Manufacturing method of printed circuit board (PCB) coil and PCB coil

A PCB circuit board and coil technology, applied in the direction of multi-layer circuit manufacturing, containing printed electrical components, etc., can solve the problems of signal interference, uneven winding and uniform distribution of multi-layer coils, and achieve excellent electromagnetic performance and guaranteed parameters The effect of consistency and small parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

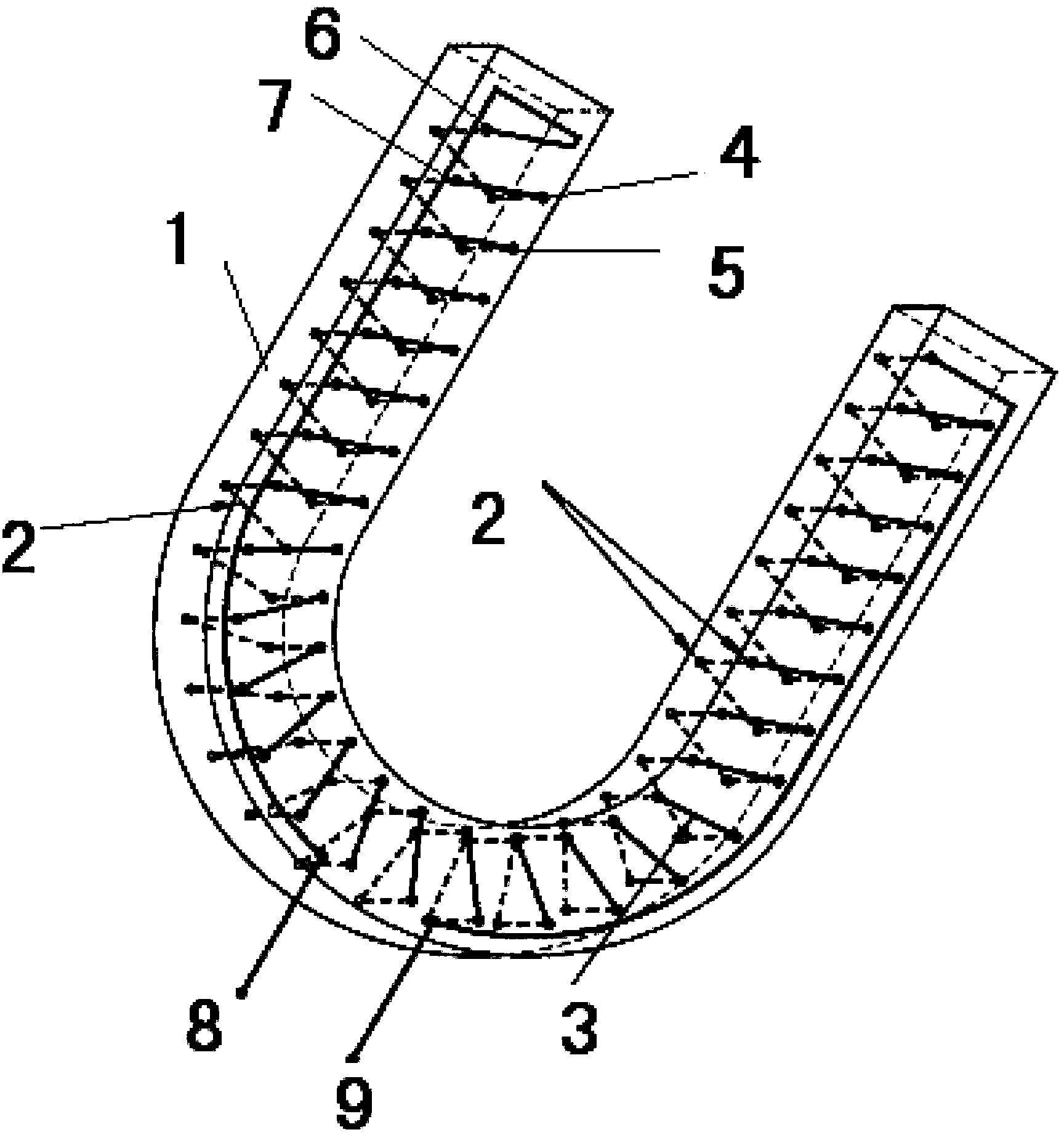

[0032] Embodiment 1: see figure 1 , the present embodiment provides a kind of preparation method of U-shaped PCB coil, and it comprises the following steps:

[0033] (1) Use the electronic design automation EDA software to design the wiring of the PCB coil;

[0034] (2) A single-layer U-shaped double-sided PCB circuit board 1 is set;

[0035] (3) On the U-shaped PCB circuit board 1 described in step (2), a plurality of via holes 2 are arranged, and the inner and outer sides of the via holes 2 are arranged in an orderly manner;

[0036] (4) according to the wiring design of step (1), at the upper surface and the lower surface of U-shaped PCB circuit board 1 described in step (2), carry out etching wiring respectively;

[0037] (5) Fill conductive material in the via hole 2 described in step (3), and the via hole electrically connects the double-sided PCB circuit board through electroplating copper plating, so that the upper and lower copper wires 3 are electrically connected;...

