High-performance Halbach type permanent magnet rotor used for flywheel energy storage system

A flywheel energy storage and permanent magnet rotor technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit, control mechanical energy, etc., can solve the problems that limit the performance improvement and utilization rate of permanent magnets, reduce the weight of the rotor, increase the permanent magnet Effect of magnetomotive force and eddy current elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

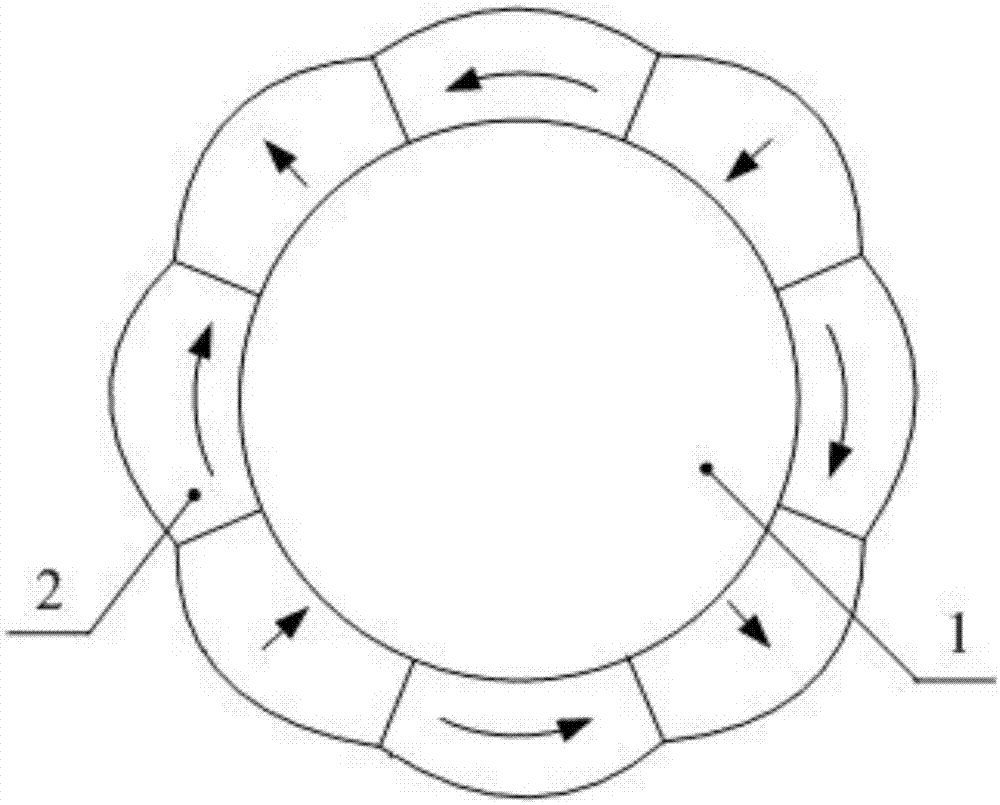

[0017] Such as figure 1 As shown, a high-performance Halbach-type permanent magnet rotor used in a flywheel energy storage system includes a circumferentially magnetized permanent magnet block 2 and a radially charged permanent magnet block 2 and a rotor shaft 1; the circumferential and radially charged Magnetic permanent magnet blocks 2 are staggered, and the magnetization direction changes at 90° to form a permanent magnet array; the permanent magnet array is surface-mounted on the outer wall of the rotor shaft 1 to form a permanent magnet inner rotor structure, and the three-phase stator winding is placed on the permanent magnet outside of the inner rotor.

[0018] The bottom of the permanent magnet block 2 magnetized in the circumferential direction and the permanent magnet block 2 magnetized in the radial direction is in the shape of an arc, and the arc diameter at the bottom of each permanent magnet block 2 is less than the diameter of the rotor shaft 1, and the permanen...

Embodiment 2

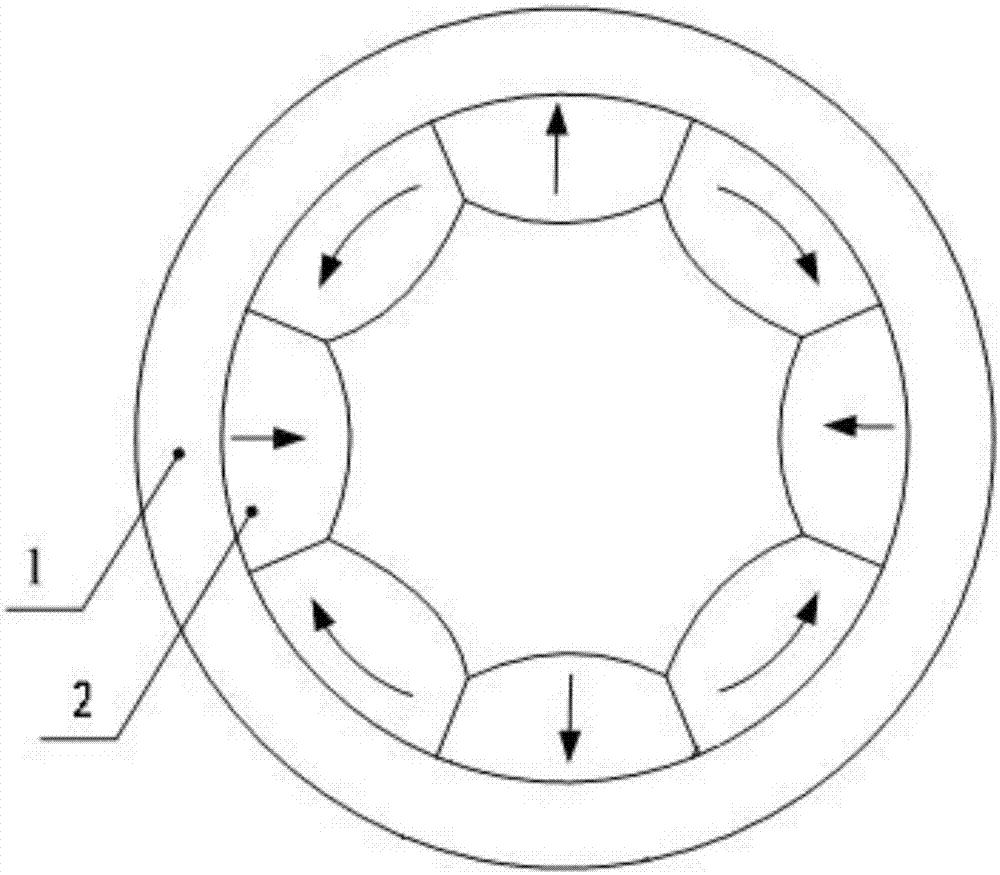

[0021] Such as figure 2 As shown, a high-performance Halbach-type permanent magnet rotor used in a flywheel energy storage system includes a permanent magnet block 2 magnetized in the circumferential direction, a permanent magnet block 2 magnetized in the radial direction and a hollow rotor shaft 1; where the circumferential direction and The radially magnetized permanent magnet blocks 2 are staggered, and the magnetizing direction changes at 90° to form a permanent magnet array; the permanent magnet array is surface-mounted on the inner wall of the hollow rotor shaft 1 to form a permanent magnet outer rotor structure, three-phase stator The windings are placed inside the permanent magnet outer rotor.

[0022] The bottom of the permanent magnet block 2 magnetized in the circumferential direction and the permanent magnet block 2 magnetized in the radial direction is in the shape of an arc, and the arc diameter at the bottom of each permanent magnet block 2 is less than the dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com