Patents

Literature

31results about How to "Good added value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

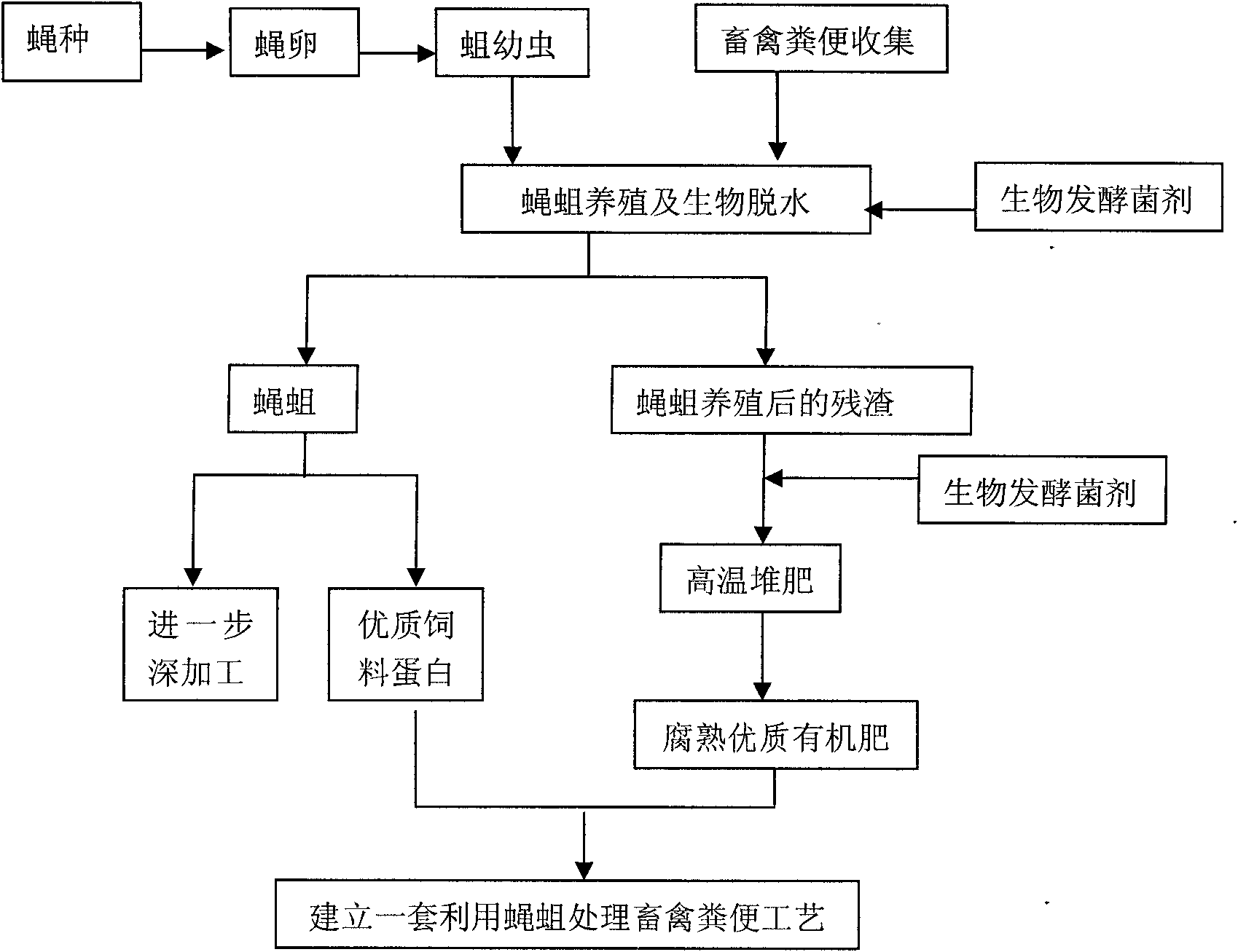

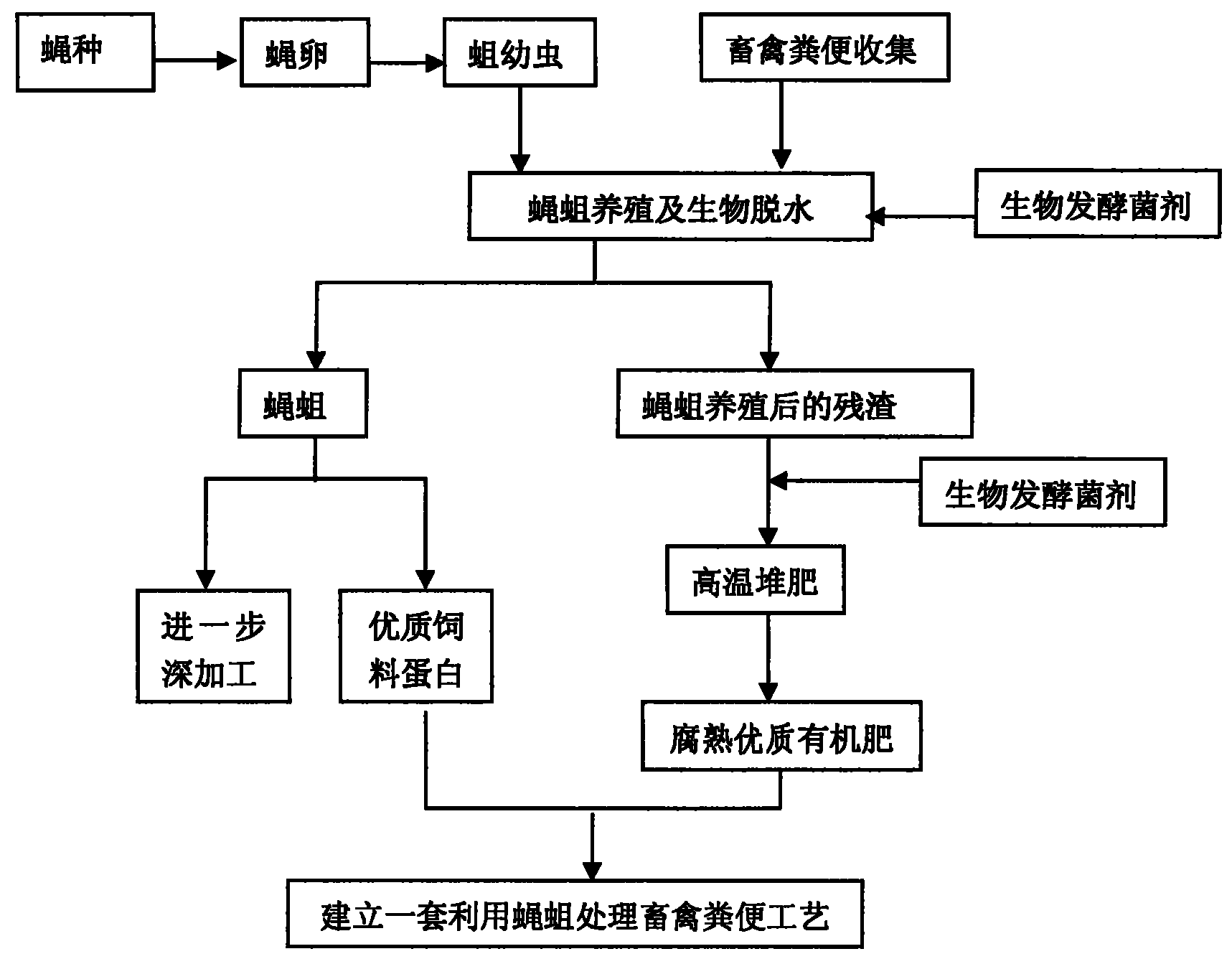

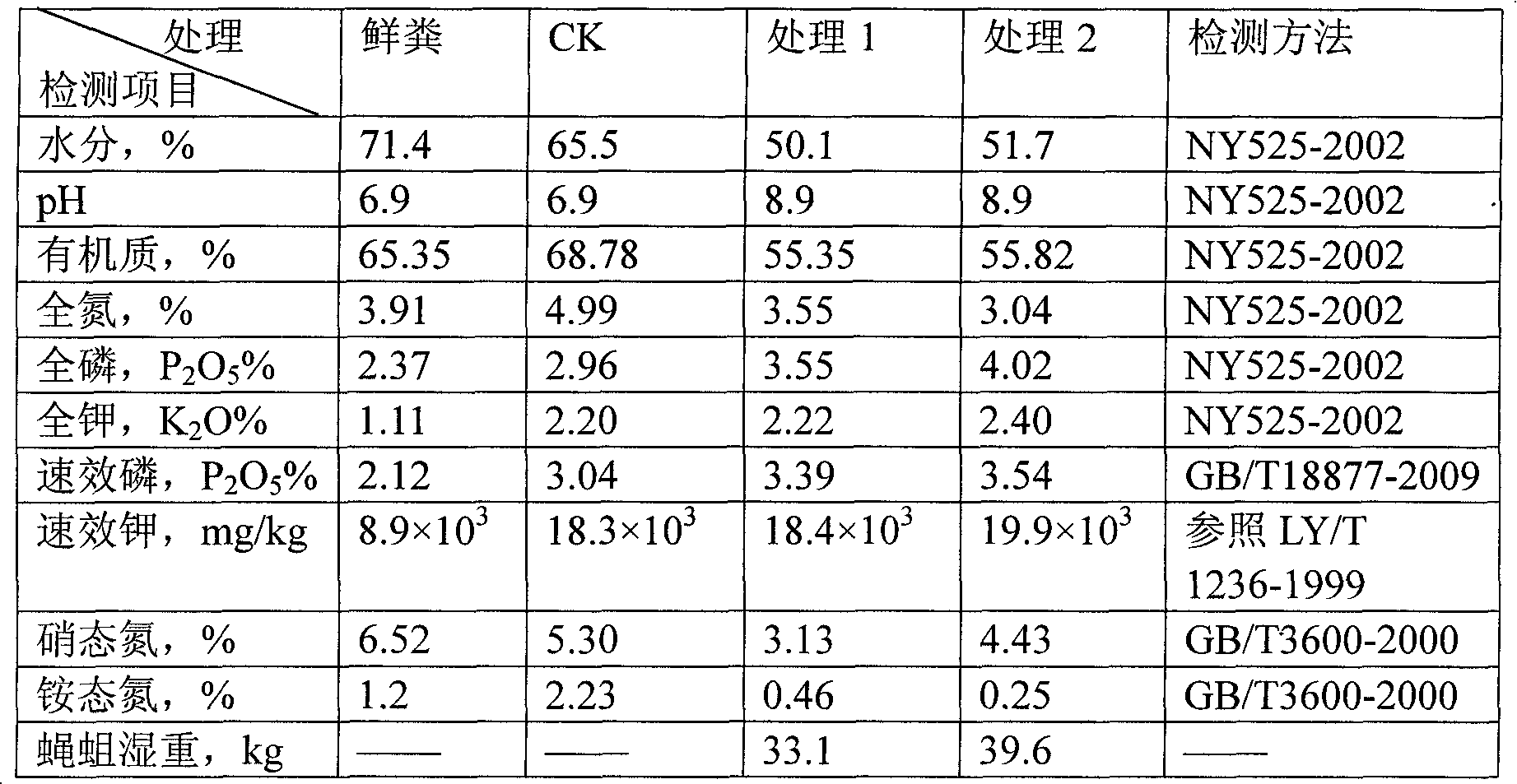

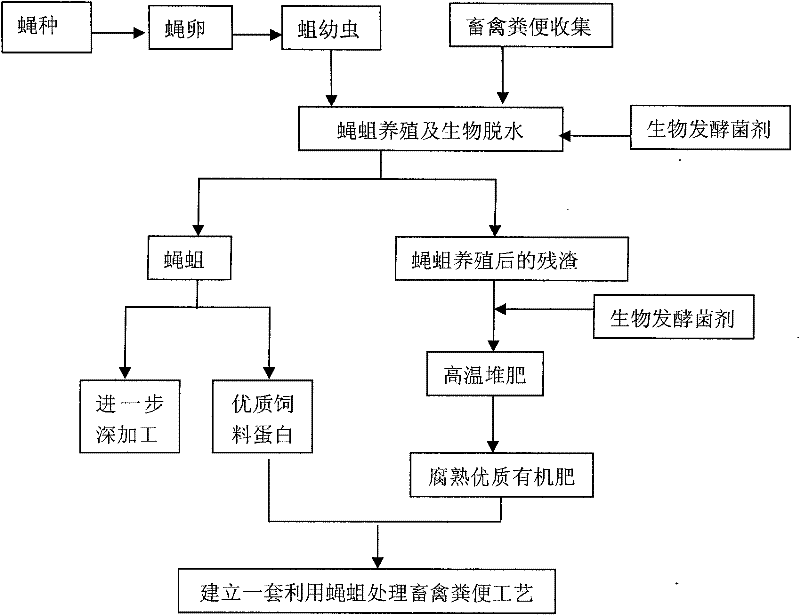

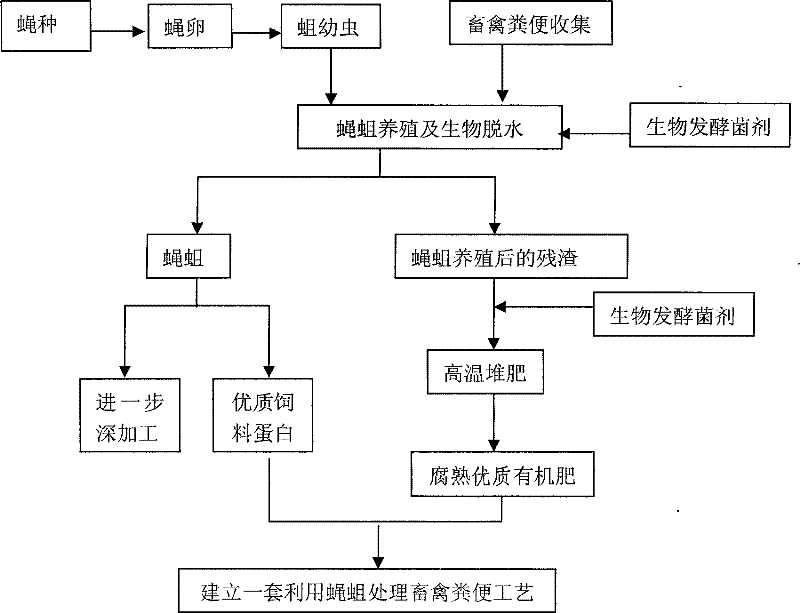

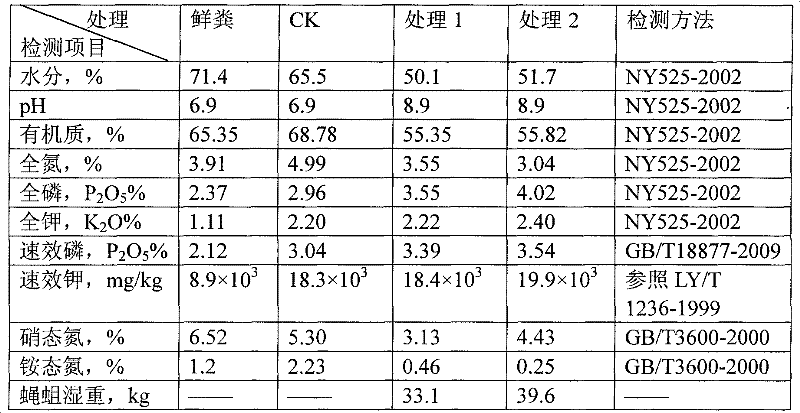

Composting method for biologically dehydrating livestock manure

ActiveCN101774828ALower initial moisture contentReduce moisture contentBio-organic fraction processingClimate change adaptationBiotechnologyLivestock manure

The invention provides a composting method for biologically dehydrating livestock manure, which comprises the following steps: under the condition of adding biological fermentation strains, horizontally laying the livestock manure, adding fly maggots for fermenting, and then, adding the livestock manure and biological fermentation strains in batches, wherein the fermentation period is 3-7 days, and the fermentation condition is 22-42 DEG C. The invention also provides a composting method for biologically dehydrating the livestock manure, which comprises the following steps: under the condition of adding the biological fermentation strains, horizontally laying the livestock manure, and then, adding the fly maggots for fermenting, wherein the fermentation period is 7-12 days, and the fermentation condition is 10-22 DEG C. The invention reduces the initial water content of livestock manure composting by microbiological synergistic action, fully performs the action of composting fermentation strains, does not need to add auxiliary materials for regulating the water content of the livestock manure, reduces the treatment cost of the livestock manure, and improves the composting quality. Meanwhile, the culture of fly maggots provides a large amount of high-quality feed protein and raw materials for further processing to better recycle organic wastes, thereby realizing the purposes of protecting environment and increasing efficiency and yield agriculturally.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Method for extracting cannabidiol-containing hemp extract

InactiveCN107898826AImprove extraction efficiencyHigh in CBDPlant ingredientsFood scienceActivated carbonCentrifugation

