Preparation of surface load magnetic alloy particle carbon nano-tube composite material

A carbon nanotube and magnetic alloy technology, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problem of no nano-alloy particles, and achieve simple preparation methods, excellent magnetic properties, and complete alloy crystals. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

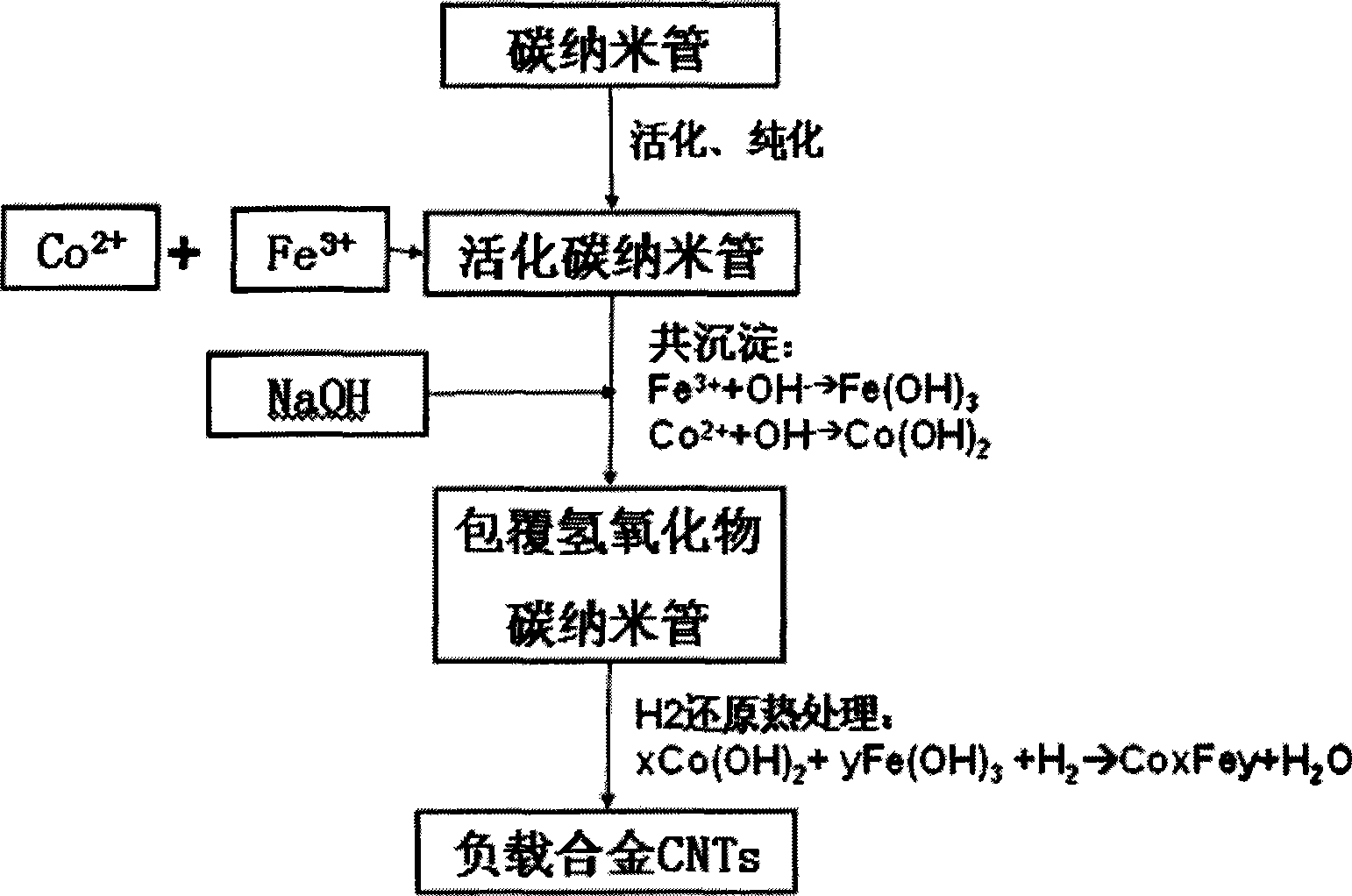

Method used

Image

Examples

Embodiment 1

[0025] Take 0.36 g of multi-walled carbon nanotubes for pretreatment. The treatment process is: (a) ultrasonically disperse the carbon nanotubes into concentrated sulfuric acid (60%wt) and concentrated nitric acid (67%wt) (volume ratio 1:1) (b) reflux heating the mixed solution for 2 to 4 hours; (c) stop heating, dilute the solution to take out the carbon nanotubes, rinse with deionized water until neutral, and dry for later use;

[0026] The pretreated carbon nanotubes were placed in 1500 ml of deionized water, and dispersed evenly by ultrasonic. Take by weighing 3.569 grams of analytically pure cobalt chloride hexahydrate (CoCl 2 ·6H 2 O), 4.054 grams of ferric chloride hexahydrate (FeCl 3 ·6H 2 O), dissolved in the carbon nanotube solution that has been configured. In addition, 4 grams of sodium hydroxide was dissolved in 1 liter of deionized water to make an alkaline solution, which was slowly added dropwise to the above-mentioned carbon nanotube mixed solution, and at...

Embodiment 2

[0030] Take 0.72 g of multi-walled carbon nanotubes for pretreatment. The treatment process is: (a) ultrasonically disperse the carbon nanotubes into concentrated sulfuric acid (60%wt) and concentrated nitric acid (67%wt) (volume ratio 1:1) (b) reflux heating the mixed solution for 2 to 4 hours; (c) stop heating, dilute the solution to take out the carbon nanotubes, rinse with deionized water until neutral, and dry for later use;

[0031] The pretreated carbon nanotubes were placed in 1000 ml of deionized water, and dispersed uniformly by ultrasonic. Weigh 2.379 grams of analytically pure cobalt chloride hexahydrate (CoCl 2 ·6H 2 O), 2.703 grams of ferric chloride hexahydrate (FeCl 3 ·6H 2 O), dissolved in the carbon nanotube solution that has been configured. In addition, 4 grams of sodium hydroxide was dissolved in 1 liter of deionized water to form an alkaline solution, which was added dropwise to the above mixed solution with a peristaltic pump at a rate of 2ml / min, whil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com