Patents

Literature

38results about How to "Good electromagnetic performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

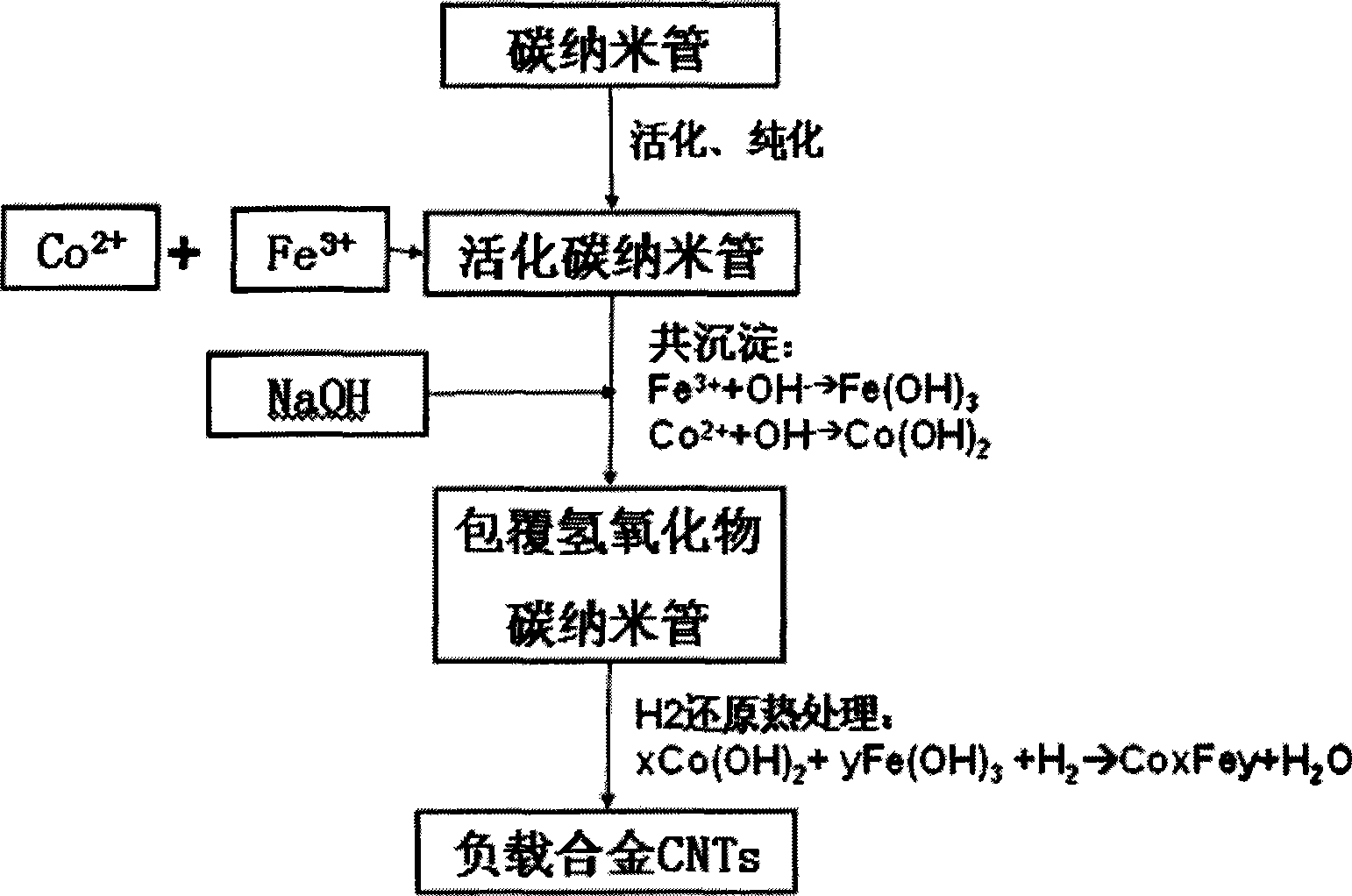

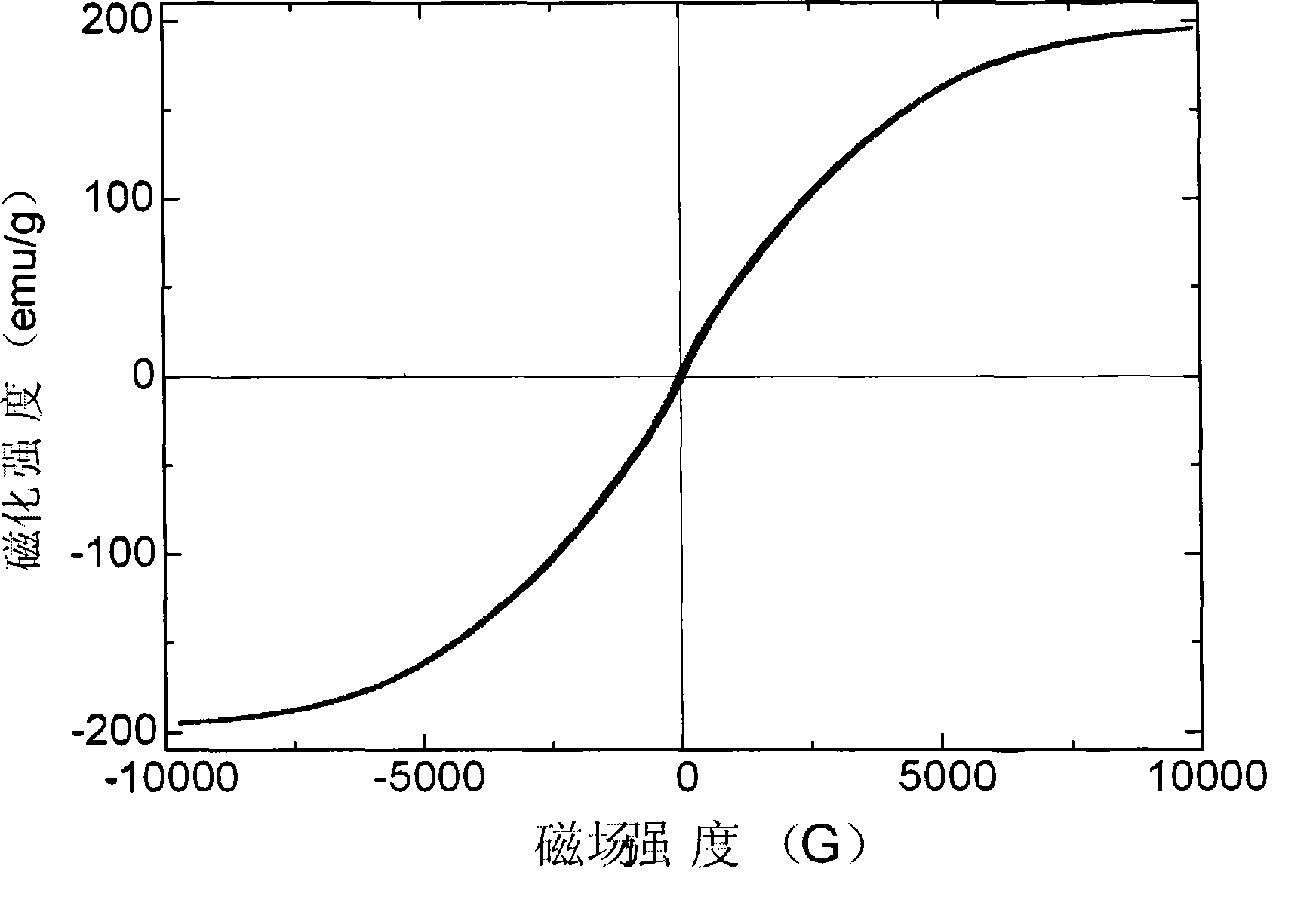

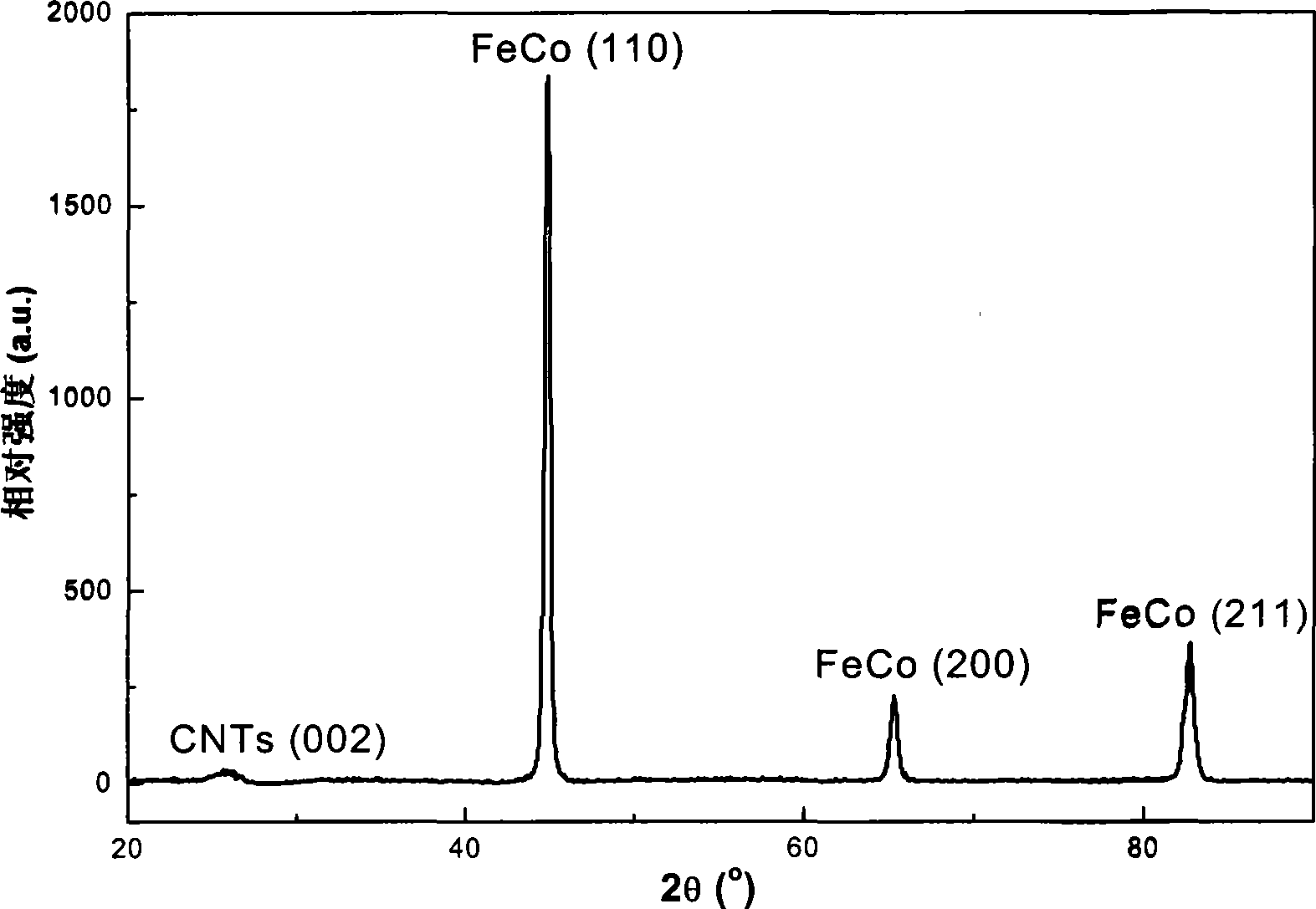

Preparation of surface load magnetic alloy particle carbon nano-tube composite material

InactiveCN101503579AGood electromagnetic performanceCrystallization intactOther chemical processesPigment physical treatmentCarbon nanotubeCrystallinity

The invention discloses a preparation method for carbon nano tube surface loaded magnetic alloy nano particle composite material, which belongs to the field of electromagnetic wave absorbing material preparation. The preparation method comprises the following steps: after purifying and activating a carbon nano tube, evenly dispersing the carbon nano tube to chloride salt solution of iron, cobalt and nickel, slowing adding an alkali solution dropwise into the solution in the fierce agitation process, and regulating the pH value of the solution and making iron ions, cobalt ions and nickel ions be coprecipitated onto the surface of the carbon nano pipe in the form of hydroxide according to the alloy proportion set when the solution is prepared; taking out a deposit by centrifugation or filtering; and after drying the deposit, carrying out the heat treatment of the deposit in the reducing atmosphere to obtain the carbon nano tube composite material loaded with magnetic alloy particles. The preparation method adopts a simple process. As no impurity element is introduced into the preparation process, the obtained magnetic alloy particles have high degree of crystallinity and excellent magnetic properties. In addition, the method has easy regulation of the alloy components. The composite material prepared by the method is significantly applied in the fields of electromagnetic interference resistance, stealth, microwave darkrooms, and the like.

