Sludge drying/pyrolysis/gasification/incineration integrated treatment system

A technology of pyrolysis gasification and treatment system, which is applied in the field of sludge drying, pyrolysis, gasification and incineration integrated treatment system, can solve the problems affecting the combustion of boilers and kilns, large energy consumption, and high operating costs, and achieves trouble-free, High degree of mechanization, good drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

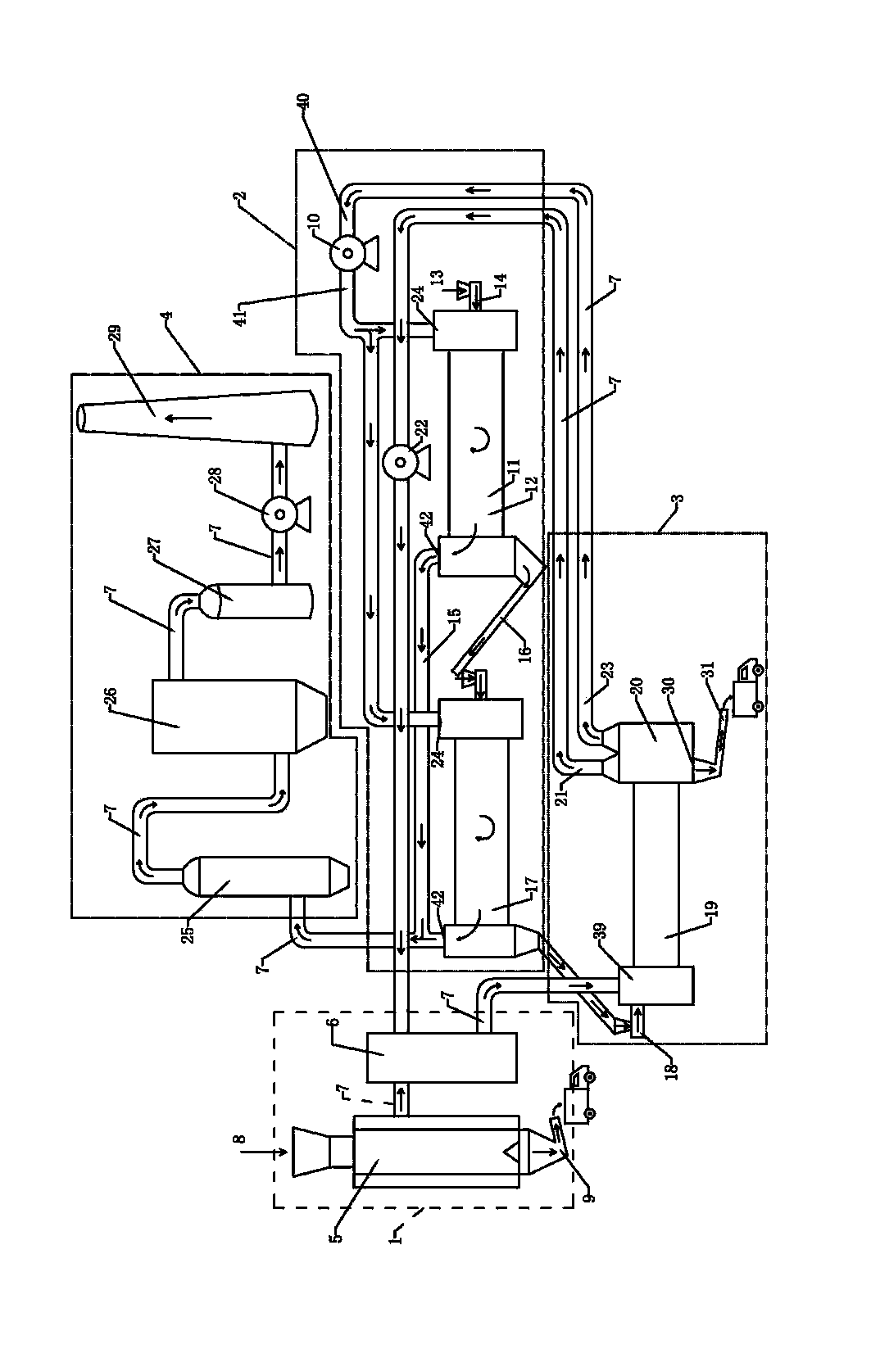

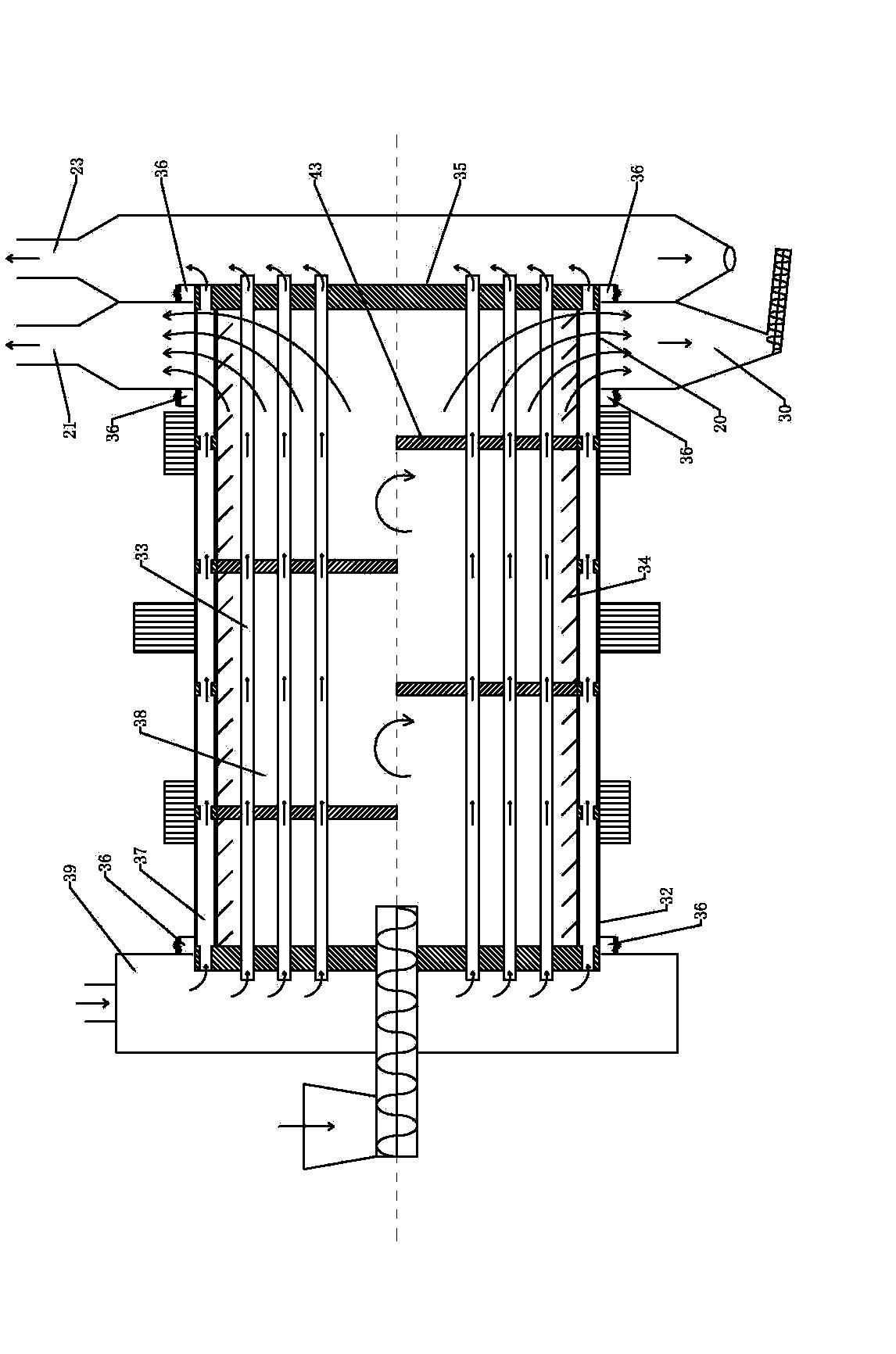

[0014] Embodiment 1: as figure 1 As shown, the sludge drying, pyrolysis, gasification and incineration integrated treatment system includes a combustion system 1, a drying system 2, a pyrolysis gasification system 3 and a flue gas purification system 4, and the combustion system 1 includes a gas generator 5 and an incinerator 6 , the gas generator 5 is connected with the incinerator 6 through the pipeline 7, a coal inlet 8 is provided above the gas generator 5, a cinder conveyor 9 is provided below, and the drying system 2 includes a fan 10 and a 1-5 stage dryer 11, The inlet end 40 of the fan 10 is connected to the flue gas outlet pipe 23, the outlet end 41 of the fan 10 is respectively connected to the inlet ports 24 of the dryers of each stage, and the end of the first stage dryer 12 is provided with a sludge inlet 13 And the sludge conveyor 14, the flue gas outlet 42 of the dryers at all levels is directly connected to the flue gas purification system 4 through the flue ga...

Embodiment 2

[0015] Embodiment 2: The drying system 2 includes a fan 10 and a second-stage dryer 11, and the rest are the same as in Embodiment 1.

Embodiment 3

[0016] Embodiment 3: the flue gas purification system 4 also includes a dioxin processor 27, and the two ends of the dioxin processor 27 are respectively connected with the dust removal desulfurizer 25 and the induced draft fan 28 through the pipeline 7, and the rest are the same as in the embodiment 1 or the embodiment 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com