Method for growing REBCO high-temperature superconductor

A high-temperature superconducting and growth furnace technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of unsatisfactory Y211 particle content, large RE211 particles, time-consuming and labor-intensive, etc., to achieve inhibition of dissolution and diffusion, The effect of increasing concentration and improving thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

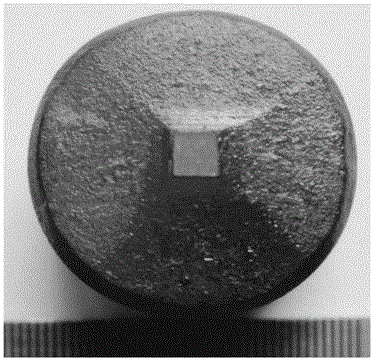

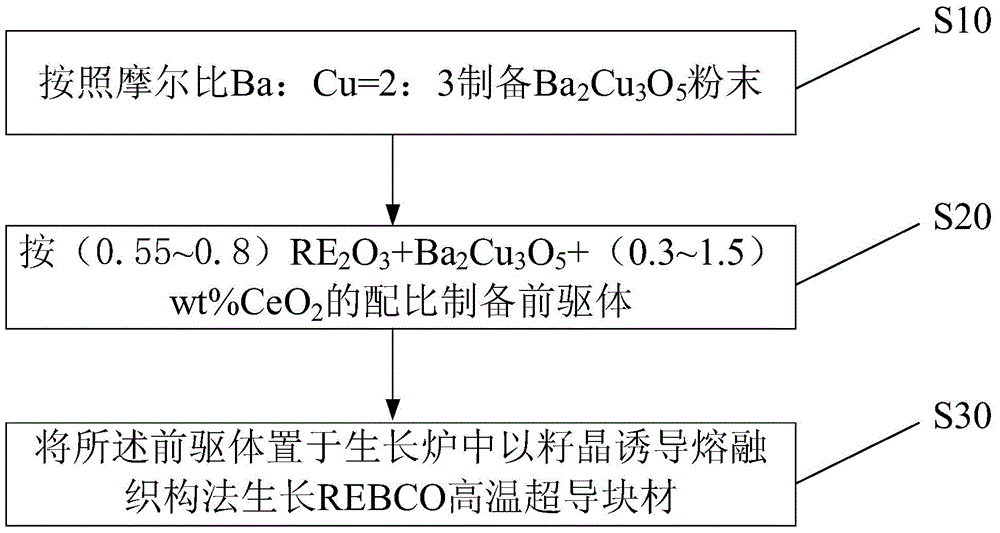

[0049] A method for growing YBCO high-temperature superconducting bulk material, comprising the following steps:

[0050] 1. According to the molar ratio of Ba:Cu=2:3, BaCO 3 Mix with CuO powder to get BaCO 3 +CuO powder;

[0051] 2. To the BaCO described in step 1 3 +CuO powder is mixed with absolute ethanol and then wet-milled to obtain BaCO 3 +CuO slurry, wet grinding time is 2-4 hours;

[0052] 3. Dry the BaCO obtained in step 2 3 +CuO slurry to prepare Ba 2 Cu 3 o 5 powder;

[0053] 4. Put the Ba in step 3 2 Cu 3 o 5 The powder was sintered in the air at 900°C for 48 hours and this grinding and sintering process was repeated twice to finally obtain Ba 2 Cu 3 o 5 powder.

[0054] 5. The Ba obtained in step 4 2 Cu 3 o 5 Powder according to 0.75Y 2 o 3 +Ba 2 Cu 3 o 5 +(0.3~1.5)wt%CeO 2 After fully grinding and mixing the ingredients, take 10g of the mixed powder and put it into the mold.