Owner:TSINGHUA UNIV

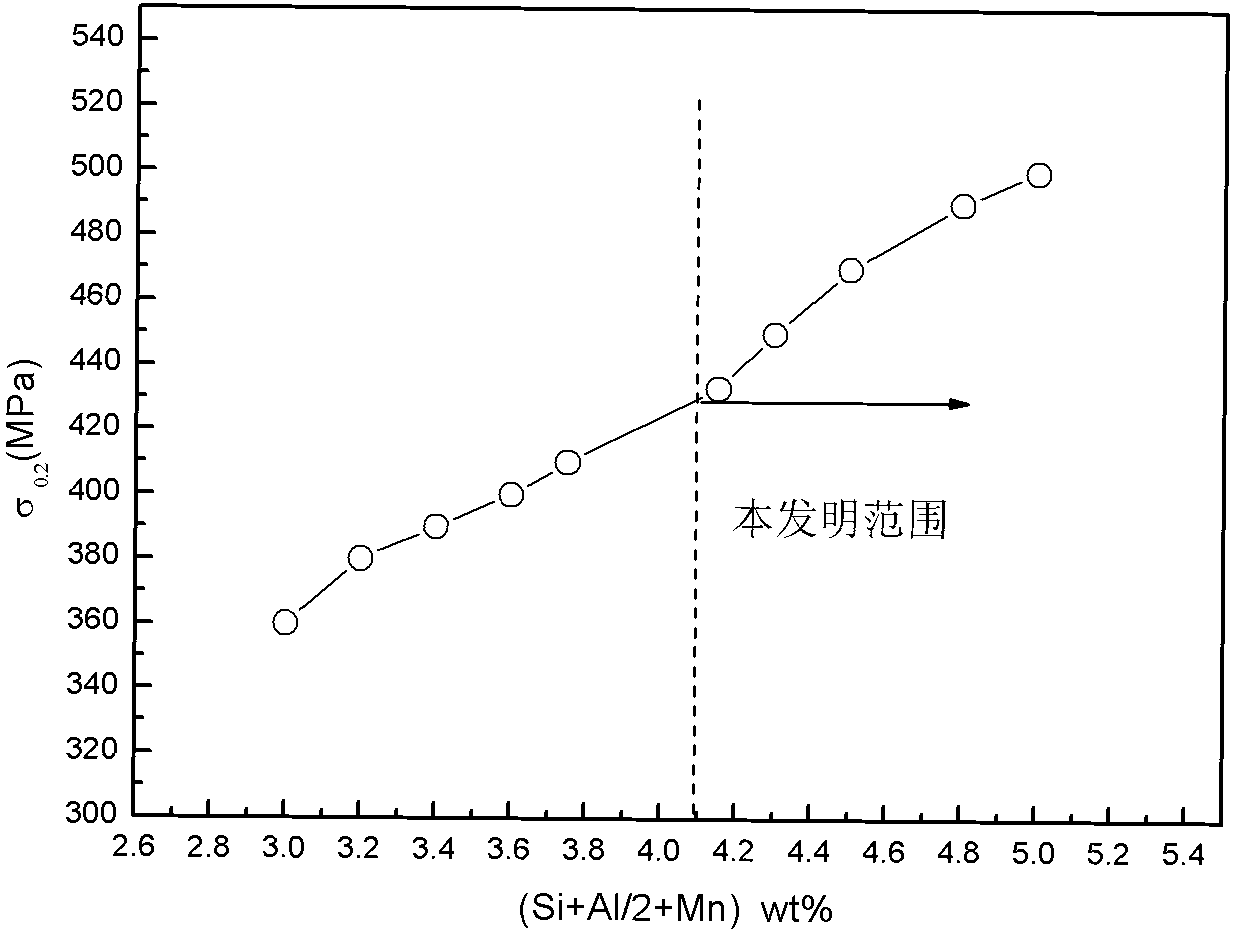

Non-oriented silicon steel for rotor and production method thereof

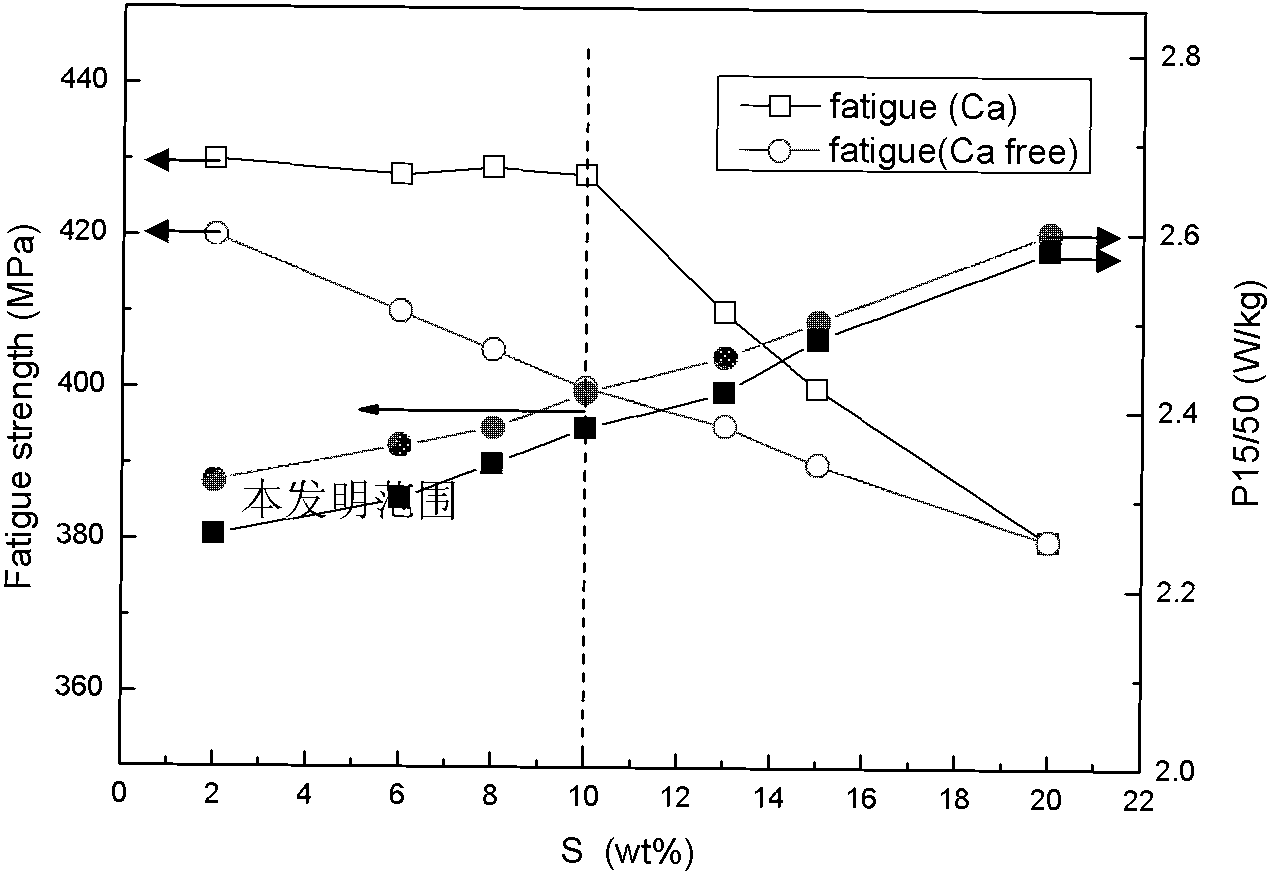

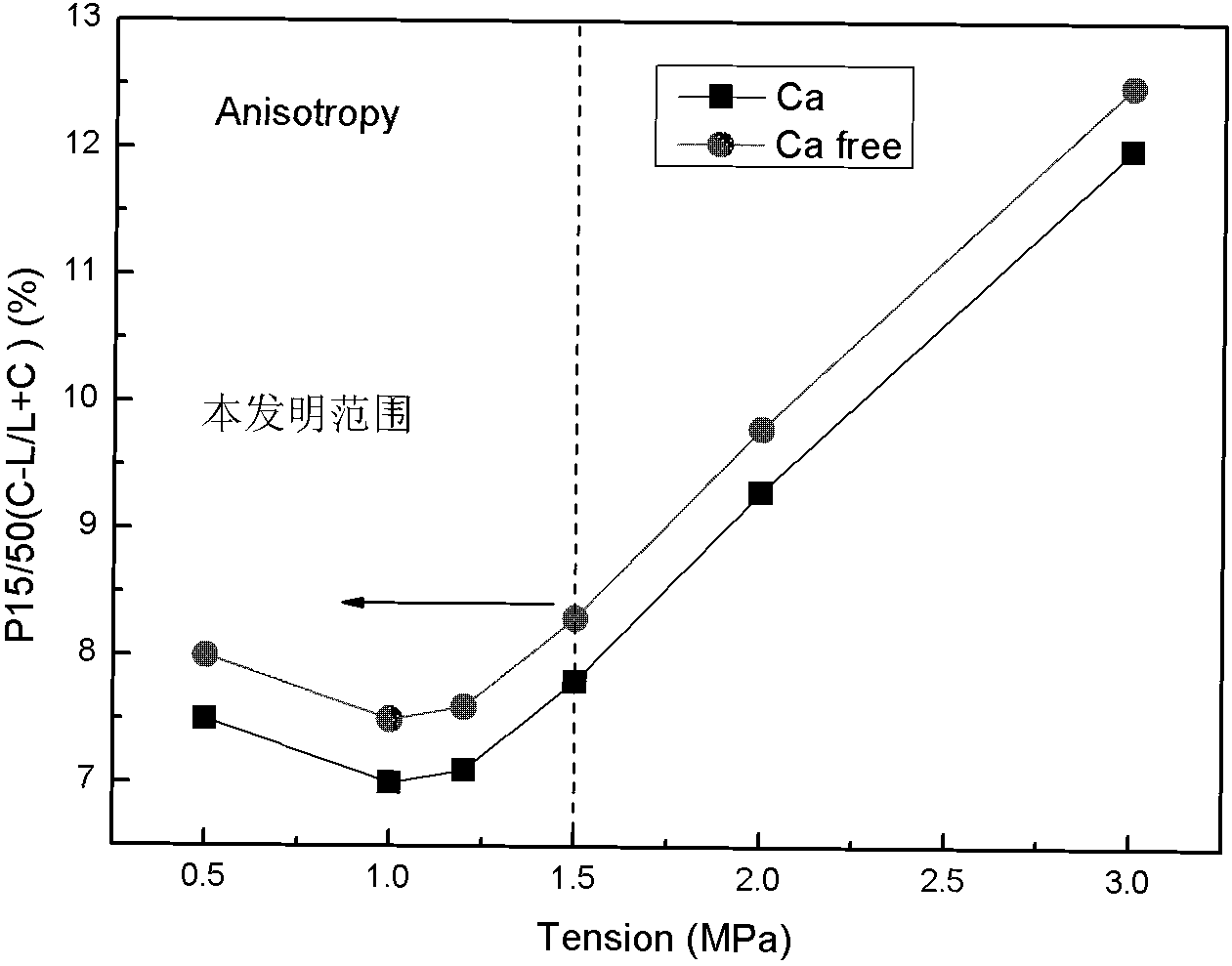

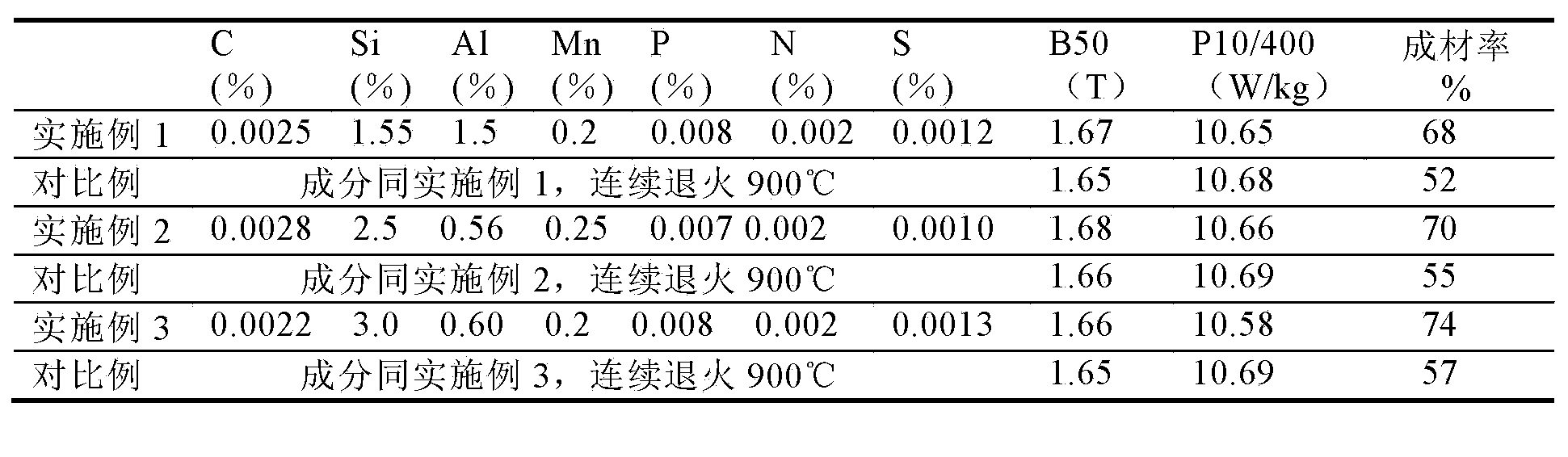

The invention discloses a non-oriented silicon steel for a rotor and a production method thereof. The steel consists of the following components in percentage by weight: 0.001-0.004% of C, 2.5-4.0% of Si, 0.5-1.5% of Al, 0.10-1.50% of Mn, not more than 0.02% of P, not more than 0.001% of S, not less than 4.1% and not more than 6.0% of Si+Al / 2+Mn, not more than 0.002% of N, not more than 0.005% of B and the balance of Fe and inevitable impurities. The production method mainly comprises the following steps of: refining process, namely sequentially deoxidizing Si and Al, and finally, adding CaSi alloy for Ca treatment; heating a casting blank in a heating furnace to be 1100 DEG C, insulating and then rolling; normalizing, carrying out acid cleaning and cold rolling, wherein the reduction rate is 70-78%; and tensioning and annealing a belt, wherein the temperature is 920-980 DEG C, and the tension is controlled between 0.5MPa and 1.5MPa. By utilizing the method, electrical sheets with excellent electromagnetic property, yield strength and fatigue performance can be obtained, the annealing temperature is reduced, the production energy consumption can be decreased, and furthermore, the production cost is lowered.

Owner:BAOSHAN IRON & STEEL CO LTD

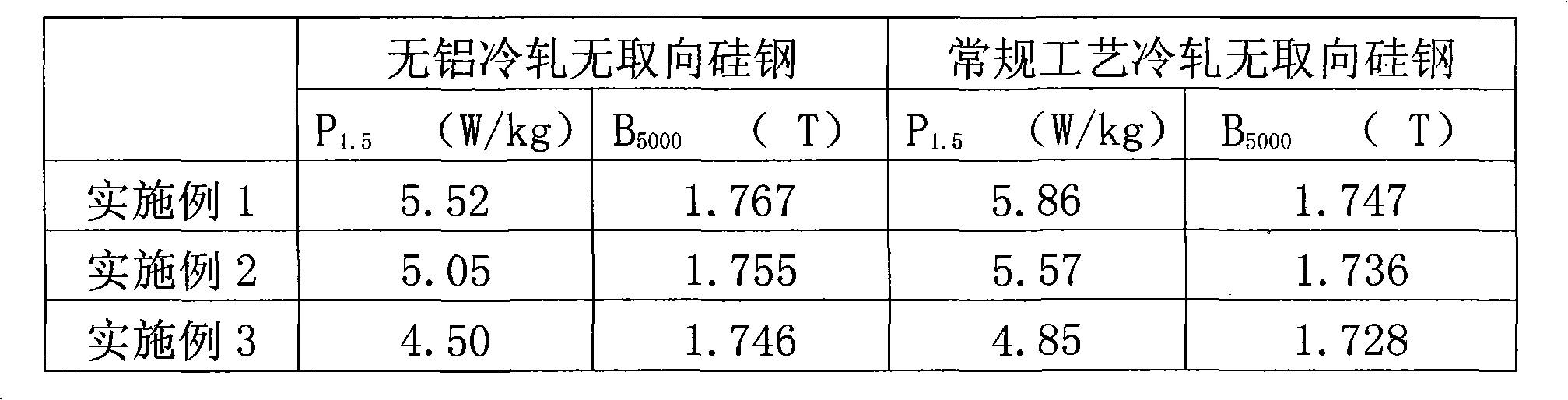

Method for producing aluminum-free steel grade of cold milling non-oriented silicon steel

ActiveCN101992210AReduce manufacturing costGood electromagnetic performanceProgramme control in sequence/logic controllersMetal rolling arrangementsSocial benefitsHydrogen

The invention relates to a method for producing aluminum-free steel grade of cold milling non-oriented silicon steel, which comprises the following steps of: controlling the quantity of Als to be not more than 0.0010 percent and the content of residual elements easily forming nitrides; adopting low-temperature heating and controlled-temperature milling for hot milling; adopting primary cold method milling or secondary cold method milling with the middle annealing for cold milling; and carrying out the integrated control measures such as wet hydrogen decarburization, recrystallization temperature annealing and the like. Thereby, the mass production of efficient aluminum-free cold milling non-oriented silicon steel can be realized with low production cost under the condition of the traditional equipment, the electromagnetic performance of the efficient aluminum-free cold milling non-oriented silicon steel is superior to the cold milling non-oriented silicon steel produced by the same-trademark conventional process, the iron loss is averagely reduced by about 0.4W / kg, the magnetic strength is averagely improved by 0.2T, and the method not only meets the market requirements, but also has obvious economic benefits and social benefits.

Owner:ANGANG STEEL CO LTD

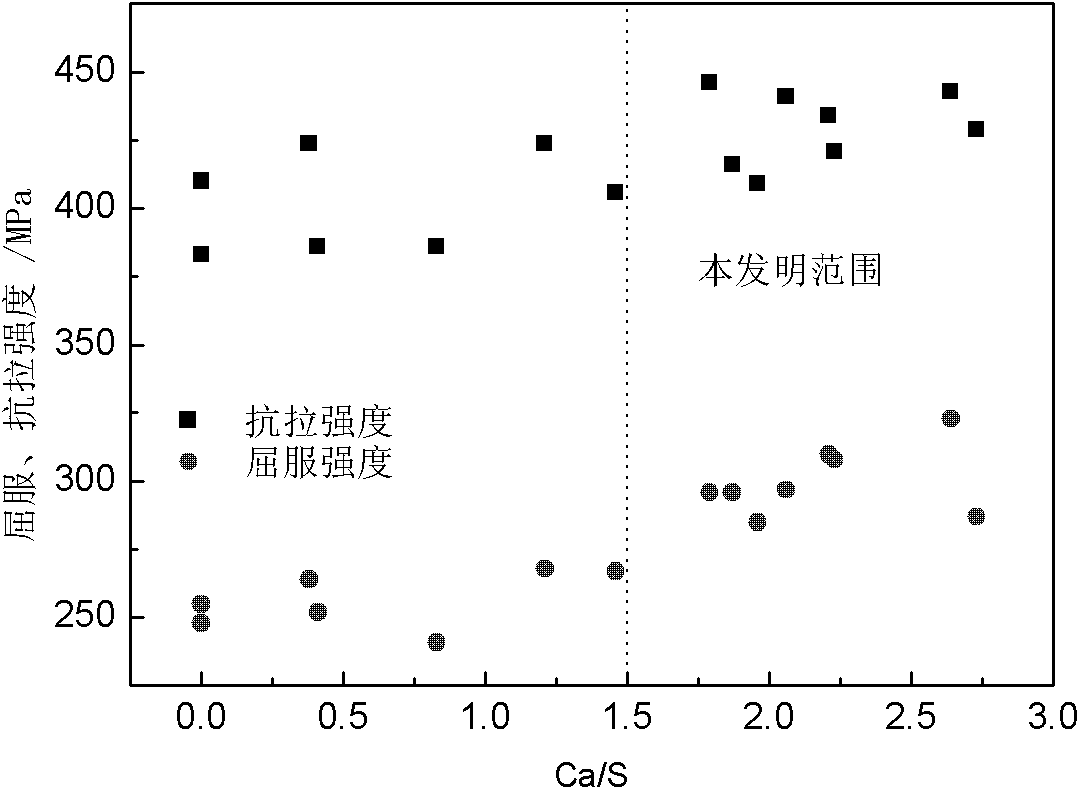

High-yield-strength non-oriented electrical steel plate and manufacturing method thereof

InactiveCN102758150AGood electromagnetic performanceHigh yield strengthRoll mill control devicesMetal rolling arrangementsSteelmakingAlloy

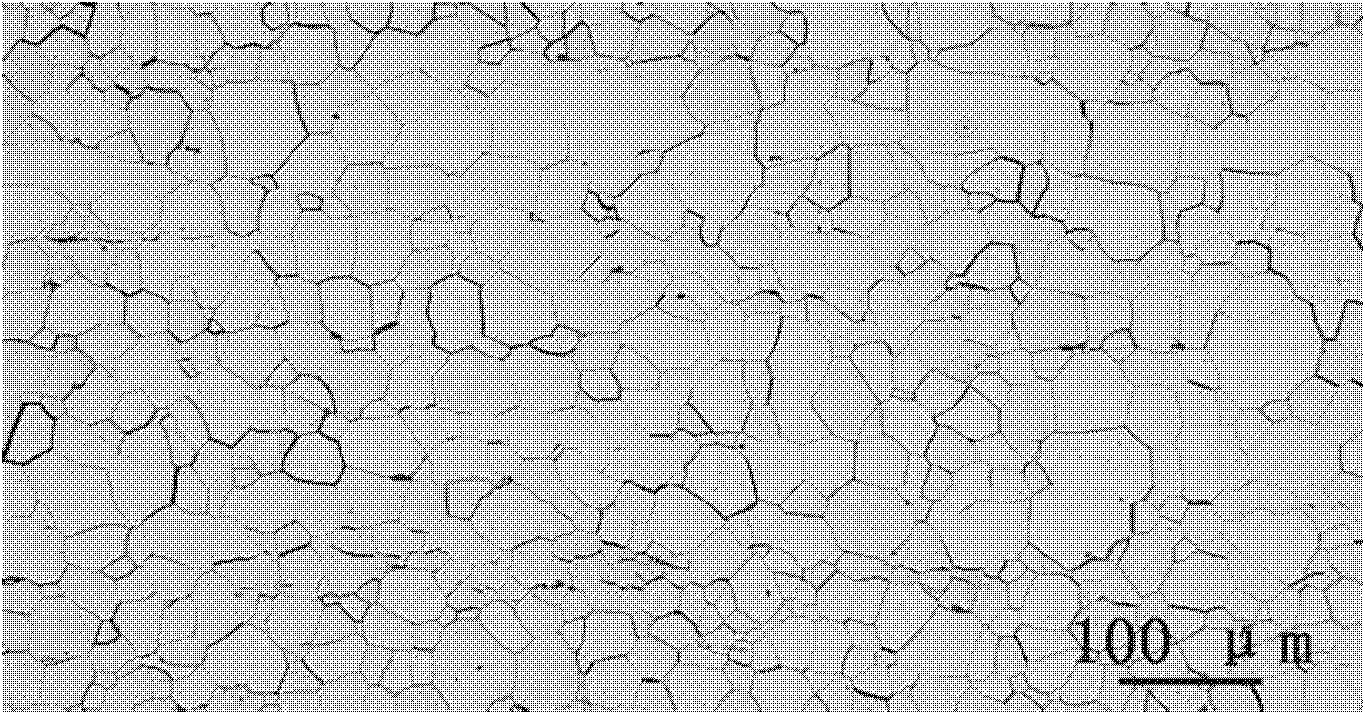

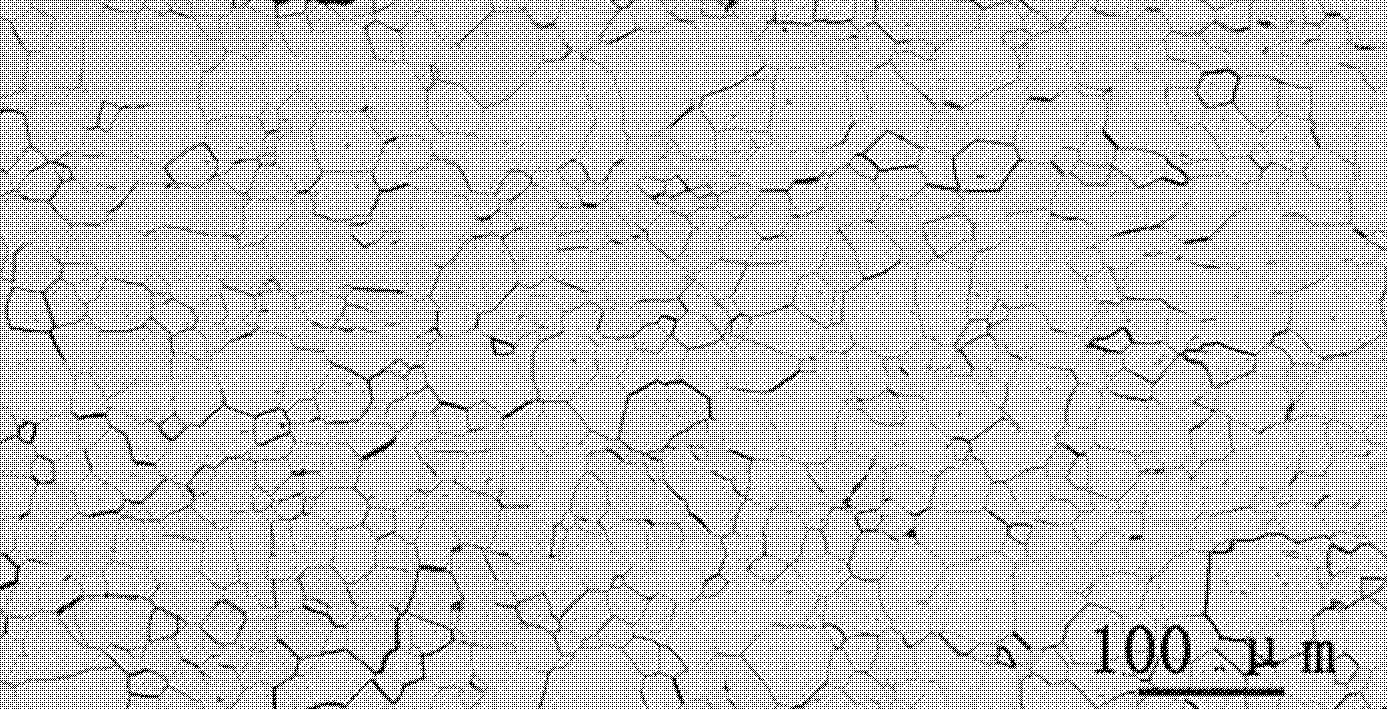

Disclosed are a high-yield-strength non-oriented electrical steel plate and a manufacturing method thereof. The manufacturing method includes that firstly, slabs are produced by preprocessing, smelting, vacuum refining and continuous casting of molten iron, and during the finish refining, molten steel is subjected to calcium treatment with CaSi cored wires, 0.5-2.0kg / t of steel is added, killing time of continuous cast molten steel is within 30 minutes, and the ratio of calcium to sulphur in the steel ranges from 1.5 to 2.8 after the calcium treatment; secondly, hot rolling, normalizing, acid pickling and cold rolling processes are performed, wherein rolling with 1-5 passes is performed in a rough rolling section of the hot rolling process, and the initial temperature of slabs is equal to or higher than 1000 DEG C while the rolling speed is equal to or higher than 9m / s in a finish rolling section of the hot rolling process; and thirdly, annealing and insulating coating processes are performed so that finished non-oriented electrical steel plates are obtained, wherein the temperature of a soaking section is controlled to be 800 DEG C-950 DEG C during continuous annealing, and the size of crystal grains of the electrical steel plates ranges from 20 micrometers to 90 micrometers. The quantity of alloy added in the steelmaking process can be reduced obviously so that expenses for alloy are saved greatly. The manufacturing method of the high-yield-strength non-oriented electrical steel plate has the advantages of convenience in operation, simplicity and convenience in control, low cost, control accuracy and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Annealing method of cold-rolled non-oriented electrical steel thin strip

ActiveCN103882211AGood electromagnetic performanceImprove yieldFurnace typesHeat treatment furnacesSteel platesElectrical steel

The invention provides an annealing method of cold-rolled non-oriented electrical steel thin strips, which comprises the following steps: 1) performing normalized acid pickling, then performing cold rolling to reach a thickness of 0.15-0.20 mm, uniformly spraying a MgO aqueous solution on a steel plate surface in a cold rolling final finished product pass process; 2) after cold rolling, performing cover annealing by coils under the protection of N2+H2, wherein the volume percent of N2 is 10%-90% and the volume percent of H2 is 10%-90%, performing heat preservation at 400-500 DEG C for 2-10 hours, then performing recrystallization annealing at 850-1000 DEG C for 8-20 hours; 3) washing off the MgO coating with 3%-8% diluted H2SO4 before stretching annealing, performing stress-relieving annealing at 500-900 DEG C, and applying tension force which is controlled to be 0.8-5 KN. The method of the invention adopts cover furnace annealing, and performs a stretching flattening process after annealing, which not only obtains excellent electromagnetic performance, but also ensures good plate shape, greatly increases the yield, reduces strip breaking, and increases the yield by 10%-20%. The method of the invention is widely applicable to variable frequency motors, and extends the application field of electrical steel.

