Method for accurately controlling primary recrystallization size of oriented silicon steel

A technology of oriented silicon steel and recrystallization, which is applied in the direction of heat treatment process control, manufacturing tools, heat treatment equipment, etc., and can solve the problem that the control accuracy cannot meet the requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

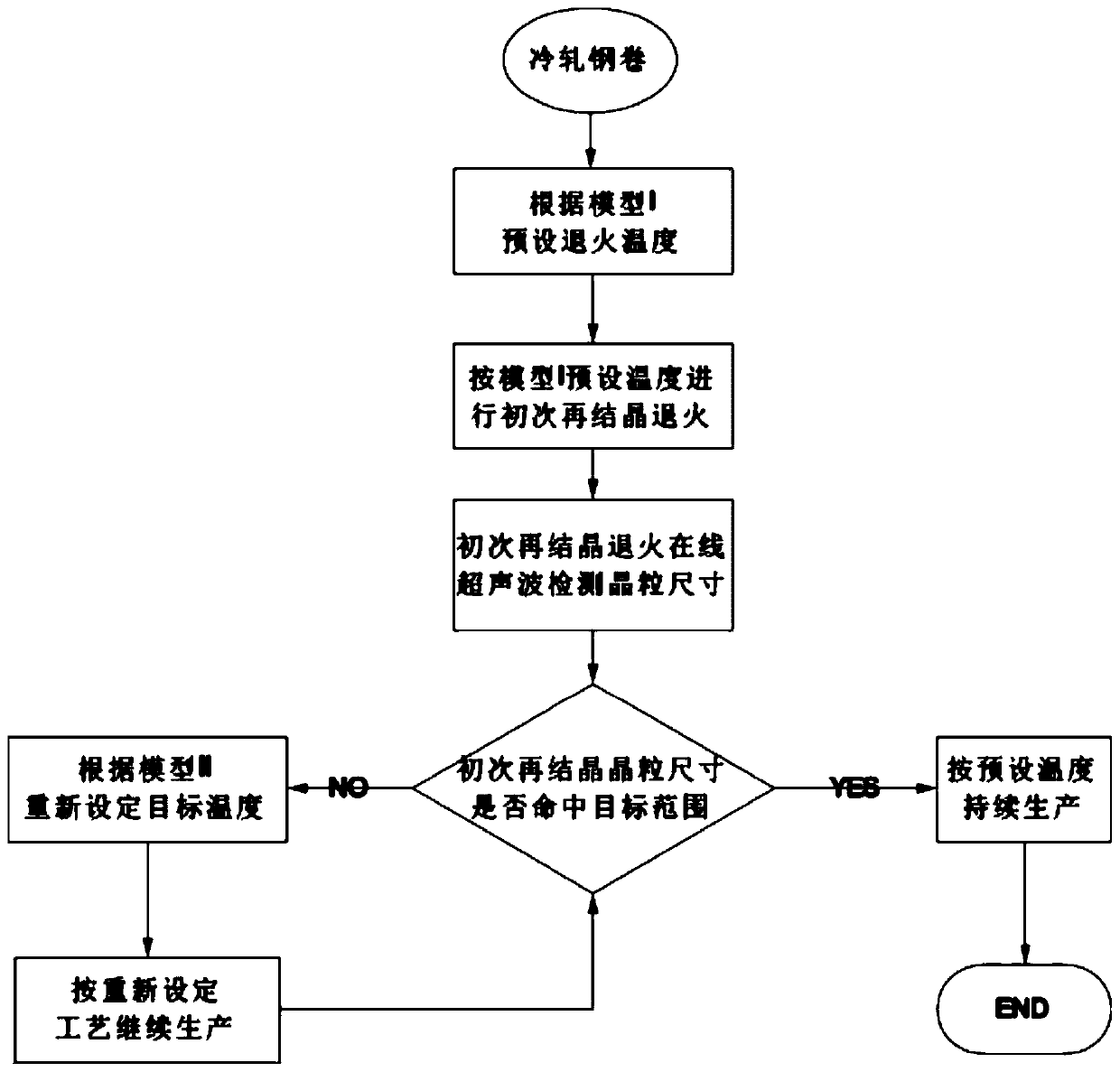

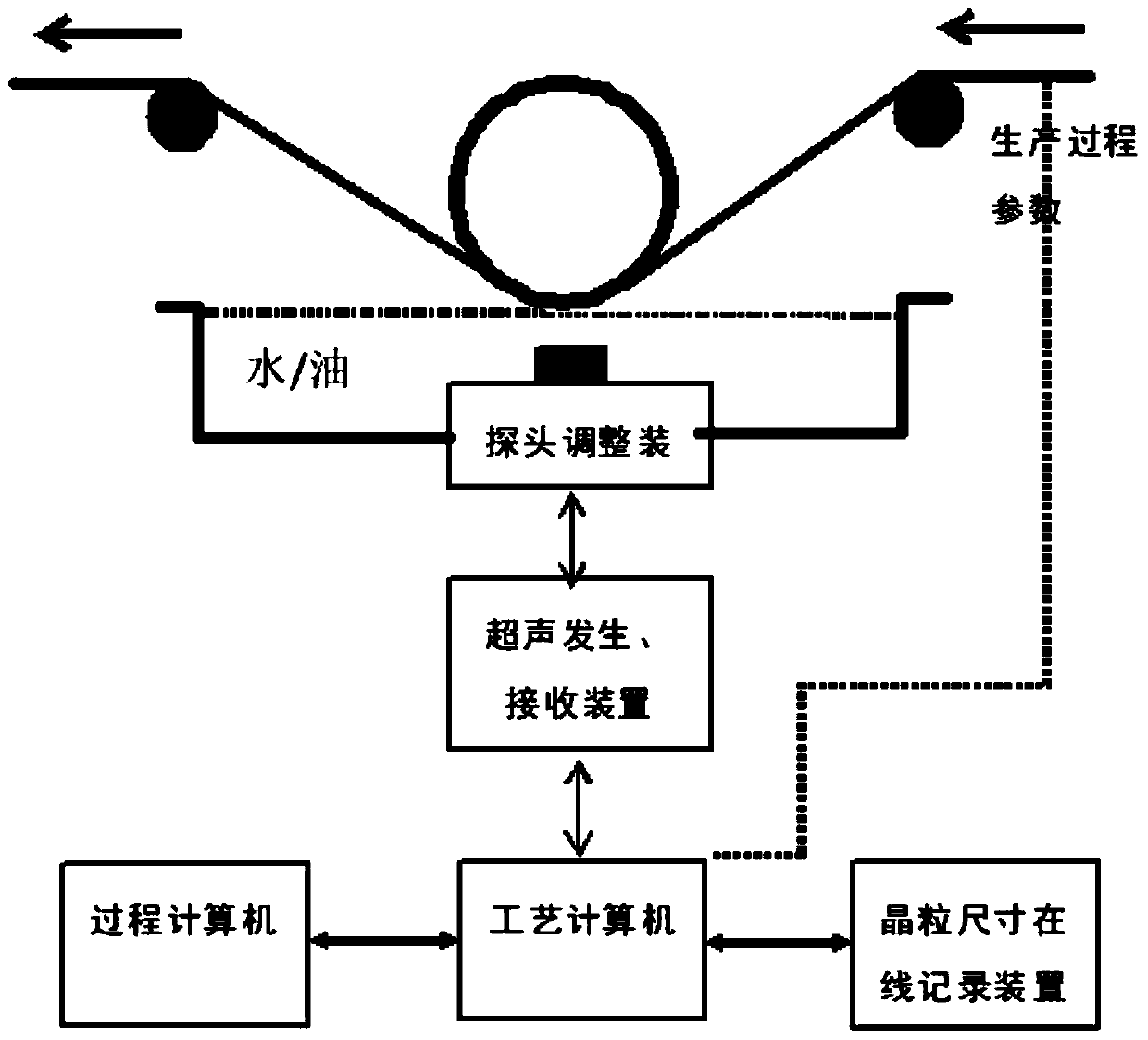

