Production method for non-oriented electrical steel product with excellent longitudinal electromagnetic properties

A technology of oriented electrical steel and production method, which is applied in the field of cold-rolled silicon steel, can solve the problems that the longitudinal electromagnetic properties of non-oriented electrical steel products cannot meet the requirements of use, and achieve the effect of adapting to special industry needs, easy to realize, and excellent longitudinal electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

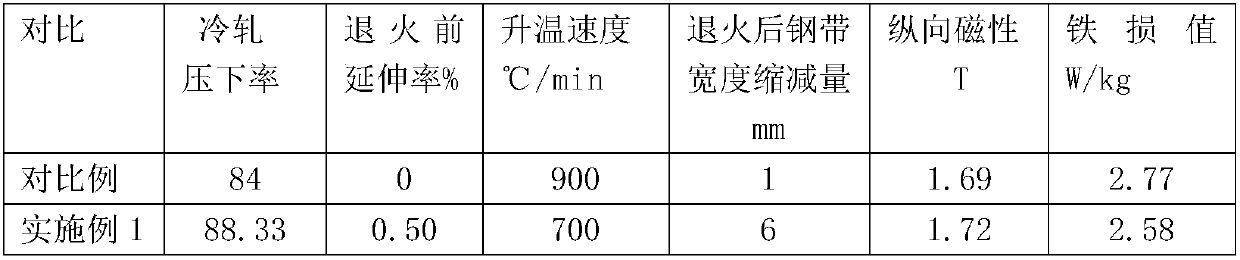

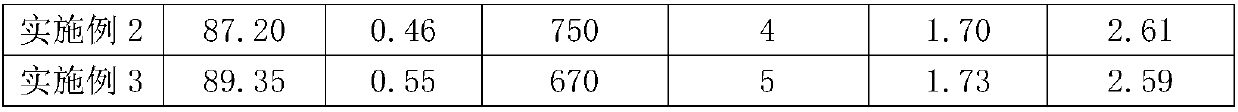

[0016] A kind of non-oriented electrical steel product production method with excellent longitudinal electromagnetic properties of the present invention, comprising:

[0017] 1) Determine the thickness of hot-rolled raw materials according to the specifications of the finished product, and control the overall reduction rate of cold rolling to a maximum reduction rate of 86% to 95%;

[0018] 2) Taking the yield strength of the electrical steel cold-rolled steel strip corresponding to the heating temperature as a reference, increase the tension of the steel strip into the furnace, control the elongation of the cold-rolled steel strip from 0.50% to 5.00%, and change the stress of the cold-rolled steel strip by changing the stress of the steel strip. The original energy storage form of the main texture components of the post-111 orientation, 110 orientation, and 100 orientation;

[0019] 3) Increase the tension control of the heating section of the annealing furnace during the hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com