The invention discloses a method for preparing cannabidiol-containing hemp extract. The method comprises the following steps: taking mature industrial hemp seeds, drying the hemp seeds, removing impurities, and crushing the hemp seeds for later use; carrying out extraction on the crushed hemp seeds with ethanol with the concentration being 95-100% (V / V) according to a solid-liquid ratio of 1:5 to1:20; filtering the obtained extract, and carrying out reduced pressure concentration to obtain industrial hemp seed extract; dissolving the obtained hemp seed extract in ethanol, and carrying out low-temperature winterization; centrifuging the obtained winterized suspension by using a centrifuge or a filtration technique; decolorizing a supernatant obtained after the centrifugation by using activated carbon, and filtering the supernatant; and carrying out rotary evaporation on a filtrate obtained after the filtration to obtain the cannabidiol-containing hemp extract. The product obtained in the invention has the advantages of high CBD content, good color and good physiological characteristics. The method has the advantages of simple process, easiness in industrial application, and promotion of the development and utilization of high added value products of hemp.

Owner:云南谷益美农业开发有限公司

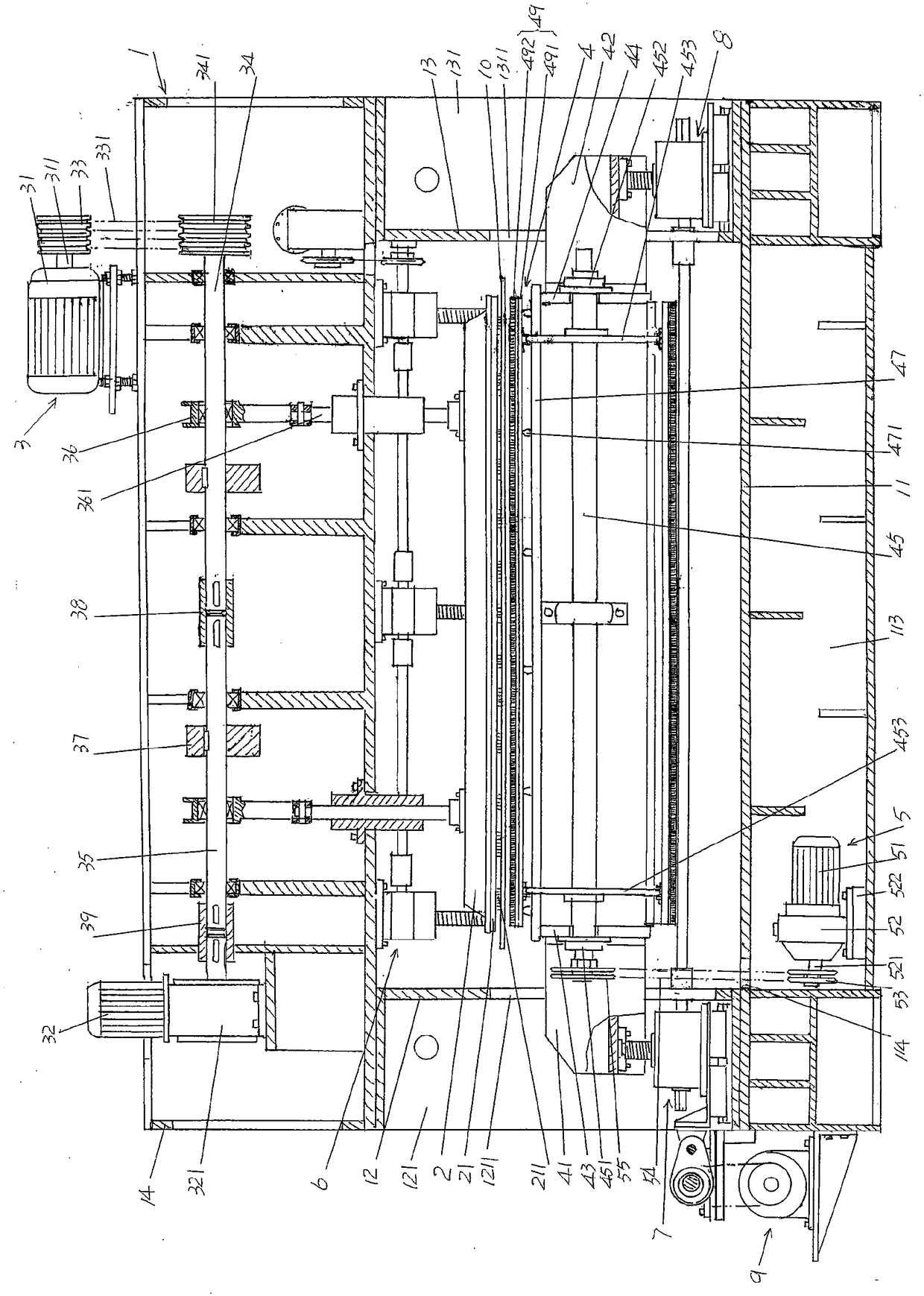

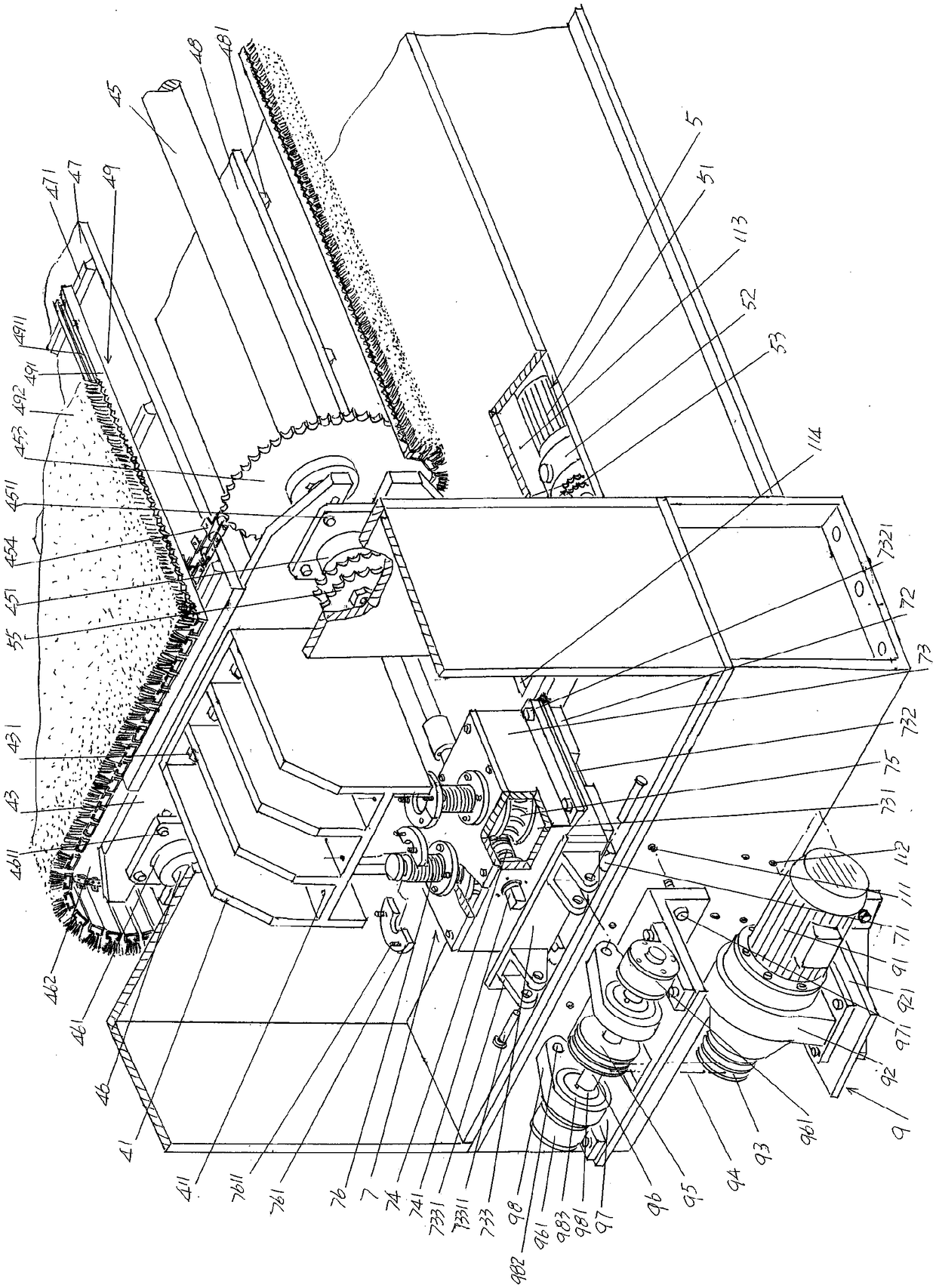

Jacquard raising needle machine

PendingCN108179552ARaise the gradeGood effectPattern makingNeedling machinesEngineeringPower transmission

Disclosed is a jacquard raising needle machine. The machine comprises a machine frame, and the machine frame comprises a base, left and right box frames and a top beam; a double shaft needle beam driving mechanism is arranged on the top beam, the needle beam is connected with the double shaft needle beam driving mechanism, a needle plate is arranged on the side, facing downwards, of the needle beam, and raising needles are arranged on the needle plate; a raising mechanism is arranged on the part between the left and right box frames; a brush curtain power transmission mechanism is arranged onthe base and connected with the raising mechanism; a net stripping plate is connected with a net stripping plate adjustment mechanism, and the net stripping plate lifting adjustment mechanism is arranged below the top beam. The machine is characterized in that the machine further comprises brush curtain frame left and right lifting adjustment mechanisms and a brush curtain frame traction mechanism, the brush curtain frame left and right lifting adjustment mechanisms are arranged on the left and right box frames, the brush curtain frame traction mechanism is arranged on the left end of the baseand connected with the brush curtain left lifting adjustment mechanism, and the raising mechanism is connected with the part between the brush curtain frame left and right lifting adjustment mechanisms. The machine has the advantages that the level of non-woven products is improved, and the edge effect of suede patterns and the overall effect of the suede patterns are improved.