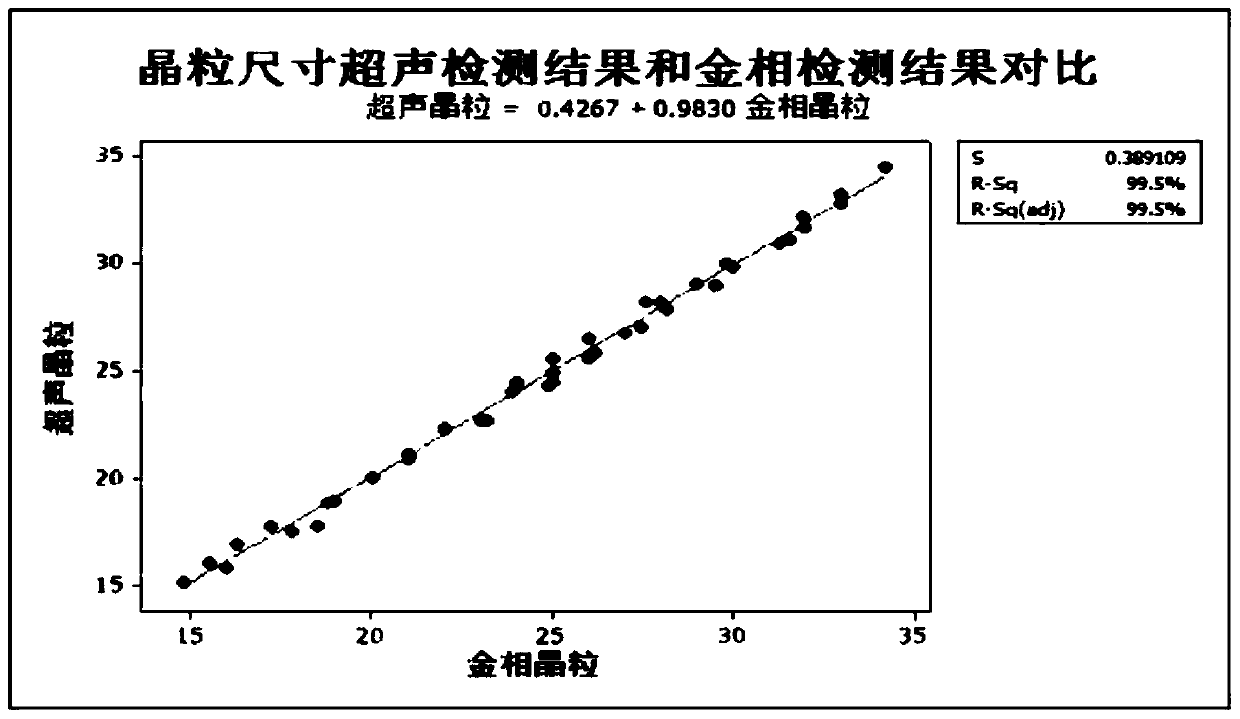

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0036] Combined process figure 1 , a method for accurately controlling the primary recrystallization size of grain-oriented silicon steel, comprising the following steps:

[0037] S1, select steel coils for processing oriented silicon steel, and cold-roll them;

[0038] S2. After the steel coil is cold-rolled, the initial recrystallization annealing temperature setting model I is established according to the relationship between the initial recrystallization annealing temperature setting and the target grain size of the oriented silicon steel, and the annealing temperature target setting value is calculated;

[0039] The primary recrystallization annealing temperature setting model I is

[0040]

[0041] b1, b2, b3, b4: constants, which need to be fitted to the differences of different steel types;

[0042] Primary rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com