Owner:ANGANG STEEL CO LTD

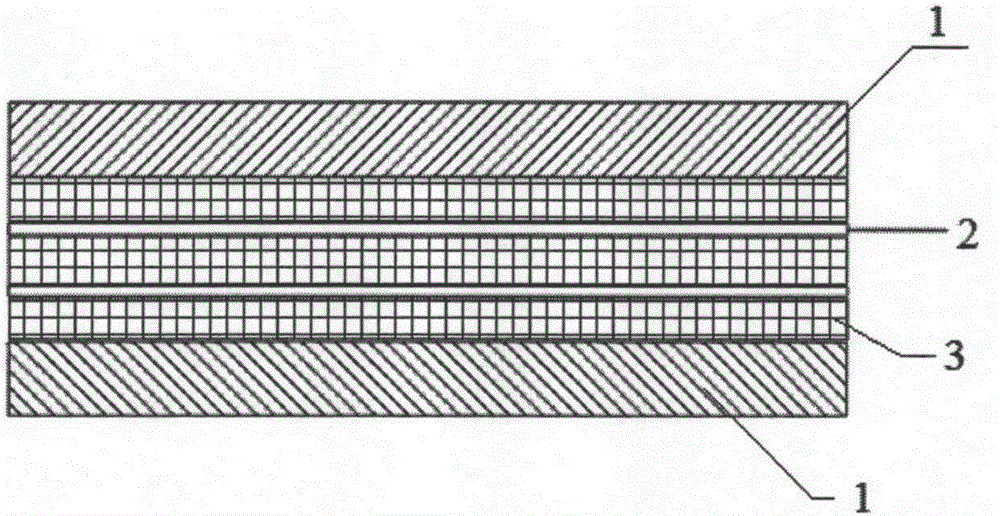

Flexible stretchable electromagnetic shielding fabric and preparation method thereof

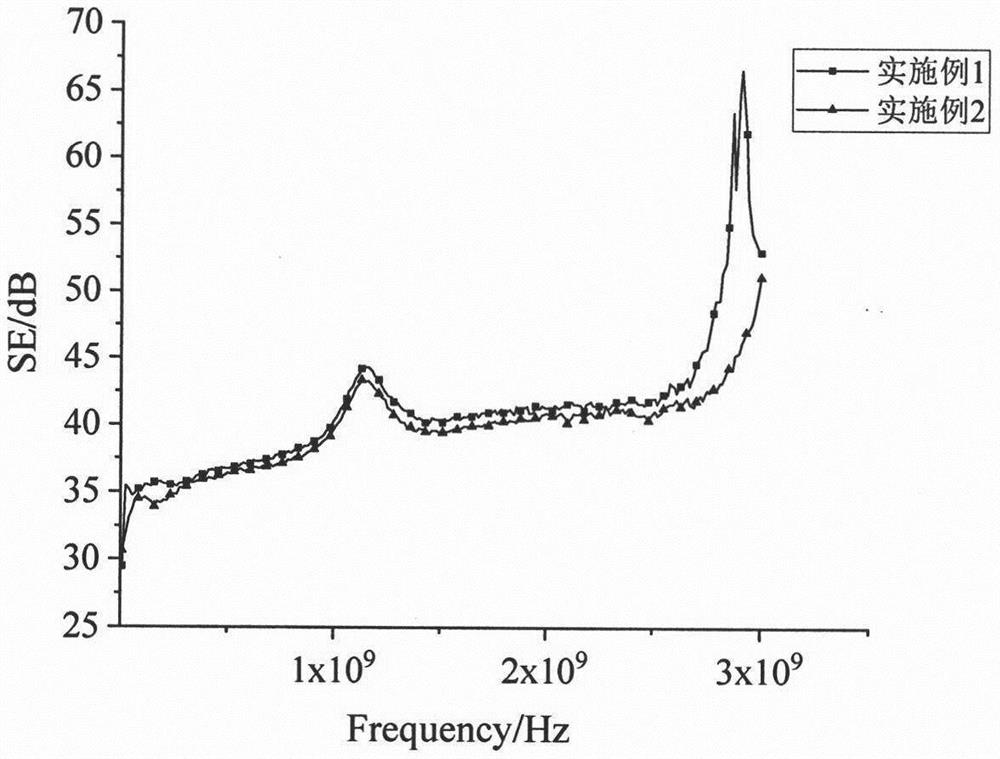

ActiveCN106012553AGood flexibilityIncrease elasticityFibre treatmentComposite filmElectromagnetic shielding

The invention provides a flexible stretchable electromagnetic shielding fabric and a preparation method thereof. The method for preparing the flexible stretchable electromagnetic shielding fabric comprises the following steps: selecting a spandex stretch fabric as an elastic adhesion matrix, applying a certain tension to two ends of the fabric, stretching the fabric to a certain elongation and fixing, and coating a layer of liquid elastic adhesives on the surface of the elastic adhesion matrix; performing pressure dipping on a flexible nano electromagnetic shielding composite film on the liquid elastic adhesives, coating a layer of liquid elastic adhesives on the upper side of the flexible nano electromagnetic shielding composite film, allowing the composite film to be adhered to another spandex stretch fabric, and curing the adhesives under a certain conditions; releasing the tension applied to the elastic adhesion matrix so as to drive the flexible nano electromagnetic shielding composite film to retract, thereby obtaining the flexible stretchable electromagnetic shielding fabric. The flexible stretchable electromagnetic shielding fabric disclosed by the invention has the characteristics of high elasticity, high elongation, excellent electromagnetic shield property and the like.

Owner:DONGHUA UNIV

Flexible stretchable electromagnetic shielding film and preparation method thereof

InactiveCN106003888AGood flexibilityIncrease elasticityLamination ancillary operationsMagnetic/electric field screeningEngineeringElectromagnetic shielding

The invention provides a flexible stretchable electromagnetic shielding film and a preparation method thereof. The preparation method of the flexible stretchable electromagnetic shielding film comprises the following steps: selecting an elastic membrane as an elastic adhesion matrix, stretching the elastic membrane to a certain elongation, then fixing the elastic membrane, and coating a liquid elastic adhesive layer on the surface of the elastic membrane; crushing a flexible nano electromagnetic shielding complex film on the liquid elastic adhesive layer, coating resin with protective effect at the upper side of the flexible nano electromagnetic shielding complex film to form a resin layer, and curing the liquid elastic adhesive and the resin under certain conditions; and releasing a tensile force applied onto the elastic adhesion matrix, so as to drive the flexible nano electromagnetic shielding complex film to retract, namely the flexible stretchable electromagnetic shielding film is obtained. The prepared flexible stretchable electromagnetic shielding film has good elasticity, high elongation (20-50%) and excellent electromagnetic shielding property (electromagnetic wave absorptivity is more than or equal to 99% at the frequency of 1-5GHz) and can bear certain bending and compression deformation.

Owner:DONGHUA UNIV

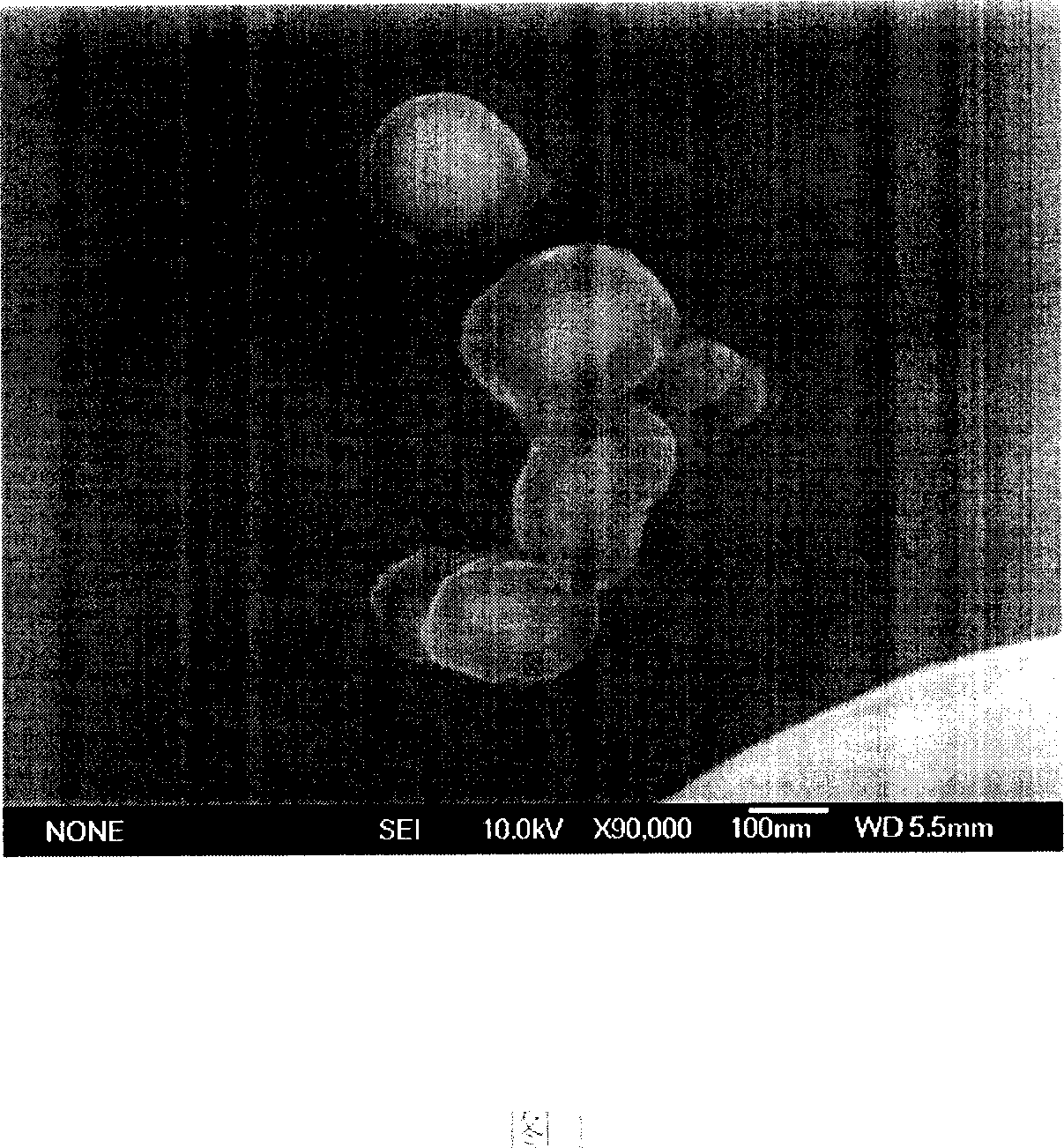

Prepn process of composite onion-shaped fullere material with homogeneous grain size

InactiveCN1931717AUniform particle sizeControllable growthNanostructure manufactureReaction temperatureNitrogen

The present invention discloses preparation process of composite onion-shaped fullerene material with homogeneous grain size. Through chemical vapor deposition with zeolite of different types and homogeneous pore size as template, added catalyst and cheap inert gas and nitrogen as carrier gas, and in effectively controlled technological parameters, including reaction temperature, time, gas flow rate, etc. composite onion-shaped fullerene material in homogeneous grain size is prepared. The technological process of the present invention is simple and fast, and the prepared onion-shaped fullerene has high purity, stable performance and other advantages and great latent application value.

Owner:TAIYUAN UNIV OF TECH

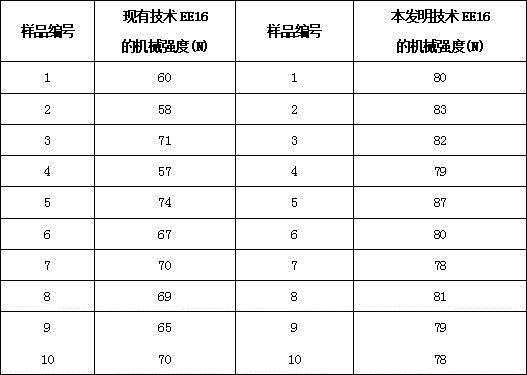

Manganese-zinc power ferrite material and element preparation method of manganese-zinc power ferrite material

ActiveCN106830916AHigh mechanical strengthGood electromagnetic performanceInorganic material magnetismManganeseUltimate tensile strength

The invention discloses a manganese-zinc power ferrite material and an element preparation method of the manganese-zinc power ferrite material. The manganese-zinc power ferrite material is prepared from a main material and an auxiliary material; the main material is prepared from the following components in percentage by mol: 51.5 mol percent to 53.5 mol percent of Fe2O3, 6.5 mol percent to 8.5 mol percent of ZnO and the balance of Mn3O4; the auxiliary material is a fluxing agent, a modifying agent or a toughening agent; the manganese-zinc power ferrite material is prepared from the following components in parentage by weight: 0.03 weight percent to 0.05 weight percent of V2O5, 0.01 weight percent to 0.03 weight percent of Nb2O3, 0.02 weight percent to 0.04 weight percent of CaCO3, 0.05 weight percent to 0.10 weight percent of ZrO2 and 0.10 weight percent to 0.20 weight percent of Y2O3; the mechanical strength and toughness of a magnetic core element are effectively improved. The fragility of the soft magnetic ferrite magnetic core element is improved and the problems of damages in a transportation process and devices are broken when being applied to automatic assembling are reduced.

Owner:江西尚朋电子科技有限公司

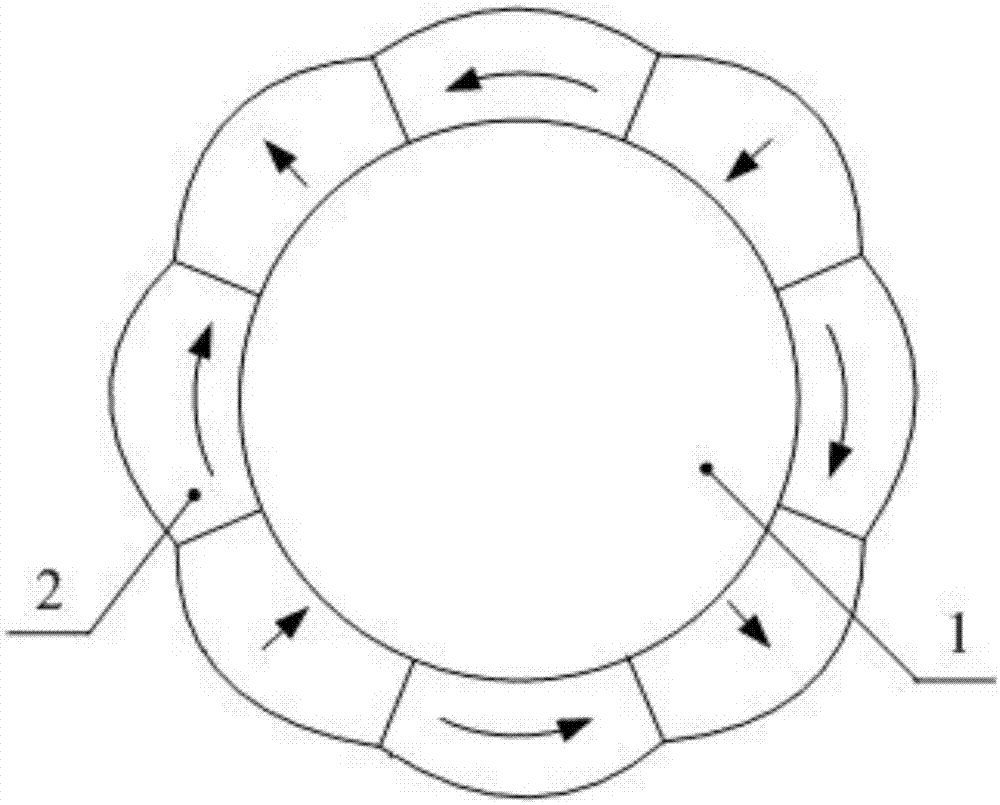

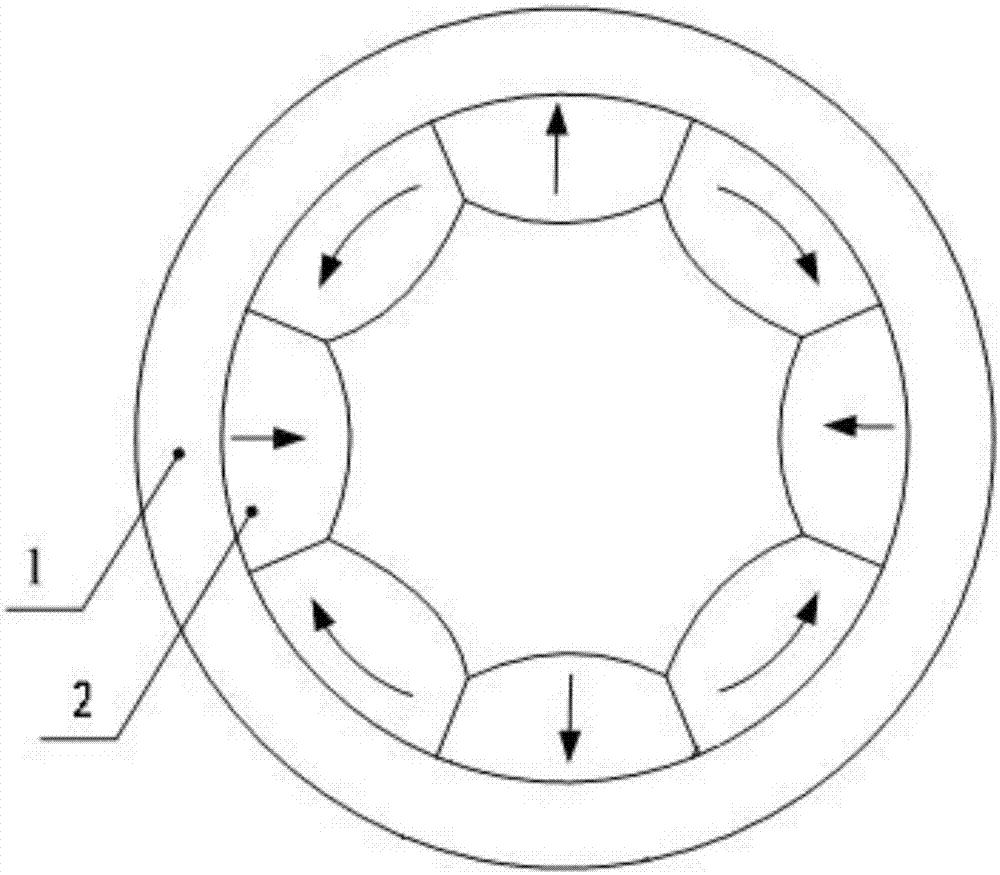

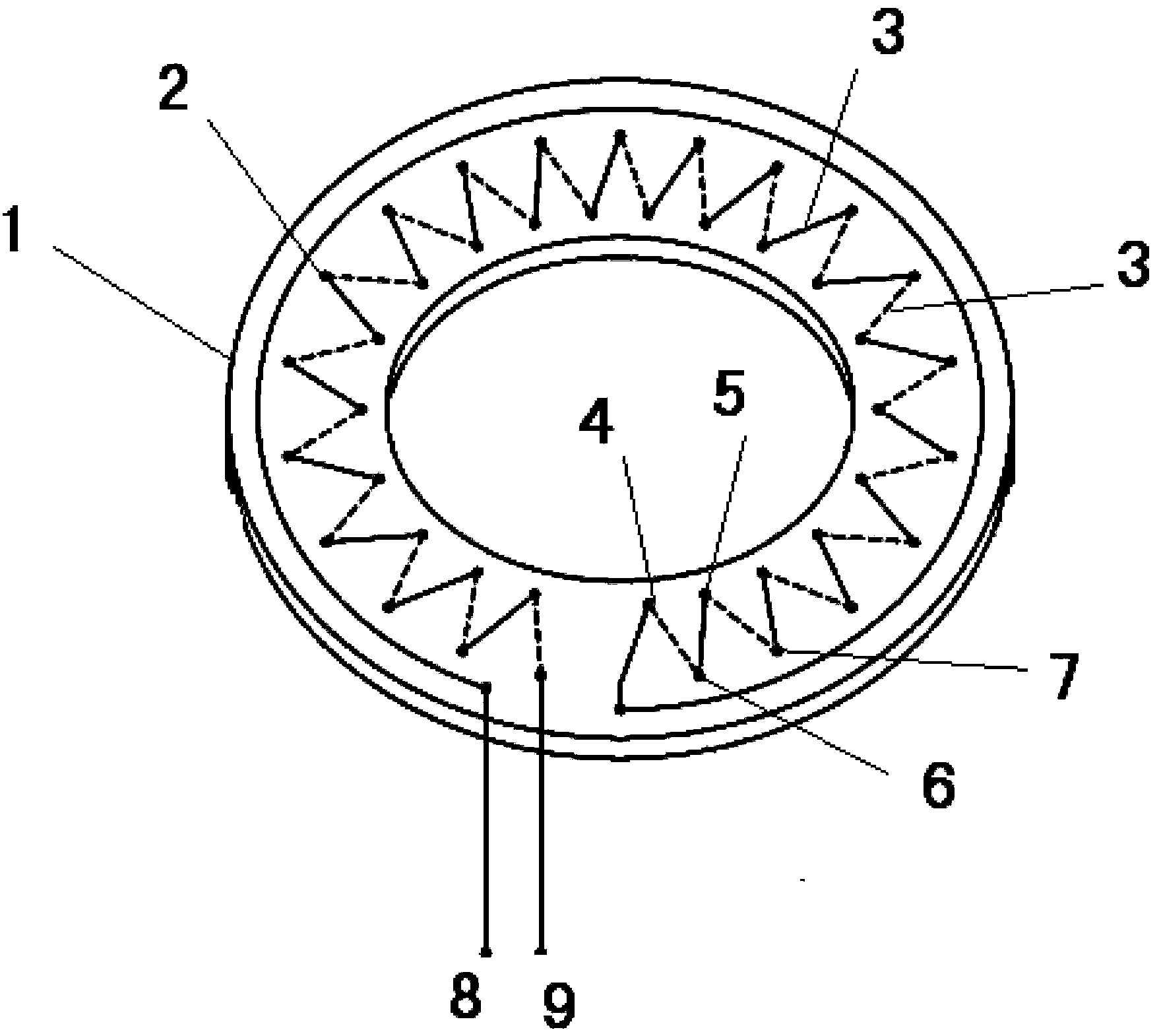

High-performance Halbach type permanent magnet rotor used for flywheel energy storage system

PendingCN107104528AReduce harmonic contentReduce lossMagnetic circuit rotating partsMechanical energy handlingPermanent magnet rotorMagnetomotive force

The invention discloses a high-performance Halbach type permanent magnet rotor used for a flywheel energy storage system. The high-performance Halbach type permanent magnet rotor comprises a rotor shaft and a Halbach type permanent magnet array adhered onto the rotor shaft, wherein the Halbach type permanent magnet array is formed by arranging permanent magnet blocks magnetizing in radial directions and peripheral directions alternately, and the magnetizing directions change at 90 degrees in sequence; the bottom of each permanent magnet block is arc-shaped, and the diameter of the arc-shaped bottom of each permanent magnet block is smaller than that of the rotor shaft respectively. According to the high-performance Halbach type permanent magnet rotor used for the flywheel energy storage system disclosed by the invention, the bottom of each permanent magnet block is arc-shaped, actually the shapes of the permanent magnet blocks are locally adjusted on the basis of straight lines or oblique lines, and the harmonic content of the magnetic field distribution of the permanent magnet array is effectively reduced, so that the magnetic field distribution is more close to the shape of a sine; and meanwhile, the permanent magnet magnetomotive force can also be increased, the thermal parameters are reduced, and low loss and excellent electromagnetic performance of the motor are finally obtained.