Owner:常熟市伟成非织造成套设备有限公司

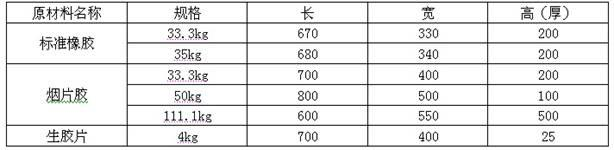

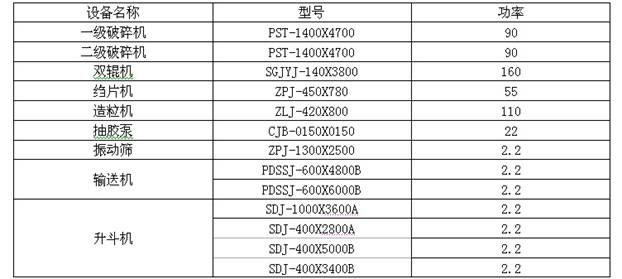

Process for processing rubber

The invention relates to the field of chemical industry, in particular to a process for processing natural rubber. The process comprises procedures of crushing, creping, granulating, baking, weighing and packaging; the process is characterized by using a twin-roll machine for prewashing and extruding after crushing; during the granulating process, a vibration screen is added for separating water and glue from purities; the granulating procedure is repeated for 3 times; and the creping procedure is repeated for 10 times. According to the processing process of the invention, a selection range of raw materials can be widened; according to the process, the hazardous substances such as impurities and ashes and the like of the rubber can be removed; the rubber can obtain excellent consistence, and can satisfy requirements of producing high-quality products such as radial ply tires; and the similar imported materials can be replaced, so that the current situation of importing the similar rubber can be changed.

Owner:KUNMING GAOSHEN CHEM +1

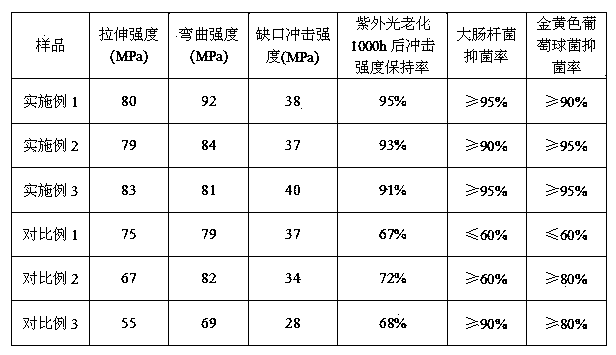

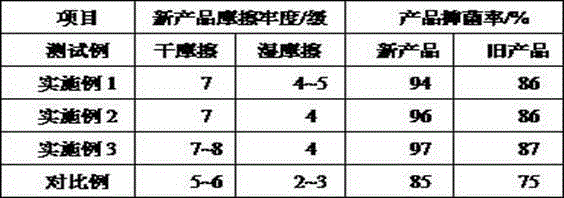

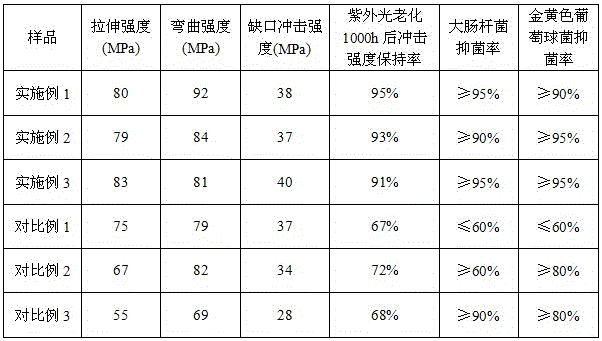

Anti-aging antimicrobial PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) blend alloy and preparation method thereof

ActiveCN104194300ADry evenlyDrying, through 1000-5000 rpm high-speed stirringPolymer scienceMechanical equipment

The invention relates to an anti-aging antimicrobial PC / ABS (polycarbonate / acrylonitrile-butadiene-styrene) blend alloy and a preparation method thereof. The alloy comprises the following components in parts by weight: 10-25% of ABS, 30-50% of PC, 0.5-5% of optically-stable antimicrobial agent, 0.5-5% of ultraviolet absorbent, 15-45% of nano filler and 1-5% of other additive. The preparation method comprises the following steps: proportionally drying the raw materials in a blast drying oven, and uniformly stirring with a 1000-5000r high-speed stirrer; and carrying out extrusion, granulation and drying on the raw materials with a specific-temperature single screw extruder to obtain granules. The alloy has the advantages of favorable aging resistance, excellent antimicrobial property and favorable mechanical properties, and can be used for automobile interior decorations, electronic and electric appliances, mechanical equipment, furniture supplies and other products.

Owner:STARWAY INTERNATIONAL HOME LIVING CO LTD

Sponge foam soft-type full-grain flat leather production process

ActiveCN109628655AImprove overall utilizationGood added valueWax coatingsTanning treatmentLower gradeEconomic benefits

The invention relates to the technical field of leather manufacturing process, and provides a sponge foam soft-type full-grain flat leather production process. According to the sponge foam soft-type full-grain flat leather production process, low-grade heavy-weight cowhide is used as raw leather, a traditional wet dyeing and finishing process framework is broken through, first neutralization and filling is carried out after a softening process, then chrome retanning is carried out, second neutralization and filling is carried out, meanwhile a certain amount of grease is added in the softening,neutralization and filling processes, and materials with selective filling are mainly adopted in the filling process to finally prepare the high-quality and high-utilization full-grain flat leather with good softness, good foam feeling, a uniform and fine grain surface and no obvious position difference. The sponge foam soft-type full-grain flat leather production process effectively solves the problems of coarse grain surfaces, obvious disability, large grain size, a low utilization rate and the like existing in the processing process of the low-grade heavy-weight cowhide, reduces the production cost of manufacturing high-quality and high-utilization sponge foam soft-type full-grain flat leather for enterprises, improves the utilization rate of the low-grade cowhide and the value of finished leather, and brings considerable economic benefits to the enterprises.

Owner:XINGYE LEATHER TECH CO LTD

3D printing preparation method of skin tissue engineering scaffold and in vitro cell toxicity testing method of the same

InactiveCN107998451AIncrease added valueImprove mechanical propertiesAdditive manufacturing apparatusMicrobiological testing/measurementPorosityBiocompatibility Testing

The invention provides a 3D printing preparation method of a skin tissue engineering scaffold and an in vitro cell toxicity testing method of the scaffold. The 3D printing preparation method comprisesthe following steps: preparation of double aldehyde nano-crystalline cellulose used for a scaffold material, preparation of a gelatin solution, preparation of a double aldehyde nano-crystalline cellulose and gelatin compound hydrogel, and printing of the 3D tissue engineering scaffold. The problem that the tissue engineering scaffold needs the requirements of high porosity and high precision is solved by using a 3D biological printing technology. DAC is taken as a cross-linking agent, cross-linking occurs with GEL through a Schiff base reaction to form a network structure, so that the 3D printing tissue engineering scaffold has excellent mechanical property and is unlikely to crack, and simultaneously the additional value of plant fiber is also improved. The DAC / GEL hydrogel has good biocompatibility, is free of toxic and / or side effects or immunologic rejection, has biological activity besides degradation characteristic, and is extremely beneficial for the growth and differentiationof cells and the implementation of cell functions.

Owner:YANGZHOU UNIV

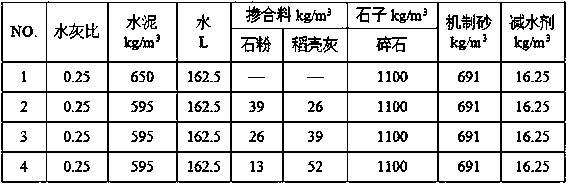

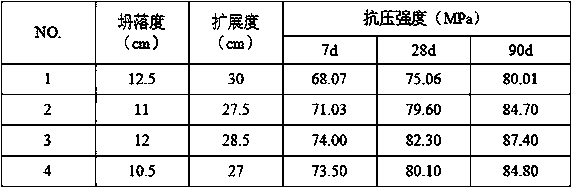

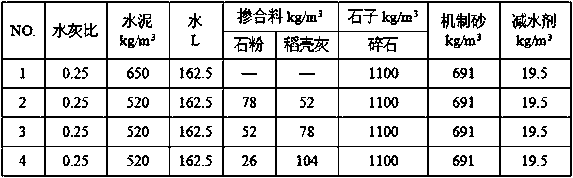

High-performance artificial sand concrete prepared by using mountain flour and rice hull ash as admixture

The invention discloses high-performance artificial sand concrete prepared by using mountain flour and rice hull ash as admixtures. One cubic meter of concrete is prepared from the following raw materials in parts by weight: 500 to 650 parts of cement, 60 to 140 parts of admixtures, 1000 to 1100 parts of coarse aggregates, 650 to 730 parts of artificial sand, 150 to 170 parts of water and 13 to 18parts of water reducing agents, wherein the admixtures are the mountain flour and the rice hull ash. In the used mixed admixtures, the mountain flour and the rice hull ash have rich resources; the raw materials are cheap and can be easily obtained; by selecting the mixed admixtures in the proper proportion, high-performance concrete with good work performance and higher compressive strength is obtained; the utilization rate and the additional value of the mountain flour and the rice hull ash are improved; meanwhile, the use quantity of cement is reduced; the supply pressure of the high-performance concrete on the cement and superfine slag powder is relieved; the concrete manufacturing cost is reduced; the sustainable development requirements are met.

