Flexible graphene/barium ferrite composite fabric and preparation method thereof

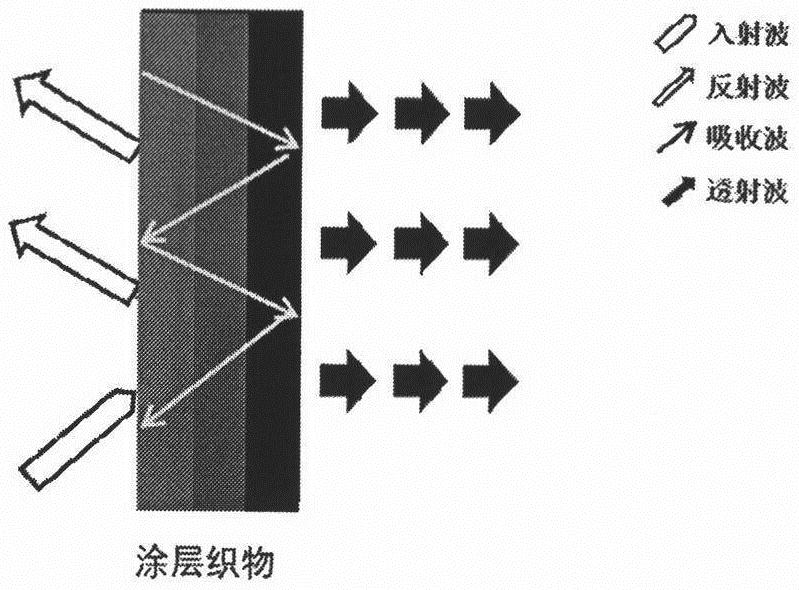

A barium ferrite and composite fabric technology, applied in textiles and papermaking, etc., can solve the problems of easy agglomeration and poor impedance matching of graphene, and achieve the effect of improving impedance matching, good electromagnetic performance, and good softness and comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

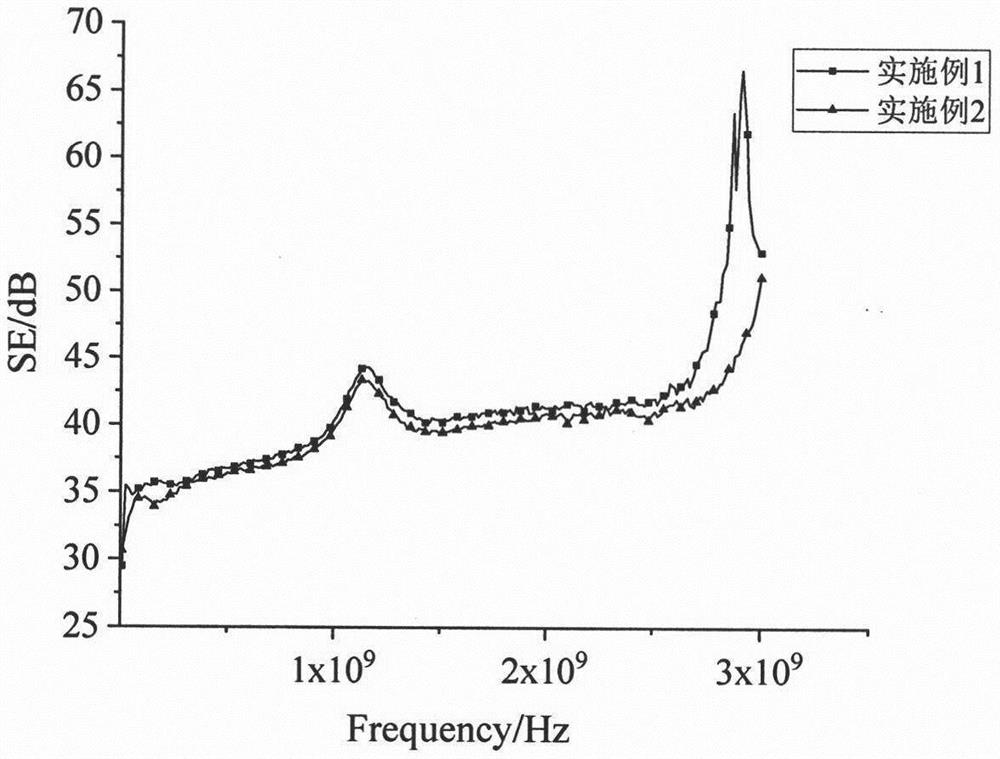

Embodiment 1

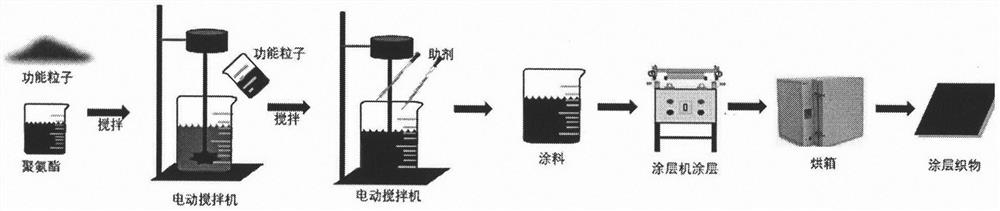

[0026] Flexible graphene / barium ferrite composite fabric and preparation method thereof, comprising the following steps:

[0027] Preparation of paint:

[0028] (1) Weigh 100g resin, 3g graphene and 30g barium ferrite powder.

[0029] (2) First, set the one-way series motor to stir the resin at 800rpm / min. During the stirring process, add graphene particles to the resin one by one. After adding the functional particles, increase the speed of the mixer to 2000rpm / min. Slowly drip Add appropriate amount of defoamer and thickener to make the paint mix evenly.

[0030] (3) Same as step 2, adding magnetic barium ferrite powder into resin to prepare barium ferrite coating.

[0031] Fabrication of flexible graphene / barium ferrite composite fabric:

[0032] (1) Choose 30×40cm fabric as the base fabric, and fix it flat on the needle board frame.

[0033] (2) First set the coating thickness to 0.4mm, first apply the graphene coating evenly on the surface of the fabric, place the sin...

Embodiment 2

[0036] Flexible graphene / barium ferrite composite fabric and preparation method thereof, comprising the following steps:

[0037] Preparation of paint:

[0038] (1) Weigh 100g resin, 3g graphene and 30g barium ferrite powder.

[0039] (2) First, set the one-way series motor to stir the resin at 800rpm / min. During the stirring process, add graphene particles to the resin one by one. After adding the functional particles, increase the speed of the mixer to 2000rpm / min. Slowly drip Add appropriate amount of defoamer and thickener to make the paint mix evenly.

[0040] (3) Same as step 2, adding magnetic barium ferrite powder into resin to prepare barium ferrite coating.

[0041] Fabrication of flexible graphene / barium ferrite composite fabric:

[0042] (1) Choose 30×40cm fabric as the base fabric, and fix it flat on the needle board frame.

[0043] (2) Firstly, set the coating thickness to 0.4 mm, firstly apply the barium ferrite coating evenly on the surface of the fabric, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com