Sustained-release polycarboxylic high-performance water reducing agent and preparation method thereof

A slow-release polycarboxylic acid and high-performance technology, which is applied in the field of concrete water-reducing agent and its preparation, can solve the problem that the concrete slump performance cannot be satisfied, the water-reducing rate of the water-reducing agent is low, and the water-reducing function does not have a slow-release effect and other problems, to achieve the effect of high water reducing rate, excellent slump retention performance and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

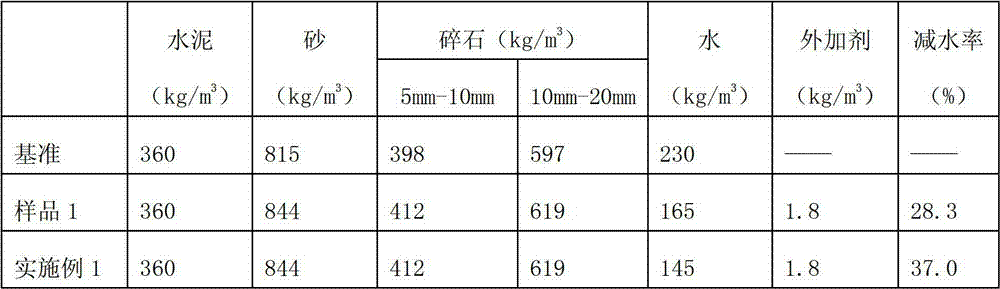

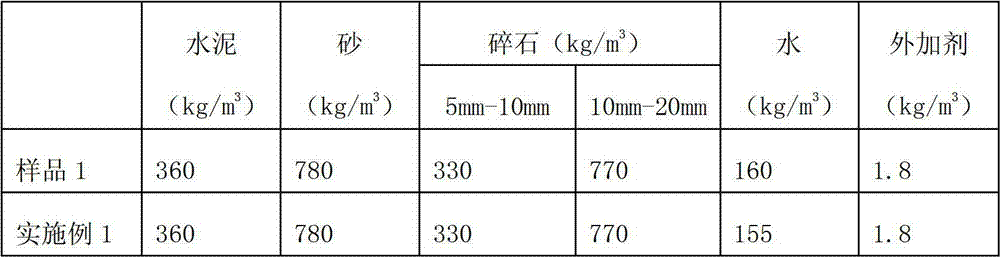

Examples

Embodiment 1

[0041] 0.13mol of monomer A is methylalkenyl polyoxyethylene with a degree of polymerization of 30-60;

[0042] 0.32mol monomer B is acrylic acid;

[0043] 0.01mol monomer C is sodium methacrylate;

[0044] 0.12mol monomer D is acrylamide;

[0045] 0.05mol monomer E is ethyl acetate;

[0046] The initiator is a mixture of sodium sulfate and potassium persulfate in a ratio of 1:1;

[0047] The chain transfer agent is mercaptoacetic acid;

[0048] Preparation steps:

[0049] a. Dissolve monomer C, monomer D, monomer E, and monomer B in an equimolar amount to monomer D in deionized water, stir evenly, and obtain a small monomer solution for use;

[0050] B, the chain transfer agent is dissolved in deionized water, stirred evenly, and the chain transfer agent solution is obtained for use; the consumption of the chain transfer agent is 0.05% by weight of the total monomer weight of the reaction;

[0051] c. Put the monomer A and deionized water into the reaction container and...

Embodiment 2

[0054] 0.13mol of monomer A is allyl polyoxyethylene ether with a degree of polymerization of 30-60;

[0055] 0.32mol monomer B is methacrylic acid;

[0056] 0.01mol monomer C is sodium methacrylate;

[0057] 0.12mol monomer D is 2-acrylamido-methylpropanesulfonic acid;

[0058] 0.05mol monomer E is styrene;

[0059] The initiator is hydrogen peroxide;

[0060] The chain transfer agent is a mixture of mercaptoacetic acid, 2-mercaptopropionic acid and 3-mercaptopropionic acid in a ratio of 1:1:1;

[0061] Preparation steps:

[0062] a. Dissolve monomer C, monomer D, monomer E, and monomer B in an equimolar amount to monomer D in deionized water, stir evenly, and obtain a small monomer solution for use;

[0063] B, the chain transfer agent is dissolved in deionized water, stirred evenly, and the chain transfer agent solution is obtained for use; the consumption of the chain transfer agent is 0.2% by weight of the total monomer weight of the reaction;

[0064] c. Put the mo...

Embodiment 3

[0067] 0.13mol of monomer A is polyoxypropylene ether with a degree of polymerization of 30-60;

[0068] 0.32mol monomer B is acrylic acid;

[0069] 0.01mol monomer C is sodium methacrylate;

[0070] 0.12mol monomer D is acrylamide;

[0071] 0.05mol monomer E is ethyl acetate;

[0072] The initiator is a mixture of sodium sulfate and hydrogen peroxide at 2:1;

[0073] Chain transfer agent is sodium bisulfite;

[0074] Preparation steps:

[0075] a. Dissolve monomer C, monomer D, monomer E, and monomer B in an equimolar amount to monomer D in deionized water, stir evenly, and obtain a small monomer solution for use;

[0076] B, the chain transfer agent is dissolved in deionized water, stirred evenly, and the chain transfer agent solution is obtained for use; the consumption of the chain transfer agent is 0.4% by weight of the total monomer weight of the reaction;

[0077] c. Put the monomer A and deionized water into the reaction container and heat to dissolve. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com