Owner:JINAN UNIVERSITY

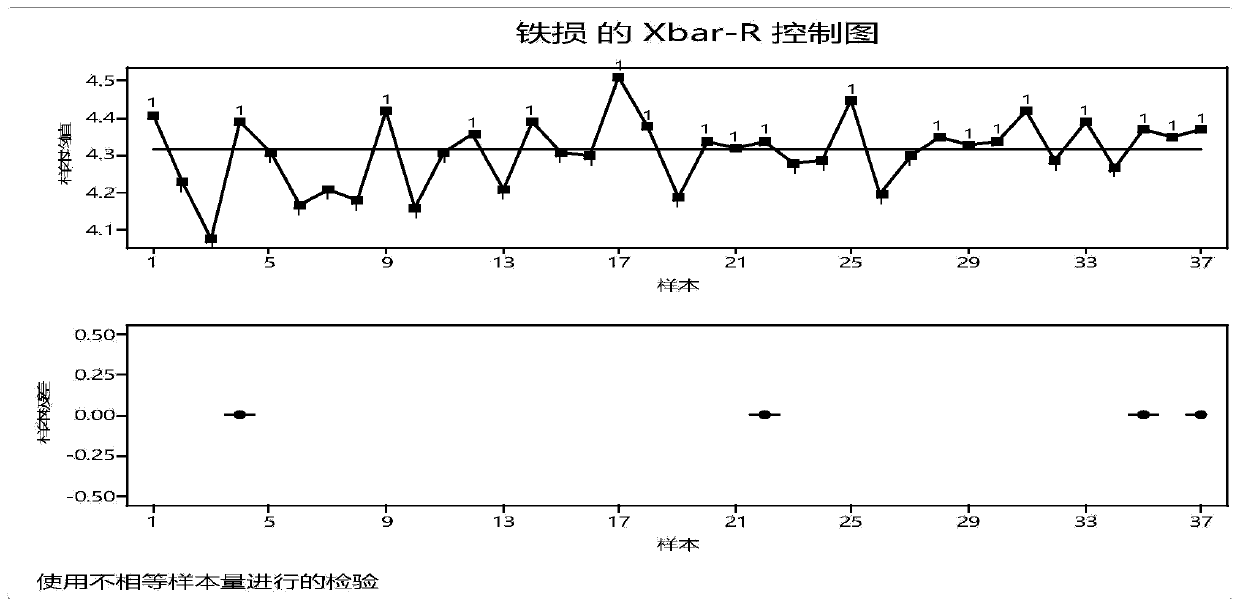

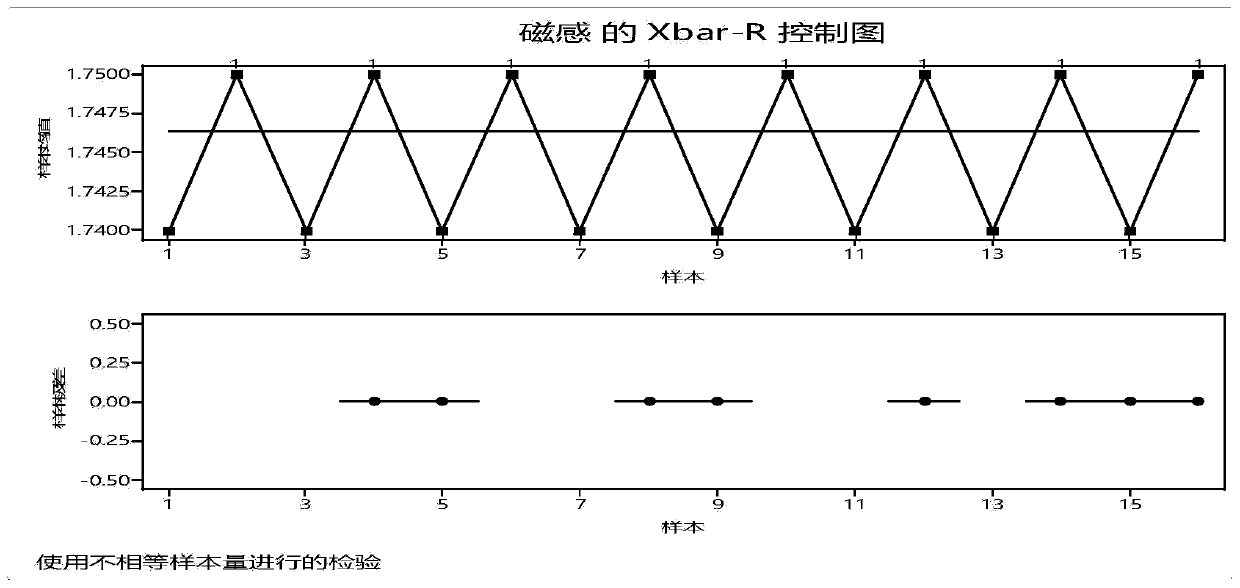

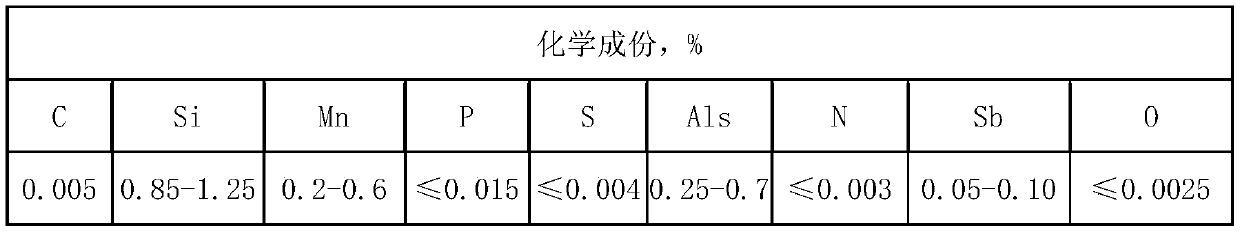

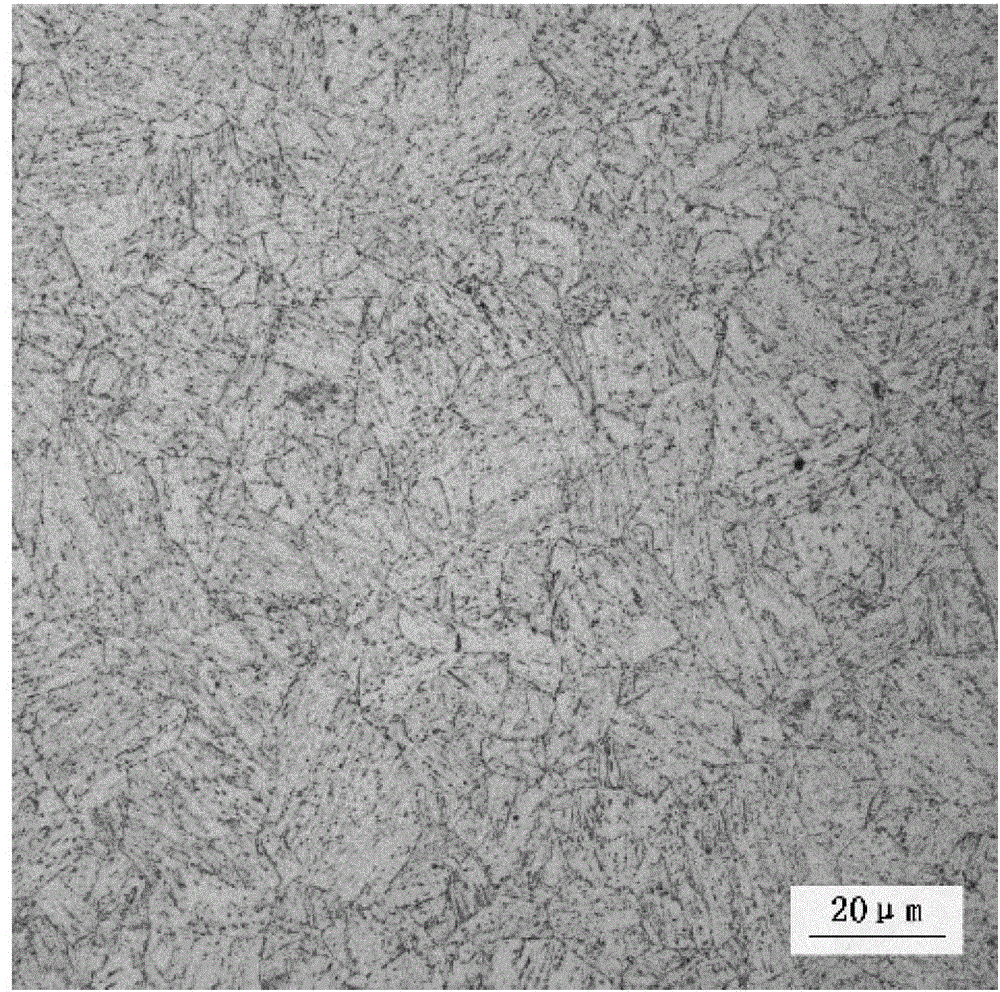

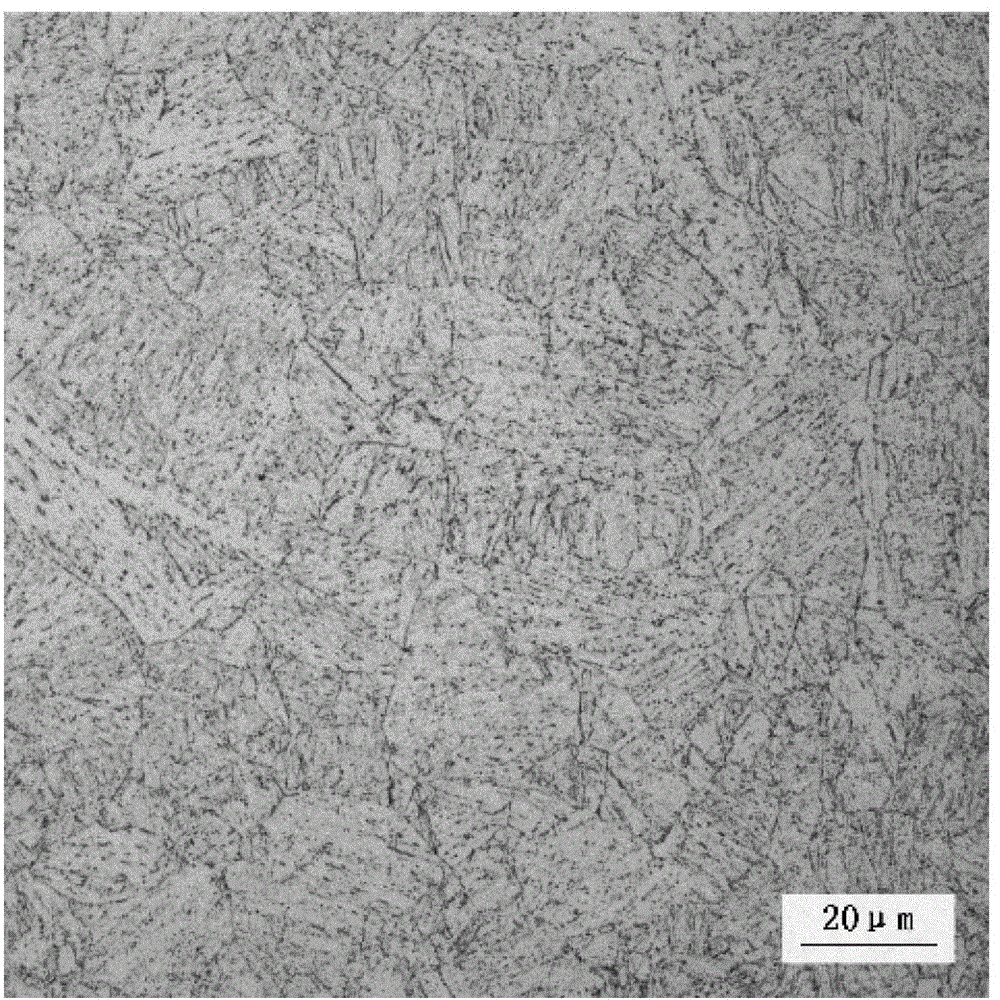

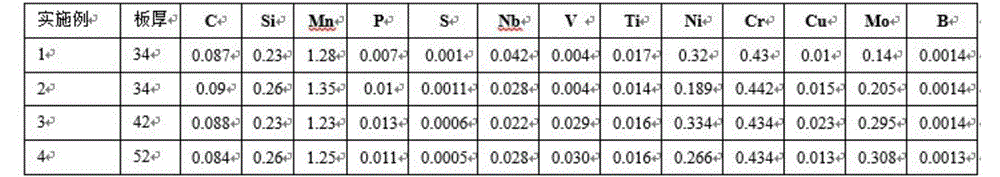

Method for producing high-magnetic-induction non-oriented silicon steel 50BW800G through normalizing-free heat treatment

The invention belongs to the technical field of material processing, and particularly provides a production process for producing high-magnetic-induction non-oriented silicon steel 50BW800G through normalizing-free heat treatment. At present, the production of Benxi steel non-oriented silicon steel 50BW800 is supplied by an FTSR production line, no normalizing annealing equipment exists in the cold rolling process, a production process for producing the high-magnetic-induction non-oriented silicon steel under the condition that a hot rolled coil is free of normalizing annealing needs to be found, and existing equipment is fully utilized for producing high-added-value products. According to the production process, through optimal design of alloy components and hot rolling and cold rolling continuous annealing processes and by utilizing the advantage that an existing FTSR short-process production line is beneficial to adopting a low-temperature heating process, a hot-rolled coil can be directly cold-rolled to the thickness of a finished product without normalizing heat treatment of the hot-rolled coil, and then final continuous annealing is carried out to produce the high-magnetic-induction non-oriented silicon steel 50BW800G, the electromagnetic performance of the product meets the requirement, the production cost is low, the electromagnetic performance is good, and the additional value of the product is increased.