Owner:SUZHOU TOPRUN ELECTRIC EQUIP

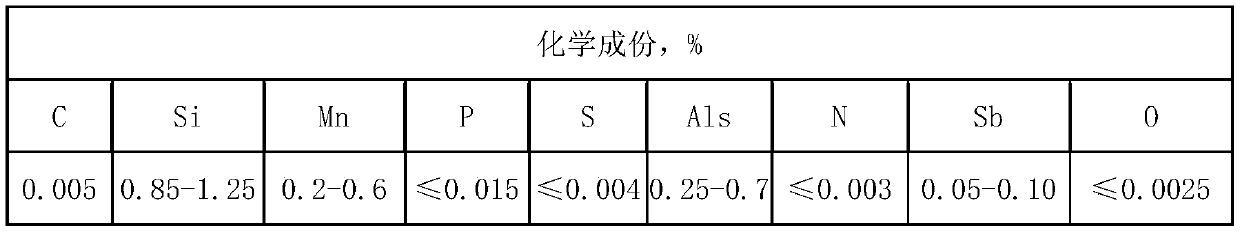

Silicon steel magnetic powder core and preparation method therefor

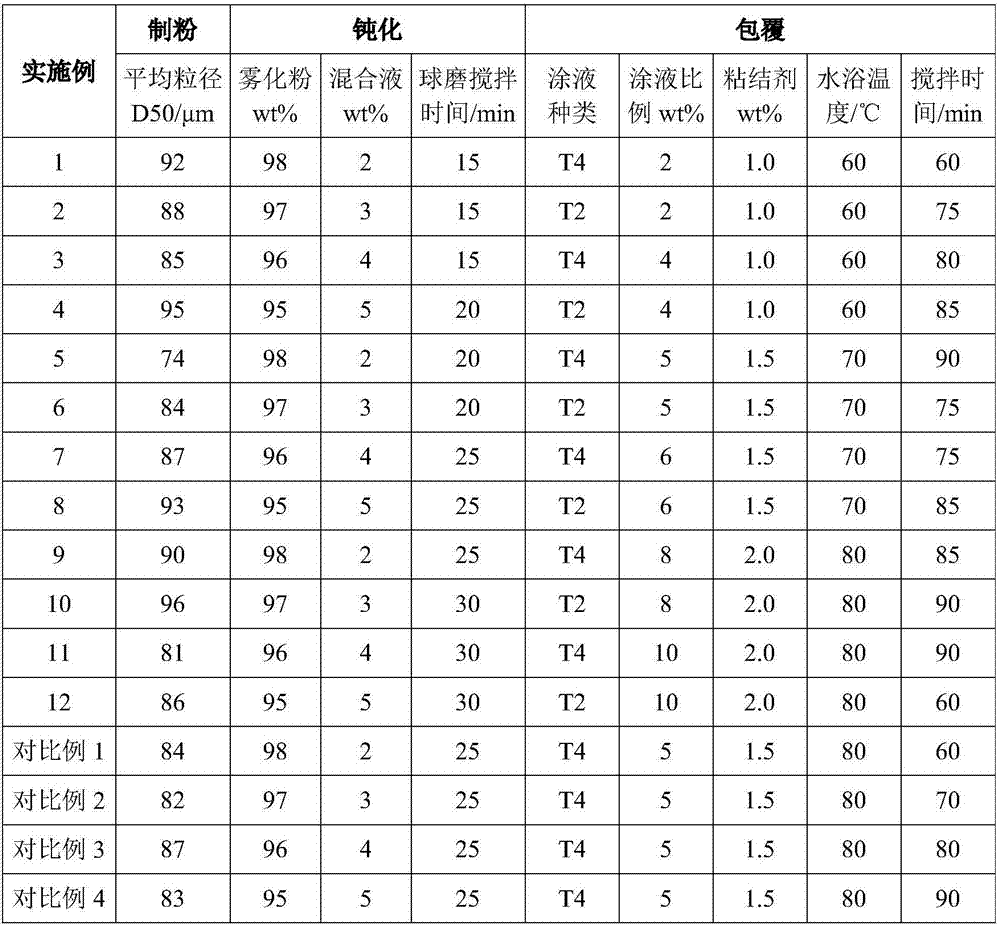

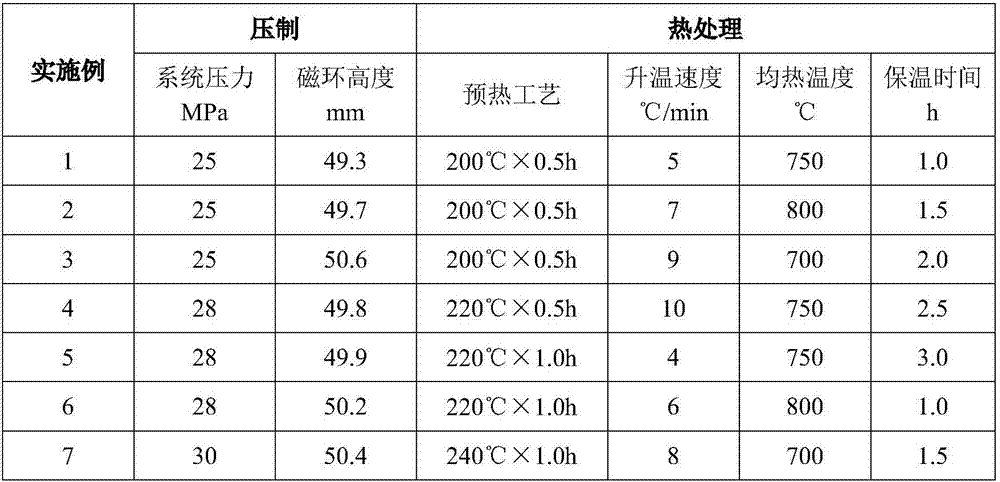

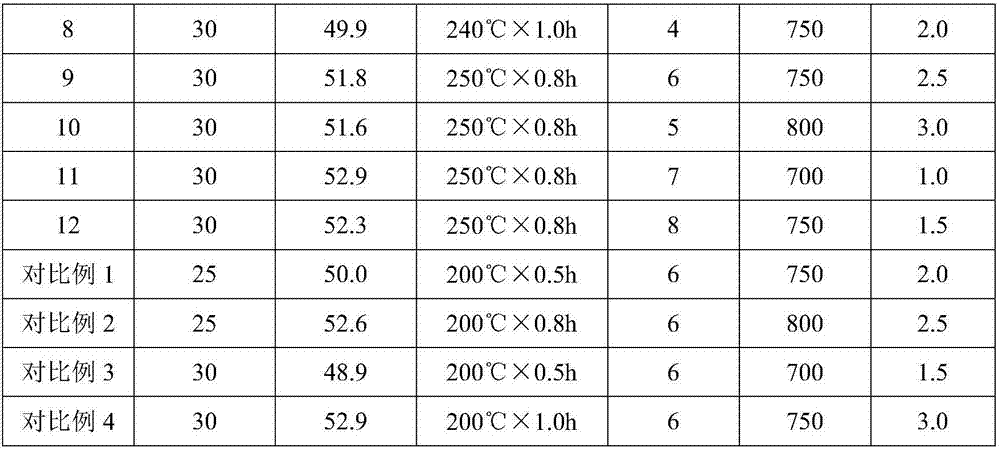

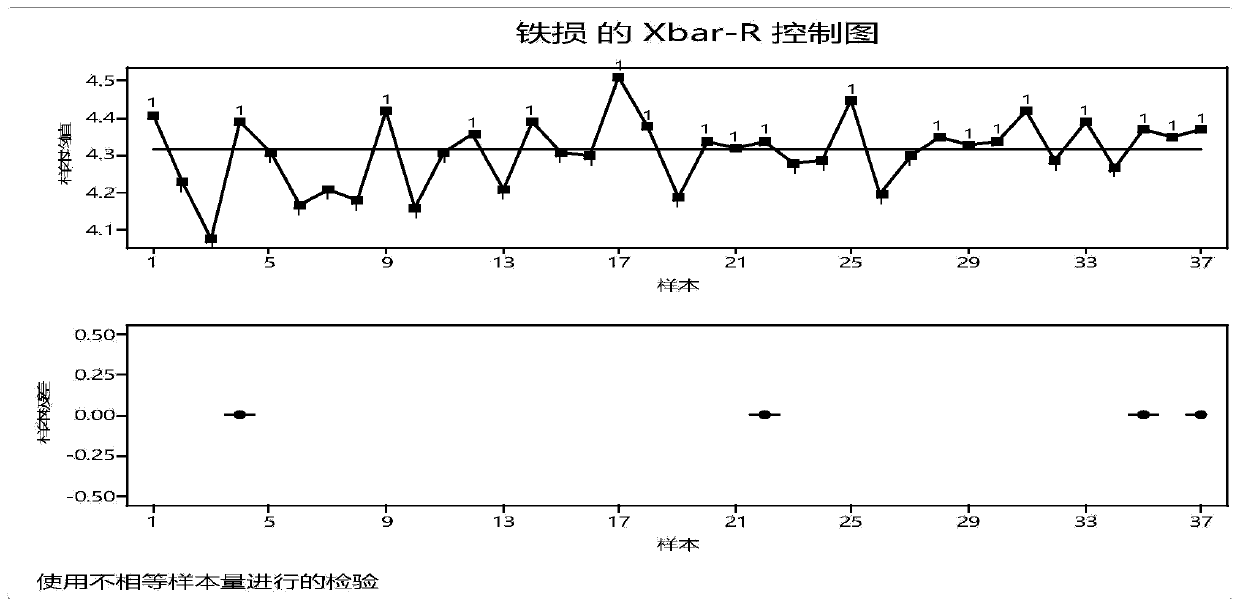

ActiveCN107424706AGood electromagnetic performanceRealize comprehensive utilizationTransportation and packagingMetal-working apparatusWaste materialImpurity

The invention discloses a silicon steel magnetic powder core and a preparation method therefor. A silicon steel sheet waste material or other silicon steel materials are taken as the main raw materials, alloy elements are added according to needs, and the target components are smelted as follows: less than or equal to 0.005wt% of C, 0.30-6.50wt% of Si, less than or equal to 0.50wt% of Mn, less than or equal to 0.20wt% f P, less than or equal to 0.005wt% of S, less than or equal to 1.5wt% of Als, less than or equal to 0.005wt% of N, and the balance of Fe and inevitable impurities, wherein (Si+Als) is greater than or equal to 1.0wt% and less than or equal to 7.5wt%; and steps of powder making, passivating, coating, pressing and heat treatment are performed to prepare the silicon steel magnetic powder core. The silicon steel magnetic powder core with excellent electromagnetic performance is obtained by taking the silicon steel sheet waste material as the main raw material for atomization and powder making, adopting a silicon steel coating liquid as a coating agent, and adopting a powder metallurgy process, so that comprehensive utilization of resources can be realized.

Owner:武汉钢铁有限公司

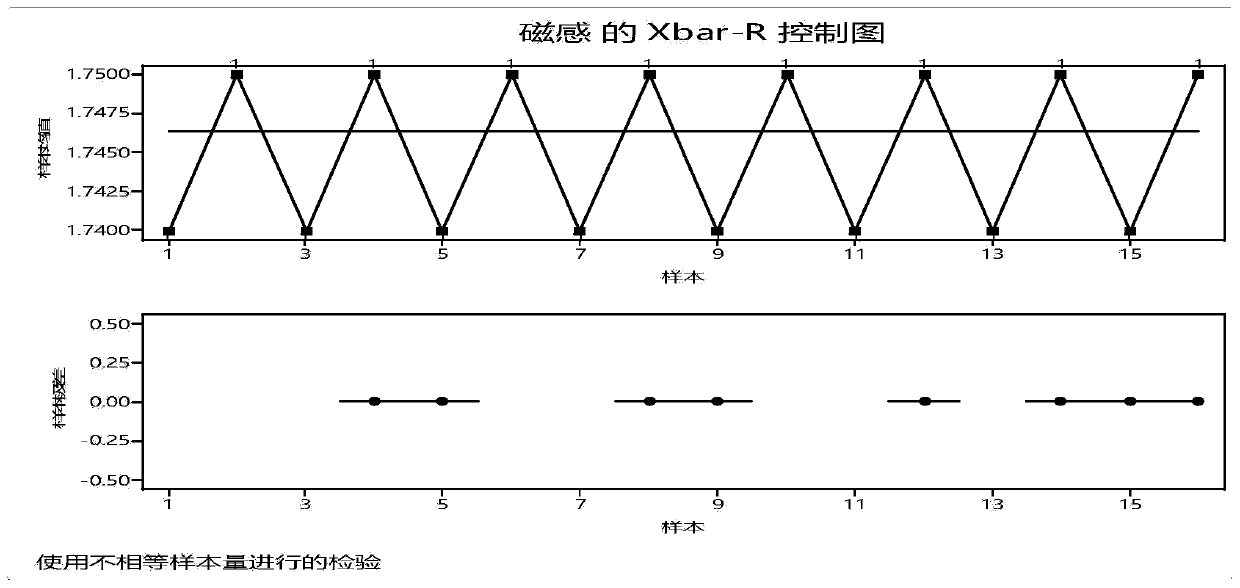

Method for producing high-magnetic-induction non-oriented silicon steel 50BW800G through normalizing-free heat treatment

The invention belongs to the technical field of material processing, and particularly provides a production process for producing high-magnetic-induction non-oriented silicon steel 50BW800G through normalizing-free heat treatment. At present, the production of Benxi steel non-oriented silicon steel 50BW800 is supplied by an FTSR production line, no normalizing annealing equipment exists in the cold rolling process, a production process for producing the high-magnetic-induction non-oriented silicon steel under the condition that a hot rolled coil is free of normalizing annealing needs to be found, and existing equipment is fully utilized for producing high-added-value products. According to the production process, through optimal design of alloy components and hot rolling and cold rolling continuous annealing processes and by utilizing the advantage that an existing FTSR short-process production line is beneficial to adopting a low-temperature heating process, a hot-rolled coil can be directly cold-rolled to the thickness of a finished product without normalizing heat treatment of the hot-rolled coil, and then final continuous annealing is carried out to produce the high-magnetic-induction non-oriented silicon steel 50BW800G, the electromagnetic performance of the product meets the requirement, the production cost is low, the electromagnetic performance is good, and the additional value of the product is increased.

Owner:BENGANG STEEL PLATES

High-magnetic shielding communication transformer and production method thereof

InactiveCN106409491AImprove permeabilityHigh strengthTransformers/inductances detailsMagnetic materialsTransformerHeat resistance

The invention discloses a high-magnetic shielding communication transformer and a production method thereof. According to the high-magnetic shielding communication transformer, a long-time working temperature of not smaller than 150 degrees centigrade can be borne, and an electromagnetic shielding level is at least T-level. Through control of a repeated circular process of forming, fixing and impacting-destressing-deformation-correcting-destressing for a molybdenum permalloy magnetic core, the molybdenum permalloy magnetic core with high stability is obtained. Through adoption of an aluminium nitride-based ceramic framework with excellent electromagnetic performance and a full-enclosed aluminium alloy shielding case and through filling of a heat conductive insulating material in the aluminium alloy shielding case, the heat resistance and shielding performance of the communication transformer provided by the invention are improved. The high-magnetic shielding communication transformer provided by the invention is high temperature resistant and is good in electromagnetic shielding effect and long in service life.

Owner:宁波华众和创工业设计有限公司

Production method of Si-free semi-processed cold-rolled non-oriented silicon steel containing Mn

InactiveCN106086591AGood electromagnetic performanceImprove electromagnetic performanceProcess efficiency improvementNational standardOxygen

The invention discloses a production method of Si-free semi-processed cold-rolled non-oriented silicon steel containing Mn. The method comprises the first step of hot metal pretreatment, wherein blast-furnace hot metal is poured into a hot metal ladle at first, and top and bottom combined converter blowing is carried out through oxygen; the second step of converter smelting; the third step of argon blowing; the fourth step of LF refining, wherein molten steel is fed into an LF refining furnace to be smelted; the fifth step of casting; the sixth step of acid pickling and cold rolling; the seventh step of annealing, wherein annealing at the temperature of 680-770 DEG C is carried out for 6-8 h after cold rolling; and the eighth step of aftertreatment. The Si-free semi-processed cold-rolled non-oriented silicon steel containing Mn is stable in product performance, good in surface quality, strip shape quality and size precision, capable of meeting national standards and client requirements, and good in product machining performance.

Owner:SOUTH CHINA UNIV OF TECH

Waste magnetic core recycling method

InactiveCN107887151ALower sintering temperatureGood lookingInductances/transformers/magnets manufactureSpray GranulationHot Temperature

The invention discloses a waste magnetic core recycling method. The waste magnetic core recycling method comprises the following steps: grinding clean waste magnetic cores; preparing PVA glue; mixingmaterials obtained in the two previous steps with an accessory ingredient, and carrying out fine grinding, spray granulation, molding and compressing, sintering and cooling to obtain recycled magneticcores. According to the method, the waste magnetic cores are recycled, the magnetic cores can be recycled in energy conservation and environment protection manners at high temperature in only one step in the manufacturing process, and the accessory ingredient is doped during grinding, so that the sintering temperature is reduced, and the product appearance is further improved. Therefore, the magnetic cores recycled in the method are extremely close to non-recycled magnetic cores in appearance, and are compact internally and excellent in electromagnetic performance.

