Flexible stretchable electromagnetic shielding fabric and preparation method thereof

An electromagnetic shielding and elastic fabric technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of poor bonding force between metal and fabric, serious pollution in the preparation process, poor product shielding performance, etc., and achieve stable electromagnetic shielding performance and wide application. Foreground, the effect of absorbing frequency bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

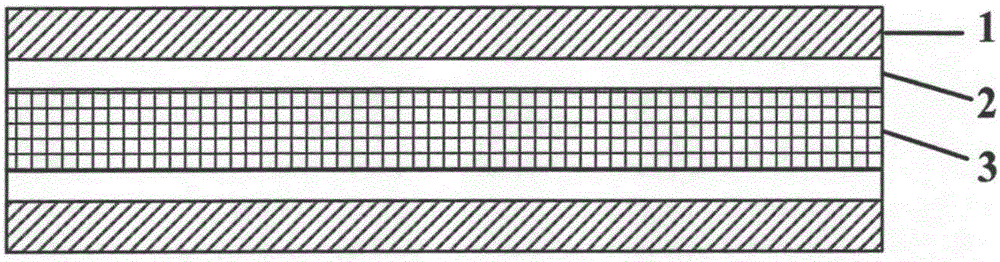

[0031] Example 1: Ultrathin Elastic and Stretchable Electromagnetic Shielding Fabric

[0032] A method for preparing a flexible and stretchable electromagnetic shielding fabric, the specific steps are:

[0033] The first step: immerse the carbon nanotube film in the graphene suspension for 3 hours, take it out, and dry it naturally at room temperature to obtain a flexible nano-electromagnetic shielding composite film 3, and pass conductive silver at both ends of the flexible nano-electromagnetic shielding composite film 3 Adhesive copper wire electrodes.

[0034] The carbon nanotube film is 60×40cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), made of multi-walled carbon nanotubes, the diameter of carbon nanotubes is 20nm, the film thickness is 20μm, the porosity is 75%, and the tensile strength is about 200MPa , the conductivity is about 1×10 5 S / m. The concentration of the graphene suspension is 2mg / ml (New ...

Embodiment 2

[0042] Example 2: Polyester electromagnetic shielding fabric

[0043] A method for preparing a flexible and stretchable electromagnetic shielding fabric, the specific steps are:

[0044] The first step: immerse the carbon nanotube film in the graphene suspension for 3 hours, take it out, and dry it naturally at room temperature to obtain a flexible nano-electromagnetic shielding composite film 3, and pass conductive silver at both ends of the flexible nano-electromagnetic shielding composite film 3 Adhesive copper wire electrodes.

[0045] The carbon nanotube film is 60×40cm 2The carbon nanotube film (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), made of multi-walled carbon nanotubes, the diameter of carbon nanotubes is 20nm, the film thickness is 20μm, the porosity is 75%, and the tensile strength is about 200MPa , the conductivity is about 1×10 5 S / m. The concentration of the graphene suspension is 2mg / ml (New Material Co., Ltd.), impr...

Embodiment 3

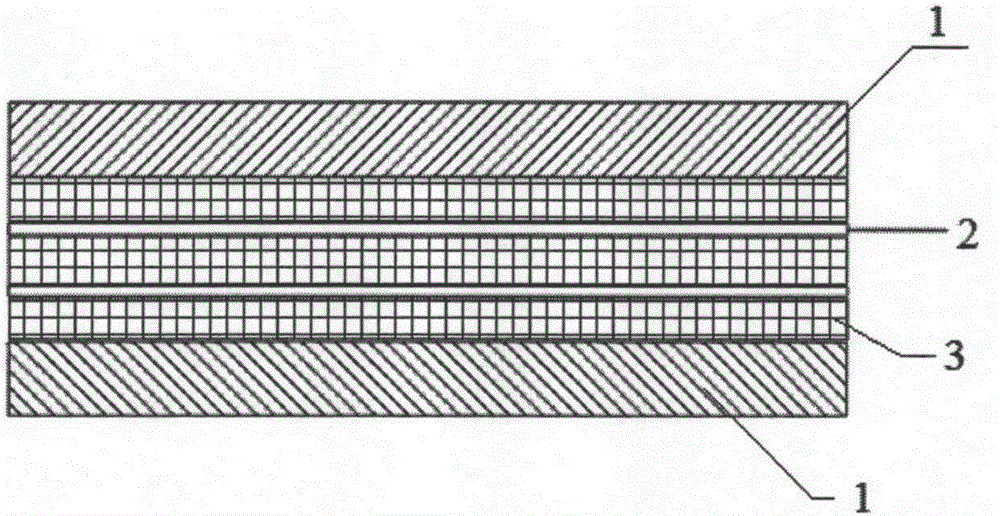

[0053] Embodiment 3: wear-resistant elastic electromagnetic shielding fabric with ultra-high shielding effectiveness

[0054] A method for preparing a flexible and stretchable electromagnetic shielding fabric, the specific steps are:

[0055] The first step: immerse three carbon nanotube films in the graphene suspension for 3 hours, take them out, and dry them naturally at room temperature to obtain three layers of flexible nano-electromagnetic shielding composite films 3, of which two layers of flexible nano-electromagnetic shielding composite films One end of 3 is attached to a copper wire electrode by coating conductive silver glue.

[0056] The carbon nanotube film is 60×40cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nanobionics, Chinese Academy of Sciences), made of multi-walled carbon nanotubes, the diameter of carbon nanotubes is 20nm, the film thickness is 20μm, the porosity is 75%, and the tensile strength is about 200MPa , the conductivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com