Embodiment 2

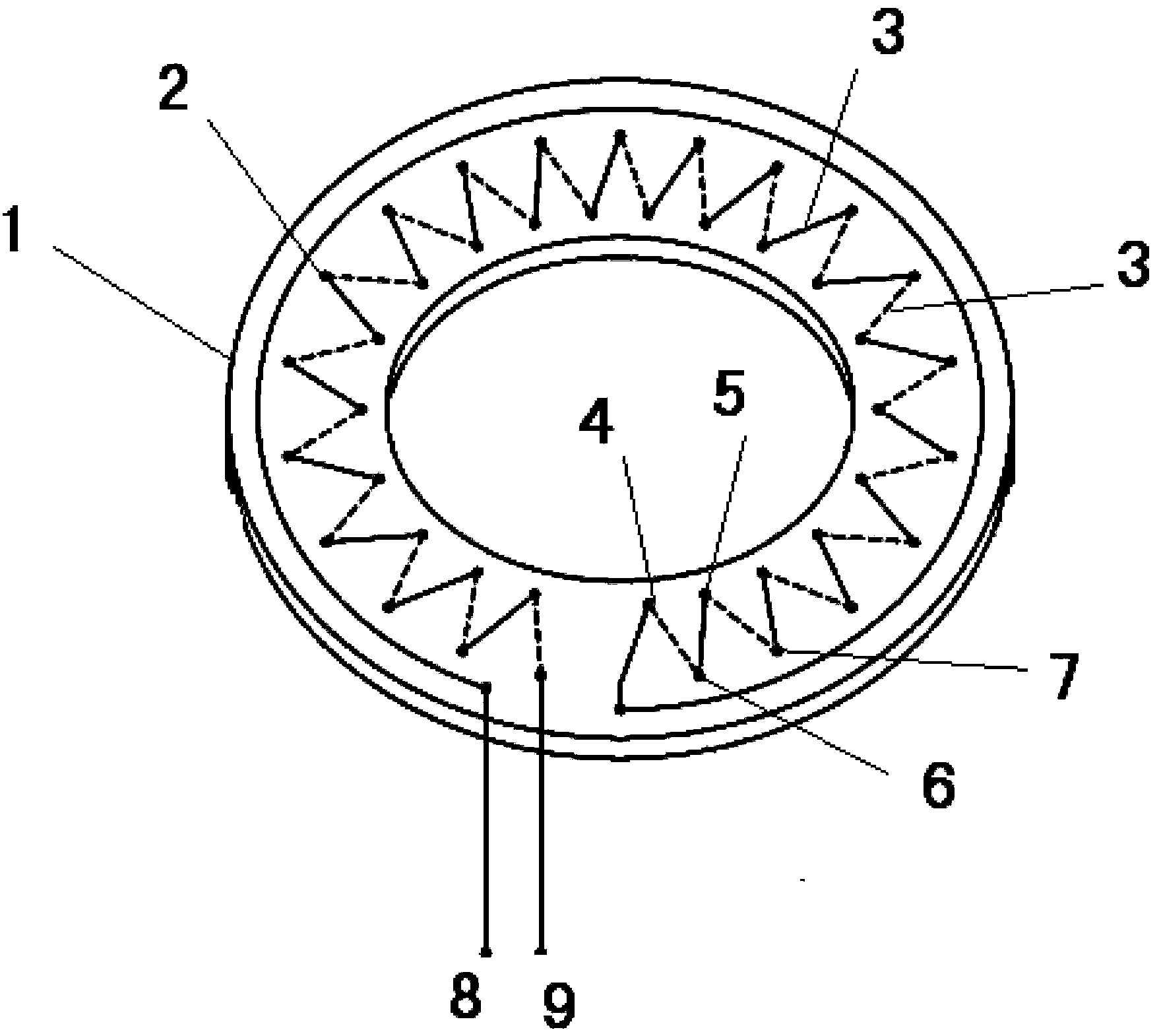

[0049] Example 2: see figure 2 , the preparation method of the ring-type PCB coil and the ring-type PCB coil provided in this embodiment, its steps and composition are basically the same as in Example 1, the difference is that:

[0050] A kind of preparation method of annular PCB coil, it comprises the following steps:

[0051](1) Use the electronic design automation EDA software to design the wiring of the PCB coil;

[0052] (2) A single-layer annular double-sided PCB circuit board 1 is set;

[0053] (3) On the annular PCB circuit board 1 described in step (2), a plurality of via holes 2 are set, and the inner and outer sides of the via holes 2 are arranged in an orderly manner;

[0054] (4) according to the wiring design of step (1), on the upper surface and the lower surface of the annular PCB circuit board 1 described in step (2), carry out etching wiring respectively;

[0055] (5) Fill conductive material in the via hole 2 described in step (3), and the via hole elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com