Method and equipment for water washing of clothes

A technology for clothing and washing water, applied in the field of clothing production, can solve the problems of wasted labor, large production costs, long working hours, etc., and achieve the effects of saving labor costs, saving water consumption, and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

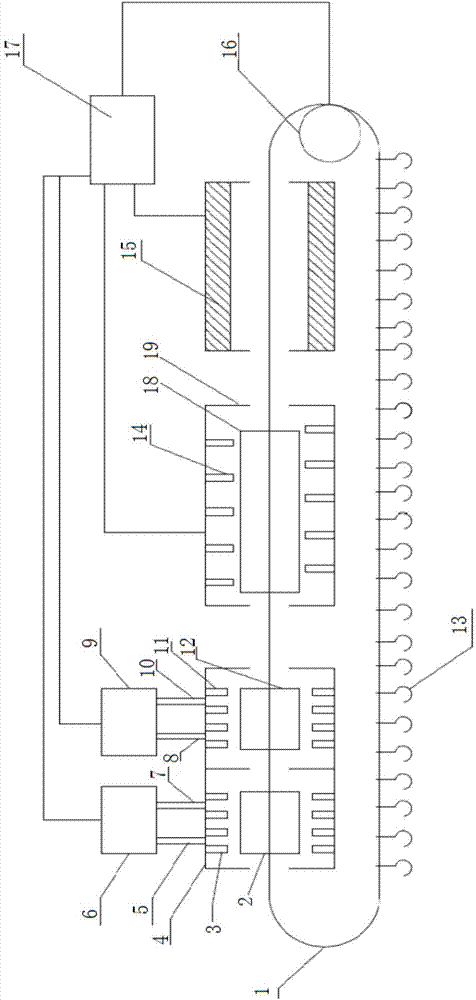

[0049] This embodiment provides a kind of clothes washing equipment, its structure is as figure 1 shown.

[0050] The clothes washing equipment provided by the present invention includes a vertical spray washing system, a vertical negative pressure dehydration system, a drying system, a transmission system and a control system 17;

[0051] The vertical spray washing system includes a spray chamber 4, a pre-spray nozzle 3 and a spray nozzle 11, the number of the pre-spray nozzle 3 is 40, and the quantity of the spray nozzle 11 is 20; the spray chamber 4 adopts The barrier device is divided into two studios, which are respectively the pre-spray studio and the spray studio. The entrance of the material working chamber is the opening of the barrier device; two rows of pre-spraying nozzles 3 opposite to each other are respectively arranged on the two side walls of the pre-spraying working chamber, and the pre-spraying nozzles 3 on each side wall They are all aligned up and down; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com