Owner:ZHONGSHAN DONGCHEN MAGNETIC ELECTRONICS PROD CO LTD

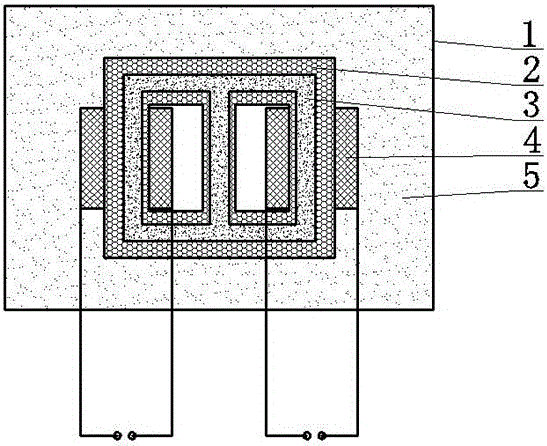

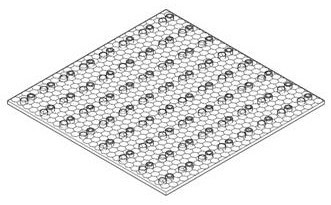

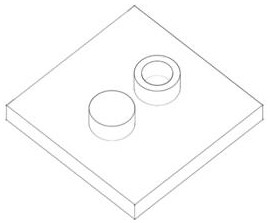

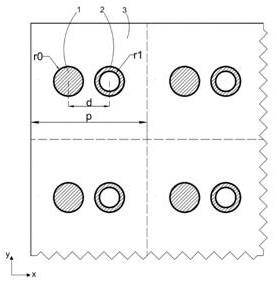

Manufacturing method of printed circuit board (PCB) coil and PCB coil

InactiveCN103384456APrecisely control the number of turnsPrecise control of line lengthPrinted electric component incorporationMultilayer circuit manufactureCopper platingCopper wire

The invention discloses a manufacturing method of a printed circuit board (PCB) coil. The manufacturing method is characterized by comprising the following steps that (1) wiring design is conducted on the PCB coil by using electronic design automation (EDA) software; (2) a single-layer double-faced PCB is arranged; (3) a plurality of via holes are formed in the PCB of the step (2), and the inner sides and the outer sides of the via holes are distributed orderly in a double-row mode; (4) according to the wiring design of the step (1), etching wiring is conducted on the upper surface and the lower surface of the PCB of the step (2); (5) conductive materials are filled in the via holes of the step (3), the double-faced PCB is electrically connected through the via holes through electroless copper plating so that upper copper wires and lower copper wires are electrically connected; (6) protective layer rosin water is coated on the surfaces of wires arranged in the step (4), after the rosin water is condensed, the PCB coil is obtained. The invention further discloses the PCB coil prepared through the method.

Owner:UNI TREND TECH (CHINA) CO LTD

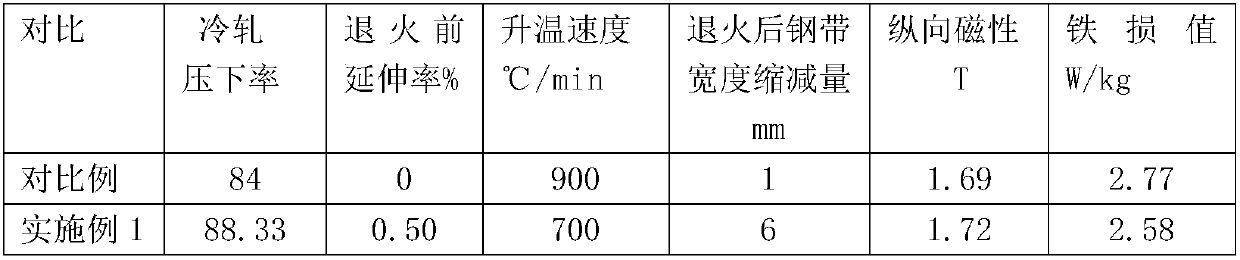

Production method for non-oriented electrical steel product with excellent longitudinal electromagnetic properties

InactiveCN107630130AExcellent longitudinal electromagnetic performanceLongitudinal Magnetic Average ImprovementFurnace typesHeat treatment furnacesReduction rateElectrical steel

The invention relates to a production method for a non-oriented electrical steel product with excellent longitudinal electromagnetic properties. The production method comprises the following steps: 1)determining the thickness of a hot-rolling raw material according to the specification of a finished product, wherein the overall reduction rate of cold rolling is a large reduction rate in a range of 86 to 95%; 2) increasing the furnace-entering tension of a steel band and controlling the elongation percentage of a cold-rolled steel band to be 0.50 to 5.00%; 3) increasing the tension control ofthe heating section of an annealing furnace during heat treatment and controlling the reduction of the width of a steel band at an outlet to be 2 to 10 mm; and 4) adjusting the length and rapid heating rate of the heating section of the annealing furnace and controlling the heating rate to be 400 to 850 DEG C / min. The production method provided by the invention employs the principles of materialsscience, is based on conventional processes, controls the reduction rate of cold rolling, fully takes the influence of steel band stress on microscopic texture and structure into consideration and controls recrystallization during heat treatment of the product, and thus, the non-oriented electrical steel product with excellent longitudinal electromagnetic properties is eventually produced.

Owner:ANGANG STEEL CO LTD

Composite magnetic material for photovoltaic inverter and preparation method thereof

ActiveCN104217832AImprove electromagnetic performanceGood electromagnetic performanceInductances/transformers/magnets manufactureMagnetic materialsMechanical crushingIngot casting

The invention relates to a composite magnetic material for a photovoltaic inverter. The composite magnetic material for the photovoltaic inverter consists of the following ingredients in percentage by weight: 3.8 weight percent to 6.5 weight percent of Cu, 0.2 weight percent to 0.5 weight percent of La, 0.1 weight percent to 0.3 weight percent of Dy, 0.4 weight percent to 0.8 weight percent of Nb, 0.3 weight percent to 0.6 weight percent of Ba, 0.3 weight percent to 1 weight percent of Sr, 0.6 weight percent to 1.2 weight percent of Mn, 0.3 weight percent to 0.9 weight percent of Sc, 0.05 weight percent to 0.2 weight percent of Cr and the balance of Fe. A preparation method of the composite magnetic material comprises the steps of raw material mixing, fusing and ingot casting, mechanical crushing and die forming. The prepared composite magnetic material for the photovoltaic inverter has high intrinsic coercive field, magnetic energy product and saturation magnetic flux density.

Owner:江苏北斗绿迅新能源科技有限公司

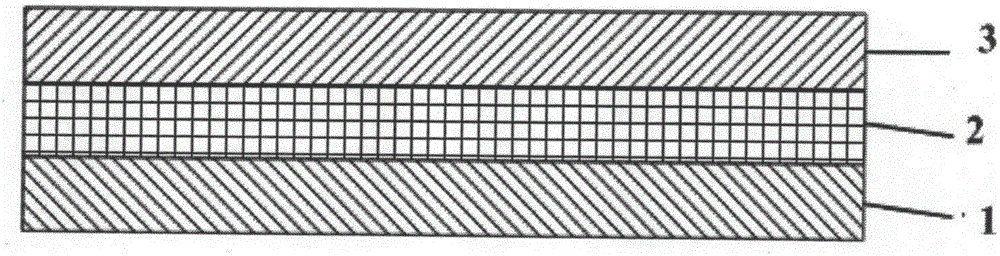

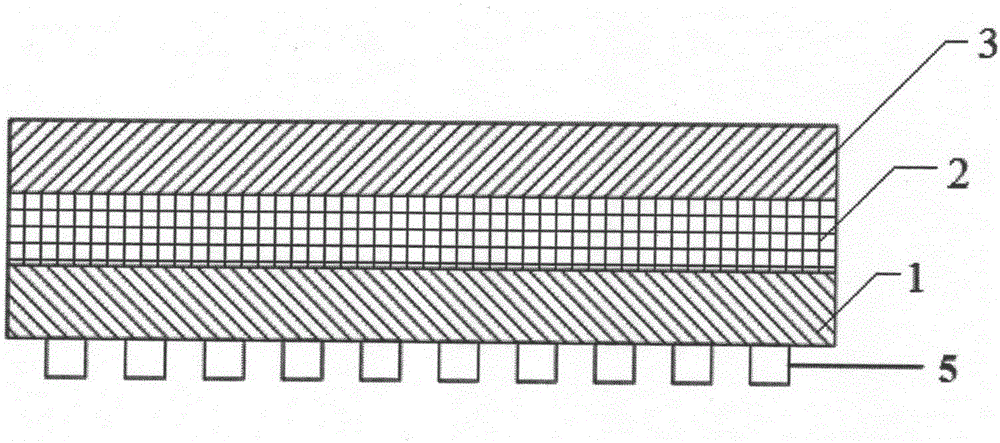

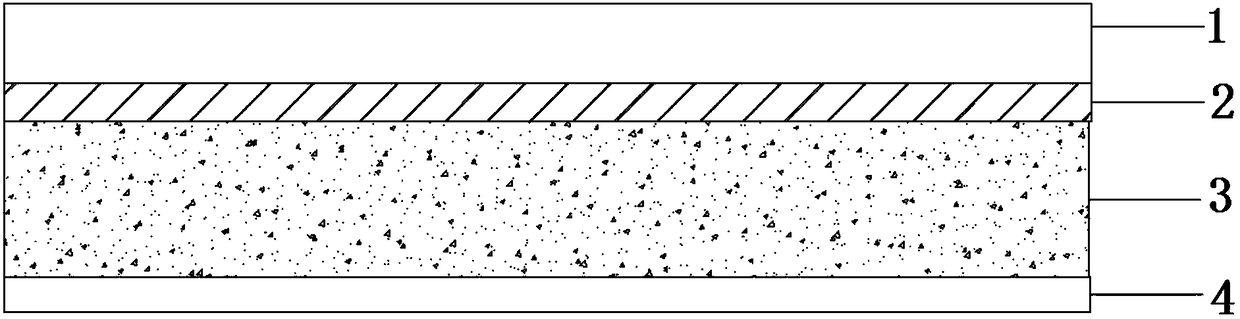

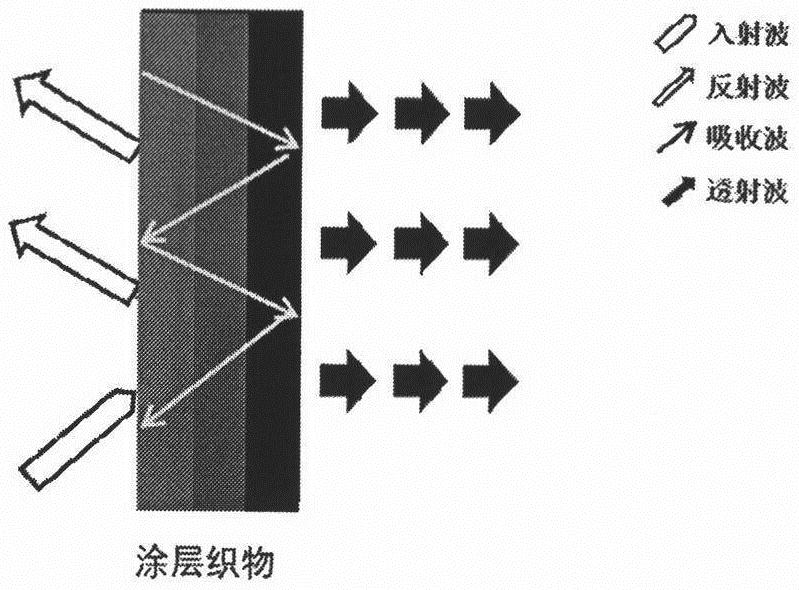

Electromagnetic shielding film and preparation method thereof

InactiveCN110713801AGood electromagnetic performanceWide electromagnetic performanceFilm/foil adhesivesIron powderAluminium powder

The invention discloses an electromagnetic shielding film and a preparation method thereof. The electromagnetic shielding film has five layers, successively being: a PET insulating layer, a metal layer, an adhesive layer, an electromagnetic shielding layer, and a pressure-sensitive adhesive layer; wherein the electromagnetic shielding layer is formed by mixing the following components in parts byweight: 25-35 parts of polypropylene, 8-16 parts of graphene, 25-35 parts of carbon black, 18-25 parts of aluminum powder, 8-12 parts of a compatilizer and 5-10 parts of carbonyl iron powder. The electromagnetic shielding film provided by the invention is simple in preparation mode, relatively low in cost, good in performance and simple to strip off and paste.

Owner:浙江磊峰塑料科技有限公司

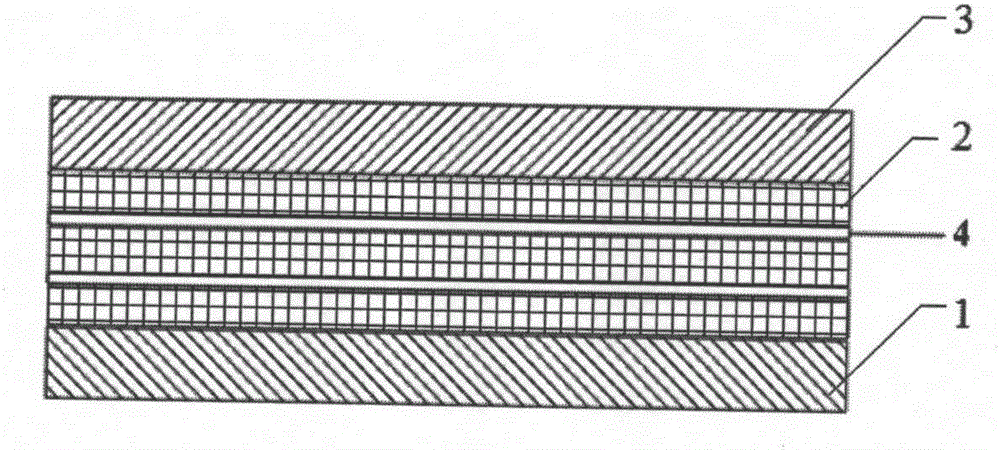

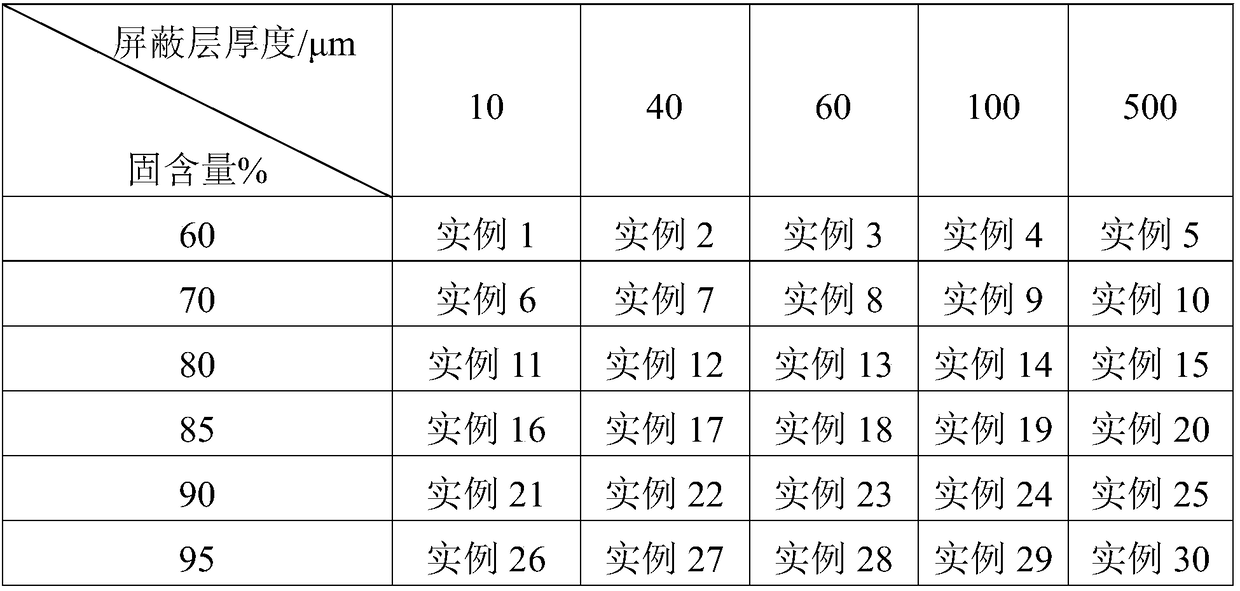

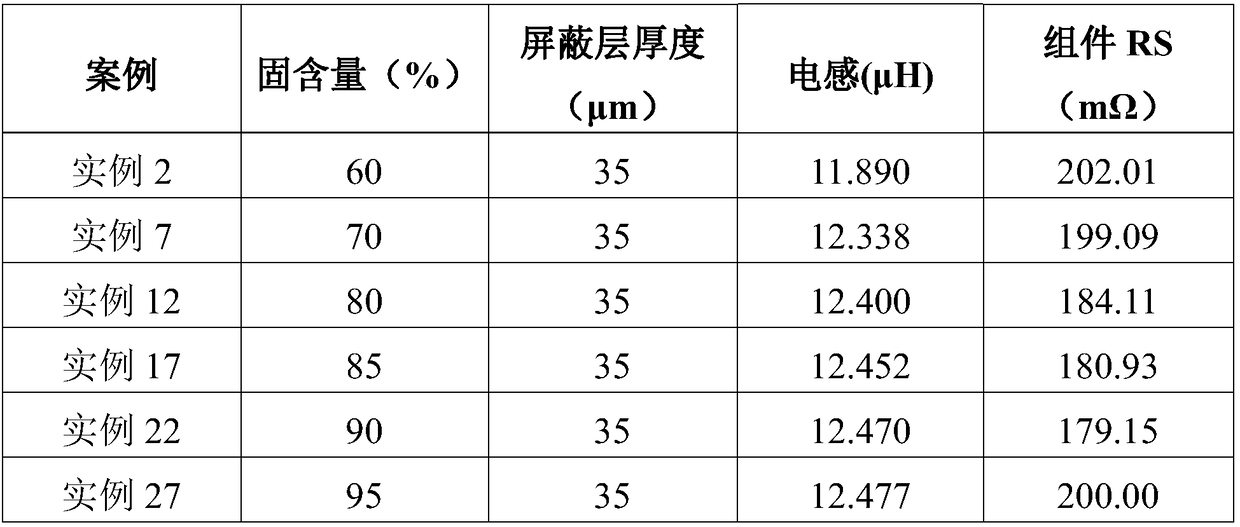

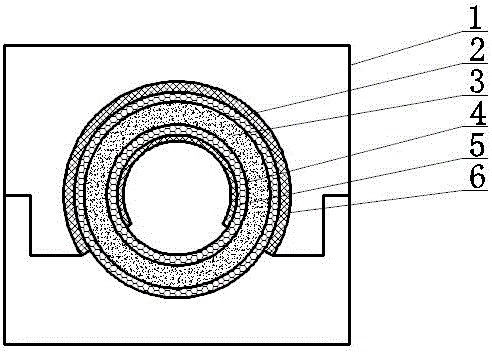

Preparation technology of ceramic shielding sheet for wireless charging and ceramic shielding sheet

InactiveCN108249958AGood electromagnetic performanceAverage permeabilityMagnetic/electric field screeningClaywaresPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a preparation technology of a ceramic shielding sheet for wireless charging. The preparation technology comprises the following steps: step 1, carrying out heat treatment on awound soft magnetic material strip; step 2, crushing the wound soft magnetic material strip subjected to the heat treatment into powder and preparing the powder into slurry; step 3, coating a naked surface of a ceramic substrate with the slurry to form a shielding layer with a certain thickness; sintering the ceramic substrate with the shielding layer to obtain the ceramic shielding sheet. The invention further discloses the ceramic shielding sheet; the ceramic shielding sheet comprises the ceramic substrate, the shielding layer and a PET (Polyethylene Terephthalate) film, wherein one naked surface of the ceramic substrate is coated with the shielding layer by utilizing a coating technology or a printing technology; the PET film is stuck on the outer surface of the shielding layer. The preparation technology of the ceramic shielding sheet, provided by the invention, is simple and feasible and high in integration automatic degree; the produced ceramic shielding sheet has thin thickness,a good shielding capability and high charging efficiency; the product has high working stability, and procedures and material cost are greatly saved.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

Common-mode inductor applying high-stability ultra-crystalline magnetic core and manufacturing method of common-mode inductor

InactiveCN106169362ASmall residual stray magnetic fluxImprove permeabilityTransformers/inductances magnetic coresMagnetic materialsGlass fiberElectromagnetic shielding

The invention discloses a common-mode inductor applying a high-stability ultra-crystalline magnetic core and a manufacturing method of the common-mode inductor. The ultra-crystalline magnetic core with high stability is obtained through controlling vacuum electro-slag remelting, single-roll chilling, molding, ultra-crystallization and distressing processing of the ultra-crystalline magnetic core; and the stability of the common-mode inductor disclosed by the invention is improved through a gap filler which is formed by mixing an aluminum nitride based ceramic framework with excellent electromagnetic performance, a fully enclosed aluminum alloy shielding case and silicone rubber with glass fibers according to a weight ratio of 9: 1. The common-mode inductor applying the high-stability ultra-crystalline magnetic core is high in stability, insensitive to temperature, long in service life, good in electromagnetic shielding performance and excellent in heat dissipation performance.

