A bamboo fiber and hemp fiber blended fabric

A bamboo fiber and hemp fiber technology, applied in the field of bamboo fiber and hemp fiber blended fabrics, can solve the problems of low added value, unsatisfactory, poor comfort, etc., and achieve the effect of novel functional design, low cost and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

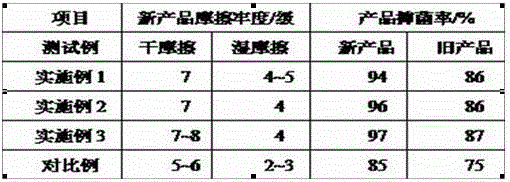

Image

Examples

Embodiment 1

[0030] A kind of bamboo fiber and hemp fiber blended fabric is obtained by blending raw materials in the following weight ratios:

[0031] Bamboo fiber 90%

[0032] Hemp fiber 3%

[0033] Flax fiber 2%

[0034] Ramie fiber 2%

[0035] Jute fiber 1%

[0036] Apocynum fiber 2%.

[0037] A preparation method of bamboo fiber and hemp fiber blended cloth, comprising the steps of:

[0038] (1) Take 90% of bamboo fiber, 3% of hemp fiber, 2% of flax fiber, 2% of ramie fiber, 1% of jute fiber and 2% of apocynum fiber by weight, and carry out blending to obtain a blended product;

[0039] (2) Dissolve chitosan in 0.8% acetic acid solution at a concentration of 0.5%, sonicate until completely dissolved without air bubbles, soak the blended product in the chitosan solution for 15 minutes, take it out and dry it;

[0040] (3) Immerse the blended fabric in the compound enzyme preparation, the dosage is 0.8% owf, the pH is 7.8, the temperature is 45°C, keep warm for 40 minutes, raise t...

Embodiment 2

[0049] A kind of bamboo fiber and hemp fiber blended fabric is obtained by blending raw materials in the following weight ratios:

[0050] Bamboo fiber 90%

[0051] Hemp fiber 3%

[0052] Flax fiber 2%

[0053] Ramie fiber 2%

[0054] Jute fiber 1%

[0055] Apocynum fiber 2%.

[0056] A preparation method of bamboo fiber and hemp fiber blended cloth, comprising the steps of:

[0057] (1) Take 90% of bamboo fiber, 3% of hemp fiber, 2% of flax fiber, 2% of ramie fiber, 1% of jute fiber and 2% of apocynum fiber by weight, and carry out blending to obtain a blended product;

[0058] (2) Dissolve chitosan in 0.8% acetic acid solution at a concentration of 0.5%, sonicate until completely dissolved without air bubbles, soak the blended product in the chitosan solution for 17 minutes, take it out and dry it;

[0059] (3) Immerse the blended fabric in the compound enzyme preparation, the dosage is 1% owf, the pH is 7.8, the temperature is 45°C, keep warm for 40 minutes, raise the...

Embodiment 3

[0068] A kind of bamboo fiber and hemp fiber blended fabric is obtained by blending raw materials in the following weight ratios:

[0069] Bamboo fiber 90%

[0070] Hemp fiber 3%

[0071] Flax fiber 2%

[0072] Ramie fiber 2%

[0073] Jute fiber 1%

[0074] Apocynum fiber 2%.

[0075] A preparation method of bamboo fiber and hemp fiber blended cloth, comprising the steps of:

[0076] (1) Take 90% of bamboo fiber, 3% of hemp fiber, 2% of flax fiber, 2% of ramie fiber, 1% of jute fiber and 2% of apocynum fiber by weight, and carry out blending to obtain a blended product;

[0077] (2) Dissolve chitosan in 0.8% acetic acid solution at a concentration of 0.5%, sonicate until completely dissolved without air bubbles, soak the blended product in the chitosan solution for 20 minutes, take it out and dry it;

[0078] (3) Immerse the blended fabric in the compound enzyme preparation, the dosage is 1.2%owf, the pH is 7.8, the temperature is 45°C, keep warm for 40 minutes, raise th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com