High-yield-strength non-oriented electrical steel plate and manufacturing method thereof

A technology of grain-oriented electrical steel sheet and manufacturing method, which is applied to manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of increasing manufacturing cost, unstable improvement effect, cold brittle strip steel, etc., and achieves excellent yield strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with embodiment.

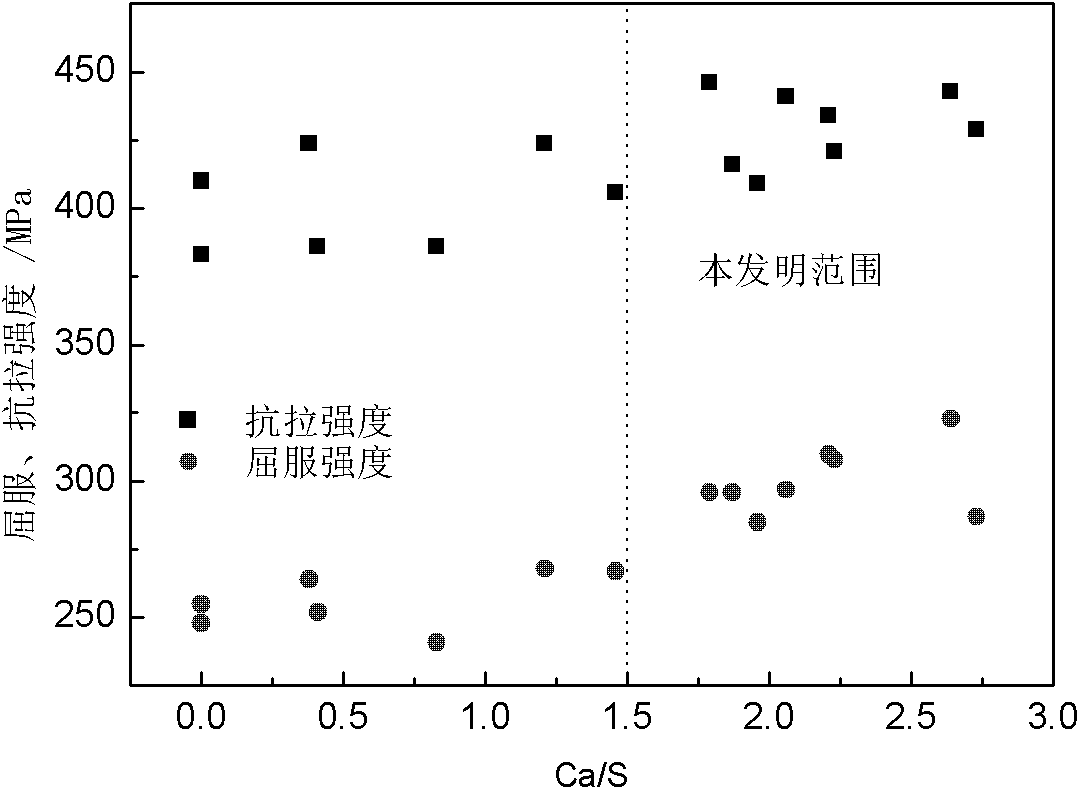

[0048] Molten iron and steel scrap are matched in proportion, smelted in a 300-ton converter, vacuum RH decarburized, deoxidized, and alloyed, followed by calcium treatment, followed by degassing and continuous steel casting, to obtain cast steel with a thickness of 170mm-250mm and a width of 800mm-1400mm. Billet; the slab is heated at 1100~1200℃×2h, after rough rolling for 1-3 passes, it is hot-rolled into a hot-rolled plate with a thickness of 2.0mm~2.8mm, and then pickled after being normalized at 850~1000℃ , Cold-rolled into 0.5mm thick cold-rolled sheet, and finally after annealing at 750-1000°C, test the electromagnetic and mechanical properties of the finished steel coil. The test results are shown in Table 1 and Table 2.

[0049] Table 1 Unit: % by weight

[0050]

C

Si

mn

P

S

Al

N

Ca / S

Fe

Example 1

0.001

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com