High-entropy alloy reinforced nickel-aluminum composite material spherical powder for 3D printing and preparation method of high-entropy alloy reinforced nickel-aluminum composite material spherical powder

A high-entropy alloy and 3D printing technology, applied in additive processing, metal processing equipment, additive manufacturing, etc., can solve problems such as high cost, complicated process, and difficult quality assurance, and achieve high added value, improved plasticity, and a good market foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

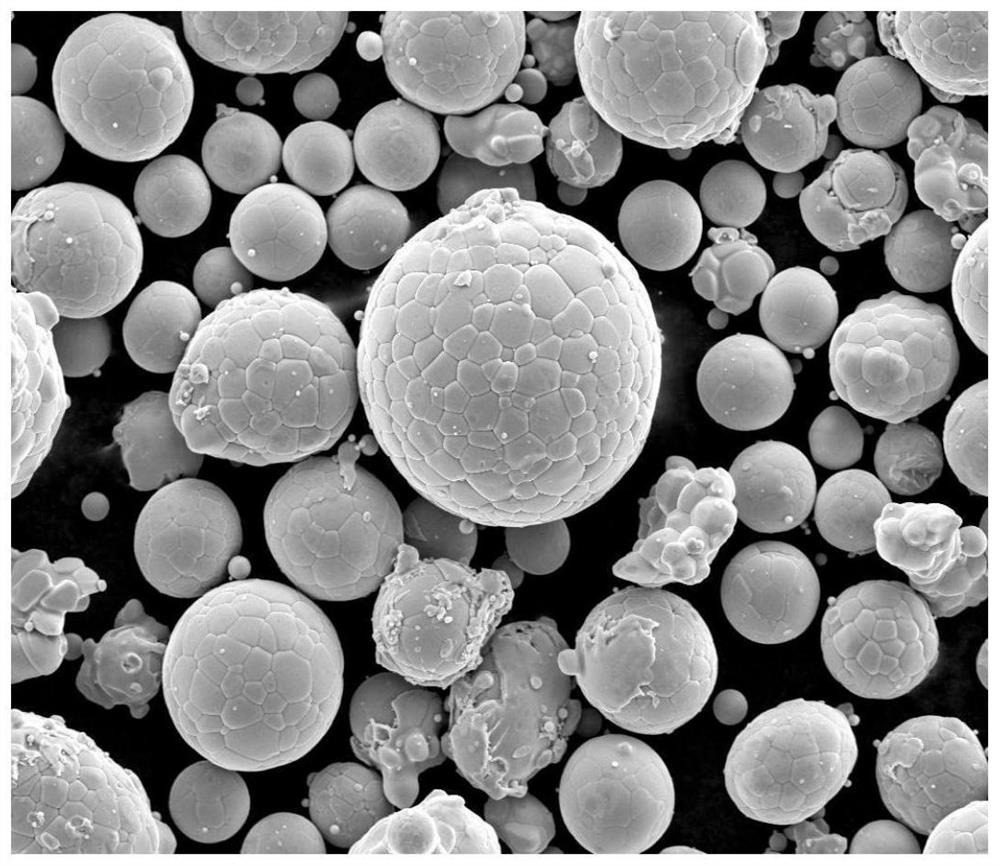

Image

Examples

preparation example Construction

[0024] A preparation method for high-entropy alloy reinforced nickel-aluminum composite material spherical powder for 3D printing, comprising the following steps:

[0025] A. After cleaning the surface of chromium, manganese, iron, cobalt and nickel elemental metals, put them into the crucible with induction coil in proportion;

[0026] B. Vacuumize the high-frequency induction melting furnace;

[0027] C. Under vacuum protection, turn on the copper coil of the high-frequency induction power supply to heat the metal in the crucible, and the current intensity is 80-90A. After it is completely melted, pour it into the tundish to make the alloy solution fall evenly;

[0028] D. After the first droplet falls, open the argon gas valve, and the liquid will become small droplets under the action of high-pressure gas, and solidify into solid particles;

[0029] E. Clean up the crucible, then clean the surface of the nickel and aluminum elemental metals, put them into the crucible wit...

Embodiment 1

[0039] Using this method to prepare CrMnFeCoNi reinforced NiAl spherical powder

[0040] Prepare CrMnFeCoNi reinforced NiAl spherical powder according to the following steps:

[0041] A, surface treated, chromium, manganese, iron, cobalt, nickel simple substance are put into the crucible with induction coil, each metal atomic ratio is 20%: 20%: 20%: 20%: 20%;

[0042] B. Vacuum the high-frequency induction melting furnace equipment, and the vacuum degree is 4.5×10 -3 Pa;

[0043] C. Under vacuum protection, turn on the copper coil of the high-frequency induction power supply to heat the raw materials. The current intensity is stabilized at 80A from 20A, 30A, 40A, 50A, and 60A. After it is completely melted, pour it into the tundish to make the alloy solution fall evenly. ;

[0044] D. After the first droplet falls, open the argon gas valve, and the liquid will become small droplets under the action of high-pressure gas, and solidify into solid particles;

[0045] E, after ...

Embodiment 2

[0049] Using this method to prepare Cr25Mn25Fe20Co15Ni15 reinforced Ni3Al spherical powder

[0050] Prepare Cr25Mn25Fe20Co15Ni15 reinforced Ni3Al spherical powder according to the following steps:

[0051] A, surface treated, chromium, manganese, iron, cobalt, nickel simple substance are put into the crucible with induction coil, each metal atomic ratio is 25%: 25%: 20%: 15%: 15%;

[0052] B. Vacuum the equipment with a vacuum degree of 4.5×10 -3 Pa;

[0053] C. Under vacuum protection, turn on the high-frequency induction power supply copper coil to heat the raw materials. The current intensity is stabilized at 90A from 20A, 30A, 40A, 50A, and 60A. After it is completely melted, pour it into the tundish to make the alloy solution fall evenly. ;

[0054] D. After the first droplet falls, open the argon gas valve, and the liquid will become small droplets under the action of high-pressure gas, and solidify into solid particles;

[0055] E, after nickel, aluminum elemental m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com