Method for producing high-magnetic-induction non-oriented silicon steel 50BW800G through normalizing-free heat treatment

A 50BW800G, grain-oriented silicon steel technology, applied in the field of material processing, can solve the problems of improving the electromagnetic properties, unable to normalize the annealing of hot-rolled raw material coils, etc., and achieve the effect of increasing added value, good electromagnetic properties, and satisfactory electromagnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

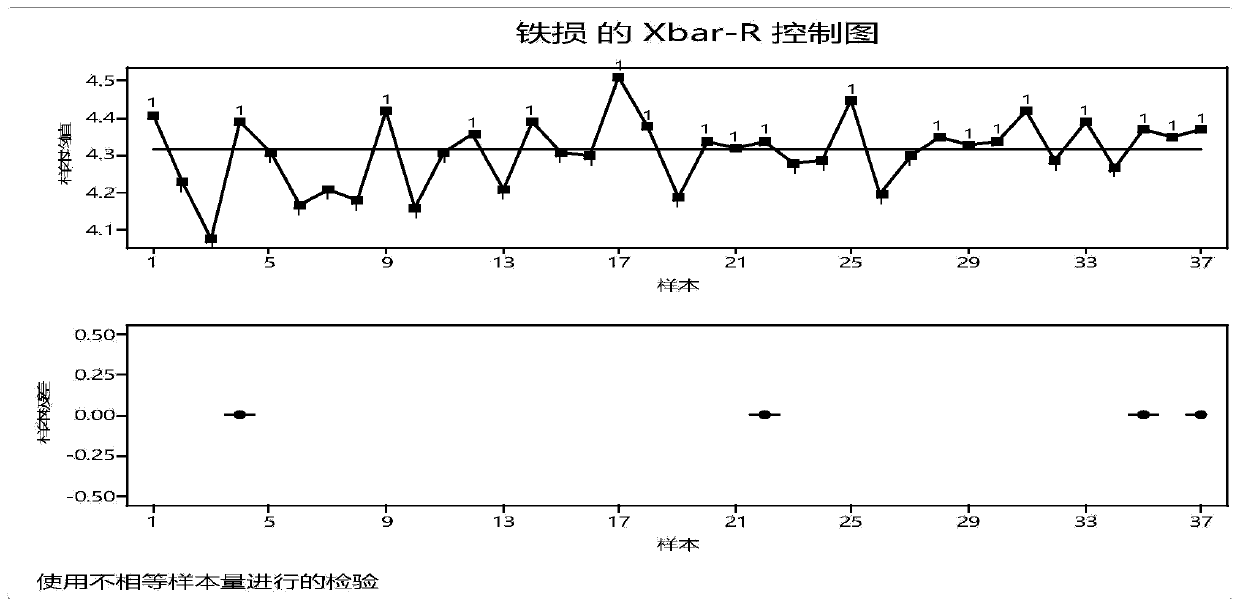

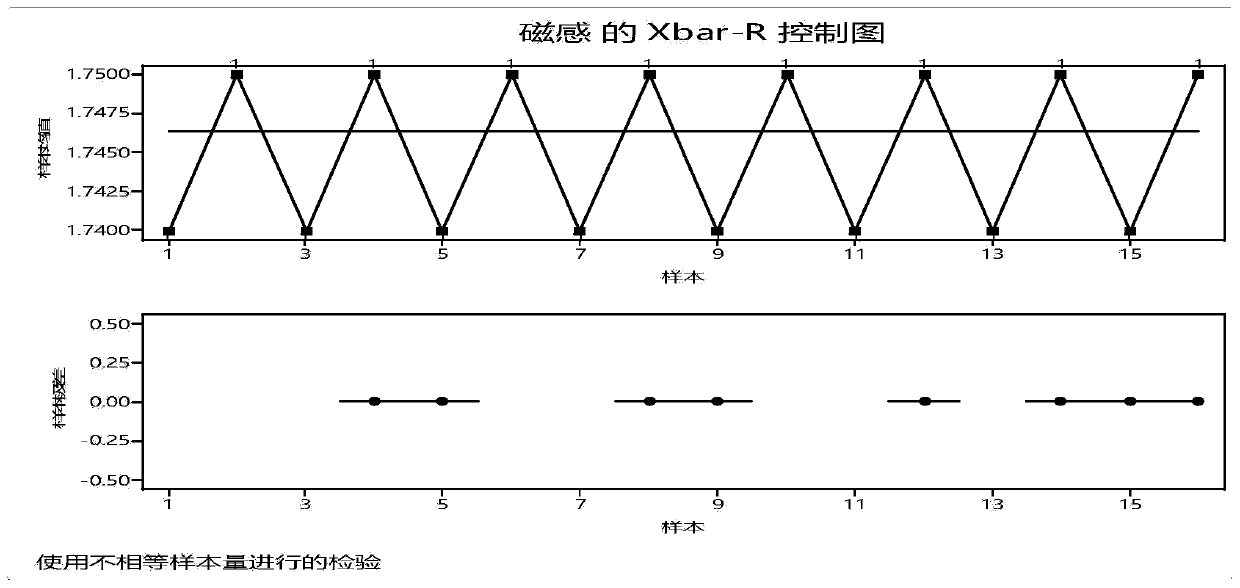

Image

Examples

Embodiment 1

[0030] The invention provides a method for producing high magnetic induction non-oriented silicon steel 50BW800G by anomalous heat treatment, comprising the following steps:

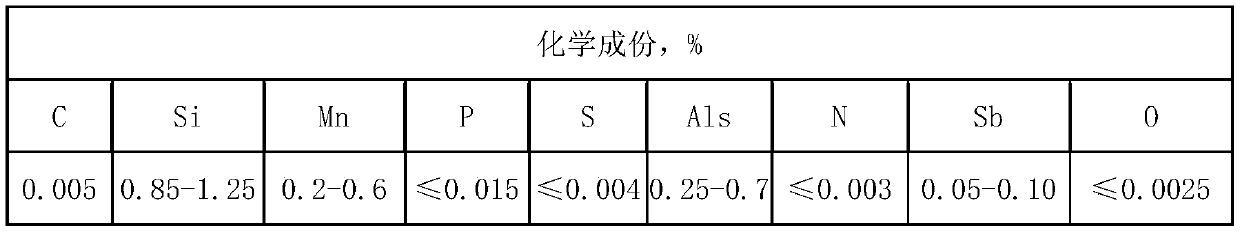

[0031] Step 1) Steel composition design:

[0032] The composition of the steel used is shown in the following table according to weight percentage:

[0033]

[0034] Compared with ordinary 50BW800 products, the alloying element Sb is added, and the rest of the ingredients are the same.

[0035] Step 2) hot rolling production:

[0036] The molten steel is made into a slab with a thickness of 70-85mm through the FTSR continuous casting machine. The slab adopts a low-temperature heating process, and the heating temperature is ≤1100°C; it can reduce the solid solution of inclusions such as MnS and AlN in the steel; after 7 racks of heating A hot-rolled steel plate with a thickness of 2.55mm was rolled. The final rolling temperature was controlled at 900°C and the coiling temperature was controlled at 72...

Embodiment 2

[0040] The invention provides a method for producing high magnetic induction non-oriented silicon steel 50BW800G by anomalous heat treatment, comprising the following steps:

