High-performance artificial sand concrete prepared by using mountain flour and rice hull ash as admixture

A technology of concrete and artificial sand, applied in the field of building materials, to achieve the effects of cheap and easy raw materials, increased utilization and added value, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

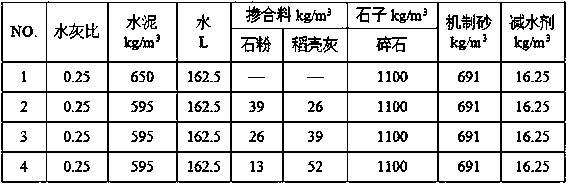

[0030] The preparation of the four kinds of concrete, the ratio of the raw materials used are shown in Table 1.

[0031] Raw material ratio of concrete in Table 1 4

[0032]

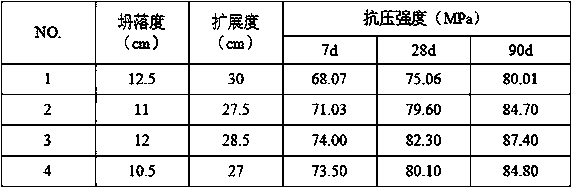

[0033] Test the working performance and compressive strength of the concrete in the above 4, and the results are shown in Table 2.

[0034] Table 2 Work performance and compressive strength of four kinds of concrete

[0035]

[0036] It can be seen from Table 1 and Table 2 that the first group is compared with the data of the second, third, and fourth groups, and it can be seen that when the mixed admixture is used to replace 10% of the cement in the concrete, the workability and compressive strength of the concrete prepared are excellent. Concrete made from pure cement. From the comparison between the data of the 2nd, 3rd, and 4th groups, it can be seen that when the mass ratio of stone powder and rice husk ash in the mixed admixture is 1:1.5, the working performance and compressive strength of ...

Embodiment 2

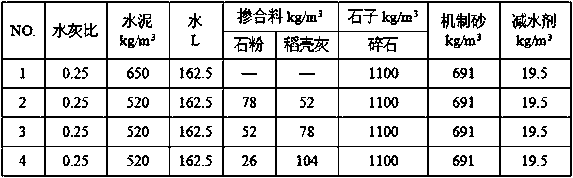

[0039] The ratio of the admixture in Example 1 was changed from 10% to 20%, and the consumption of other raw materials was unchanged, and the concrete in Preparation 4 was shown in Table 3 for the consumption of each raw material.

[0040] Table 3 Raw material ratio of 4 kinds of concrete

[0041]

[0042] Test the working performance and compressive strength of the concrete in the above 4, and the results are shown in Table 4.

[0043] Table 4 Work performance and compressive strength of 4 kinds of concrete

[0044]

[0045] It can be seen from Table 3 and Table 4 that the first group is compared with the data of the second, third and fourth groups, and it can be seen that when the mixed admixture is used to replace 20% of the cement in the concrete, the workability and compressive strength of the concrete prepared are excellent. Concrete made from pure cement. From the comparison between the data of the 2nd, 3rd, and 4th groups, it can be seen that when the mass ratio ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com