Silicon steel magnetic powder core and preparation method therefor

A magnetic powder core and silicon steel technology, which is applied in the field of metal magnetic powder cores, can solve problems such as unfavorable large-scale preparation, and achieve the effect of comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

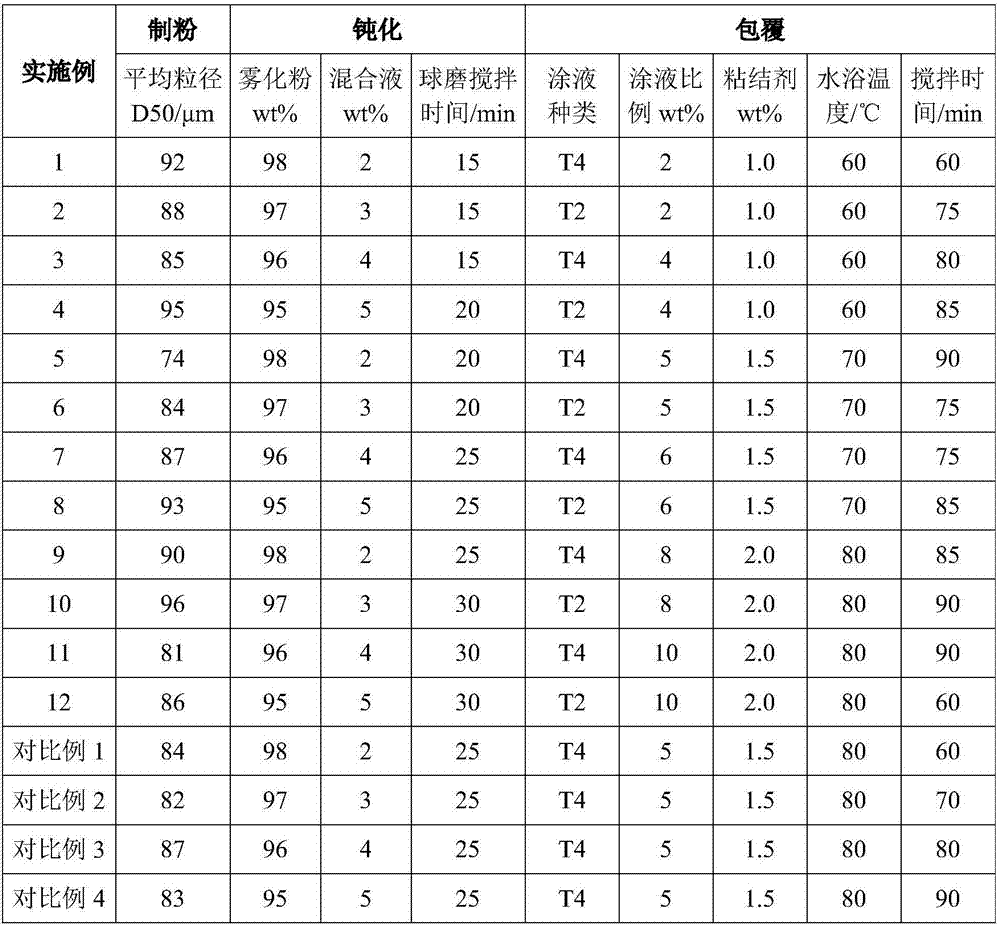

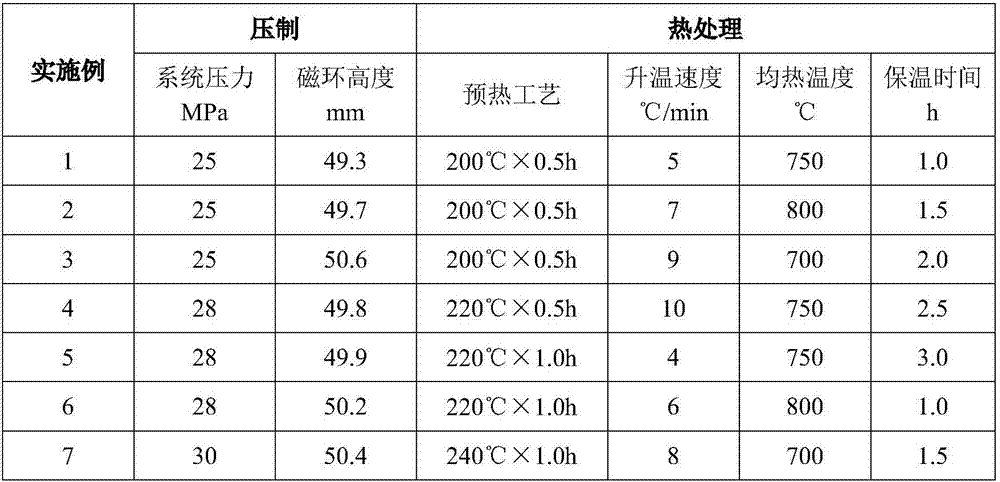

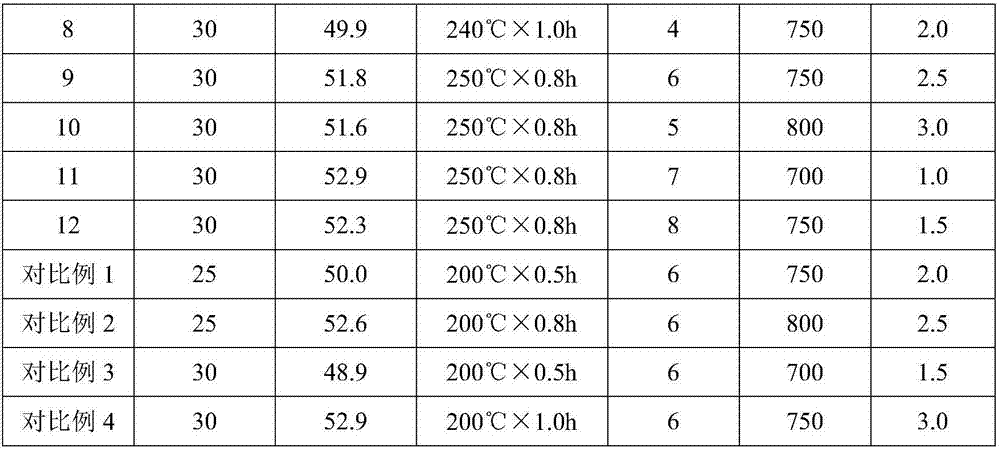

[0027] The present invention will be further described in detail below in conjunction with specific examples.

[0028] The silicon steel magnetic powder core provided by the present invention uses silicon steel sheet waste or other silicon steel materials as the main raw material, and adds a small amount of alloy elements as needed, and smelts to the following target composition range: C: ≤ 0.005wt%, Si: 0.30wt% ~ 6.50 wt%, Mn: ≤0.50wt%, P: ≤0.20wt%, S: ≤0.005wt%, Als: ≤1.5wt%, N: ≤0.005wt%, the rest are Fe and unavoidable impurities, and at the same time meet 1.0 wt%≤(Si+Als)≤7.5 wt%. Its average particle size is 70-100μm. After being processed into a ring, the magnetic induction intensity at 50Hz is B 5000 Greater than 500mT, high frequency iron loss P 0.1 / 20K It is 30-55w / kg.

[0029] The action mechanism of each element in the present invention is described below.

[0030] C: C is a harmful element, and its excessive content will deteriorate the magnetic properties. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com