Method for synthesizing calcium carbonate from desulfurized gypsum through solid-phase grinding

A desulfurization gypsum and solid-phase grinding technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problems of solvent waste, high energy consumption cost, cumbersome process, etc., and achieve the effects of reducing solvent waste, good crystallinity, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 5g of desulfurized gypsum, assuming its main component is CaSO 4 2H 2 O mass fraction is 90%, reactant CaSO 4 2H 2 The molar ratio of O to sodium carbonate was 0.80 for feeding. The solid raw materials are weighed and poured into a mortar, fully ground and mixed for 40 minutes. The reaction product was ground, washed with deionized water, filtered to remove soluble salts, and the remaining solid was dried in hot air at 70°C to obtain the final product fine powder calcium carbonate.

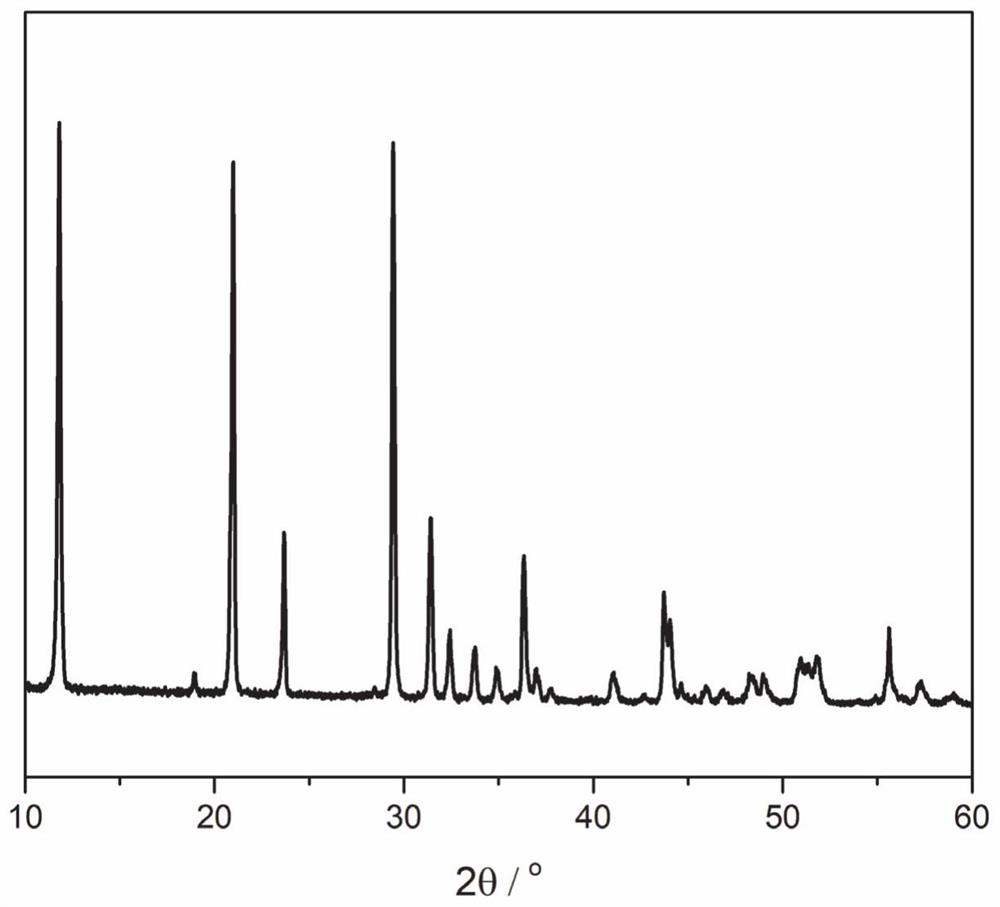

[0027] The XRD characterization results of the raw material desulfurized gypsum are as follows: figure 1 As shown, the main component of raw material desulfurization gypsum is CaSO 4 2H 2 O.