Owner:宁波华众和创工业设计有限公司

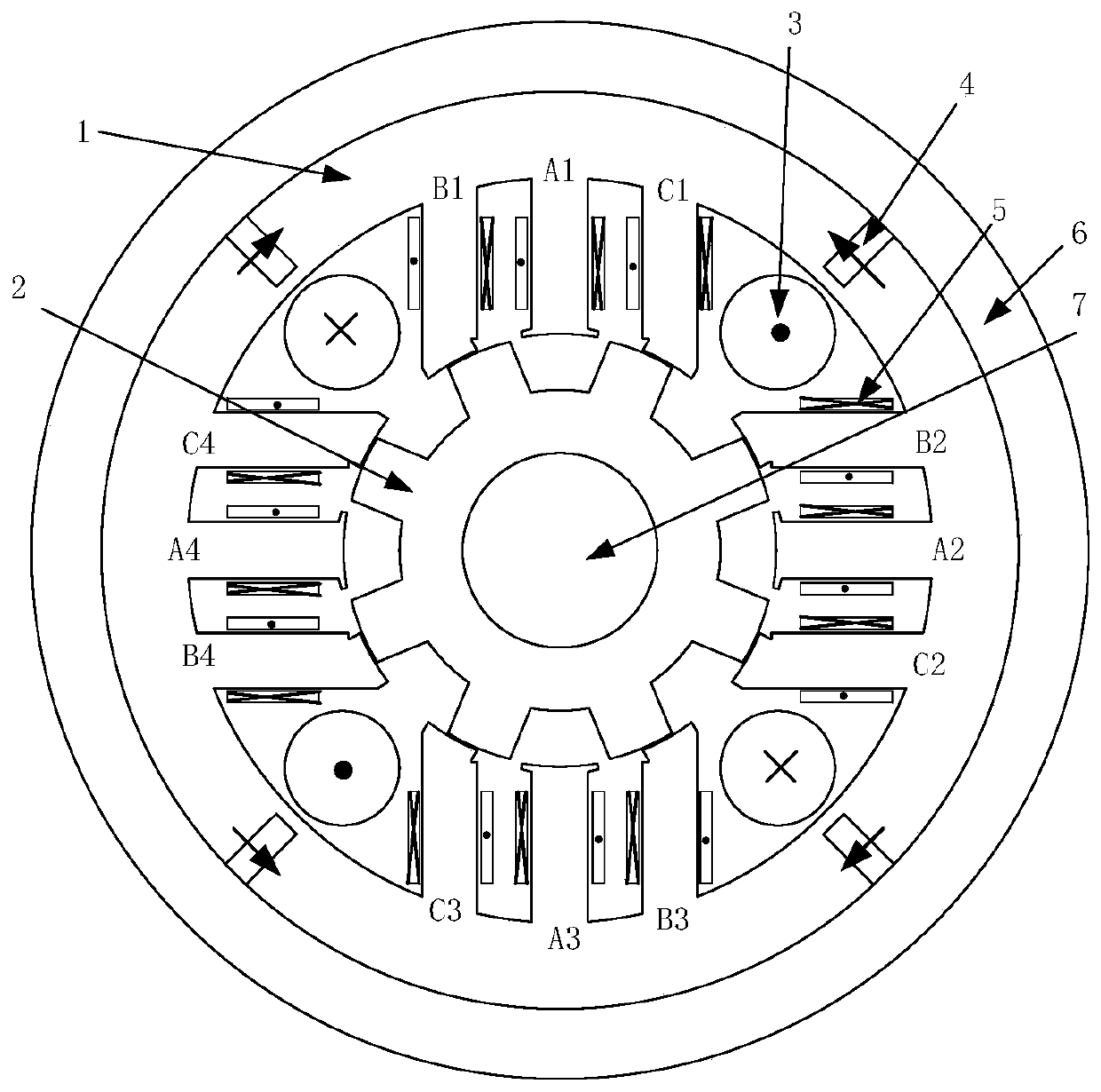

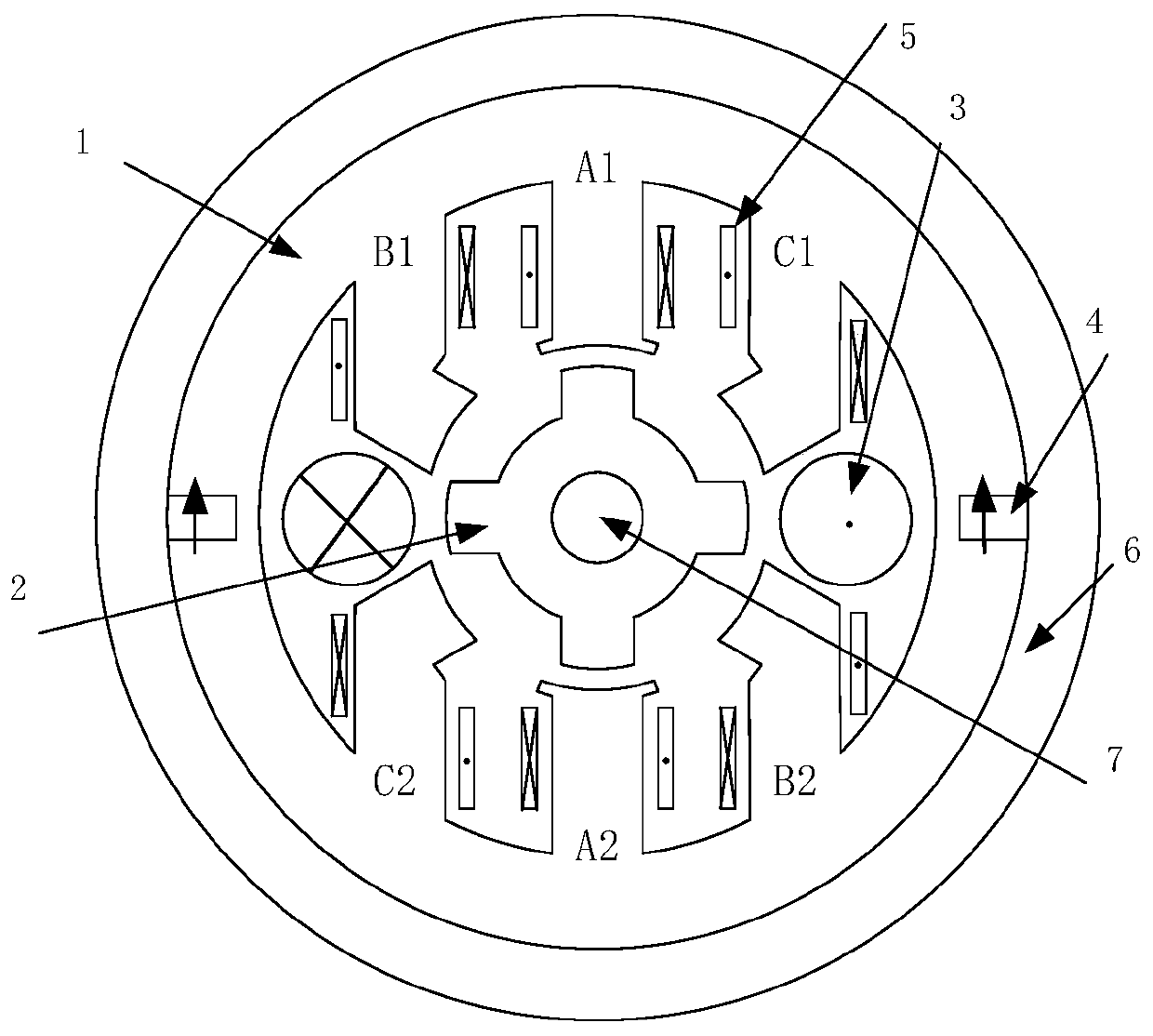

LTL-type double-salient-pole hybrid excitation generator

InactiveCN110289707AImproved positive and negative symmetryReduce copper consumptionMagnetic circuit rotating partsMagnetic circuit stationary partsThree-phaseConductor Coil

The invention discloses an LTL-type double-salient-pole hybrid excitation generator, and belongs to the field of double-salient-pole structure motors. The motor comprises a stator iron core, a rotor iron core, an excitation winding, a permanent magnet, an armature winding, a motor shell and a rotating shaft. The stator iron core and the rotor iron core are of a double-salient-pole structure, and each main pole in the stator iron core comprises three stator poles. The rotor iron core is positioned in the stator iron core and is fixed with the rotating shaft; the exciting winding is wound in the main pole of the stator core in a centralized winding manner; the permanent magnet is embedded in a yoke part of the stator iron core, wherein one end is connected with the motor shell, and the other end is connected with a magnetic isolation bridge of the stator iron core; the armature winding is wound in the stator pole of the stator iron core in a centralized winding manner; and the motor shell is fixed outside the stator iron core. The motor winding is large in space, the three-phase inductance symmetry is good, three-phase voltage imbalance caused by local saturation does not exist, the operation efficiency is high, and uncontrolled rectification output voltage fluctuation is low.

Owner:ZHEJIANG UNIV

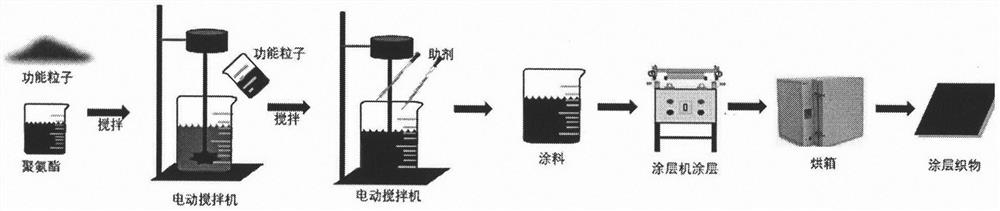

Flexible graphene/barium ferrite composite fabric and preparation method thereof

PendingCN112281503ASoft and comfortableImproving Impedance MatchingTextiles and paperFerrite powderGraphene

The invention discloses a flexible graphene / barium ferrite composite fabric and a preparation method thereof. The preparation method comprises the following steps of (1) preparing a coating: a, weighing a certain mass of graphene, barium ferrite and resin; b, stirring the resin, adding graphene in the stirring process, increasing the rotating speed, stirring for a certain time, and slowly dropwiseadding a defoaming agent and a thickening agent in the stirring process to uniformly disperse the mixture; and c, slowly adding barium ferrite powder into the resin as in the step 2 to prepare the barium ferrite coating. (2) preparing a coated fabric, namely a, flatly fixing a conductive fabric on a needle plate frame; B, selecting the coating thickness and the coating speed, uniformly coating the coating on the surface of the fabric, and changing the coating sequence of the two coatings (firstly coating graphene and then coating barium ferrite; or firstly coating barium ferrite and then coating graphene) to prepare two kinds of composite fabrics respectively; and c, drying the coated fabric in a drying oven to obtain the flexible graphene / barium ferrite composite fabric.

Owner:TIANJIN POLYTECHNIC UNIV

Hot rolling method for non-oriented electrical steel thin strip

InactiveCN105779728AReduce iron loss of finished productGood electromagnetic performanceSteel platesElectrical steel

The invention provides a hot rolling method for a non-oriented electrical steel thin strip. The electrical steel thin strip comprises, by weight, C<=0.003%, 3.5%-7.0% of Si, Al<=3.0%, 0.10%-1.50% of Mn, P<=0.03%, S<=0. 01%, N<=0.05%, and the balance Fe and unavoidable impurities. Before finish rolling, a plurality of slabs are stacked together to be rolled, the slabs are the same in thickness and component, and the thickness of each slab is 30-40 mm. The rolling starting temperature is controlled to be 950 DEG C or below. In the rolling process, cooling water in a rack is stopped. The final rolling temperature is controlled to be 800 DEG C or above. The coiling temperature is controlled to be 700 DEG C or below. Each roll of steel plate is rolled to be 0.2-0.7 mm. Slow cooling is conducted after coiling. After slow cooling, edge cutting and roll division are conducted. According to the hot rolling method, hot stacking continuous rolling is adopted, and the final rolling temperature is raised, so that a hot rolled plate is fully recrystallized, and the finished product iron loss is further reduced. The electromagnetic property is excellent, the production efficiency is improved, the steel plate is even in thickness, and the hot rolling method is suitable for high-speed stamping and automatic lamination.

Owner:ANGANG STEEL CO LTD

Preparation method of extremely-thin high-magnetic-induction oriented silicon steel belt

InactiveCN111996351AGuaranteed heredityAvoid problems that tend to cause deviations in the final Gaussian orientationSteel beltMachining

The invention discloses a preparation method of an extremely-thin high-magnetic-induction oriented silicon steel belt. According to the method, finished oriented silicon steel 0.15-0.35 mm thick is used as the raw material, and the preparation process route includes first-time cold rolling, first-time high-temperature annealing, second-time cold rolling, second-time high-temperature annealing andrefinement of the magnetic domain. Compared with the prior art, the method has the beneficial effects as follows: the problem of difficulty in machining of the extremely-thin oriented silicon steel belt can be solved, the Goss texture inheritance can be guaranteed through matching of the proper cold rolling reduction ratio and annealing process, the magnetic induction B8 of the extremely-thin oriented silicon steel belt can be increased to 1.89-1.94 T, and the extremely-thin oriented silicon steel belt having the excellent electromagnetic performance can be prepared.

Owner:ANGANG STEEL CO LTD

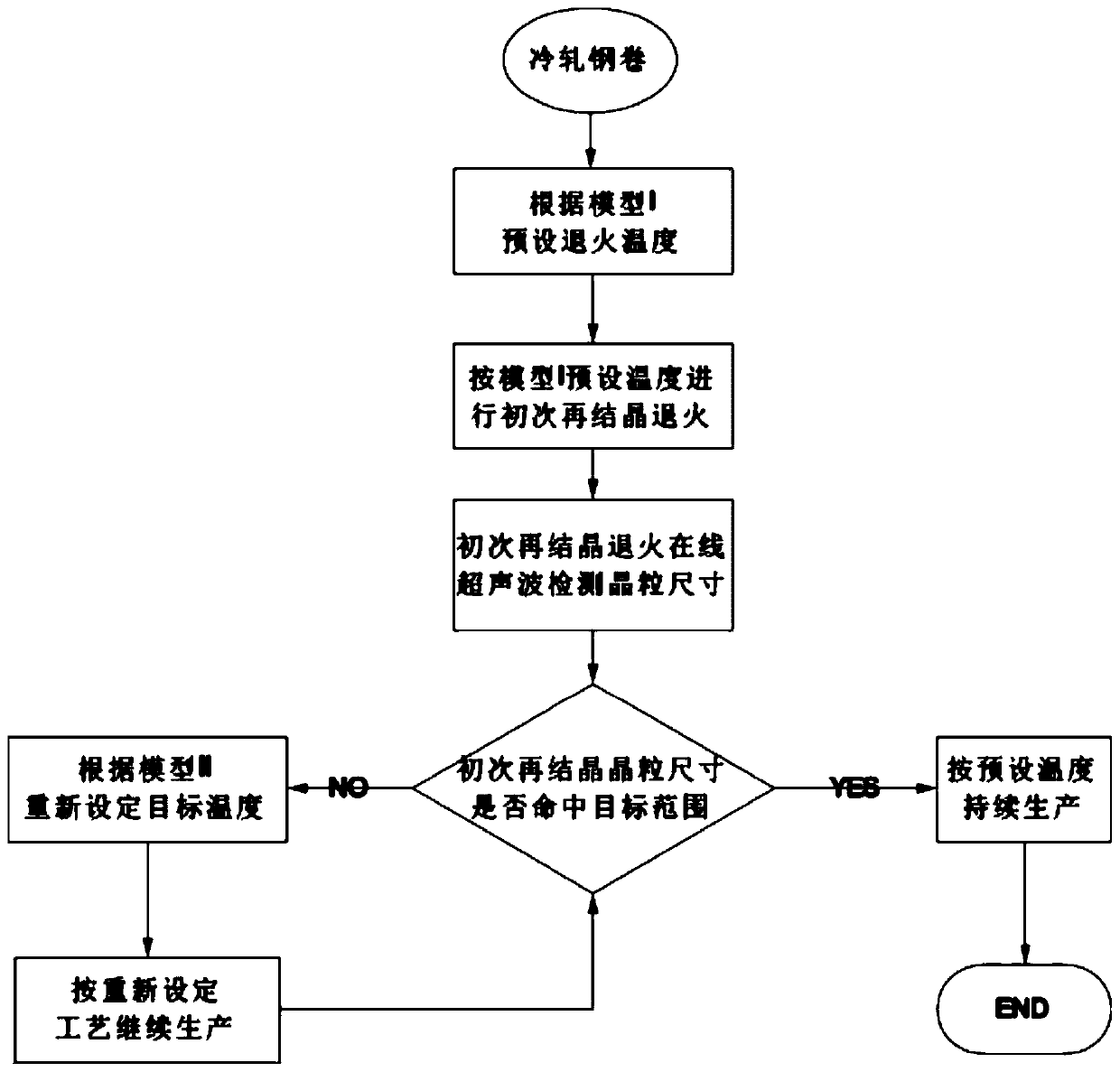

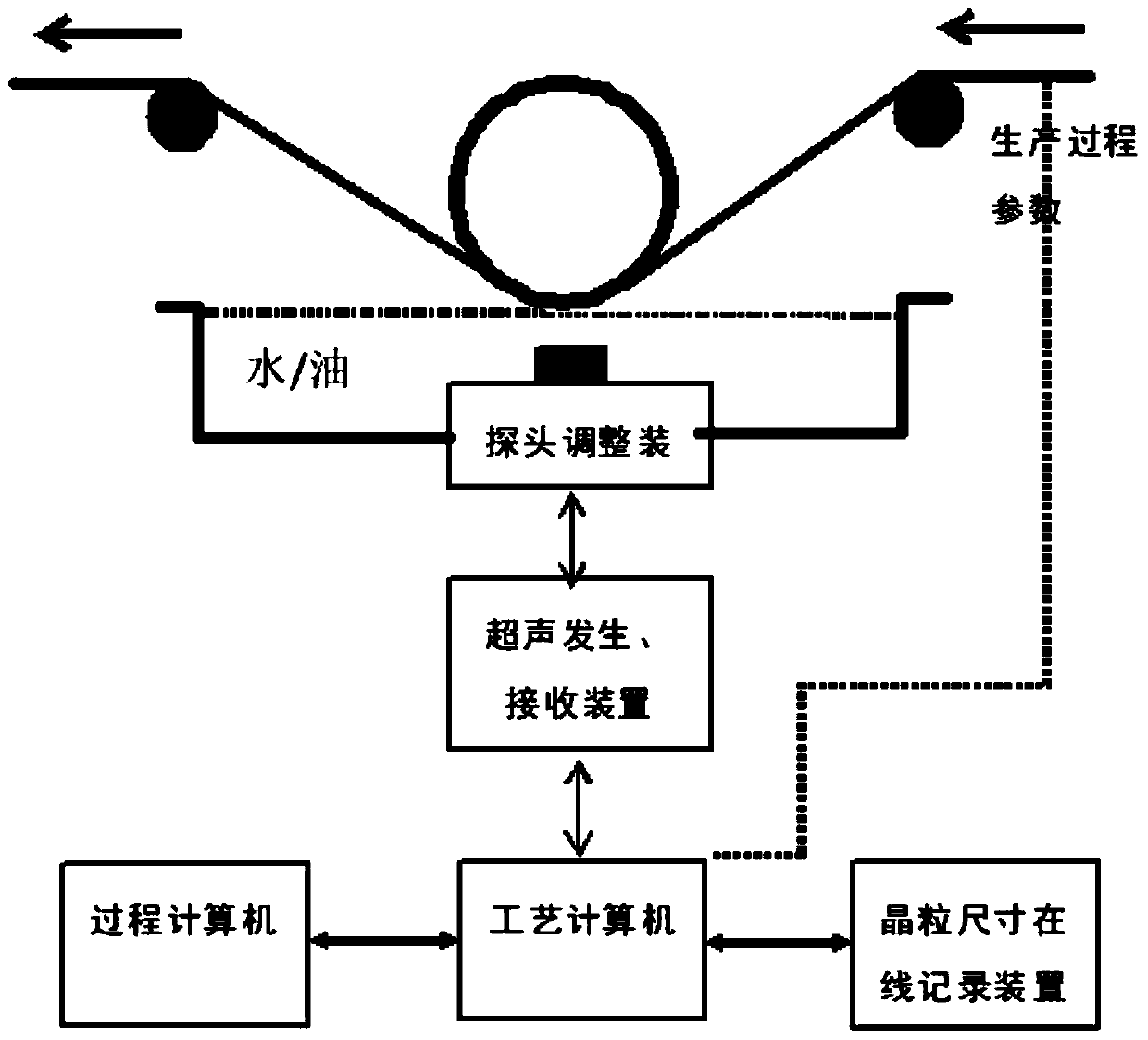

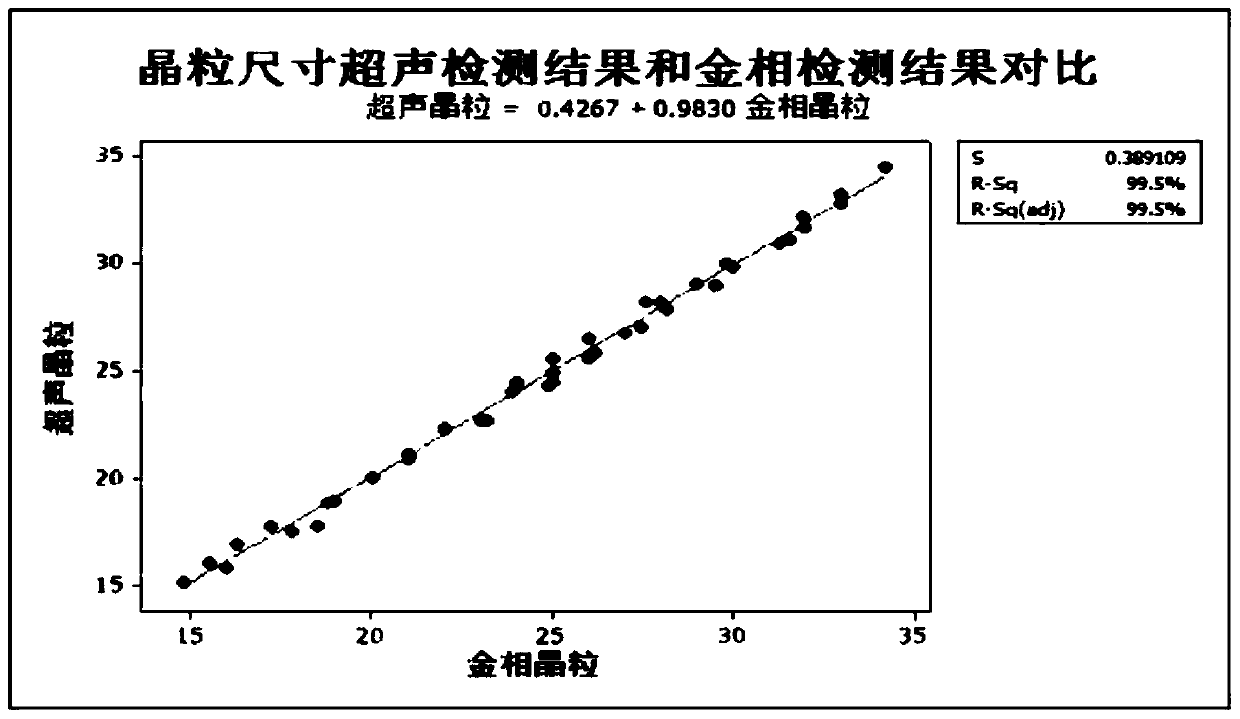

Method for accurately controlling primary recrystallization size of oriented silicon steel

ActiveCN111424166AImprove performanceSatisfy Feedback ControlHeat treatment process controlMetallurgyDecarburization

The invention discloses a method for accurately controlling the primary recrystallization grain size of oriented silicon steel. Dynamic adjustment of decarburization annealing process is guided in real time by online detection of the primary recrystallization grain size, so that ideal and stable primary recrystallization grains are obtained stably, conditions are created for perfect high-temperature annealing secondary recrystallization, andthe oriented silicon steel with good performance is obtained stably. According to the method, on-line evaluation on the effect of decarburization annealingprocess is achieved by online rapid detection of the primary recrystallization grain size, so that the dynamic process adjustment scheme is guided; on the basis of grain size detection, on-line real-time adjustment of decarburization annealing temperature is achieved by a grain size adjustment model; by adjustment of the process online and in real time, the primary recrystallization structure with ideal grain size can be stably obtained, and favorable conditions are created for secondary recrystallization of the oriented silicon steel.