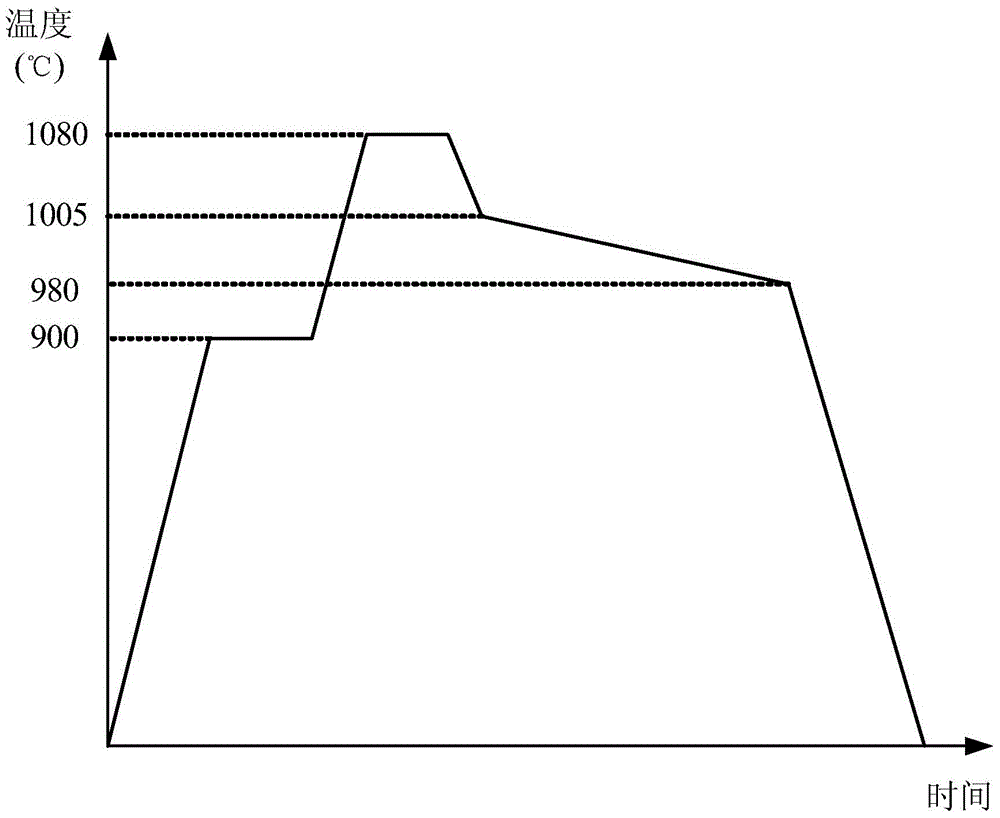

[0055] 6. Use the embedded seed crystal method to press the p...

Embodiment 2

[0064] A method for growing NdBCO high-temperature superconducting bulk material, comprising the following steps:

[0065] 1. According to the ratio of Ba: Cu = 2: 3, BaCO 3 Mix with CuO powder to get BaCO 3 +CuO powder;

[0066] 2. To the BaCO described in step 1 3+CuO powder is mixed with absolute ethanol and then wet-milled to obtain BaCO 3 +CuO slurry, wet grinding time is 2-4 hours;

[0067] 3. Dry the BaCO obtained in step 2 3 +CuO slurry to prepare Ba 2 Cu 3 o 5 powder;

[0068] 4. Put the Ba in step 3 2 Cu 3 o 5 The powder was sintered in the air at 900°C for 48 hours and this grinding and sintering process was repeated twice to finally obtain Ba 2 Cu 3 o 5 powder.

[0069] 5. The Ba obtained in step 4 2 Cu 3 o 5 Powder press 0.75Nd 2 o 3 +Ba 2 Cu 3 o 5 +(0.3~1.5)wt%CeO 2 After fully grinding and mixing the ingredients, take 10g of the mixed powder and put it into the mold.

[0070] 6. Use the embedded seed crystal method to press the powder de...

Embodiment 3

[0078] A method for growing SmBCO high-temperature superconducting bulk material, comprising the following steps:

[0079] 1. According to the ratio of Ba: Cu = 2: 3, BaCO 3 Mix with CuO powder to get BaCO 3 +CuO powder;

[0080] 2. To the BaCO described in step 1 3 +CuO powder is mixed with absolute ethanol and then wet-milled to obtain BaCO 3 +CuO slurry, wet grinding time is 2-4 hours;

[0081] 3. Dry the BaCO obtained in step 2 3 +CuO slurry to prepare Ba 2 Cu 3 o 5 powder;

[0082] 4. Put the Ba in step 3 2 Cu 3 o 5 The powder was sintered in the air at 900°C for 48 hours and this grinding and sintering process was repeated twice to finally obtain Ba 2 Cu 3 o 5 powder.

[0083] 5. The Ba obtained in step 4 2 Cu 3 o 5 Powder by 0.75Sm 2 o 3 +Ba 2 Cu 3 o 5 +(0.3~1.5)wt%CeO 2 After fully grinding and mixing the ingredients, take 10g of the mixed powder and put it into the mold.

[0084] 6. Use the embedded seed crystal method to press the powder desc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com