Method for treating wastewater in 2-propyl heptanol production device

A technology of propyl heptanol and production equipment, which is applied in the field of wastewater treatment in the production equipment of 2-propyl heptanol, can solve the problems of large load of wastewater treatment plants, and achieve low energy consumption, good treatment effect and good technical effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

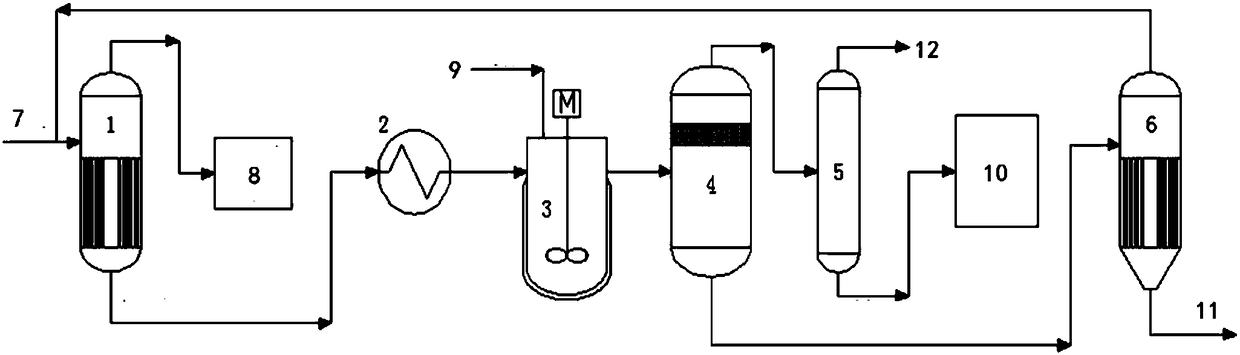

[0022] Waste water treatment method in a kind of 2-propyl heptanol production unit, such as figure 1 Shown, 1000kg / h, 95 ℃ of 2-propylheptanol waste lye wastewater (COD is 30000mg / L, NaOH 1.0wt% in the waste water, sodium pentanoate 4.5wt%, valeraldehyde 0.2wt%, amyl alcohol 0.15 wt%) into the concentration bag equipment, the concentration bag equipment is a multi-effect evaporator, the operating pressure of the evaporator is 0.1bar, the operating temperature is 103°C, the shell side of the evaporator is heated by 3barg low-pressure steam, and the waste water is evaporated and concentrated by self-circulation in the evaporator , 85kg / h of water vapor is evaporated from the top of the evaporator, and after cooling, it becomes water with a COD of 300mg / L and sent to the biochemical treatment plant for treatment; 15kg / h, 103°C concentrated liquid is discharged from the bottom of the evaporator and enters the cooler for cooling To 15°C, the cooled concentrated solution enters the ...

Embodiment 2

[0025] Waste water treatment method in a kind of 2-propyl heptanol production unit, such as figure 1 Shown, 1000kg / h, 95 ℃ of 2-propylheptanol waste lye wastewater (COD is 30000mg / L, NaOH 1.0wt% in the waste water, sodium pentanoate 4.5wt%, valeraldehyde 0.2wt%, amyl alcohol 0.15 wt%) into the concentration bag equipment, the concentration bag equipment is a multi-effect evaporator, the operating pressure of the evaporator is 0.1bar, the operating temperature is 103°C, the shell side of the evaporator is heated by 3barg low-pressure steam, and the waste water is evaporated and concentrated by self-circulation in the evaporator , 85kg / h of water vapor is evaporated from the top of the evaporator, and after cooling, it becomes water with a COD of 300mg / L and sent to the biochemical treatment plant for treatment; 15kg / h, 103°C concentrated liquid is discharged from the bottom of the evaporator and enters the cooler for cooling To 15°C, the cooled concentrated solution enters the ...

Embodiment 3

[0028] Waste water treatment method in a kind of 2-propyl heptanol production unit, such as figure 1Shown, 1000kg / h, 95 DEG C of 2-propylheptanol waste lye wastewater (COD is 50000mg / L, NaOH 1.0wt% in the wastewater, sodium pentanoate 5.1wt%, valeraldehyde 0.2wt%, pentanol 0.15 wt%) into the concentration bag equipment, the concentration bag equipment is a multi-effect evaporator, the operating pressure of the evaporator is 0.1bar, the operating temperature is 104°C, the shell side of the evaporator is heated by 3barg low-pressure steam, and the waste water is evaporated and concentrated by self-circulation in the evaporator , 84kg / h of water vapor is evaporated from the top of the evaporator, and after cooling, it becomes water with a COD of 300mg / L and sent to the biochemical treatment plant for treatment; 16kg / h, 104°C concentrated liquid is discharged from the bottom of the evaporator and enters the cooler for cooling After reaching 60°C, the cooled concentrated solution e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com