Owner:BENGANG STEEL PLATES

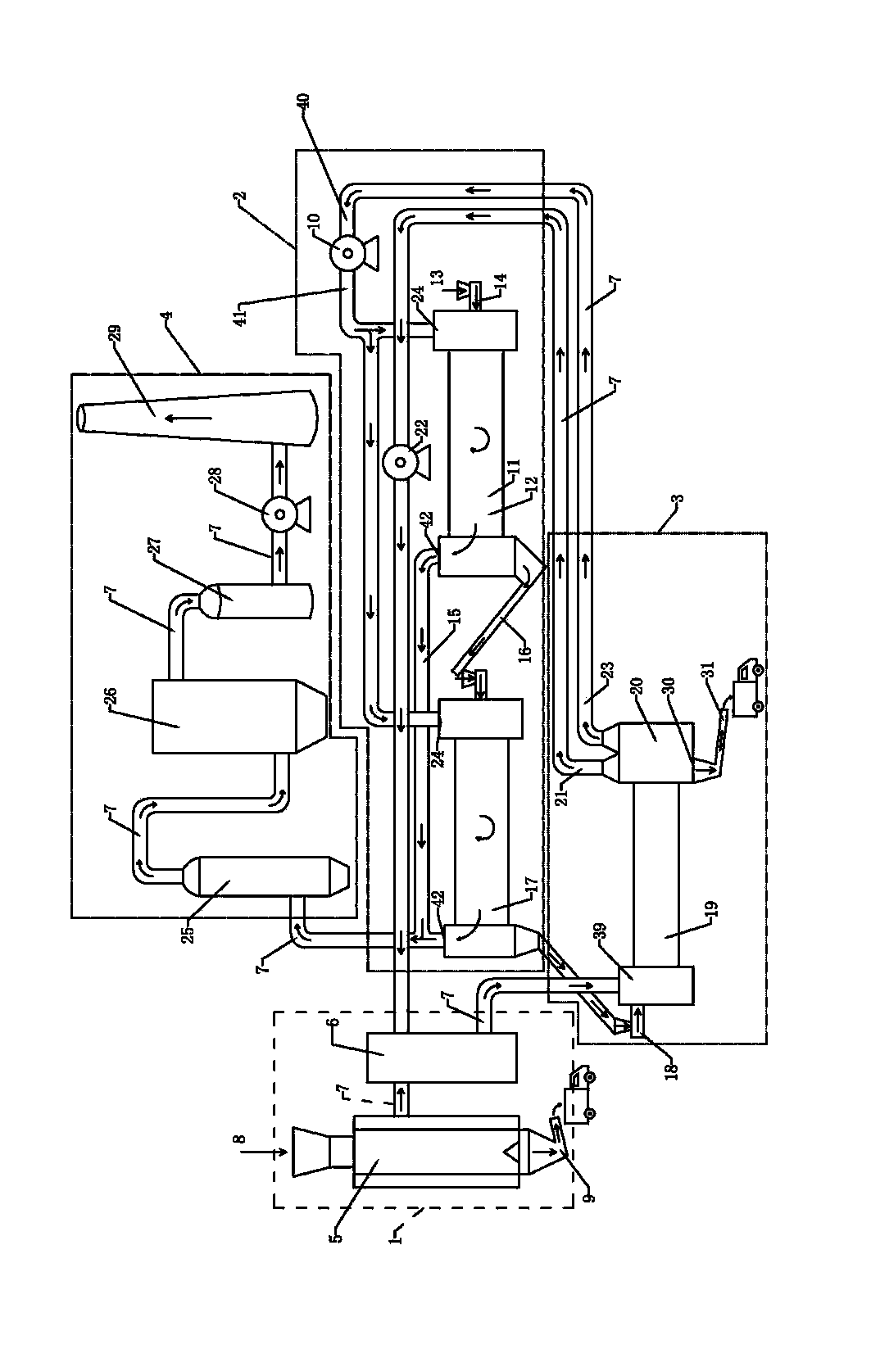

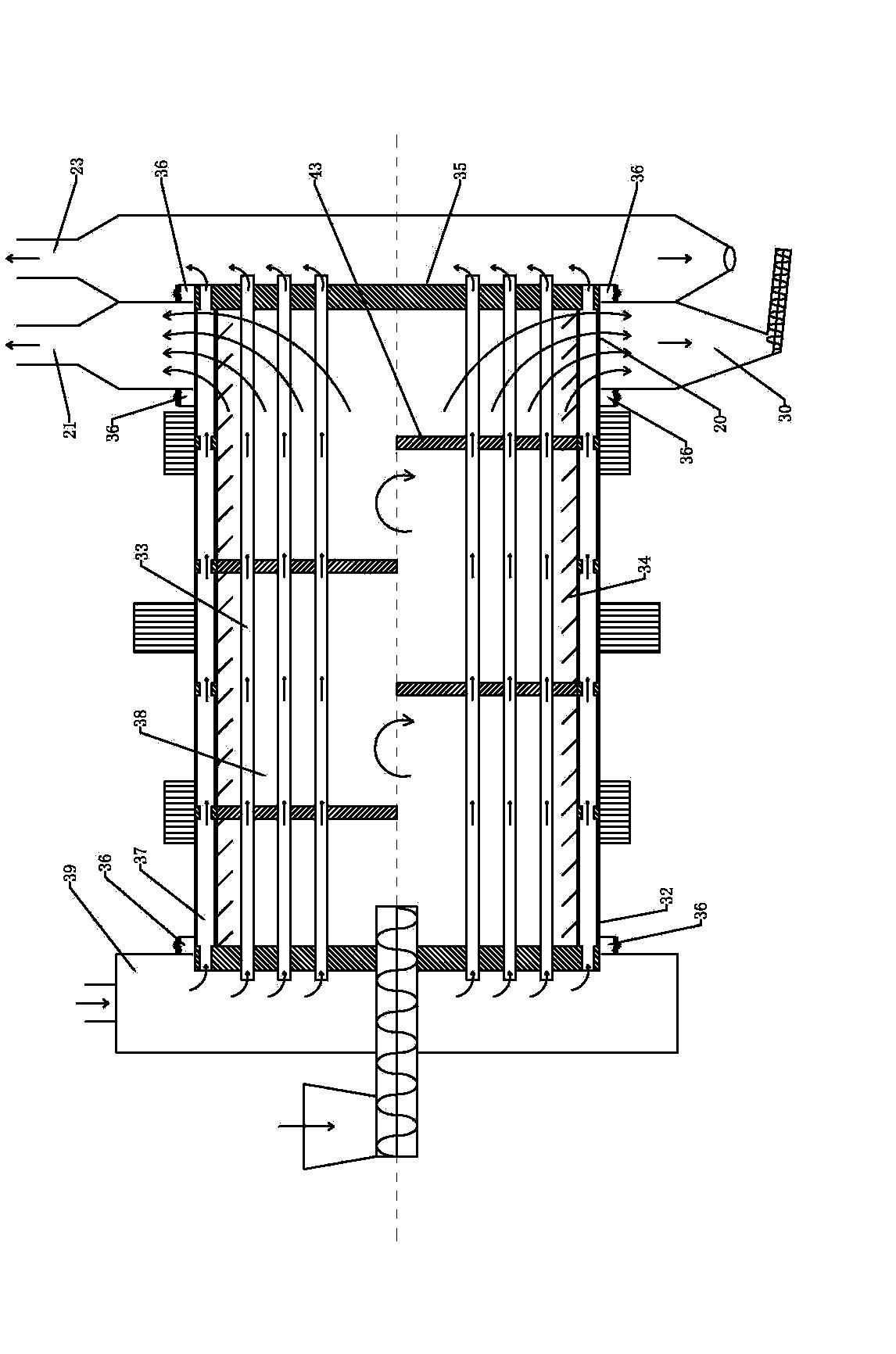

Sludge drying/pyrolysis/gasification/incineration integrated treatment system

InactiveCN103666504AGood energy saving effectSimple equipment structureSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisGas generatorPyrolysis

The invention discloses a sludge drying / pyrolysis / gasification / incineration integrated treatment system which comprises a burning system, a drying system, a pyrolysis and gasification system and a fume cleaning system, wherein the burning system comprises a gas generator and an incinerator; the drying system comprises a blower and Stage 1-5 drying machines; the pyrolysis and gasification system comprises a pyrolysis gasifier and a separator; and the fume cleaning system comprises a dedusting devulcanizer, a draught fan and a chimney which are respectively connected with each other through pipelines. The integrated treatment system disclosed by the invention has the characteristics of high safety and reliability, energy saving, emission reduction, low carbon, environment friendliness, low operating cost and the like, and realizes reduced, stabilized, harmless and recycling treatment.

Owner:浙江绍兴鸿杰节能环保科技有限公司

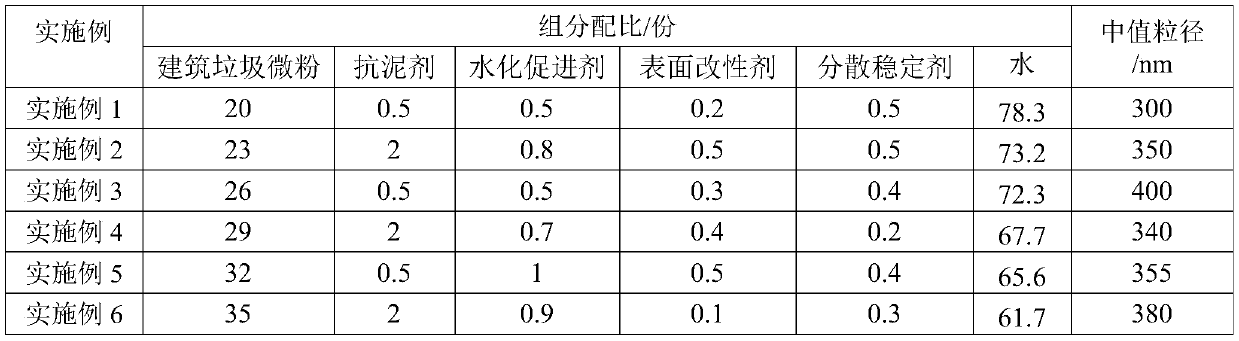

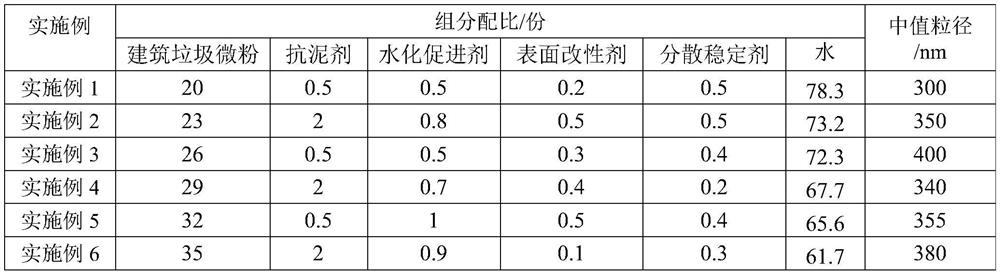

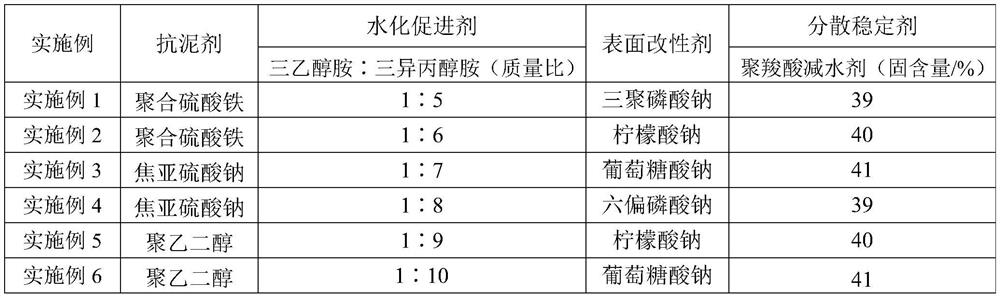

Building garbage nanometer crystal nucleus, preparation method and applications thereof

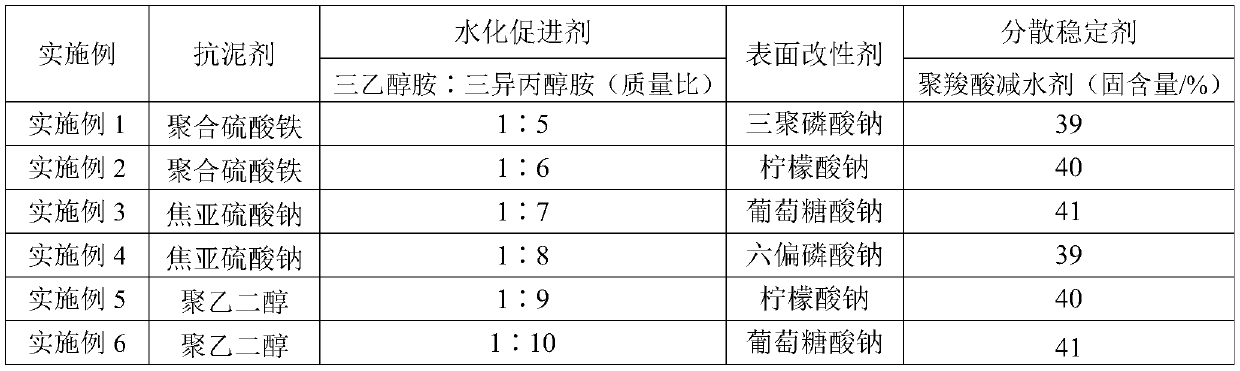

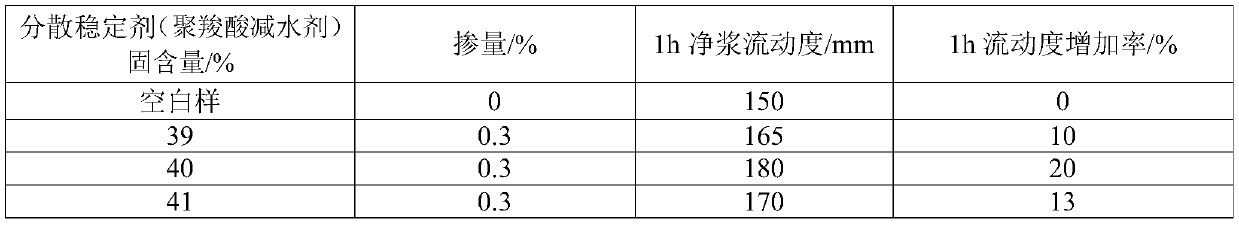

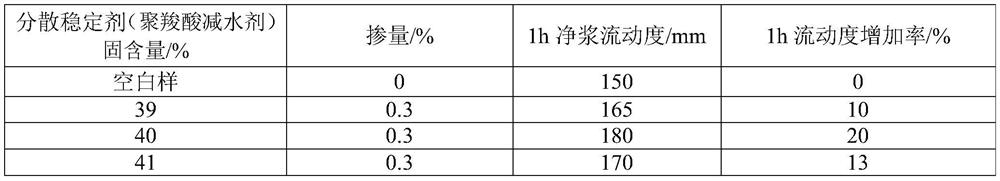

The invention provides a building garbage nanometer crystal nucleus, a preparation method and applications thereof, wherein 100 parts of the raw materials comprise, by weight, 20-35 parts of building garbage micro-powder, 0.5-2 parts of an anti-mud agent, 0.5-1 part of a hydration accelerator, 0.1-0.5 part of a surface modifier, 0.1-0.5 part of a dispersion stabilizer, and the balance of water. According to the present invention, with the building garbage nanometer crystal nucleus, the pore structure can be substantially improved, the nucleation acceleration hydration can be induced, and the early strength can be significantly improved; when 5-15% of the cement is replaced with the building garbage nanometer crystal nucleus, the 1 d compressive strength of ordinary Portland cement mortar can be improved by more than 20%, the 3 d compressive strength can be increased by more than 10%, and the 28 d compressive strength is not decreased; and the building garbage nanometer crystal nucleus provides the new direction for the resource utilization of building garbage, and greatly improve the resource utilization rate of building garbage.