Owner:BAOSHAN IRON & STEEL CO LTD

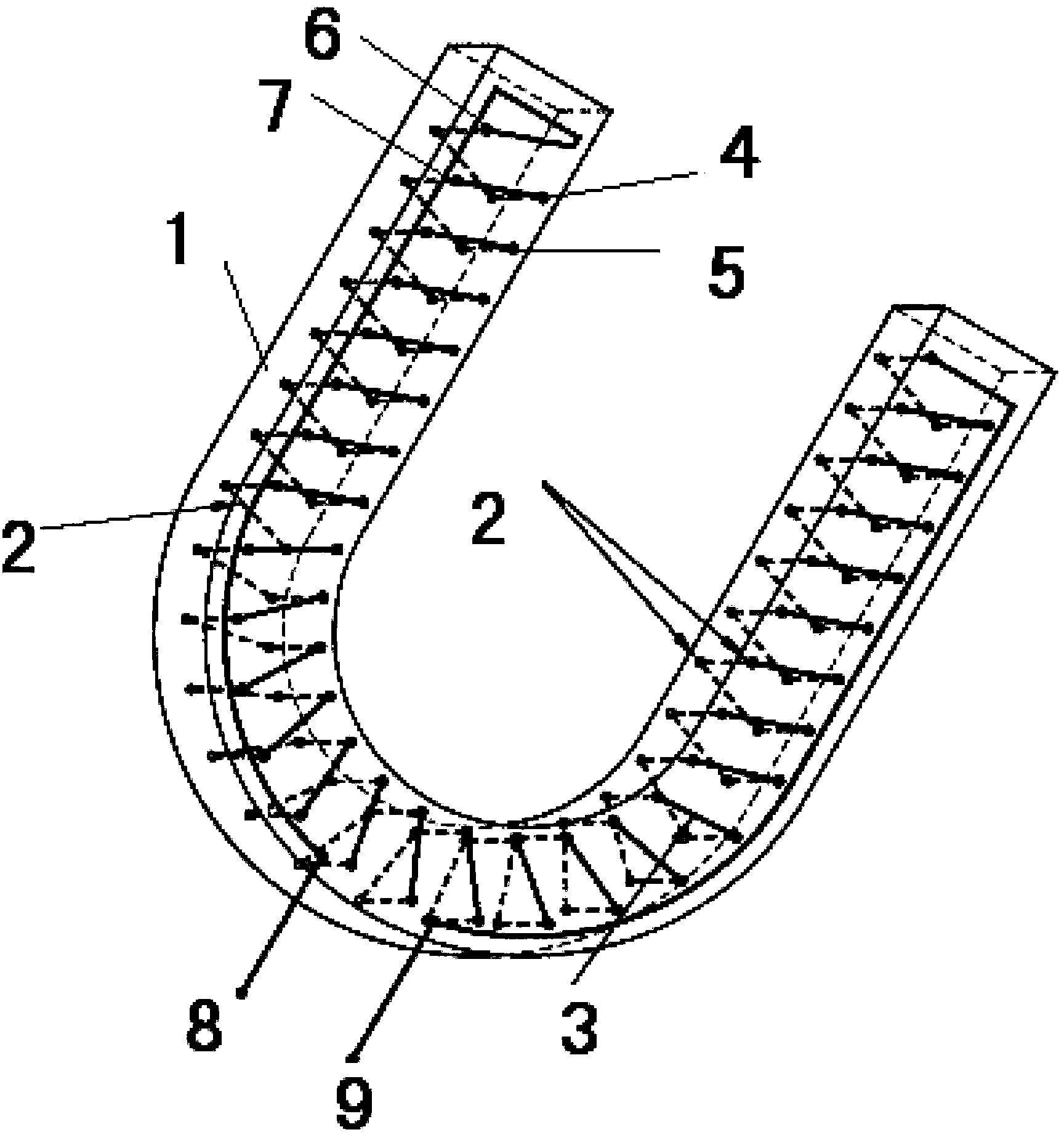

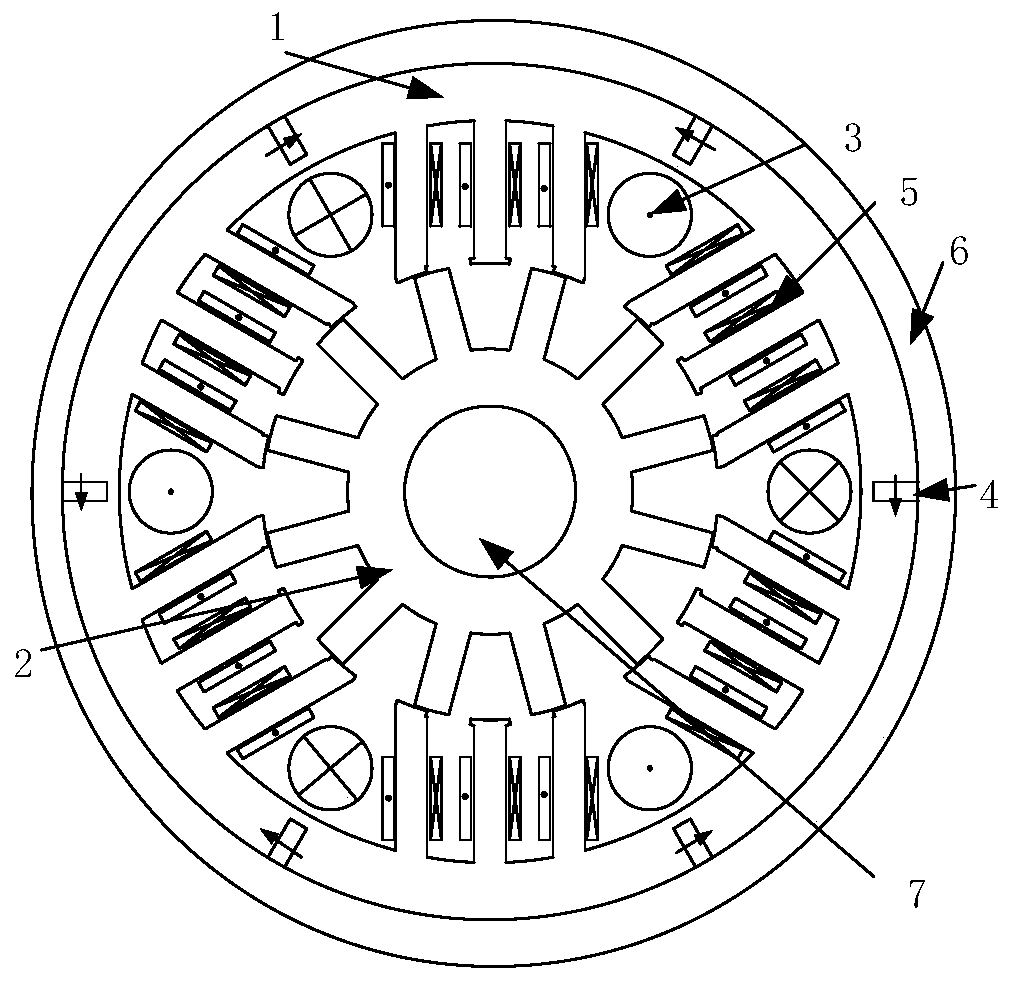

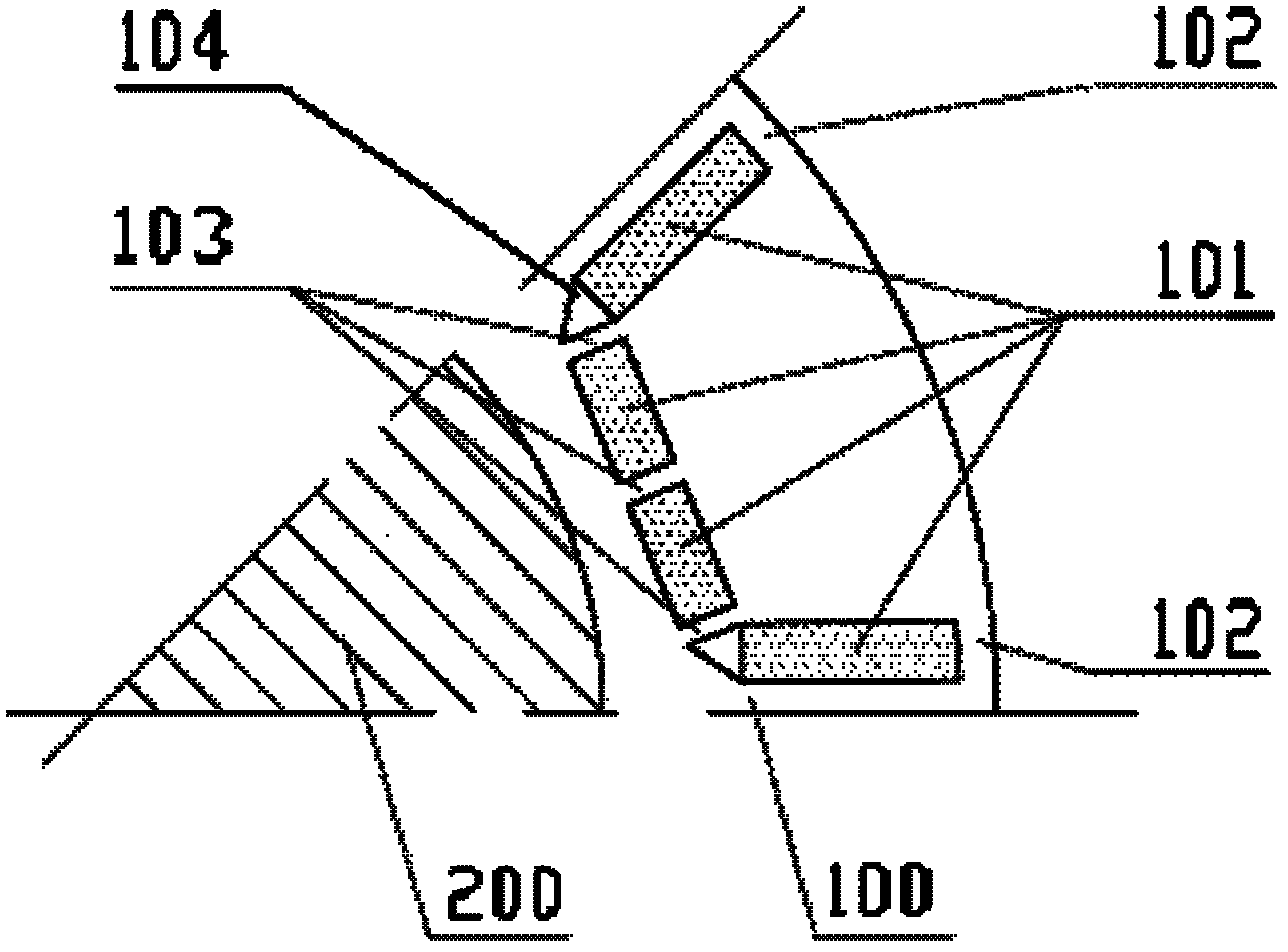

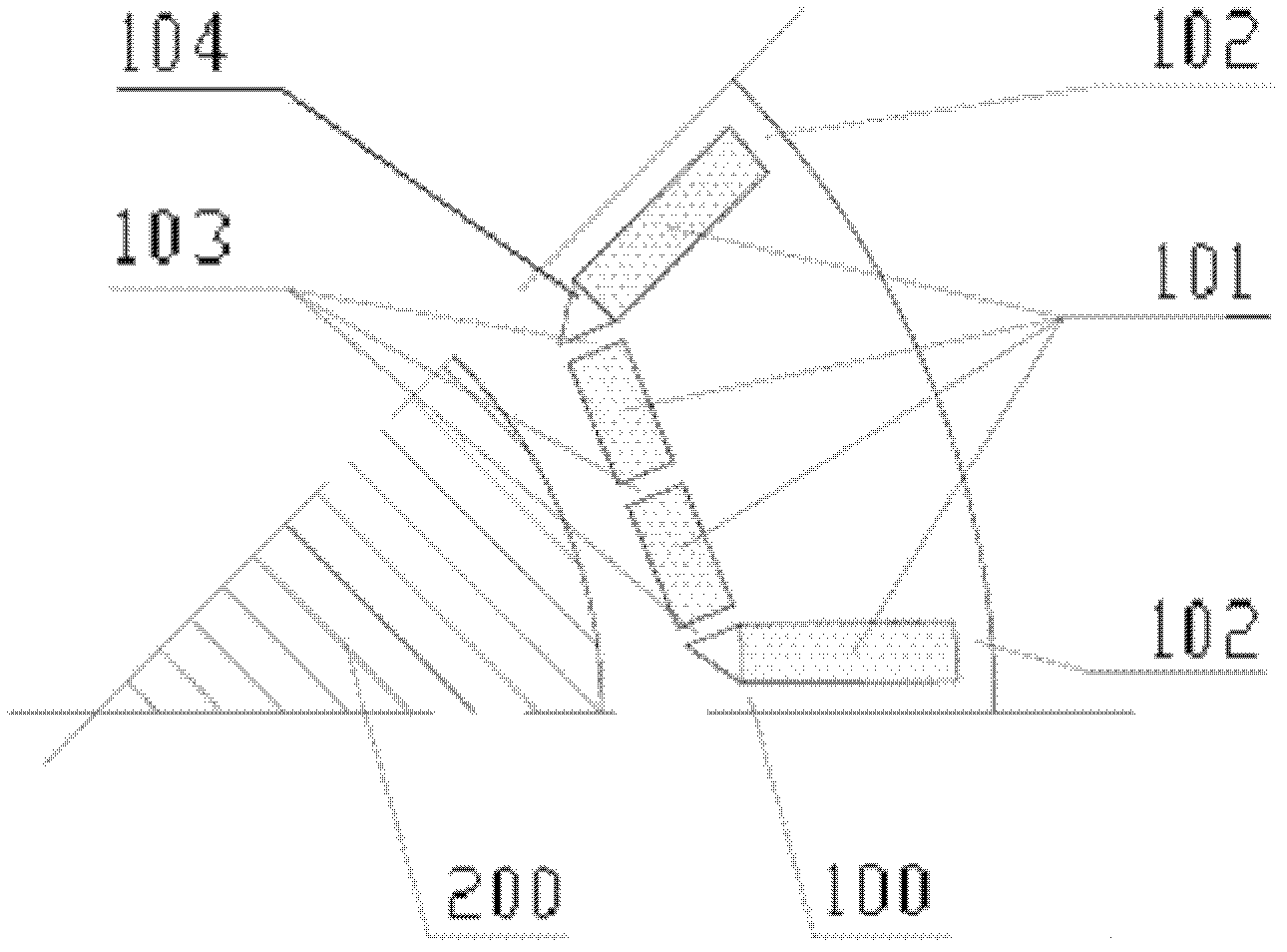

Permanent magnet synchronous motor and U-shaped rotor structure thereof

InactiveCN102386701AWith magnetic isolation effectReduce the magnetic isolation effectMagnetic circuit rotating partsSynchronous machinesPermanent magnet synchronous motorPermanent magnet synchronous generator

The invention discloses a permanent magnet synchronous motor and a U-shaped rotor structure thereof, and discloses the U-shaped rotor structure provided with a rotor core, at least three permanent magnets and a magnetism isolating bridge are respectively arranged on each pole of the rotor core, mounting holes with the number corresponding to the permanent magnets, which are used for mounting the permanent magnets, are formed on the rotor core, and a rotor core part between every two mounting holes forms a strengthening rib; the permanent magnets in each pole are in U-shaped arrangement; and the opening of the shape of the letter U faces to the outer edge of the rotor core. The strengthening ribs are arranged between the permanent magnets of each pole of the rotor structure, the mass of the rotor core and the centrifugal force produced by the mass of the permanent magnet can be borne by the strengthening ribs, so that influences caused by the centrifugal force to the intensity of the magnetism isolating bridge can be reduced; and the strengthening ribs have a good magnetism isolating effect.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

