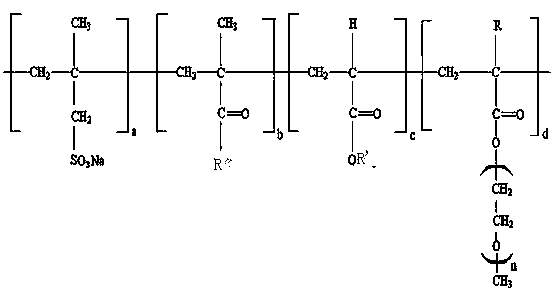

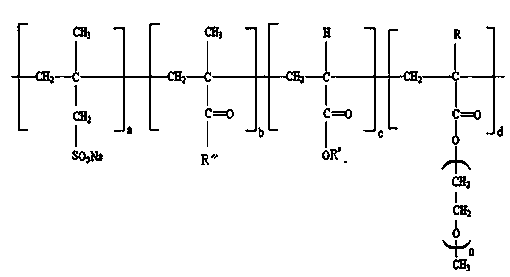

High-early-strength polycarboxylate water reducer and preparation method thereof

A high-early-strength, polycarboxylic acid technology, applied in the field of concrete admixtures, can solve the problems of restricting the application of polycarboxylate superplasticizers, and achieve the effect of stable product performance and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

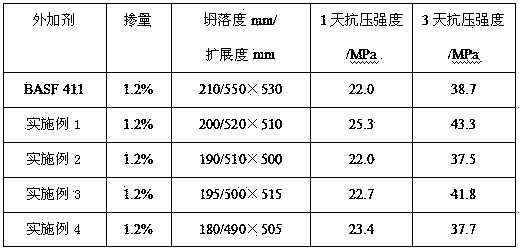

Examples

Embodiment 1

[0025] In an embodiment of the present invention, a method for preparing a high early strength polycarboxylate water reducer comprises the following steps:

[0026] (1) Esterification: Use acrylic acid and alcohol amine at 120 degrees, use sulfuric acid as a catalyst, hydroquinone as a polymerization inhibitor, and the molar ratio of acrylic acid: alcohol amine: sulfuric acid: hydroquinone is 1:1: 0.03:0.005, esterified for 6h to obtain acrylated alcoholamine with unsaturated bonds;

[0027] (2) Polymerization: Put 120.00 parts of methallyl polyoxyethylene ether with a molecular weight of 2400 and some water into a reaction vessel, raise the temperature, stir at a temperature of 70±5°C to completely dissolve the reactants, and then add Add 10.80 parts of acrylic acid, 6.33 parts of sodium methacryl sulfonate, 5.33 parts of acrylamide, 5.01 parts of acrylated alkanolamine in the container, and then add dropwise 93.00 parts of ammonium persulfate solution with a mass percentage ...

Embodiment 2

[0030] In an embodiment of the present invention, a method for preparing a high early strength polycarboxylate water reducer comprises the following steps:

[0031] (1) Esterification: Use acrylic acid and alcohol amine at 120 degrees, use sulfuric acid as a catalyst, hydroquinone as a polymerization inhibitor, and the molar ratio of acrylic acid: alcohol amine: sulfuric acid: hydroquinone is 1:1: 0.03:0.005, esterified for 6h to obtain acrylated alcoholamine with unsaturated bonds;

[0032] (2) Polymerization: put 120.00 parts of methallyl polyoxyethylene ether with a molecular weight of 2400 and some water into a reaction vessel, raise the temperature, stir at a temperature of 80±5°C to completely dissolve the reactants, and then add Add 10.80 parts of acrylic acid, 6.33 parts of sodium methacryl sulfonate, 5.33 parts of acrylamide, 5.01 parts of acrylated alkanolamine in the container, and then add dropwise 93.00 parts of ammonium persulfate solution with a mass percentage ...

Embodiment 3

[0035] In an embodiment of the present invention, a method for preparing a high early strength polycarboxylate water reducer comprises the following steps:

[0036] (1) Esterification: Use acrylic acid and alcohol amine at 120 degrees, use sulfuric acid as a catalyst, hydroquinone as a polymerization inhibitor, and the molar ratio of acrylic acid: alcohol amine: sulfuric acid: hydroquinone is 1:1: 0.03:0.005, esterified for 6h to obtain acrylated alcoholamine with unsaturated bonds;

[0037] (2) Polymerization: 120.00 parts of methallyl polyoxyethylene ether with a molecular weight of 2400 and some water, put it into a reaction container, heat up, stir at a temperature of 70±5°C to completely dissolve the reactants, and then pour into the container Add 10.80 parts of acrylic acid, 5.1 parts of sodium methacrylic sulfonate, 6.2 parts of acrylamide, 7.0 parts of acrylated alcoholamine, and then dropwise add 93.00 parts of ammonium persulfate solution with a mass percentage of 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com