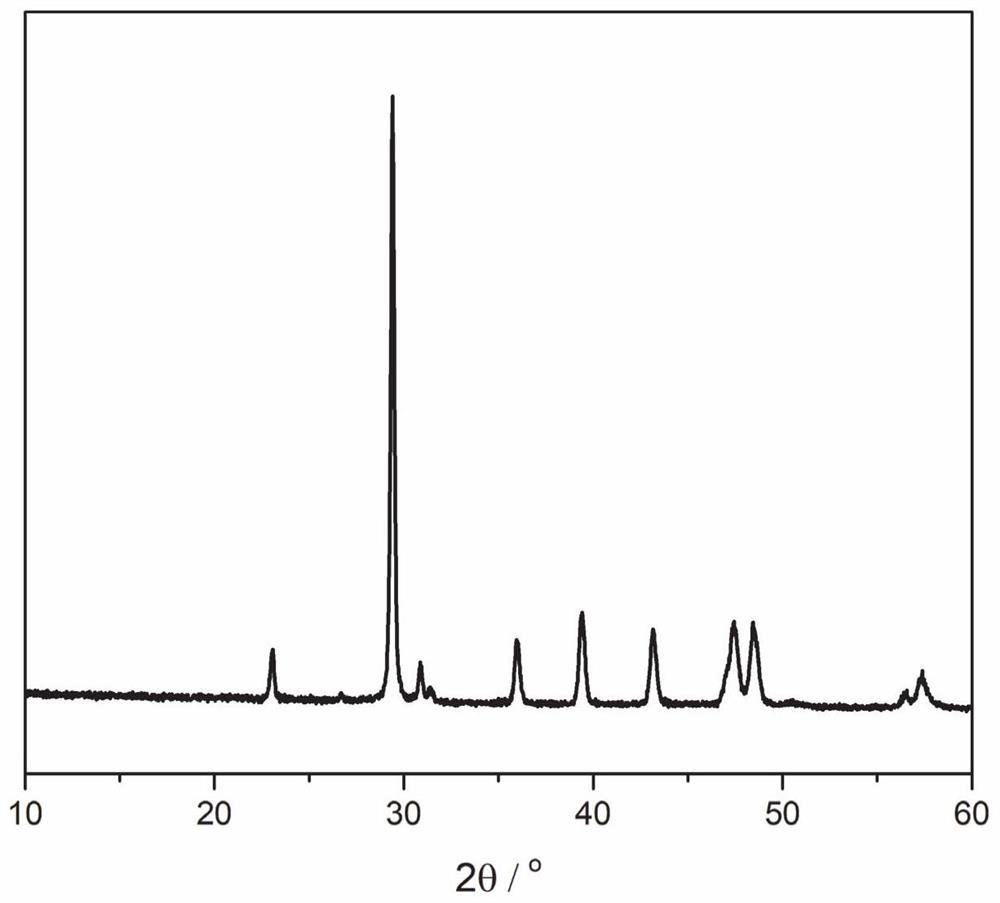

[0028] The product is CaCO 3 ,Such as figure 2 As shown, the XRD characterization results have no other miscellaneous peaks, indicating that the CaCO prepared in this example 3 Higher purity and better crystallinity.

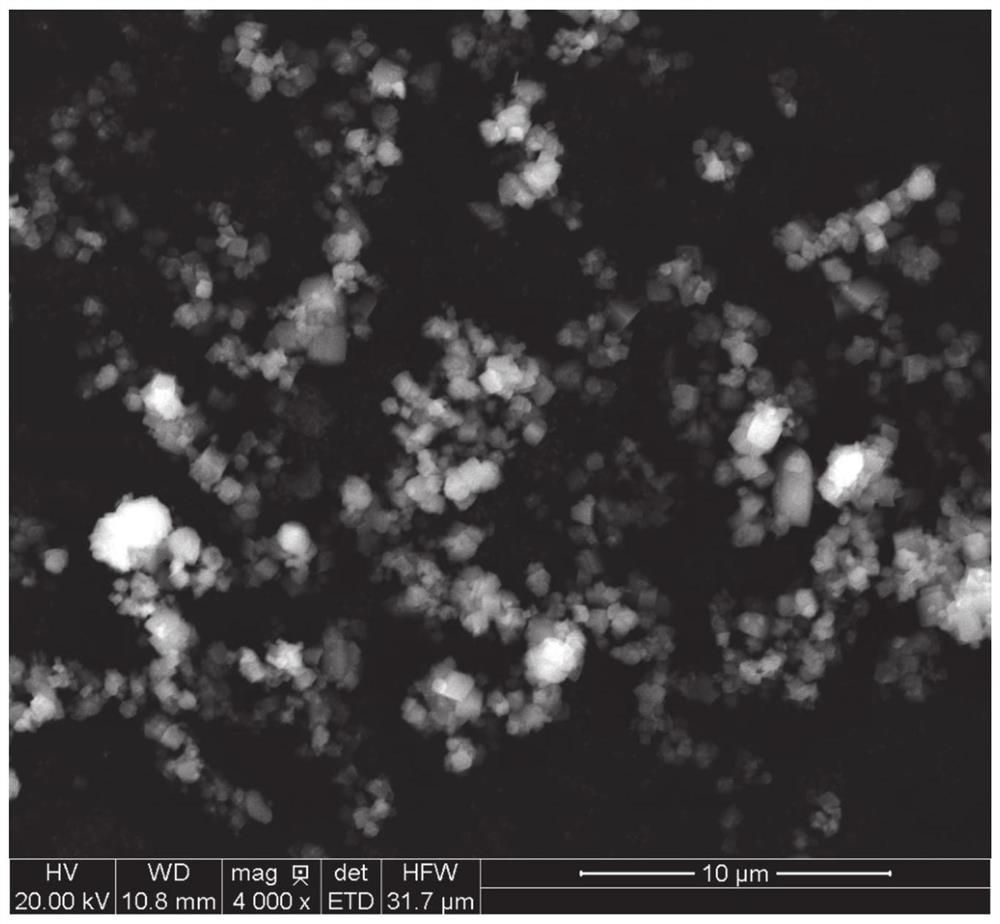

[0029] image 3 with Figure 4 All are scanning electron microg...

Embodiment 2

[0031] Weigh 5g of desulfurized gypsum, assuming its main component is CaSO 4 2H 2 O mass fraction is 90%, reactant CaSO 4 2H 2 The molar ratio of O to sodium carbonate was 0.80 for feeding. The solid raw materials are weighed and poured into a mortar, fully ground and mixed for 60 minutes. The reaction product was ground, washed with deionized water, filtered to remove soluble salts, and the remaining solid was dried in hot air at 70°C to obtain the final product fine powder calcium carbonate. There are no other miscellaneous peaks in XRD, and the overall particle size is below 2 μm.

Embodiment 3

[0033] Weigh 5g of desulfurized gypsum, assuming its main component is CaSO 4 2H 2 O mass fraction is 90%, reactant CaSO 4 2H 2 The molar ratio of O to sodium carbonate was 0.75 for feeding. The solid raw materials are weighed and poured into a mortar, fully ground and mixed for 20 minutes. The reaction product was ground, washed with deionized water, filtered to remove soluble salts, and the remaining solid was dried in hot air at 70°C to obtain the final product fine powder calcium carbonate. There are no other miscellaneous peaks in XRD, and the overall particle size is below 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com