A kind of preparation method of pcb coil pliers and pcb coil pliers

A PCB circuit board and coil technology, which is applied in the direction of assembling printed circuits containing printed electrical components and electrical components, can solve the problem of difficulty in ensuring the uniformity of winding, the number of coil turns impossible to ensure, and uneven winding of multi-layer coils and other problems, to achieve the effect of ensuring parameter consistency, excellent electromagnetic performance, and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

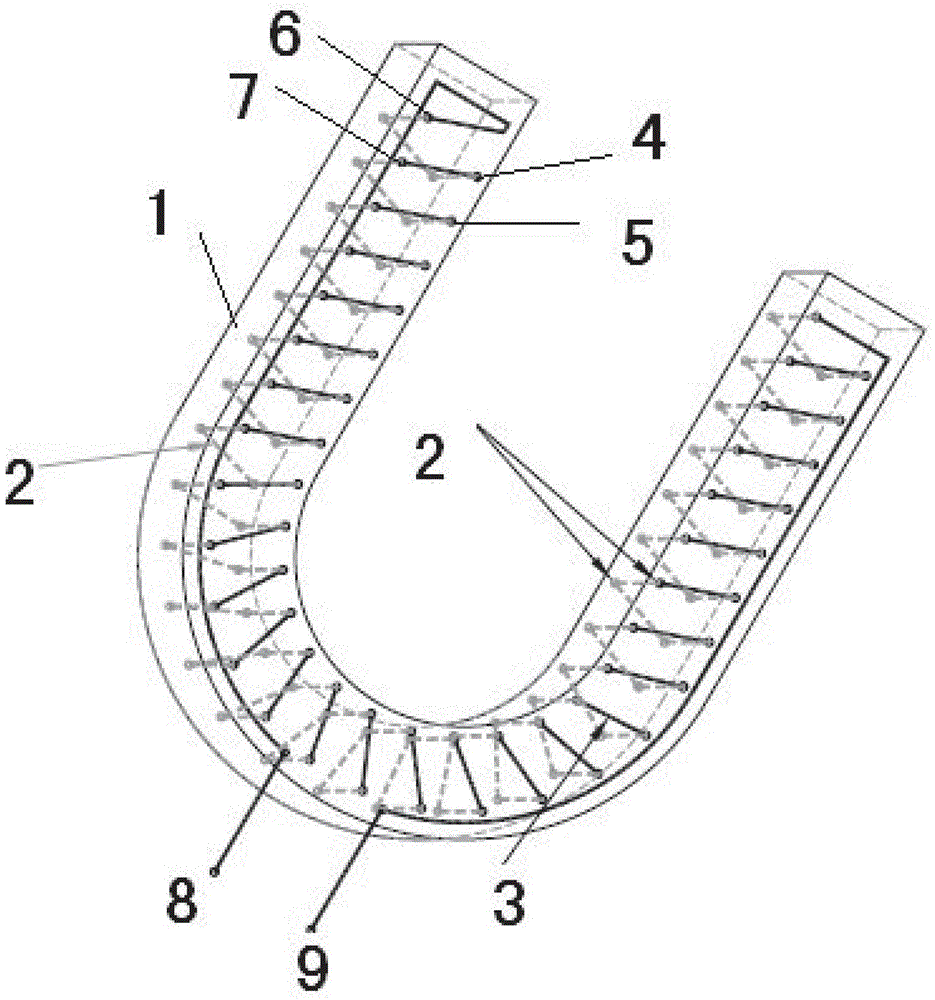

[0037] Embodiment 1: see Figure 1 to Figure 4 , the preparation method of the U-shaped PCB coil pliers head provided by the present embodiment, it comprises the following steps:

[0038] (1) Set a plurality of PCB coil basic clamp head pairs 10;

[0039] (2) The PCB coil basic clamp head described in step (1) is superimposed on 10 phases and fixed;

[0040] (3) The PCB coil basic pliers pairs 10 superimposed in step (2) are electrically connected to each other through the terminals of the PCB coil 11 , and connected in series to obtain the PCB coil pliers.

[0041] Described step (1) also comprises the following steps:

[0042] (11) Two PCB coils 11 are set, and the PCB coil 11 is a closed-loop coil that goes around clockwise, and a closed-loop coil that goes around counterclockwise;

[0043](12) The two PCB coils 11 described in step (11) are superimposed, wherein the PCB coil 11 that goes around in the clockwise direction is above the PCB coil 11 that goes around in the ...

