Manganese-zinc power ferrite material and element preparation method of manganese-zinc power ferrite material

A manganese-zinc soft magnet and soft ferrite technology, which is applied to magnetic materials, electrical components, and the magnetism of inorganic materials, can solve the problems of component brittleness and difficulty, and achieve improved brittleness, good electromagnetic properties, and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

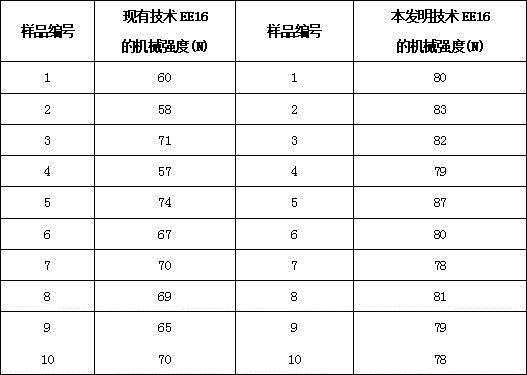

Examples

preparation example Construction

[0023] A preparation method of manganese zinc soft ferrite material as claimed in claim 1, the method steps are as follows:

[0024] (1) Powder manufacturing:

[0025] A. Ingredients: Add the main components into the ball mill in proportion, and mix them evenly with the oxide wet process;

[0026] B. One-time spray granulation: After ball milling, the mixed material that is stirred evenly is added to the spray tower for spray granulation;

[0027] C. Pre-burning: pre-fire the sprayed primary material in a rotary kiln at a temperature of 780°C to 920°C, and the pre-burning time is 45 to 60 minutes. Use an oxygen-enriched environment during pre-firing, and use a blower to introduce air into the kiln to pre-synthesize the main components and increase the degree of magnetization;

[0028] D. Doping: put the calcined material into a sand mill, add a modifier, and carry out sand milling. Pay attention to controlling the particle size of the slurry to 1.2-1.6 μm;

[0029] E. Secon...

Embodiment 1

[0037] A kind of preparation method of manganese zinc soft magnetic ferrite material, the method steps are as follows:

[0038] (1) Powder manufacturing:

[0039] A. Ingredients: The main components are added into the ball mill and uniformly mixed by oxide wet process. The main components are composed of 52.3% Fe2O3, 6.8mol% ZnO and the balance of Mn3O4. The content of the main components is 100mol%.

[0040] B. One-time spray granulation: After the ball is milled, the evenly stirred mixture is added to the spray tower for spray granulation.

[0041] C. Pre-burning: pre-fire the sprayed primary material at a temperature of 850°C in a rotary kiln, and the pre-burning time is 45 minutes. During pre-firing, blow air into the kiln with a blower to pre-synthesize the main components and increase the degree of magnetization as much as possible.

[0042] D. Doping: Put the calcined material into a sand mill, add a modifier, and carry out sand milling. Pay attention to controlling t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com