Angle-folded type clamp for three-dimensional iron cores

An iron core clip, triangular technology, applied in electrical components, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problems of not being able to play a supporting and protective role, affecting the performance of the iron core, and protecting the iron core. The ability to resist axial electrodynamic force, the effect of reducing no-load loss and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

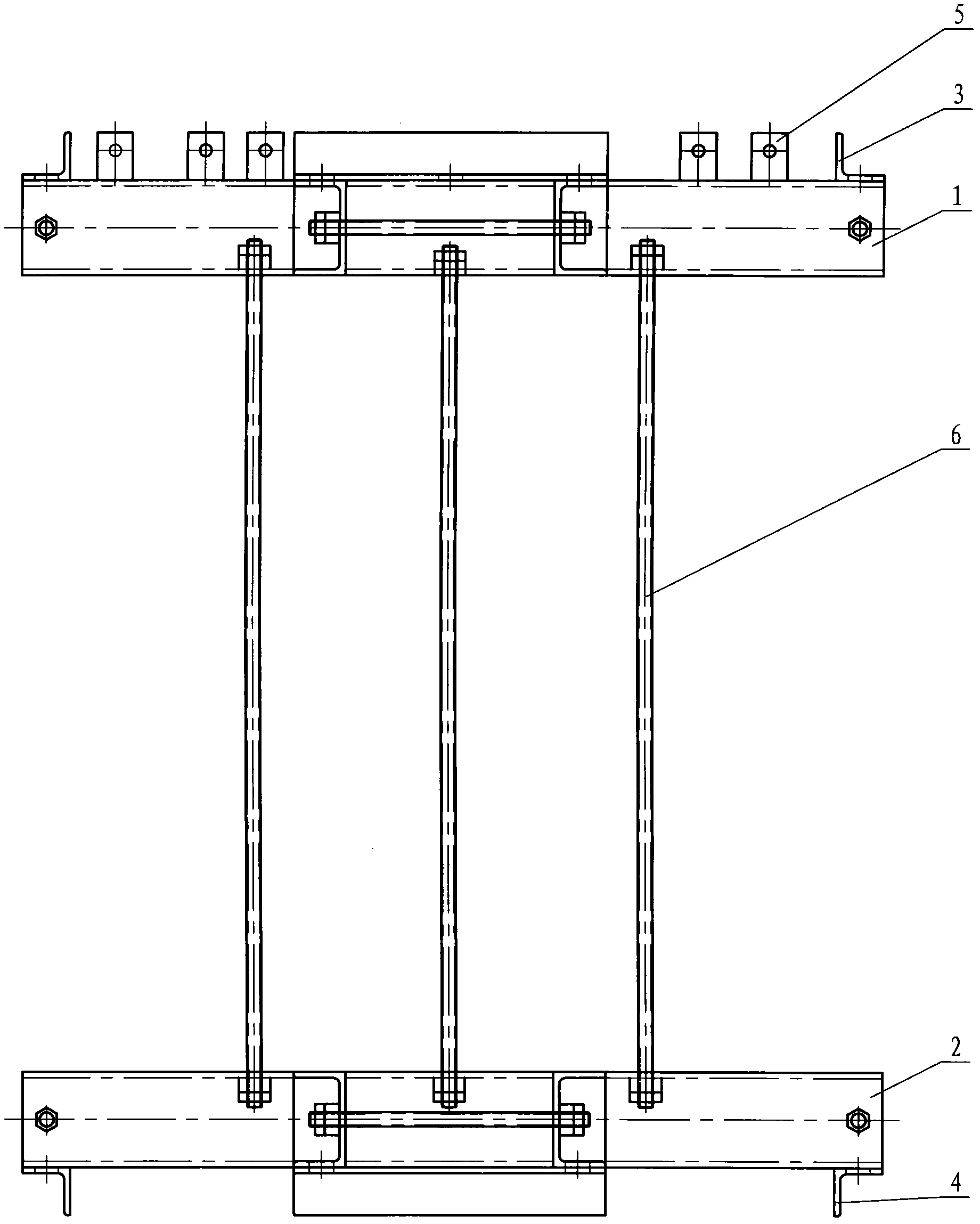

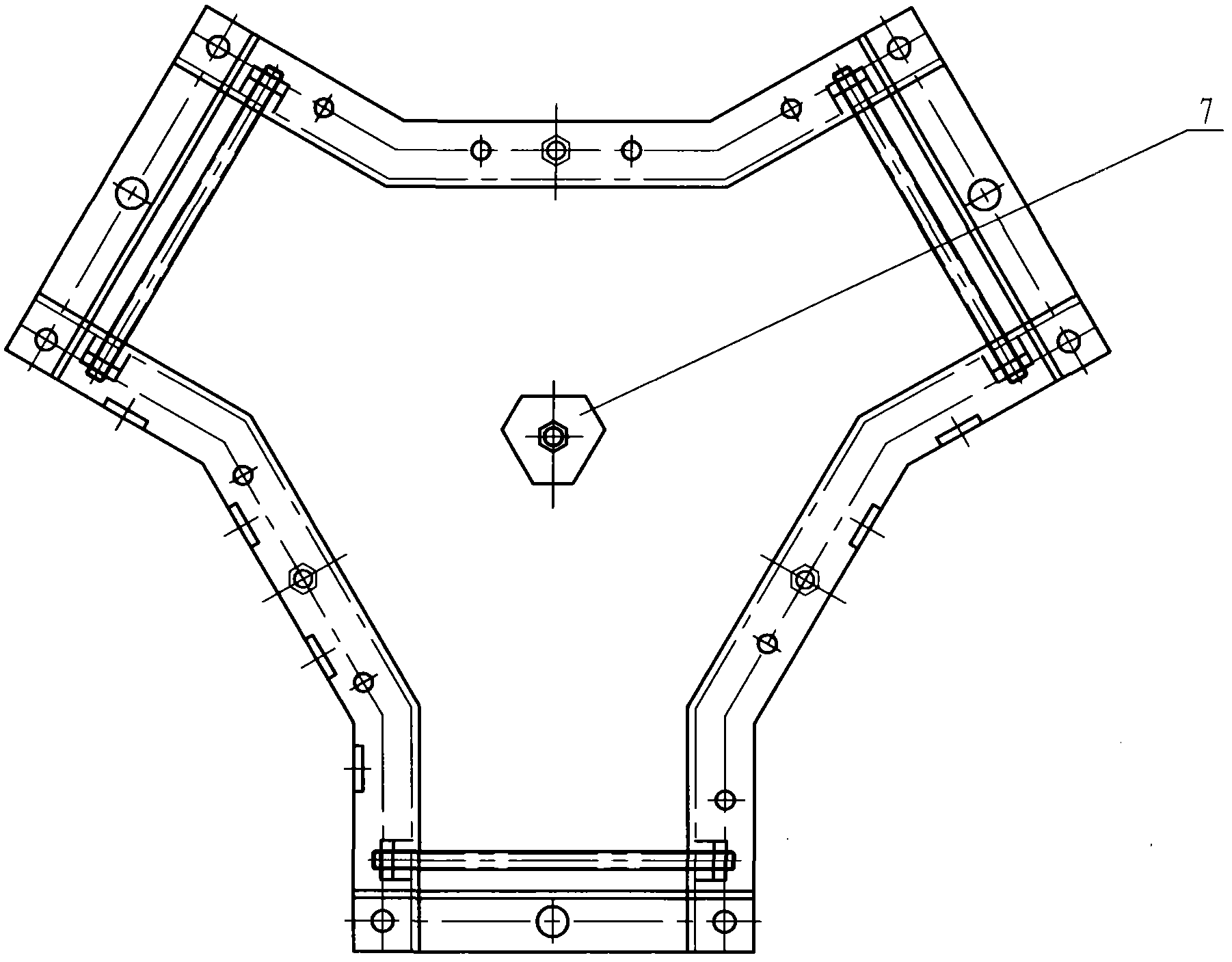