Embodiment 2

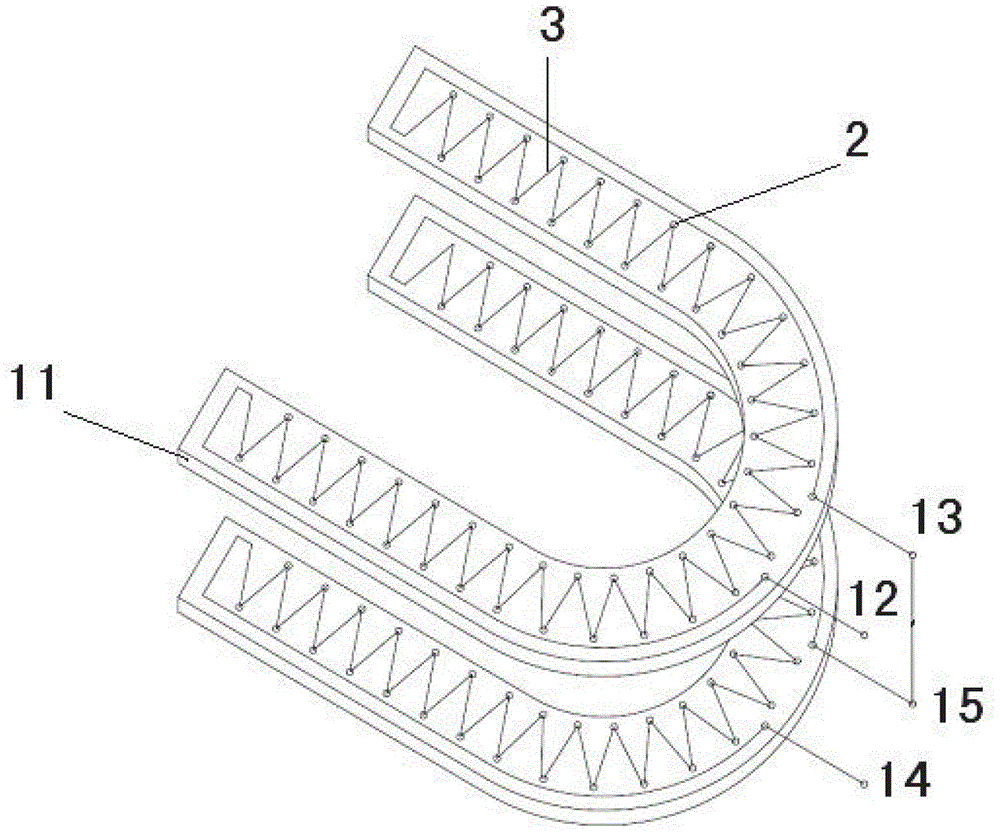

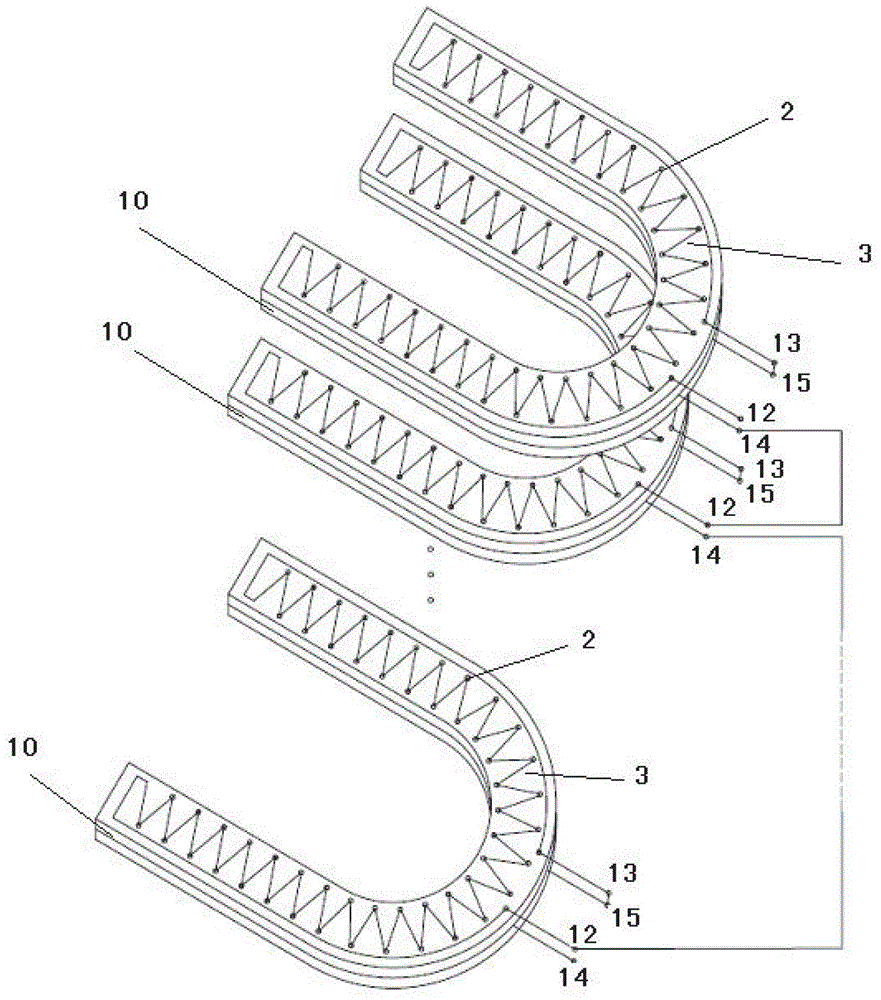

[0053] Example 2: see Figure 5 to Figure 6 , the preparation method of the fixed PCB coil pliers provided in this embodiment and the fixed PCB pliers, its steps and structure are basically the same as in Example 1, the difference is:

[0054] A preparation method of a fixed PCB coil clamp head, which comprises the following steps:

[0055] (1) Set multiple basic clamp pairs of PCB coils;

[0056] (2) Superimpose and fix the basic clamp heads of the PCB coil described in step (1);

[0057] (3) The PCB coil basic pliers pairs superimposed in step (2) are electrically connected to each other through the terminals of the PCB coil 11 , and connected in series to obtain the PCB coil pliers.

[0058] Described step (1) also comprises the following steps:

[0059] (11) Two PCB coils 11 are set, and one of the PCB coils is a closed-loop coil that goes around in a clockwise direction, and one is a closed-loop coil that goes around in a counterclockwise direction;

[0060] (12) The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com