Owner:WUHAN UNIV OF TECH

Bamboo fiber and fibrilia fiber blending cloth

InactiveCN105133135AImprove antibacterial propertiesNovel functional designWoven fabricsYarnDying processesApocynum venetum

The invention discloses a bamboo fiber and fibrilia fiber blending cloth formed by raw material according to a weight ratio of bamboo fibers taking up of 90%, hemp fibers of 3%, flax fibers of 25%, ramie fibers of 2%, jute fibers of 1% and apocynum venetum fibers of 2%. The bamboo fiber and fibrilia fiber blending cloth has great product bacteria-resisting performance, protects skin and is characterized by uvioresistant performance, wear resistance, smoothness, a moisture permeability and shrink resistance; natural finishing agent chitosan is employed in the post-processing phase for a product to further enhance cloth bacteria resisting effect; all natural plant dye-fixing agents and coloring agents are employed during the dying process; even dying, simple technology and unfading color can be achieved; no harm is caused to skin; the whole manufacturing process employs natural material during the whole manufacturing process of the blending bamboo fiber cloth, so the cloth is environment-friendly and safe and requires low cost; the cloth functions and design are novel, high-end, possesses great product comfortableness and high additional value.

Owner:JIESHOU SHUANGXIN TEXTILE

High-quality willow softening agent

InactiveCN106239670ALow elastic modulusImprove toughnessWood treatment detailsPretreatment apparatusAlkaneGlycerol

The invention discloses a high-quality willow softening agent. The softening agent is made of following components including nano diatomite, ammonia-water, potassium chloride, sorbitol, potassium polymetaphosphate, glycerol, seconary alkane sulphonate sodium, a flixweed tansymustard seed extracting solution and water. According to the willow softening agent, the ammonia-water, the nano diatomite, the potassium chloride and the potassium polymetaphosphate are compounded, in cooperation with the cooperative interactions of the flixweed tansymustard seed extracting solution and the glycerol, the obtained softening effect is good, the treatment time is short, and safety is high; and through the coordinative cooperation effect of the all components, a willow workpiece treated by the willow softening agent is high in strength after drying shaping, toughness is good, the structure is compact, the surface is smooth, and the added use value of willows is greatly improved.

Owner:阜南县中泰工艺品有限公司

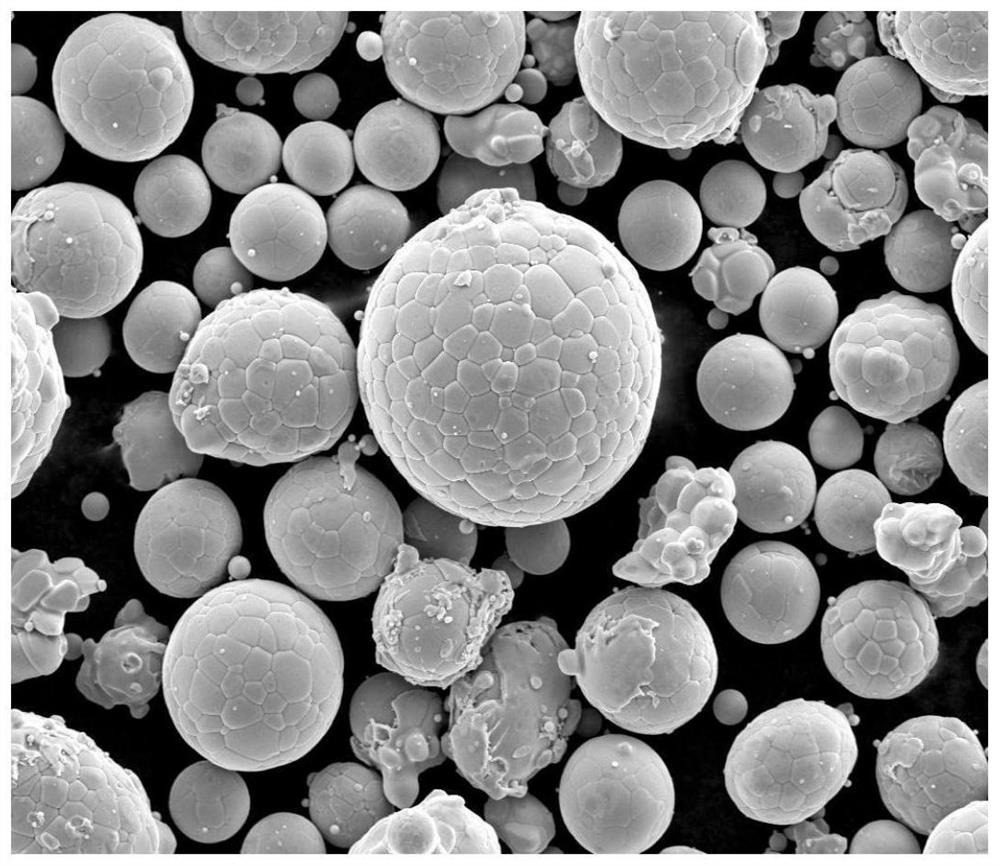

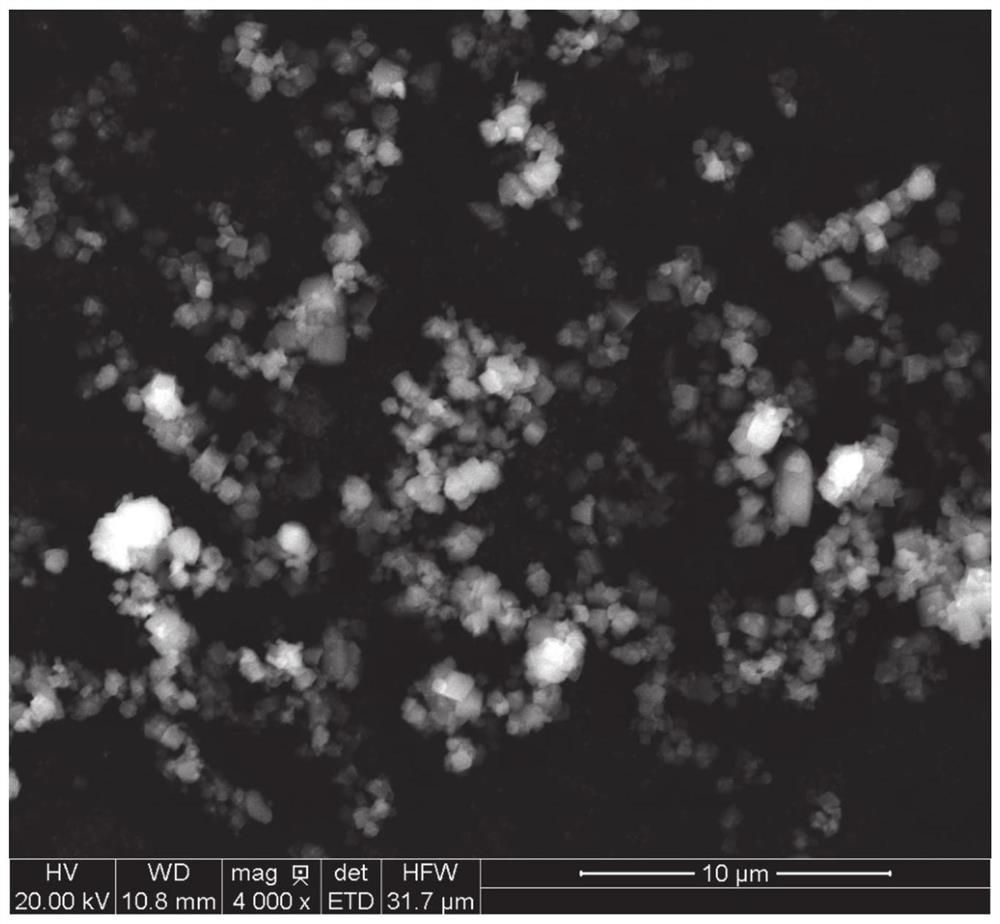

High-entropy alloy reinforced nickel-aluminum composite material spherical powder for 3D printing and preparation method of high-entropy alloy reinforced nickel-aluminum composite material spherical powder

PendingCN114107741AGood added valueImprove plasticityAdditive manufacturing apparatusTransportation and packaging3d printHigh entropy alloys

The invention relates to high-entropy alloy reinforced nickel-aluminum composite material spherical powder for 3D printing and a preparation method, the powder comprises a high-entropy alloy and a nickel-aluminum alloy, and the mass ratio of the high-entropy alloy is 10-40%; the nickel-aluminum alloy comprises the following elements in percentage by mass: 50-90% of nickel and 10-50% of aluminum; the high-entropy alloy comprises, by atomic ratio, 10%-25% of chromium, 10%-25% of manganese, 10%-25% of iron, 10%-25% of cobalt and 10%-25% of nickel. The method comprises the following steps: A, putting chromium, manganese, iron, cobalt and nickel into a crucible; b, vacuumizing; c, the crucible is heated, and the solution falls down; d, argon and solidification; e, nickel and aluminum are put into the crucible, and the steps B-D are repeated; and F, mixing in proportion. High-entropy alloy and nickel-aluminum alloy particles are prepared through an electrode induction melting gas atomization method, and the 3D printing raw material is prepared by mixing the high-entropy alloy and the nickel-aluminum alloy particles in proportion. The problems that the high-entropy alloy reinforced nickel-aluminum composite material prepared in a smelting mode is high in cost and complex in procedure are solved.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

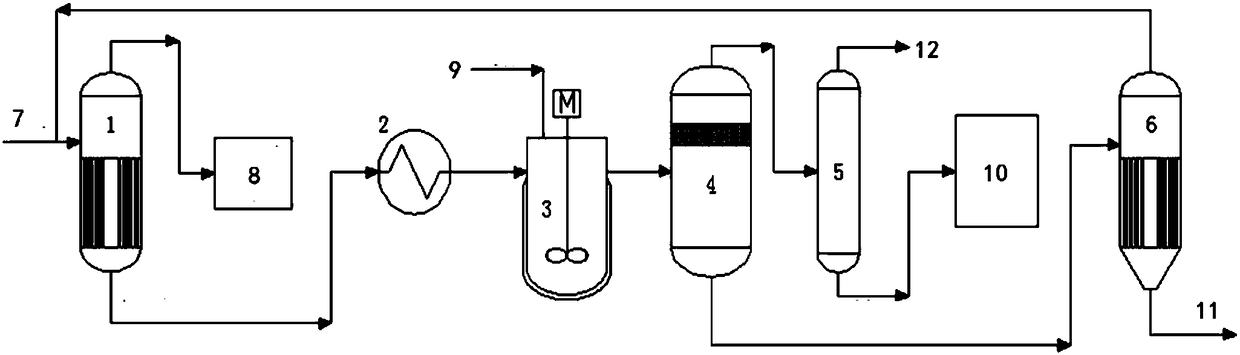

Method for treating wastewater in 2-propyl heptanol production device

InactiveCN108128982AGood added valueReduce loadWater treatment parameter controlMultistage water/sewage treatmentAdditive ingredientTower

The invention relates to a method for treating wastewater in a 2-propyl heptanol production device, and mainly solves the problem of great load of a wastewater treatment plant in the wastewater treatment process in the prior art. The method for treating wastewater in the 2-propyl heptanol production device comprises the following steps that (1) wastewater enters concentration bag equipment; concentrated liquid obtained by the concentration bag equipment is cooled by a cooler and then enters an acidification tank; water concentrated by the concentration bag equipment enters a biochemical treatment plant for biochemical treatment; (2) the concentrated liquid at an outlet of the acidification tank enters a chromatography device to obtain an organic phase and a water phase; (3) the organic phase enters a rectifying tower; valeric acid is obtained at the top of the rectifying tower; heavy ingredients of a rectification tower kettle enter an incinerator; the water phase enters an evaporativecrystallization device to obtain water and solid salts, wherein the water returns to the concentration bag equipment for reuse. The technical scheme better solves the problems, and can be used for wastewater treatment in the 2-propyl heptanol production device.