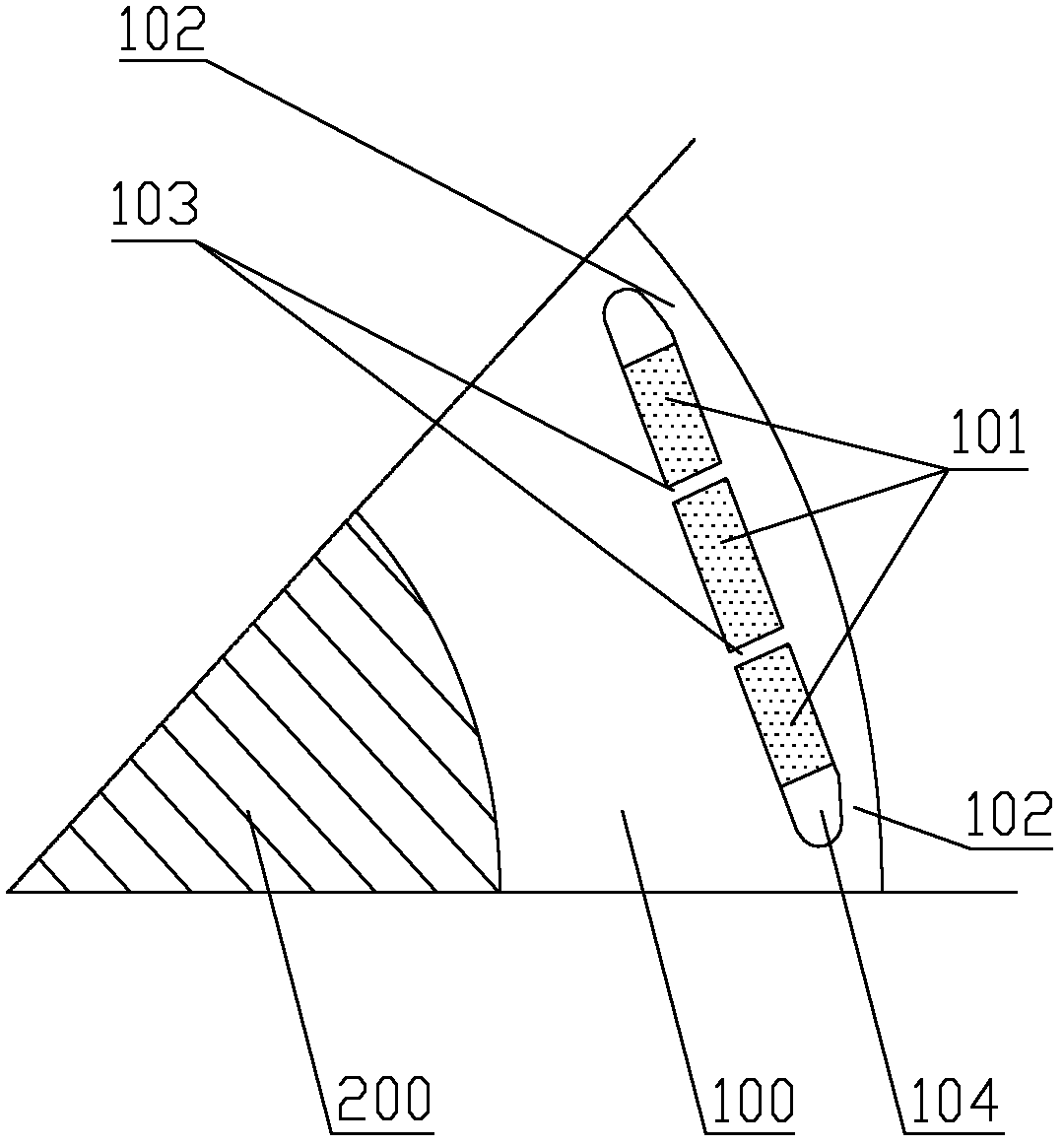

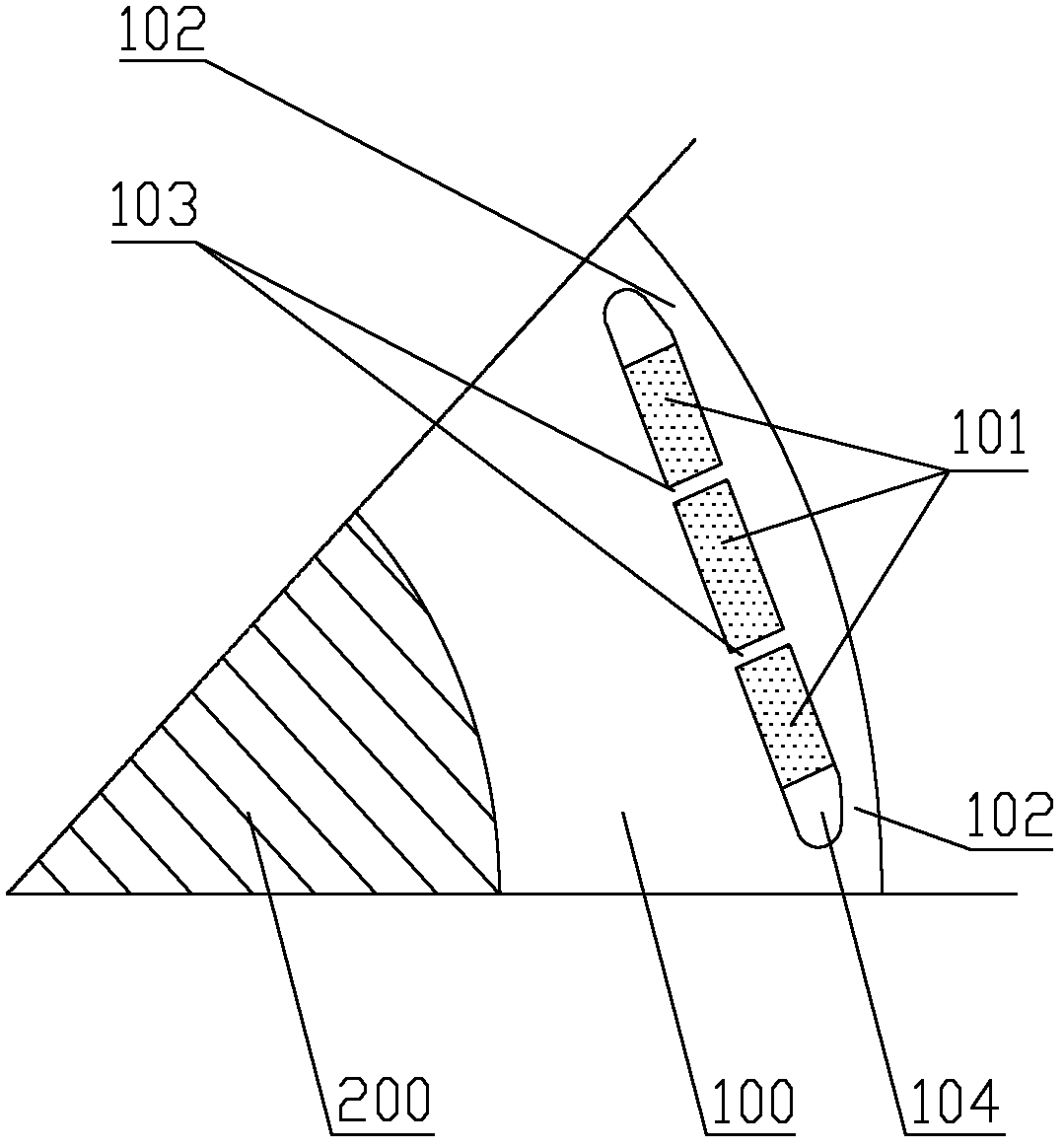

Permanent magnet synchronous motor and linear rotor structure thereof

InactiveCN102386700AGood electromagnetic performanceGuaranteed reliabilityMagnetic circuit rotating partsSynchronous machinesPhysicsPermanent magnet synchronous motor

The invention discloses a linear rotor structure of a permanent magnet synchronous motor, which is provided with a rotor core, wherein each pole of the rotor core is provided with permanent magnets and a magnetism isolating bridge, at least two permanent magnets are arranged in each pole and arranged in a linear shape, mounting holes with the number corresponding to that of the permanent magnets are formed on the rotor core, and a rotor core part between every two mounting holes forms a strengthening rib. A strengthening rib is arranged between the permanent magnets of each pole of the rotor structure, and during the operation, the mass of the rotor core and the centrifugal force produced by the mass of the permanent magnet are born by the strengthening ribs, so that influences caused by the centrifugal force to the intensity of the magnetism isolating bridge can be reduced; and the strengthening ribs have magnetism isolating effects and can ensure the running reliability of the motor.

Owner:CSR ZHUZHOU ELECTRIC CO LTD

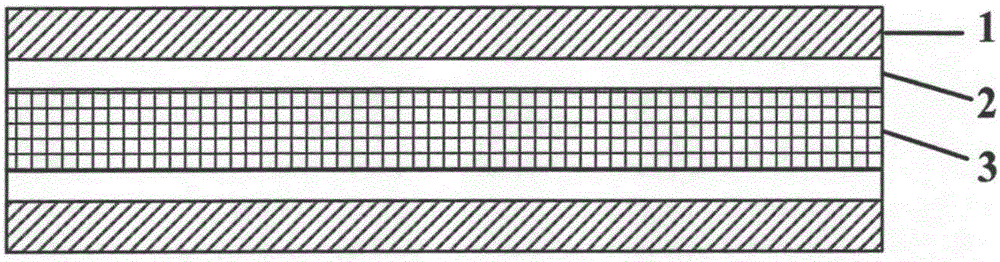

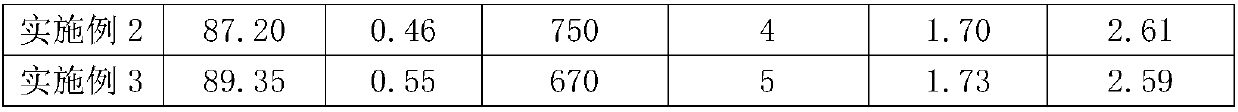

Method for realizing tunable electromagnetic induction transparency based on graphene-medium composite metasurface

ActiveCN113258295AStrong active control abilityHigh quality factorAntennasOptical elementsDielectricNano structuring

The invention discloses a method for realizing tunable electromagnetic induction transparency based on a graphene-medium composite metasurface. The composite dielectric metasurface is designed by utilizing the electromagnetic field coupling effect and the special photoelectric property of graphene so as to realize a tunable electromagnetic induction transparency phenomenon. The structure is divided into a top layer, a middle layer and a bottom layer, wherein the bottom layer is a medium substrate, the middle layer is medium nano-columns and hollow medium nano-columns which are periodically arranged, and the uppermost layer is single-layer graphene which covers the upper surface of the nano-structure. Through the design of the substrate and the middle layer nanorod material, the structure size and the like, the tunable electromagnetic induction transparency effect can be flexibly regulated and controlled in the near-infrared band. By changing the size parameters of the structure, the electromagnetic induction transparent window can realize red shift or blue shift under the condition of keeping the transmittance unchanged. In addition, the strength of the electromagnetic induction transparent window can be modulated by applying a voltage to adjust the Fermi level of the graphene, and the modulation depth can reach 54%.

Owner:ZHEJIANG UNIV OF TECH

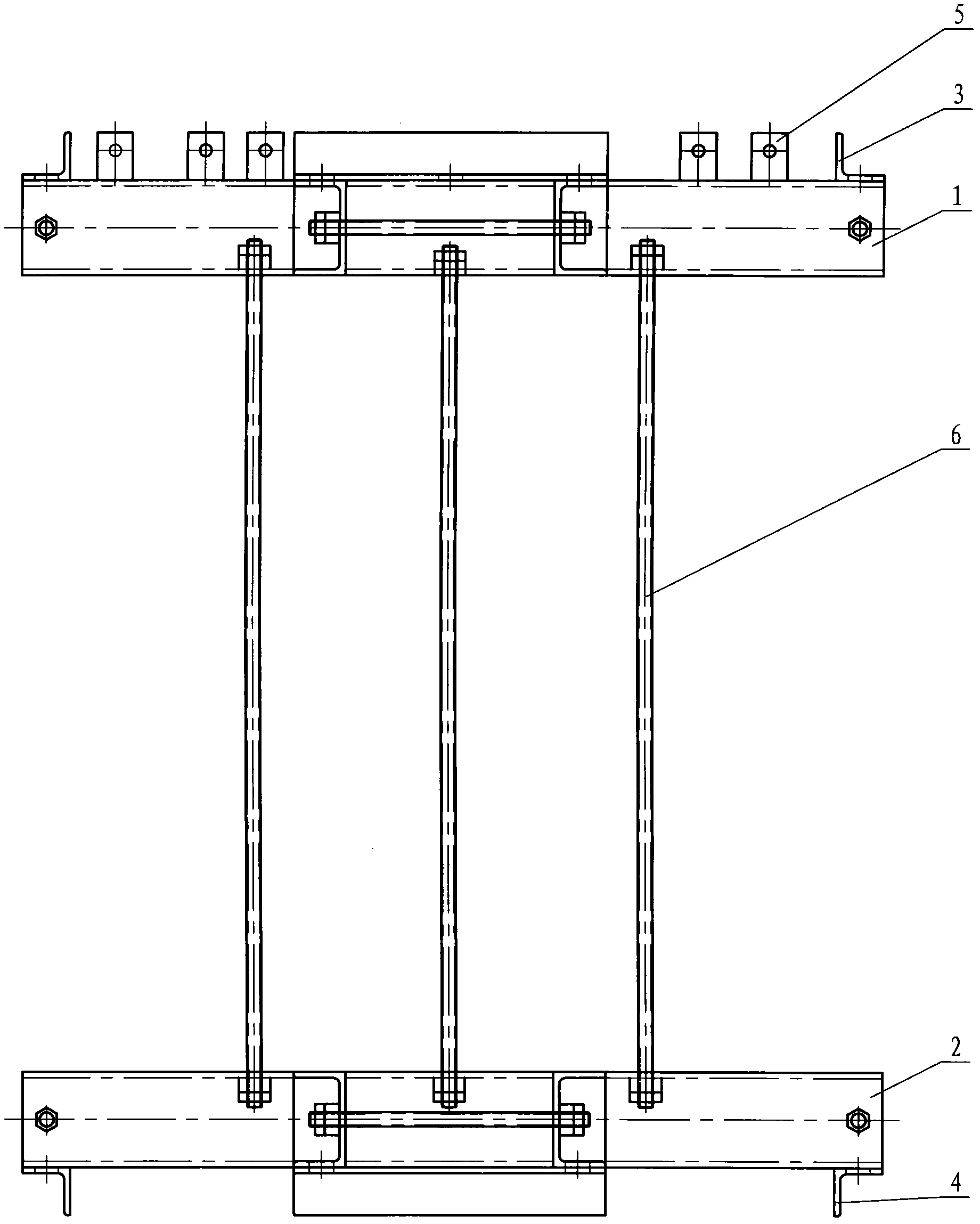

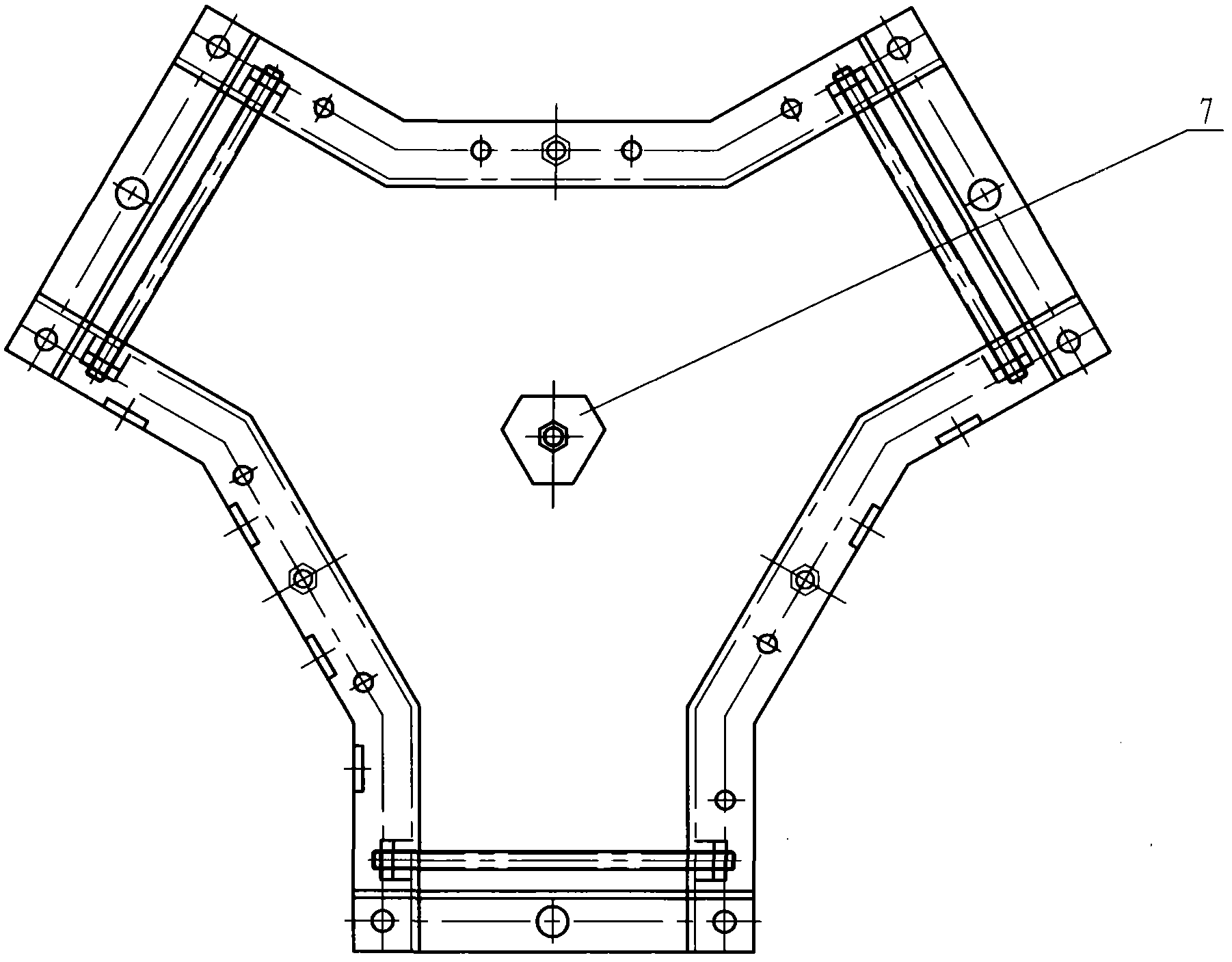

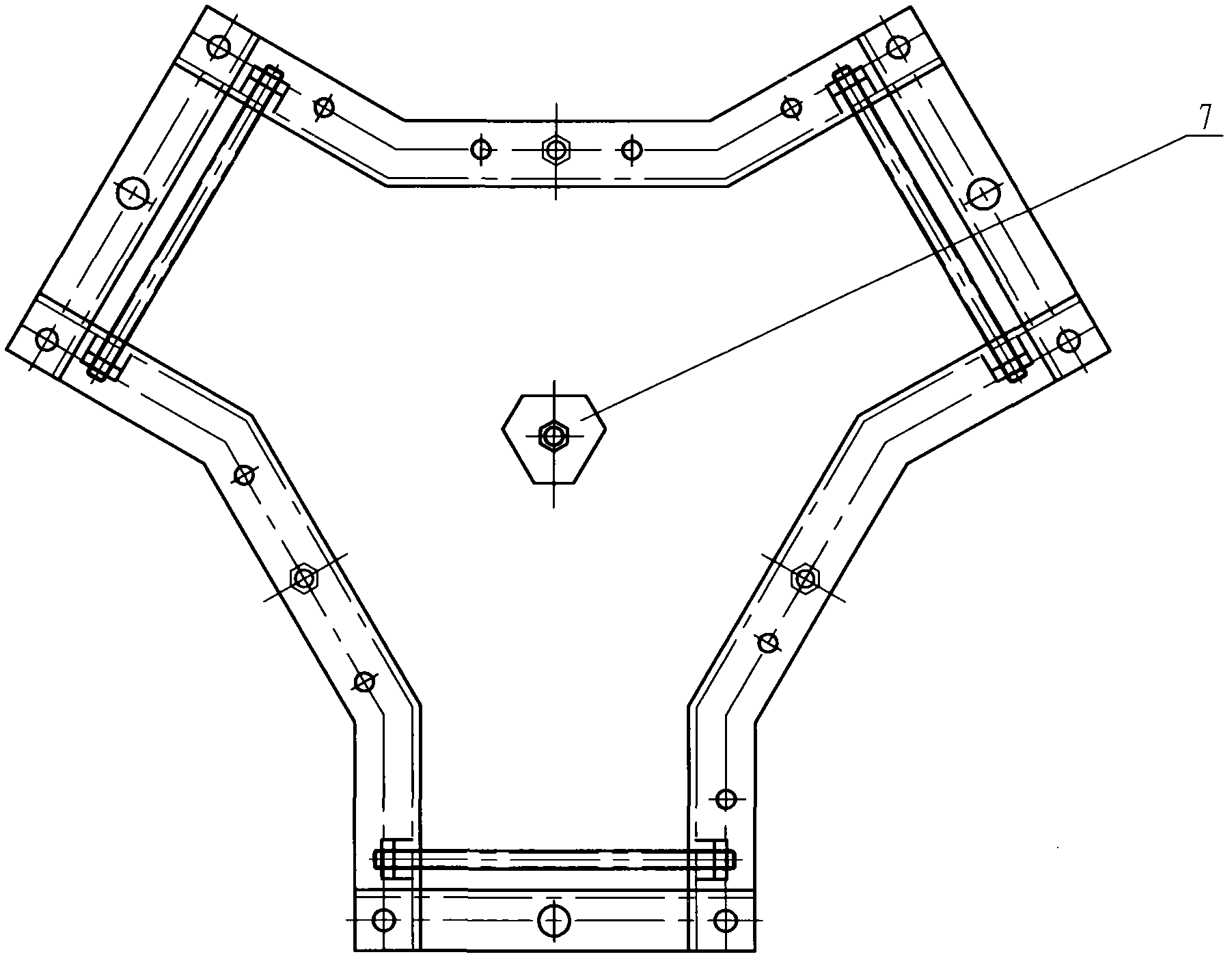

Angle-folded type clamp for three-dimensional iron cores

InactiveCN103137300AGood electromagnetic performanceElectromagnetic performance is not destroyedTransformers/inductances magnetic coresInductances/transformers/magnets manufactureElectric power transmissionElectrical force

The invention relates to a clamp, in particular to an angle-folded type clamp for three-dimensional iron cores, and belongs to the technical field of devices for electric power transmission and distribution. The angle-folded type clamp for the three-dimensional iron cores comprises six single V-shaped clamps which are formed by U-steel in a machined mode. An upper clamp is formed by three single clamps and a triangle through screws in a fixedly connected mode, and a lower lamp is formed by another three single clamps and a triangle through screws in a fixedly connected mode. Both the upper clamp and the lower clamp form a frame structure. The upper clamp and the lower clamp are connected through at least four tightly-pressing screws. At least one tight-pressing screw is connected in the middle of the upper clamp and the lower clamp. According to the angle-folded type clamp for the three-dimensional iron cores, a good electromagnetic property of an iron core is prevented from being damaged, capacity of resisting electrodynamic force when sudden short-circuit occurs is improved, and no-load loss and noise are reduced. The angle-folded type clamp for the three-dimensional iron cores is particularly suitable for the three-dimensional iron cores, simple in structure, convenient to use, practical, low in cost, capable of reducing loss and remarkable in effect of reducing noise.

Owner:蒋元华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com