Refining process of uracil by sulfuric acid method

A technology of uracil and sulfuric acid method, which is applied in the refining process of uracil by sulfuric acid method, can solve the problems of not meeting high-end applications and export-level requirements, low product yield, and impact on purity, so as to increase product competitiveness, The effect of high product purity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

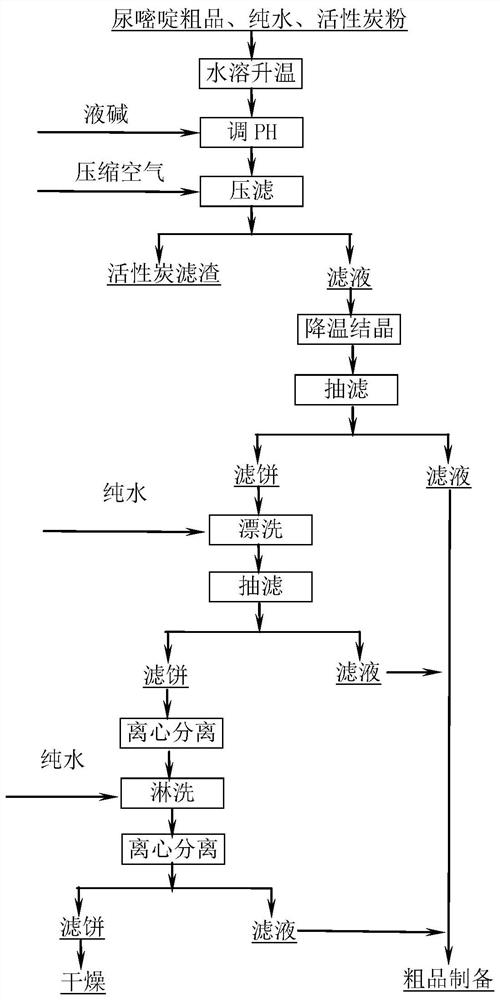

Image

Examples

Embodiment 1

[0019] Present embodiment provides a kind of sulfuric acid method uracil refining method, and its steps comprise:

[0020] Step 1: Add 3,000 kg of pure water, 500 kg of crude uracil, and 25 kg of 200-mesh activated carbon powder into an acid-resistant reactor with a capacity of 5 tons. Under stirring conditions, the water bath is heated to 50°C, and the crude uracil is completely dissolved. Gradually drop liquid caustic soda to adjust pH to 7. The mixed solution is heated to 90°C for filtration, the filter cake is activated carbon, and the filtrate is pumped into a crystallization kettle with a capacity of 5 tons to cool down in a water bath.

[0021] Step 2: Cool the filtrate to 18°C and gradually put it into the suction filtration tank, turn on the vacuum pump for negative pressure suction filtration, turn off the vacuum after the suction filtration, and inject pure water into the suction filtration tank to the liquid level of 2 / 3 of the suction filtration tank, Rotate th...

Embodiment 2

[0024] Present embodiment provides a kind of sulfuric acid method uracil refining method, and its steps comprise:

[0025] Step 1: Add 3,000 kg of pure water, 450 kg of crude uracil, and 20 kg of 150-mesh activated carbon powder into an acid-resistant reactor with a capacity of 5 tons. Under stirring conditions, the water bath is heated to 48°C, and the crude uracil is completely dissolved. Gradually drop liquid caustic soda to adjust pH to 7. The mixed solution is heated to 88°C for filtration, the filter cake is activated carbon, and the filtrate is pumped into a crystallization kettle with a capacity of 5 tons to cool down in a water bath.

[0026] Step 2: Cool the filtrate to 19°C and gradually put it into the suction filtration tank, turn on the vacuum pump for negative pressure suction filtration, turn off the vacuum after the suction filtration, inject pure water into the suction filtration tank to the liquid level of 2 / 3 of the suction filtration tank, Rotate the stir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com