Method for producing aluminum-free steel grade of cold milling non-oriented silicon steel

A technology of oriented silicon steel, aluminum-free steel, applied in metal rolling, program control in sequence/logic controller, electrical program control, etc., can solve the problem of incomplete deoxidization, resistance, fluctuation of rolling stability, and increase of inclusions and other problems, to achieve great economic and social benefits, reduce quality and cost losses, and achieve excellent electromagnetic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The chemical composition and weight percentage of steel are:

[0019] C 0.0015%, Si 0.573%, Mn 0.345%, P 0.0386%, S 0.0048%, Als 0.0010%, N 0.0018%, Ti 0.001%, Nb, V ≤ 0.0020%, respectively. The rest are inevitable impurities.

[0020] Converter smelting, strictly control the residual aluminum brought in during the alloying process of deoxidized aluminum, auxiliary materials and refractory materials. It adopts RH vacuum refining treatment, and the refining and deoxidation process adopts silicon deoxidation. The molten steel is cast into continuous casting billets by continuous casting.

[0021] For hot rolling, low temperature heating is adopted, and the heating temperature of the billet is 1080°C; for finishing rolling, temperature-controlled rolling is performed, the rolling temperature is 1030°C, the final rolling temperature is 860°C, and the coiling temperature is 693°C.

[0022] Cold rolling, using continuous rolling method to roll into finished strip with thic...

Embodiment 2

[0025] The chemical composition and weight percentage of steel are:

[0026] C 0.0020%, Si 0.85%, Mn 0.44%, P 0.037%, S 0.0052%, Als 0.0005%, N 0.0010%, Ti 0.0009%, Nb, V ≤ 0.0020%, respectively. The rest are inevitable impurities.

[0027] Converter smelting and RH vacuum refining treatment, refining and deoxidation process using silicon deoxidation and cast into continuous casting billets.

[0028] The heating temperature of the hot-rolled billet is 1150°C; the opening temperature of the finishing rolling is 1030°C, the final rolling temperature is 890°C, and the coiling temperature is 697°C.

[0029] Cold rolling, using continuous rolling method to roll into finished strip with thickness of 0.5mm at one time.

[0030] Annealing and cold rolling use continuous annealing furnace wet hydrogen decarburization annealing, coating insulation layer and other processes to make aluminum-free cold-rolled non-oriented silicon steel.

Embodiment 3

[0032] The chemical composition and weight percentage of steel are:

[0033] C 0.0010%, Si 1.15%, Mn 0.62%, P 0.0274%, S 0.0037%, Als 0.0008%, N 0.0016%, Ti 0.0019%, Nb, V ≤ 0.0020%, respectively. The rest are inevitable impurities.

[0034] Converter smelting and RH vacuum refining treatment, refining and deoxidation process using silicon deoxidation and cast into continuous casting billets.

[0035] The heating temperature of the hot-rolled billet is 1100°C; the opening temperature of the finishing rolling is 1010°C, the final rolling temperature is 870°C, and the coiling temperature is 690°C.

[0036] Cold rolling, using continuous rolling method to roll into finished strip with thickness of 0.5mm at one time.

[0037] Annealing and cold rolling use continuous annealing furnace wet hydrogen decarburization annealing, coating insulation layer and other processes to make aluminum-free cold-rolled non-oriented silicon steel.

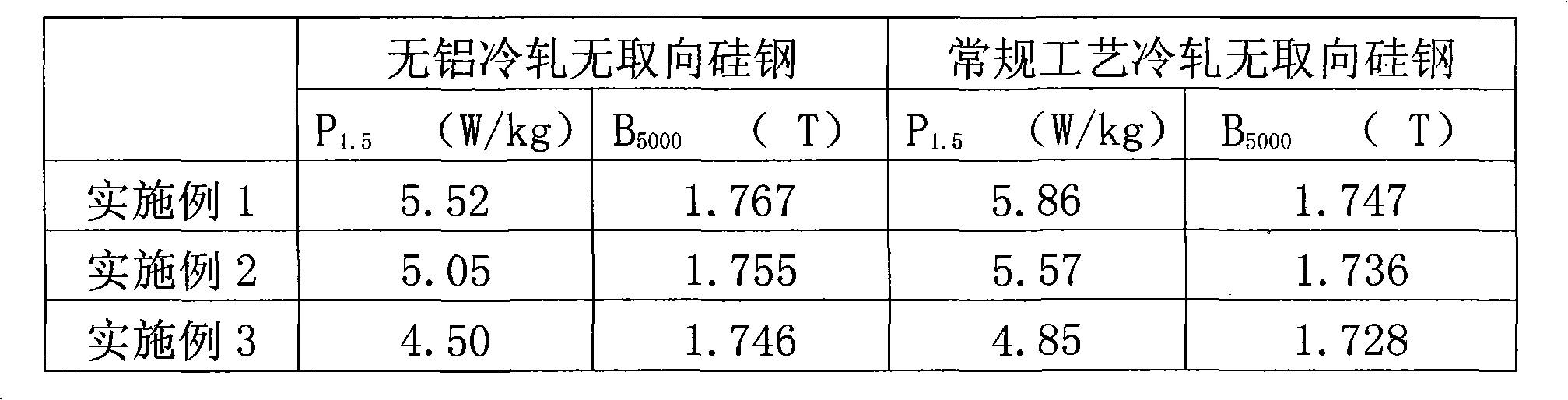

[0038] The electromagnetic properties of the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com