3D printing preparation method of skin tissue engineering scaffold and in vitro cell toxicity testing method of the same

A technology for skin tissue engineering and tissue engineering scaffolds, applied in the field of preparation of high-strength materials, can solve problems such as poor biocompatibility, poor mechanical properties, and fast degradation speed, and achieve good mechanical properties, simple operation, and good air permeability. and absorbent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of dialdehyde-based nanocellulose (DAC): The mass ratio of CNC to sodium periodate is 1:1, react in the dark at 40°C for 6 hours, and then centrifuge and dialyze until the free ions in the solution are completely removed ;

[0033] (2) Preparation of gelatin solution: add gelatin to phosphate buffered solution (PBS), and keep stirring until the gelatin is completely dissolved;

[0034] (3) Preparation of dialdehyde-based nanocellulose (DAC) / gelatin (GEL) composite hydrogel: blend 4% DAC solution and 4% GEL solution at a volume ratio of 1:1, rapidly After stirring evenly, incubate at 37°C for 2 hours;

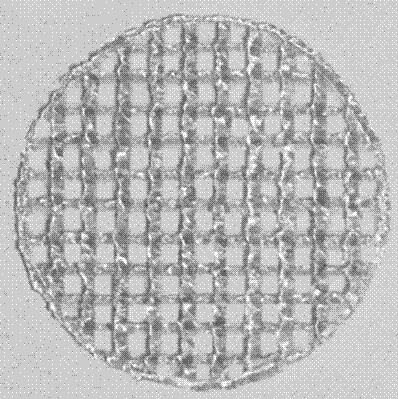

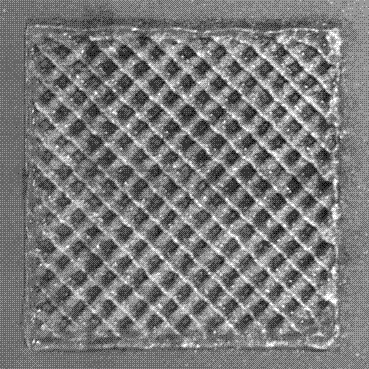

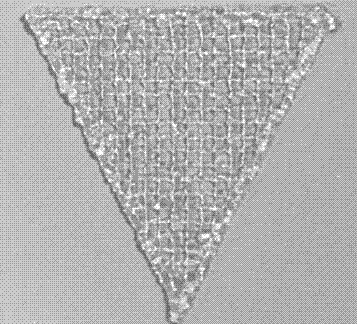

[0035] (4) Printing of 3D tissue engineering scaffolds: DAC / GEL hydrogel is loaded into the barrel, the barrel temperature is 10°C, the platform temperature is 5°C, the needle diameter is 200μm, the extrusion pressure is 0.1Mpa, and the nozzle travel speed is 15mm / S, complete the 3D printing of the tissue engineering scaffold.

Embodiment 2

[0037] (1) Preparation of dialdehyde-based nanocellulose (DAC): The mass ratio of CNC to sodium periodate is 1:2, react in the dark at 40°C for 4 hours, and then centrifuge and dialyze until the free ions in the solution are completely removed ;

[0038] (2) Preparation of gelatin solution: add gelatin to phosphate buffered solution (PBS), and keep stirring until the gelatin is completely dissolved;

[0039] (3) Preparation of dialdehyde-based nanocellulose (DAC) / gelatin (GEL) composite hydrogel: blend a 5% DAC solution with a 5% GEL solution at a volume ratio of 4:6, rapidly After stirring evenly, incubate at 37°C for 3 hours;

[0040](4) Printing of 3D tissue engineering scaffolds: DAC / GEL hydrogel is loaded into the barrel, the barrel temperature is 8°C, the platform temperature is 8°C, the needle diameter is 220μm, the extrusion pressure is 0.15Mpa, and the nozzle travel speed is 20mm / S, complete the 3D printing of the tissue engineering scaffold.

Embodiment 3

[0042] (1) Preparation of dialdehyde-based nanocellulose (DAC): The mass ratio of CNC to sodium periodate is 1:2, react in the dark at 40°C for 5 hours, and then centrifuge and dialyze until the free ions in the solution are completely removed ;

[0043] (2) Preparation of gelatin solution: add gelatin to phosphate buffered solution (PBS), and keep stirring until the gelatin is completely dissolved;

[0044] (3) Preparation of dialdehyde-based nanocellulose (DAC) / gelatin (GEL) composite hydrogel: blend a 5% DAC solution with a 5% GEL solution at a volume ratio of 6:4, rapidly After stirring evenly, incubate at 30°C for 4 hours;

[0045] (4) Printing of 3D tissue engineering scaffolds: DAC / GEL hydrogel is loaded into the barrel, the barrel temperature is 15°C, the platform temperature is 5°C, the needle diameter is 220μm, the extrusion pressure is 0.25Mpa, and the nozzle travel speed is 30mm / S, complete the 3D printing of the tissue engineering scaffold.

[0046] 4. Embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com