Owner:SINOPEC SHANGHAI ENG +1

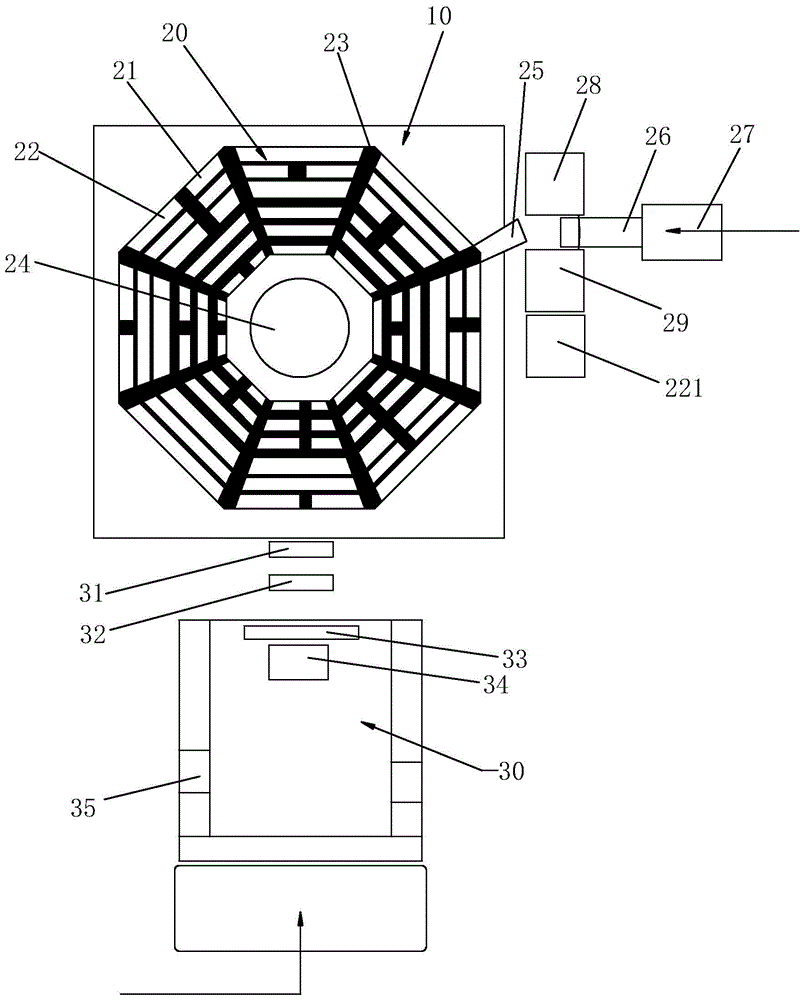

Cave type eight-diagram-body intelligent cemetery structure design

The invention relates to the technical field of human funeral and interment and sacrifice, in particular to cave type eight-diagram-body intelligent cemetery structure design. Compared with the prior art, a cave is dug near a mountain according to the cave type eight-diagram-body intelligent cemetery structure design, an ash cemetery is built in the cave, the traditional cemetery mode of building solitary graves in the surface layer of a mountain body is changed into the mode of burying cinerary caskets orderly in the cave in a collective mode, a large sacrifice square is built outside the mountain body, meanwhile, the modern network technology is utilized, big-data intelligent management is applied, live video of a hope bone table is carried out in a VIP video sacrifice chamber, and the traditional family sacrifice mode is guided into the collective cemetery sacrifice mode, so that a funeral and interment mode and a sacrifice mode are reformed, and lands can be saved greatly while social traditions are transformed; the problem of funeral and interment pollution is solved, and the quality of natural ecological environment of the human being is promoted; individual sacrifice is changed into collective sacrifice, public belief and national cohesion are promoted, and social harmony is promoted; meanwhile, the cemetery can be developed into a tourist attraction, the sacrificial culture is enriched, and the new field of human funeral and interment is creatively expanded.

Owner:沈杰斌

A highly antishock PVC tube and a preparing method thereof

InactiveCN106519495AImprove mechanical propertiesGood weather resistanceMonoglycerideMoisture absorption

A highly antishock PVC tube is disclosed. The PVC tube is prepared from, by weight, 80-100 parts of PVC resin, 3-5 parts of white carbon black, 20-30 parts of activated calcium, 2-4 parts of gypsum whisker, 0.2-0.4 part of monoglyceride stearate, 0.5-1 part of paraffin oil, 2-3 parts of a calcium-zinc stabilizer, 5-10 parts of dimethyl silicone oil, 20-30 parts of sodium dodecyl benzene sulfonate and 5-10 parts of a modification auxiliary agent. Mechanical properties and weatherability of the material are enhanced, and moisture absorption and permeability of the material are also improved, and therefore a PVC modified material for indoor decoration has good mechanical properties and moisture absorption and regulation functions, can effectively improve the comfort level of the indoor environment, and is excellent in skid resistance.

Owner:祖兴保

Method for producing gypsum fiber from calcium carbide mud

InactiveCN102923751BImprove product qualityWide range of usesSolid waste disposalCalcium/strontium/barium sulfatesSludgeSulfide

The invention discloses a method for producing plaster fiber by using carbide slurry. The method comprises steps of neutralizing the carbide slurry by using nitric acid, obtaining a calcium nitrate solution, separating solid from liquid, preparing a fine calcium nitrate solution, converting the fine calcium nitrate solution to the plaster fiber by using sulphuric acid, separating the solid from the liquid, obtaining product plaster fiber, absorbing hydrogen sulfide tail gas by using iron dichloride which is generated through soaking of iron scraps in hydrochloric acid and sodium hydroxide, and preparing ferrous sulfide. By the aid of the method, waste is used for processing waste, the waste is turned into useful things, and the problem that the carbide slurry pollutes the environment is solved. The composite plastic fiber product is good in quality, wide in application, low in cost, high in added value and good in economic benefit. By product ferrous sulfide has high added value. The method is short in process and simple to operate.

Owner:荣殿相

Method for producing plaster fiber by using carbide slurry

InactiveCN102923751AImprove product qualityWide range of usesSolid waste disposalCalcium/strontium/barium sulfatesCarbideSlurry

The invention discloses a method for producing plaster fiber by using carbide slurry. The method comprises steps of neutralizing the carbide slurry by using nitric acid, obtaining a calcium nitrate solution, separating solid from liquid, preparing a fine calcium nitrate solution, converting the fine calcium nitrate solution to the plaster fiber by using sulphuric acid, separating the solid from the liquid, obtaining product plaster fiber, absorbing hydrogen sulfide tail gas by using iron dichloride which is generated through soaking of iron scraps in hydrochloric acid and sodium hydroxide, and preparing ferrous sulfide. By the aid of the method, waste is used for processing waste, the waste is turned into useful things, and the problem that the carbide slurry pollutes the environment is solved. The composite plastic fiber product is good in quality, wide in application, low in cost, high in added value and good in economic benefit. By product ferrous sulfide has high added value. The method is short in process and simple to operate.

Owner:荣殿相

Composting method for biologically dehydrating livestock manure

ActiveCN101774828BLower initial moisture contentReduce moisture contentBio-organic fraction processingClimate change adaptationBiotechnologyLivestock manure

The invention provides a composting method for biologically dehydrating livestock manure, which comprises the following steps: under the condition of adding biological fermentation strains, horizontally laying the livestock manure, adding fly maggots for fermenting, and then, adding the livestock manure and biological fermentation strains in batches, wherein the fermentation period is 3-7 days, and the fermentation condition is 22-42 DEG C. The invention also provides a composting method for biologically dehydrating the livestock manure, which comprises the following steps: under the condition of adding the biological fermentation strains, horizontally laying the livestock manure, and then, adding the fly maggots for fermenting, wherein the fermentation period is 7-12 days, and the fermentation condition is 10-22 DEG C. The invention reduces the initial water content of livestock manure composting by microbiological synergistic action, fully performs the action of composting fermentation strains, does not need to add auxiliary materials for regulating the water content of the livestock manure, reduces the treatment cost of the livestock manure, and improves the composting quality.Meanwhile, the culture of fly maggots provides a large amount of high-quality feed protein and raw materials for further processing to better recycle organic wastes, thereby realizing the purposes ofprotecting environment and increasing efficiency and yield agriculturally.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Elephant crepe fabric

The invention is a new cotton textile, that is, a woven fabric made of pure cotton yarn. It is characterized in that the pure cotton yarn is twisted, heated and shaped by moisture, and balanced and moisturized to form a spiral weft, and then the weft twisted in the opposite direction is interwoven with the pure cotton warp to form a plain weave fabric with a creped surface. The pure cotton crepe de chine fabric of the present invention changes the limitation that the existing crepe de chine fabric can only use silk as raw materials, expands the scope of cotton fabrics, improves the technical content, increases the variety of designs and colors, satisfies the market demand, and has a good economic and social benefits.

Owner:邱利利

High-strength steel plate for 800MPa hydropower station pressure pipeline and production method thereof

Owner:SHOUGANG CORPORATION

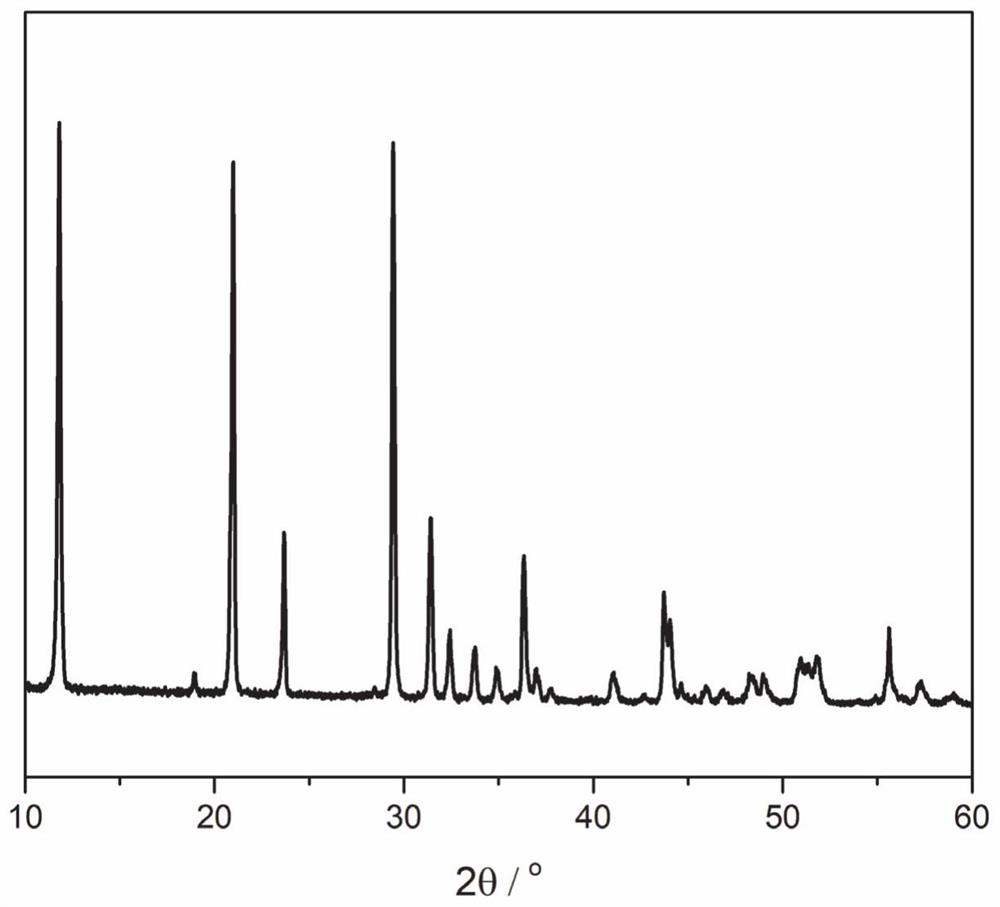

Lithium iron phosphate precursor/carbon nanotube composite material

ActiveCN111732088AImprove the problem of agglomeration and uneven compositionHas a one-dimensional structureMaterial nanotechnologyCarbon compoundsPtru catalystComposite cathode

The invention provides a lithium iron phosphate precursor / carbon nanotube composite material which is characterized in that a lithium iron phosphate precursor is metal phosphate A or metal oxide B andhas a submicron or micron structure, wherein the precursor material is uniformly distributed in a conductive network formed by carbon nanotubes, the content of the carbon nanotubes is 0.1-20 wt%, andthe content of the precursor is 80-99.9 wt%; the composite precursor material only needs to be uniformly mixed with a certain amount of lithium salt, and the lithium iron phosphate / carbon nanotube composite cathode material is obtained after a simple high-temperature solid-phase reaction. According to the invention, the iron-based catalyst is used for preparing the carbon nanotube; the iron-basedcatalyst is used as all or part of sources of metal elements in the lithium iron phosphate precursor, so that the preparation cost is reduced, the intrinsic conductivity and lithium ion diffusion coefficient of the lithium iron phosphate material are improved, the conductivity of the material is improved in combination with a conductive network constructed by the carbon nanotubes, and the comprehensive electrochemical performance of the lithium iron phosphate material is remarkably improved.

