Method for rolling liquid core under heavy reduction rate by virtue of online thickness regulating roll by utilizing continuous casting machine

A technology of thickening rolls and continuous casting machines, which is applied in the direction of metal rolling, rolling force/roll gap control, etc. It can solve the problems of limited quality effect of continuous casting slabs, large investment in thickness adjustment process, complex equipment structure, etc., to achieve Reduce the replacement of crystallizers, save rolling energy consumption, and reduce the effect of operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

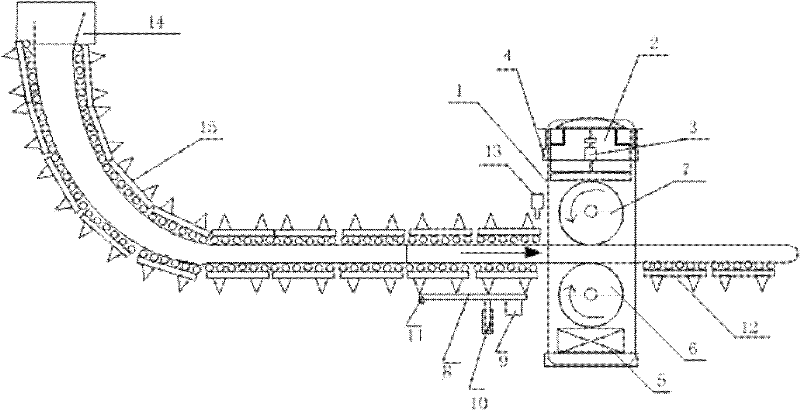

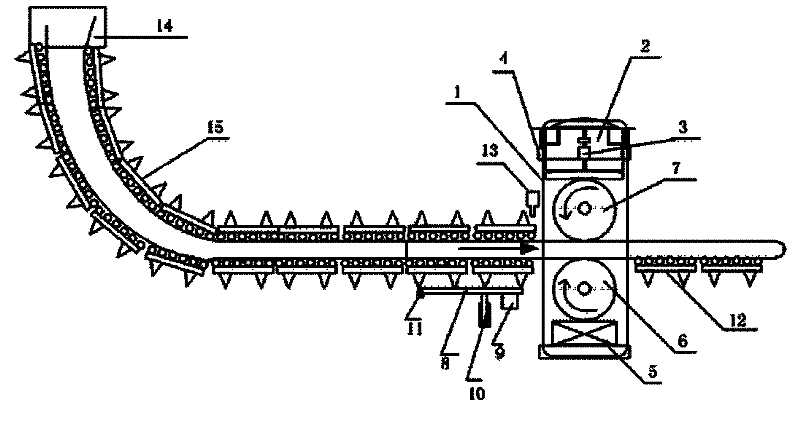

[0050] Such as figure 1 As shown, the molten steel is poured, and through the fan section and the horizontal section of the crystallizer 14 and the continuous casting machine 15, the solidification speed of the continuous casting slab is adjusted by adjusting the cooling intensity of the continuous casting machine 15 secondary cooling sections, so as to ensure that the continuous casting slab is in the When entering the two-roll mill 1, there is a liquid core thickness set according to the process model.

[0051] The continuous casting slab with a liquid core is completely solidified after being rolled to the target thickness in a single pass by the two-roll mill 1 with a large reduction; The differential rolling strategy is adopted according to the principle of second flow, so that the continuous casting slab is in a three-dimensional compressive stress state during rolling, thereby significantly improving the quality of the continuous casting slab.

[0052] Preparing for ro...

Embodiment 2

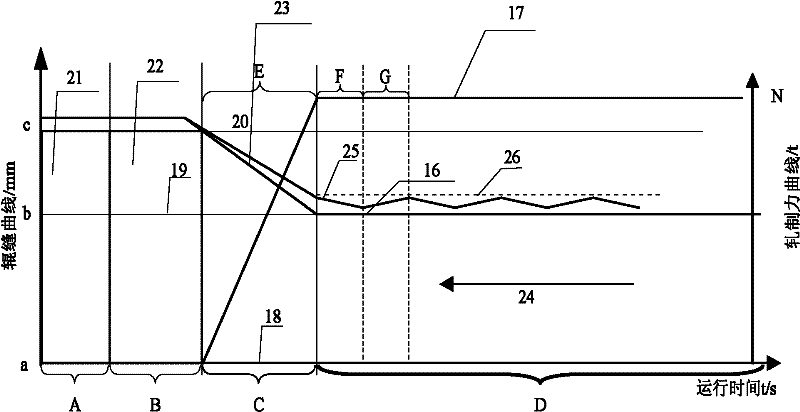

[0058] Such as figure 2 As shown in the figure, the rolling process of a conventional continuous casting slab product of a certain specification is shown. As shown in the figure, the rolling of the continuous casting slab can also be divided into: dummy rod passing stage A, head low temperature continuous casting slab passing through The stage B, the stage C and the stable stage of pressure reduction with load are the four stages of the stable rolling stage D.

[0059] After the continuous casting machine sends out the slab signal, when the dummy bar passes through stage A and the head low-temperature continuous casting slab passes through stage B, the roll gap 16 of the rolling mill swings to the position where the thickness of the continuous casting slab entrance is 20 plus 10 mm, and the dummy After the rod 21 and the low-temperature continuous casting billet 22 at the head pass through the rolling mill, they enter the stage C of reduction with load.

[0060] At this time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com