[0041] Step 1) Optimizing steel composition:

[0042] The composition of the steel used is shown in the following table according to weight percentage:

[0043]

[0044] Compared with ordinary 50BW800 products, the alloying element Sb is added, and the rest of the ingredients are the same.

[0045] Step 2) hot rolling production:

[0046] The molten steel is made into a slab with a thickness of 70-85mm through the FTSR continuous casting machine. The slab adopts a low-temperature heating process, and the heating temperature is ≤1100°C; it can reduce the solid solution of inclusions such as MnS and AlN in the steel; after 7 racks of heating A hot-rolled steel plate with a thickness of 2.55mm was rolled. The final rolling temperature was controlled at 890°C, and the coiling temperature was controlled ...

Embodiment 3

[0050] The invention provides a method for producing high magnetic induction non-oriented silicon steel 50BW800 by non-normalized heat treatment, comprising the following steps:

[0051] Step 1) Steel composition design:

[0052] The composition of the steel used is shown in the following table according to weight percentage:

[0053]

[0054] The rest is Fe and unavoidable impurities. Compared with ordinary 50BW800 products, the alloying element Sb is added, and the rest of the ingredients are the same.

[0055] Step 2) hot rolling production:

[0056] The molten steel is made into a slab with a thickness of 70-85mm through the FTSR continuous casting machine. The slab adopts a low-temperature heating process, and the heating temperature is ≤1100°C; it can reduce the solid solution of inclusions such as MnS and AlN in the steel; after 7 racks of heating A hot-rolled steel plate with a thickness of 2.55mm was rolled, the final rolling temperature was controlled at 910°C,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com