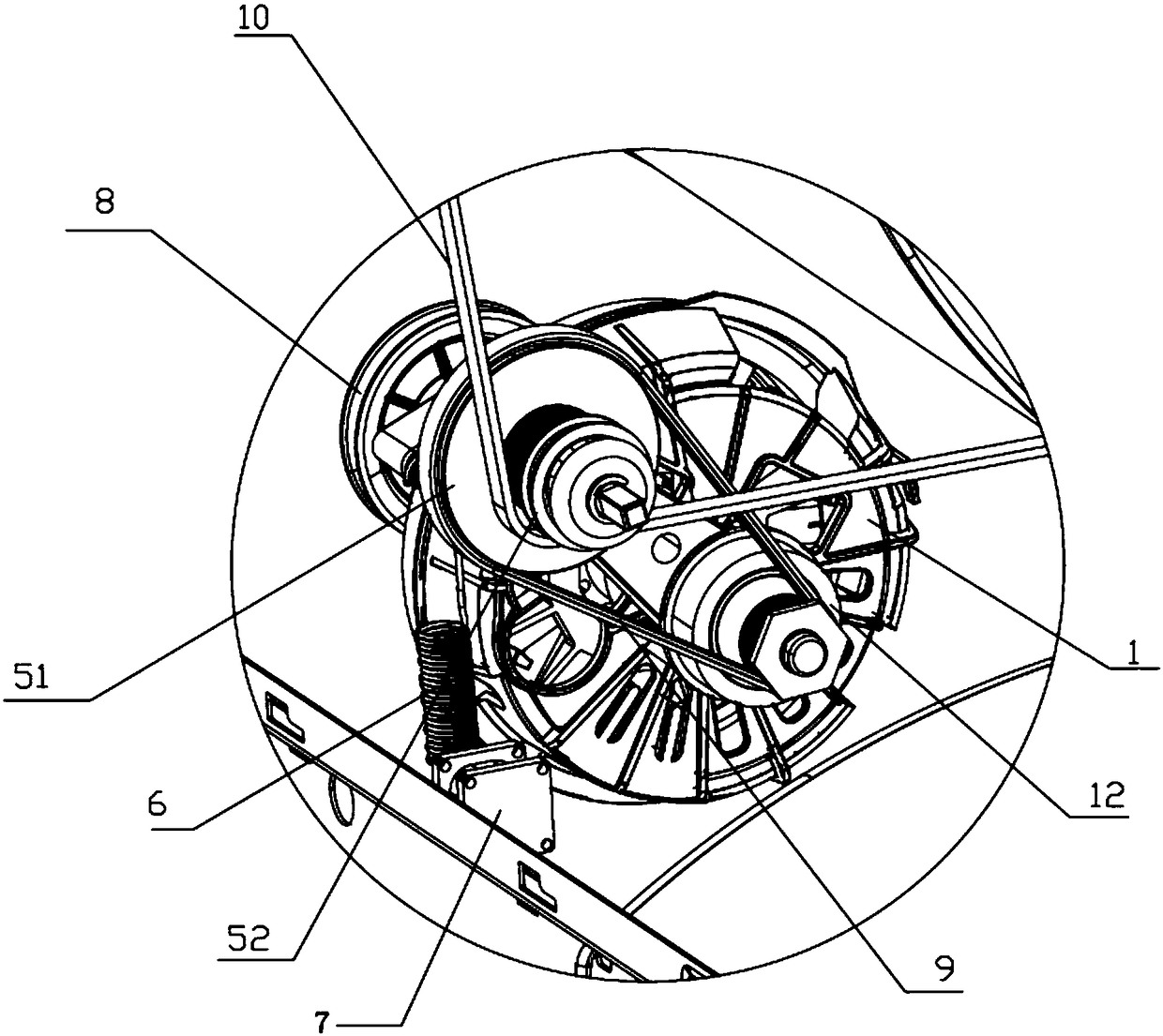

[0041] Figure 1-Figure 5 The clutch structure of the present invention and a laundry treatment device with the clutch structure are shown.

[0042] A clutch structure, including a driving motor 1, the first output end 11 of the driving motor 1 is connected to the drying fan through a pulley 8, the second output end 12 drives the driven wheel 5 to rotate, and the driven wheel 5 is connected to the drying fan through the second belt 10 The clothes processing cylinder 100 is connected to drive it to rotate, and the driven wheel 5 is relatively swingably mounted on the drive motor 1 through the rocker arm 2, so that the control motor 7 can controllably pull the rocker arm 2 to move through the spring 6 to change the position of the driven wheel 5, Adjust the tension or loosen of the second belt 10 to realize the engagement and separation of the pulley and the belt.

[0043]The laundry processing tub 100 may be a washing tub of a washing machine or a drying tub of a clothes dryer...