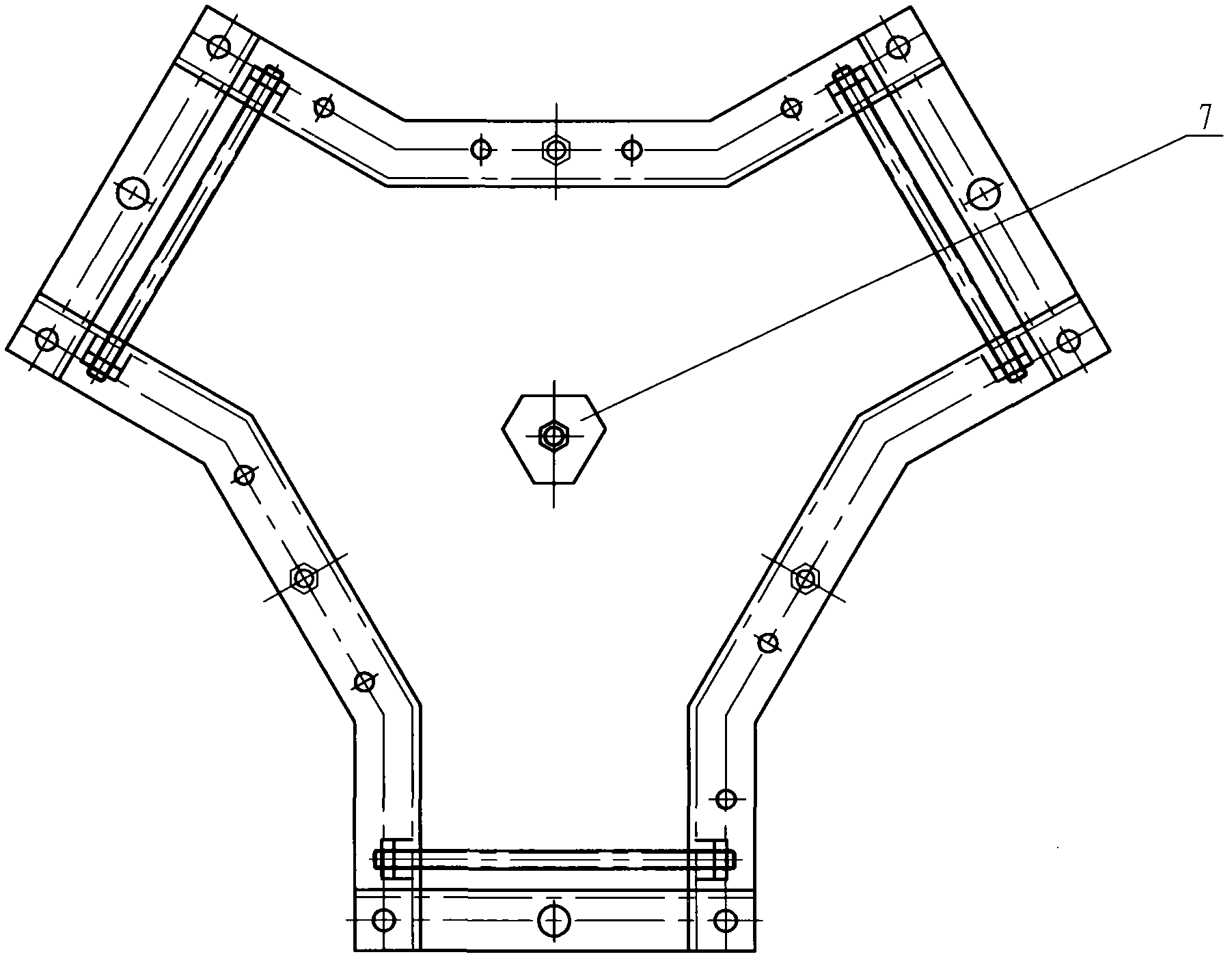

[0013] Such as figure 1 As shown, the angled three-dimensional triangular iron core clip of the present invention includes an upper clip 1 and a lower clip 2 . The upper and lower clamps are all processed by channel steel, and then fixedly connected together by triangle irons 3 and 4 to form a frame structure. The upper clamp 1 is provided with a support plate 5 for fixing the lead wires of the high and low voltage coils. There is a round hole in the middle of the triangle iron 3 connected to the upper clip 1, which is used for lifting the whole transformer. The upper clamping part 1 and the lower clamping part 2 are connected by at least four compression screws 6 , at least one compression screw 6 is connected in the middle of the upper clamping part 1 and the lower clamping part 2 . The inside of the upper clamping part 1 and the lower clamping part 2 are oppositely provided with approximately triangular pressing plates 7 whose sides are parallel to the clamping parts. Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com