Owner:CENT SOUTH UNIV

A bamboo fiber and hemp fiber blended fabric

InactiveCN105133135BImprove antibacterial propertiesNovel functional designWoven fabricsYarnDying processesApocynum venetum

The invention discloses a bamboo fiber and fibrilia fiber blending cloth formed by raw material according to a weight ratio of bamboo fibers taking up of 90%, hemp fibers of 3%, flax fibers of 25%, ramie fibers of 2%, jute fibers of 1% and apocynum venetum fibers of 2%. The bamboo fiber and fibrilia fiber blending cloth has great product bacteria-resisting performance, protects skin and is characterized by uvioresistant performance, wear resistance, smoothness, a moisture permeability and shrink resistance; natural finishing agent chitosan is employed in the post-processing phase for a product to further enhance cloth bacteria resisting effect; all natural plant dye-fixing agents and coloring agents are employed during the dying process; even dying, simple technology and unfading color can be achieved; no harm is caused to skin; the whole manufacturing process employs natural material during the whole manufacturing process of the blending bamboo fiber cloth, so the cloth is environment-friendly and safe and requires low cost; the cloth functions and design are novel, high-end, possesses great product comfortableness and high additional value.

Owner:JIESHOU SHUANGXIN TEXTILE

A kind of lithium iron phosphate precursor/carbon nanotube composite material

ActiveCN111732088BHas a one-dimensional structureImprove conductivityMaterial nanotechnologyCarbon compoundsPtru catalystComposite cathode

The invention provides a lithium iron phosphate precursor / carbon nanotube composite material, which is characterized in that the lithium iron phosphate precursor is metal phosphate A or metal oxide B, and has a submicron or micron structure; the precursor material is evenly distributed In the conductive network composed of carbon nanotubes, the content of carbon nanotubes is 0.1-20wt%, and the content of precursors is 80-99.9wt%. The composite precursor material only needs to be uniformly mixed with a certain amount of lithium salt. A lithium iron phosphate / carbon nanotube composite positive electrode material is obtained after a simple high-temperature solid-state reaction. The invention utilizes an iron-based catalyst to prepare carbon nanotubes, and the iron-based catalyst is used as all or part of the source of metal elements in the lithium iron phosphate precursor, which reduces the preparation cost and improves the intrinsic conductivity and lithium ion diffusion of the lithium iron phosphate material Coefficient, combined with the conductive network constructed by carbon nanotubes to improve the conductivity of the material, significantly improve the comprehensive electrochemical performance of lithium iron phosphate materials.

Owner:CENT SOUTH UNIV

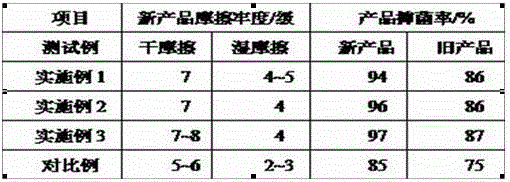

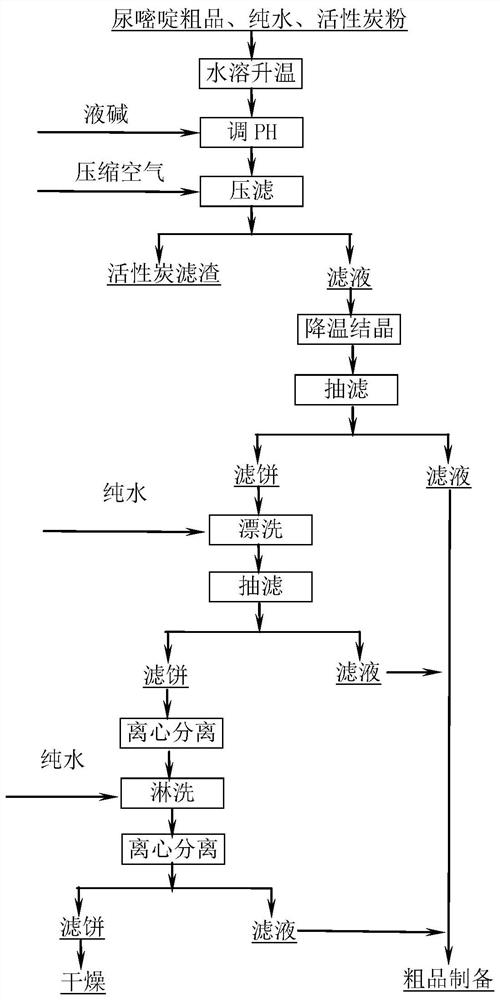

Refining process of uracil by sulfuric acid method

PendingCN113121452AAchieve separationImprove filtration efficiencyOrganic chemistryActivated carbonActivated charcoal powder

The invention belongs to the technical field of mold locking machine equipment, and particularly relates to a process for refining uracil by a sulfuric acid method, which comprises the following steps: adding a uracil crude product, water and activated carbon powder into a refining kettle, heating the mixture in a water bath under a stirring condition to completely dissolve the uracil crude product, gradually dropwise adding liquid caustic soda to adjust the pH value to 7, and cooling the mixture to room temperature; then heating the mixed solution to 85-90 DEG C for filtering out activated carbon and cooling the filtrate to 15-18 DEG C or below for crystallization. The method is applied to deep refining of a sulfuric acid method uracil crude product, the obtained high-purity uracil can meet the high-end application requirement, the export requirements that the main grade is larger than or equal to 99.9% and the sulfate is smaller than or equal to 0.03% are met, wherein the product competitiveness can be greatly improved. The method is simple in process and remarkable in economic benefit, and solves the problems that in the prior art, the yield of a uracil preparation product is not high and is about 60%, the purity is easily influenced by sulfate, chloride and other impurities and is about 98-99%, only low-end application requirements can be met, high-end application and export-grade requirements cannot be met, and the additional value is low.

Owner:甘肃堡昌化工有限公司

A kind of construction waste nano crystal core and its preparation method and application

ActiveCN110255957BImprove resource utilizationEasy to fillEnvironmental engineeringCompressive strength

The invention provides a construction waste nano crystal nucleus and its preparation method and application. The raw material of the construction waste nano crystal nucleus comprises the following components in parts by weight: construction waste micropowder: 20-35 parts, anti-mud agent: 0.5 ~2 parts, hydration accelerator: 0.5-1 part, surface modifier: 0.1-0.5 part, dispersion stabilizer: 0.1-0.5 part, and the balance is water; the construction waste micropowder, the anti-mud agent, The total parts of the hydration accelerator, the surface modifier, the dispersion stabilizer and the water are 100 parts. The construction waste nanocrystal nucleus of the present invention can greatly improve the pore structure, induce nucleation to accelerate hydration, and significantly improve the early strength. When 5-15% of cement is replaced, the 1d compressive strength of ordinary Portland cement mortar can be improved More than 20%, the 3d compressive strength is increased by more than 10%, and the 28d compressive strength does not decrease. The invention provides a new direction for resource utilization of construction waste, and greatly improves the resource utilization rate of construction waste.

Owner:WUHAN UNIV OF TECH

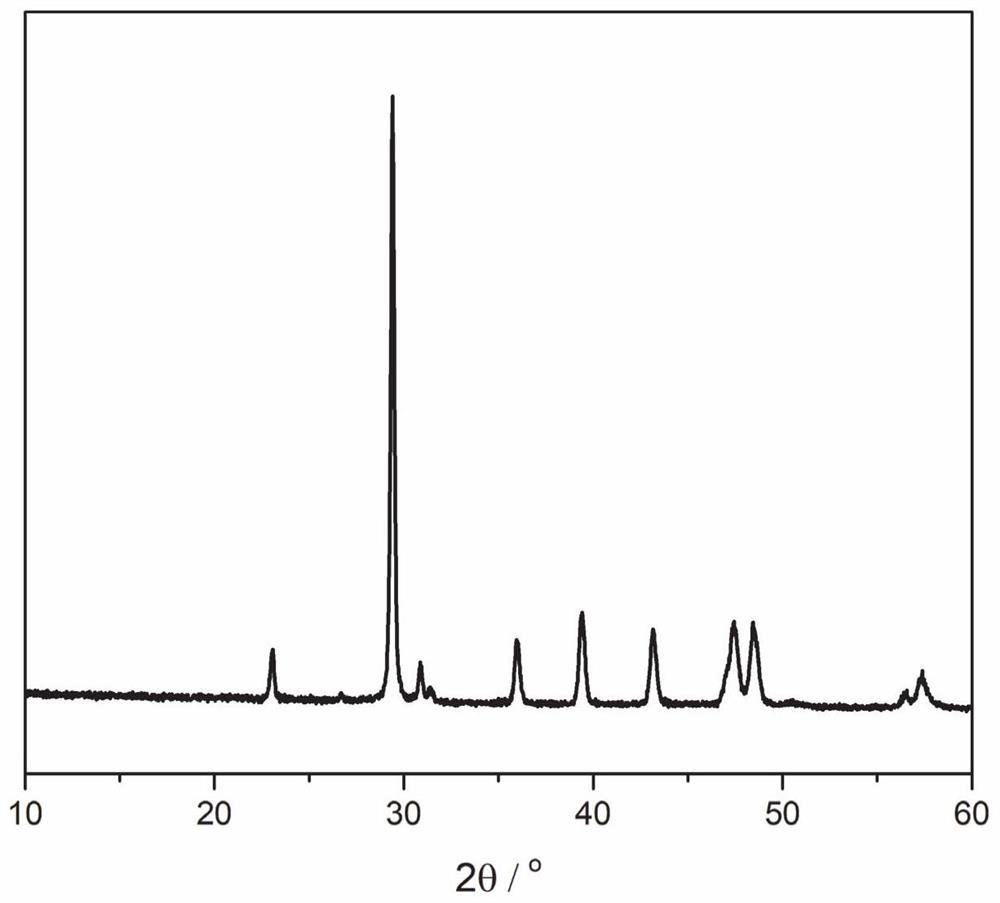

Method for synthesizing calcium carbonate from desulfurized gypsum through solid-phase grinding

InactiveCN113023758ASmall particle sizeHigh purityCalcium/strontium/barium carbonatesSolid carbonFluid phase

The invention relates to a method for synthesizing calcium carbonate from desulfurized gypsum through solid-phase grinding. The method comprises the following steps: step 1, weighing the desulfurized gypsum and a solid carbon source in proportion; step 2, mixing the desulfurized gypsum and the solid carbon source weighed in the step 1, and fully grinding to enable the desulfurized gypsum and the solid carbon source to react, so as to obtain a grinding reaction product after the grinding is completed; and step 3, washing the grinding reaction product obtained in the step 2 with a washing agent, filtering the washing product to remove soluble salt, and drying the residual solid to obtain fine powder calcium carbonate. The overall particle size of the obtained calcium carbonate is 1-5 microns. The method has the beneficial effects that the use of a liquid-phase solvent is reduced to the greatest extent, and unnecessary solvent waste is reduced; the synthesis process is only simple grinding and mixing of primary raw materials, and is more simplified compared with a traditional method; great industrial application prospects are realized; and the obtained product is calcium carbonate which has good crystallinity, small particle size, high purity and a high added value.

Owner:ZHEJIANG ZHENENG TECHN RES INST +1

Anti-aging antibacterial pc/abs blended alloy and preparation method thereof

Owner:STARWAY INTERNATIONAL HOME LIVING CO LTD

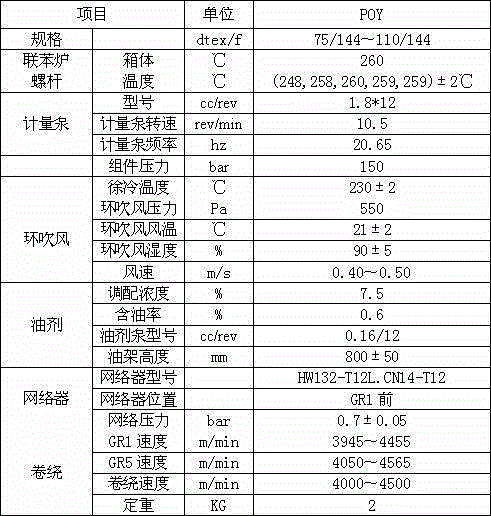

A kind of porous micro-denier nylon 6 pre-oriented yarn, preparation method and equipment thereof

ActiveCN102517679BImproved post-stretch propertiesOptimize production process conditionsArtificial thread manufacturing machinesArtifical filament manufactureYarnMethacrylate

The invention, relating to a melt spinning technique of a high-molecular polymer, provides a porous microfine denier polyamide 6 pre-oriented yarn, its preparation method and device. Random copolymer additive of methacrylate, maleic anhydride and styrene are added in the screw melt extrusion step, and the obtained pre-oriented yarn has the breaking tenacity of 3.20-3.70 cN / dex and the breaking elongation of 60-100 %. According to the invention, a routine FDY device and related production technology conditions are improved, the aggregation structure adjustment, high order orientation, and crystalline supramolecular structure in the stretch forming process of a spinneret are effectively controlled, the melt mixing uniformity and pressure stability are further increased, the winding tensile stress and unevenness of the yarn are effectively adjusted and controlled, and the after-stretching performance of the porous microfine denier polyamide 6 pre-oriented yarn is raised. According to the product provided by the invention, the maximum benefits of the enterprise can be achieved.

Owner:WUJIANG YATAI CHEM TEXTILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com