Embodiment 2

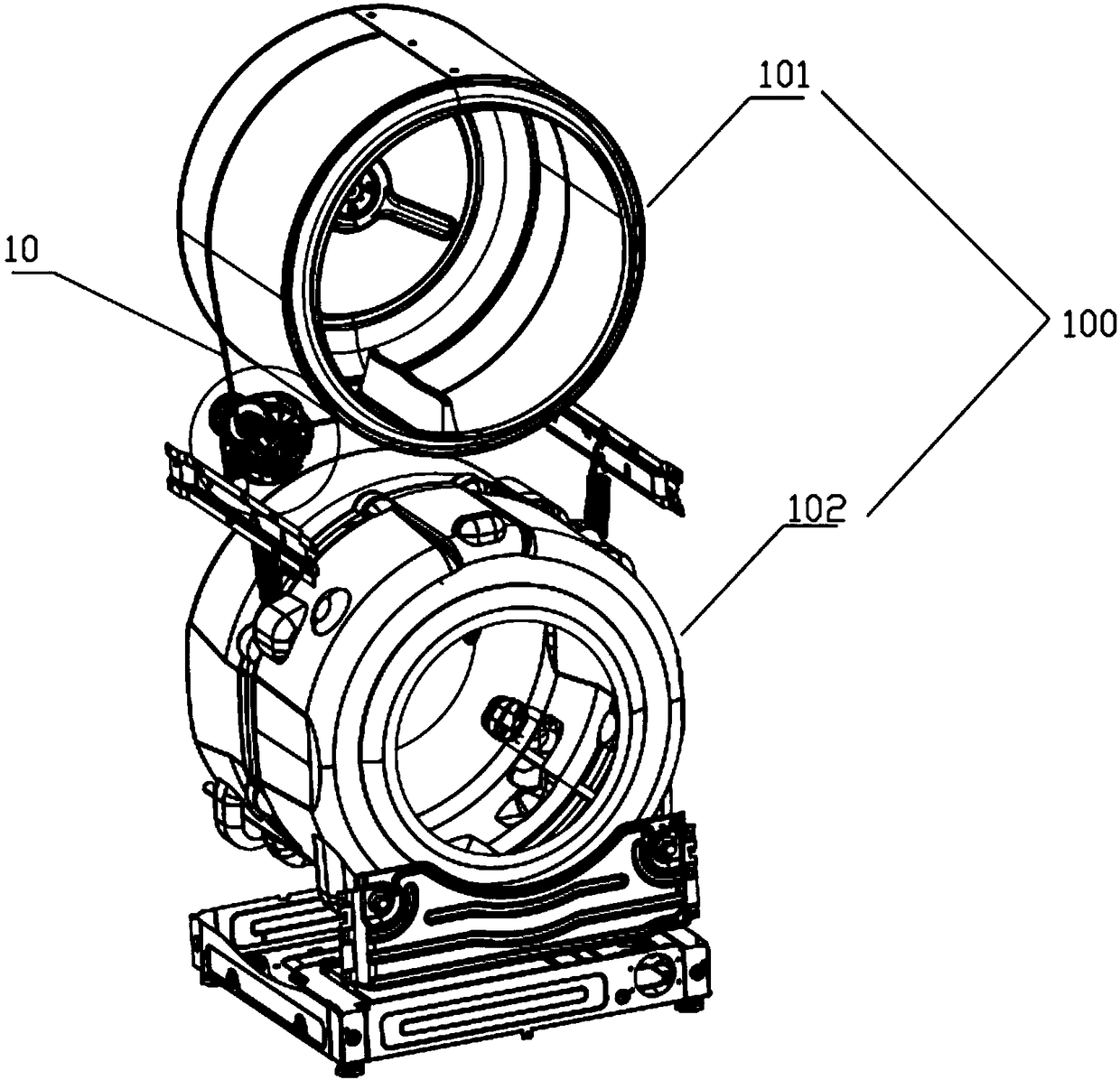

[0071] The difference between this embodiment and Embodiment 1 is that the clutch structure is used for a double-drum washing machine including two drums arranged up and down, both drums have a drying function, and use the same drying and condensing system.

[0072] The purpose of this embodiment is to solve how to realize the drying function of the two cylinders of the double-drum washing machine respectively, so as to avoid driving the other cylinder to rotate together when one of the cylinders is running and drying when it is not needed, which can not only save energy, but also It is also possible to control the laundry treatment steps of the two drums separately.

[0073] A clutch structure, including a driving motor 1, the first output end 11 of the driving motor 1 is connected to the drying fan through a pulley 8, the second output end 12 drives the driven wheel 5 to rotate, and the driven wheel 5 is connected to the drying fan through the second belt 10 The clothes proc...

Embodiment 3

[0093] A clutch structure, including a driving motor 1, one output end of the driving motor 1 is connected to the drying fan through a pulley 8, and the other output end 8 is connected to the driven wheel 5 through a second belt 10. The clothes processing cylinder is connected to 100, and a rocker arm 2 is arranged between the drive motor 1 and the driving wheel. The rocker arm 2 is connected to one end of the spring 6, and the other end of the spring 6 is connected to the control motor 7 and adjusted by it to control the driven wheel 5 and the first wheel. The meshing state of the two belts 10.

[0094] The laundry processing cylinder described in this embodiment is a clothes drying cylinder of a clothes dryer.

[0095] One end of the driven wheel 5 connected to the rocker arm 2 is provided with a first fixed post 3 connected to one end of the spring 6, and the wheel 71 of the control motor 7 is provided with a second fixed post connected to the other end of the spring 6. 4....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com