Multi-channel and multi-aperture dispensing device

A dispensing device and multi-aperture technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of affecting the production process, insufficient precision of gas extrusion, and the impact of discharge and feeding speed on dispensing speed, etc. , to achieve the effect of improving accuracy, reducing manual intervention and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

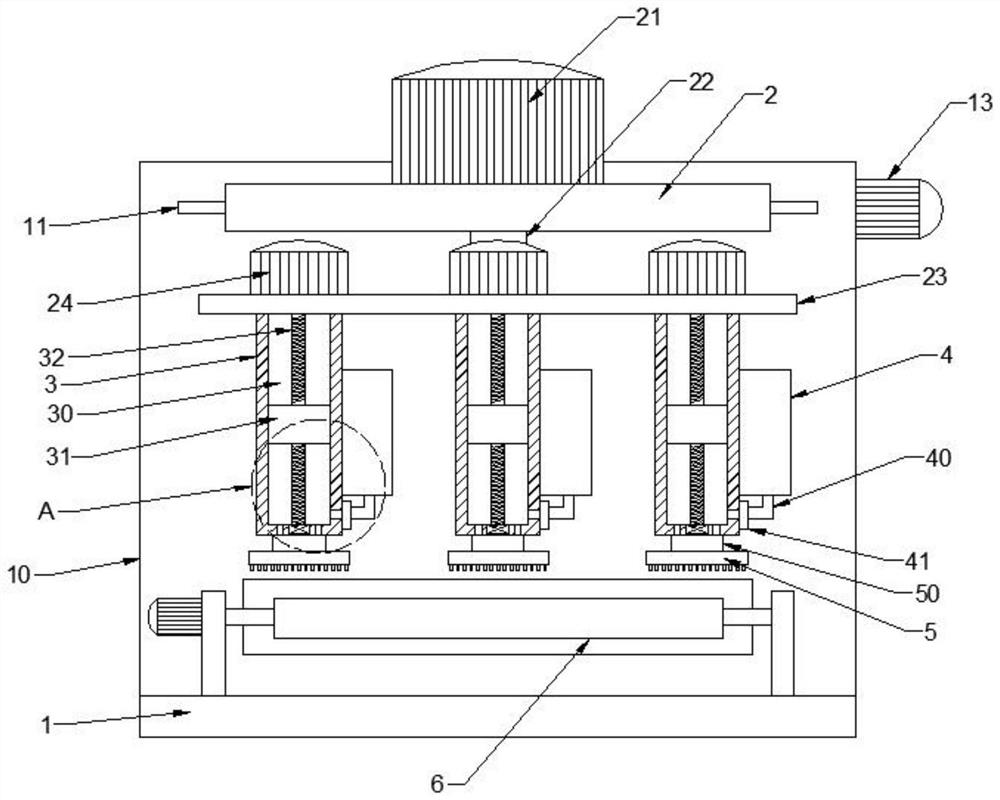

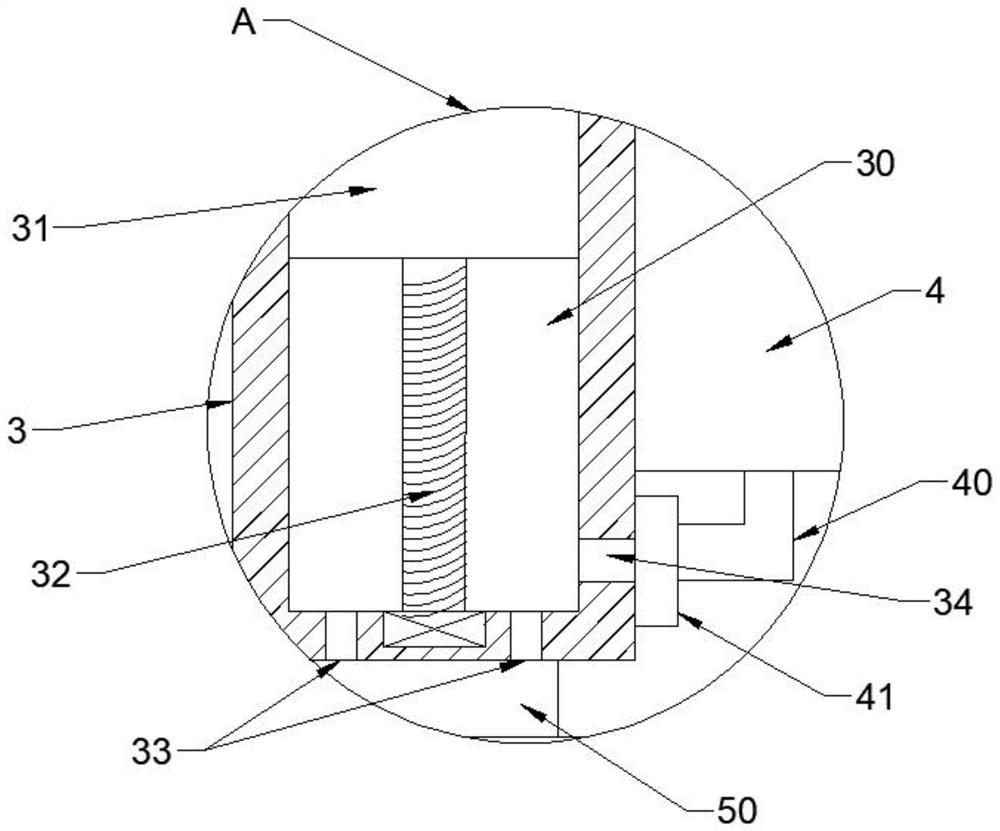

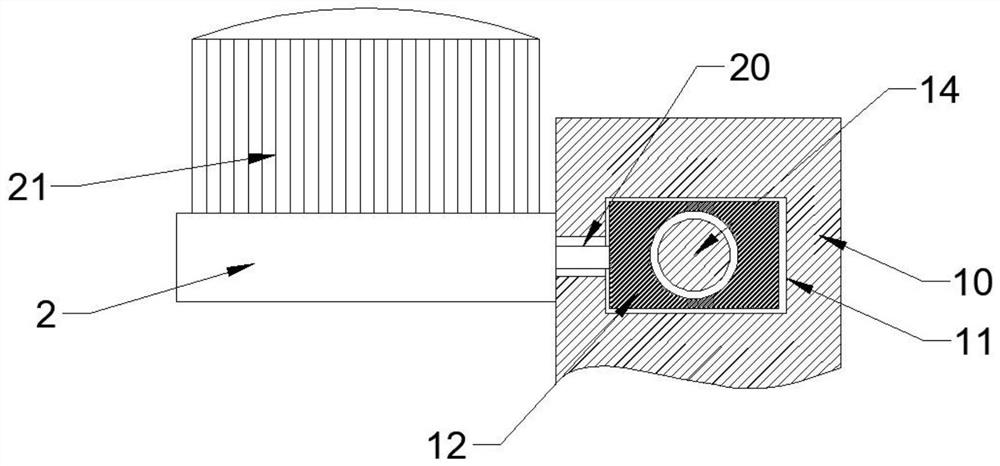

[0023] see Figure 1~3 , in an embodiment of the present invention, a multi-channel multi-aperture dispensing device includes a base 1, and a transmission device 6 for delivering dispensing objects is installed on the top surface of the base 1, and the transmission device 6 The top is provided with a plurality of dispensing heads 5 for dispensing glue on the conveying device 6, and the dispensing heads 5 are provided with dispensing needles with various apertures, and the dispensing heads 5 are integrally installed on the supply The bottom of the material box 3, the side wall of the material supply box 3 is equipped with a material storage box 4 for storing the rubber material, and the material supply box 3 is provided with a rubber material in the material storage box 4 that is extracted and fed to the dispensing head 5. The delivery screw mechanism for feeding at the center, the connection between the material storage box 4 and the dispensing head 5 and the supply box 3 are ...

Embodiment 2

[0031] The difference between this embodiment and embodiment 1 is:

[0032] The feed valve 41 and the discharge valve 50 are solenoid valves, and the solenoid valve cooperates with an external controller to realize the automatic opening and closing of the feed valve 41 and the discharge valve 50 in an automatic electric form so as to cooperate with the push block 31 to move up and down Complete feeding and discharging actions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com