Anti-aging antimicrobial PC/ABS (polycarbonate/acrylonitrile-butadiene-styrene) blend alloy and preparation method thereof

An anti-aging, mixed gold technology, applied in the field of polymer materials, can solve the problems of limited PC application, high processing temperature, large residual stress, etc., to achieve good social value and experience value, increase added value, and improve the effect of mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

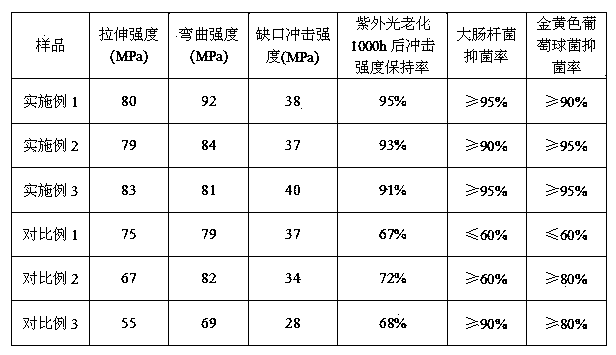

Examples

Embodiment 1

[0019] An aging-resistant and antibacterial PC / ABS blended alloy and a preparation method thereof, the formula consists of:

[0020] High viscosity ABS (5% butadiene, density 1.04 g / cm 3 ) is 12%;

[0021] PC (with a density of 1.18 g / cm 3 , molecular weight is 40000) is 40%;

[0022] Photostable antibacterial agent nano-titanium dioxide (50nm) is 3%;

[0023] UV absorber benzophenones is 2%;

[0024] Light calcium carbonate (particle size is 1um) is 40%;

[0025] Antioxidant 1010 is 1%;

[0026] The compatibilizer ABS-g-MAH is 2%.

[0027] The preparation method of aging-resistant and antibacterial PC / ABS blended alloy is as follows: fully dry high-viscosity ABS, Dow PC, light-stable antibacterial agent, ultraviolet absorber, nanofiller and other additives in an 80°C blast oven, and pass 1000-rpm high-speed mixer stirs evenly; then the raw materials are extruded, granulated, After drying, PC / ABS alloy particles can be obtained.

Embodiment 2

[0029] An aging-resistant and antibacterial PC / ABS blended alloy and a preparation method thereof, the formula consists of:

[0030] High viscosity ABS (6% butadiene, density 1.05 g / cm 3 ) is 20%;

[0031] PC (with a density of 1.19 g / cm 3 , molecular weight is 50000) is 30%;

[0032] Light stable antibacterial agent nano-titanium dioxide (100nm) is 4%;

[0033] UV absorber salicylic acid is 4%;

[0034] Hard calcium carbonate (particle size is 10um) is 40%;

[0035] Antioxidant 168 is 1%;

[0036] The compatibilizer ABS-g-MAH is 1%.

[0037] The preparation method of aging-resistant and antibacterial PC / ABS blended alloy is as follows: fully dry high-viscosity ABS, Dow PC, light-stable antibacterial agent, ultraviolet absorber, nanofiller and other additives in an 80°C blast oven, and pass The high-speed mixer at 2000 rpm stirs evenly; then the raw materials are extruded, granulated, After drying, PC / ABS alloy particles can be obtained.

Embodiment 3

[0039] An aging-resistant and antibacterial PC / ABS blended alloy and a preparation method thereof, the formula consists of:

[0040] High viscosity ABS (butadiene content 7%, density 1.06 g / cm 3 ) is 25%;

[0041] PC (with a density of 1.20 g / cm 3 , molecular weight is 60000) is 50%;

[0042] Photostable antibacterial agent nano-titanium dioxide (200nm) is 3%;

[0043] The ultraviolet absorber benzotriazepine is 4%;

[0044] Nano calcium carbonate (particle size is 100nm) is 15%;

[0045] Antioxidant 264 is 1%;

[0046] The compatibilizer ABS-g-MAH is 2%.

[0047] The preparation method of aging-resistant and antibacterial PC / ABS blended alloy is as follows: fully dry high-viscosity ABS, Dow PC, light-stable antibacterial agent, ultraviolet absorber, nanofiller and other additives in an 80°C blast oven, and pass 3000-rpm high-speed mixer stirs evenly; then the raw materials are extruded, granulated, After drying, PC / ABS alloy particles can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com