Flexible stretchable electromagnetic shielding film and preparation method thereof

An electromagnetic shielding film, electromagnetic shielding technology, applied in the fields of magnetic field/electric field shielding, chemical instruments and methods, electrical components, etc. Excellent electromagnetic shielding performance, stable electromagnetic shielding performance, and the effect of improving electromagnetic shielding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

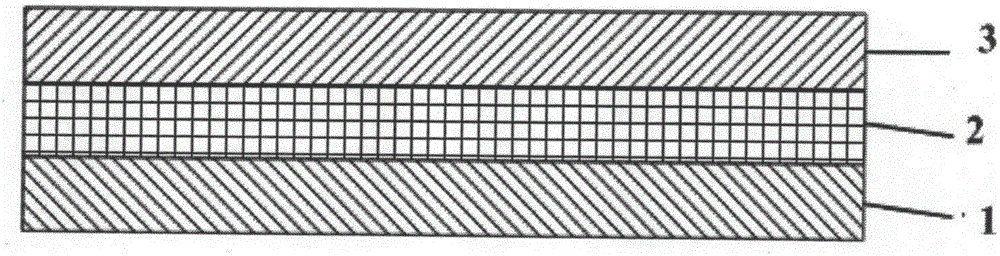

[0034] Example 1: Ultra-thin elastic stretchable electromagnetic shielding film

[0035] A method for preparing a flexible and stretchable electromagnetic shielding film, the specific steps are:

[0036] The first step: immerse the carbon nanotube film in the graphene suspension for 3 hours, immerse once, take it out, and dry it naturally at room temperature to obtain a flexible nano electromagnetic shielding composite film 2, and conduct electricity at both ends Silver glue adheres to copper wire electrodes;

[0037] The selected size of the carbon nanotube film is 20×28cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is made of multi-walled carbon nanotubes. The diameter of the carbon nanotubes is about 20nm, the film thickness is 20um, the porosity is 75%, and the tensile strength is about 200MPa, conductivity is about 1×10 5 S / m; the graphene suspension with the concentration of the graphene suspension of 2 mg / ml (N...

Embodiment 2

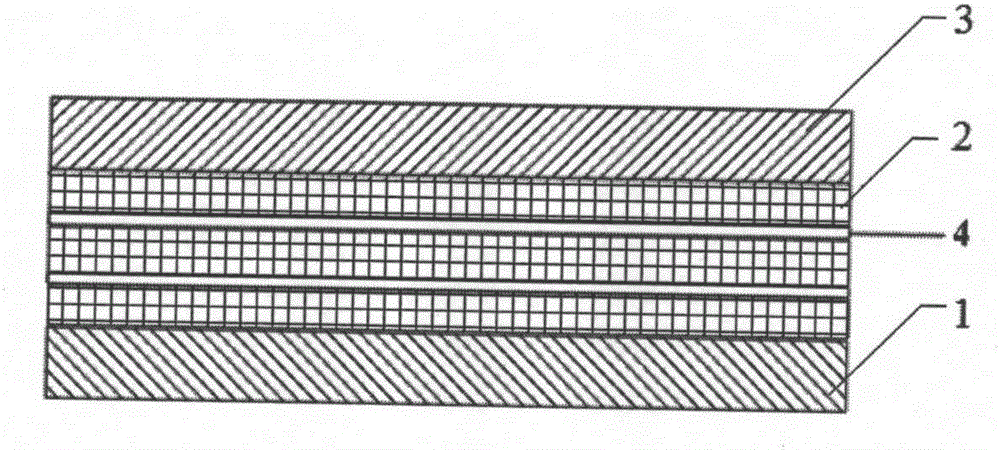

[0045] Example 2: Flexible electromagnetic shielding film with ultra-high shielding effectiveness

[0046] A method for preparing a flexible and stretchable electromagnetic shielding film, the specific steps are:

[0047] Step 1: Immerse 3 carbon nanotube films in graphene suspension for 3 hours, immerse once, take it out, and dry naturally at room temperature to obtain 3 layers of flexible nano electromagnetic shielding composite film 2 in it One end of the two pieces is coated with conductive silver glue to adhere the copper wire electrode;

[0048] The selected size of the carbon nanotube film is 20×30cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is made of multi-walled carbon nanotubes. The diameter of the carbon nanotubes is about 20nm, the film thickness is 20um, the porosity is 75%, and the tensile strength is about 200MPa, conductivity is about 1×10 5 S / m; the graphene suspension with the concentration of the...

Embodiment 3

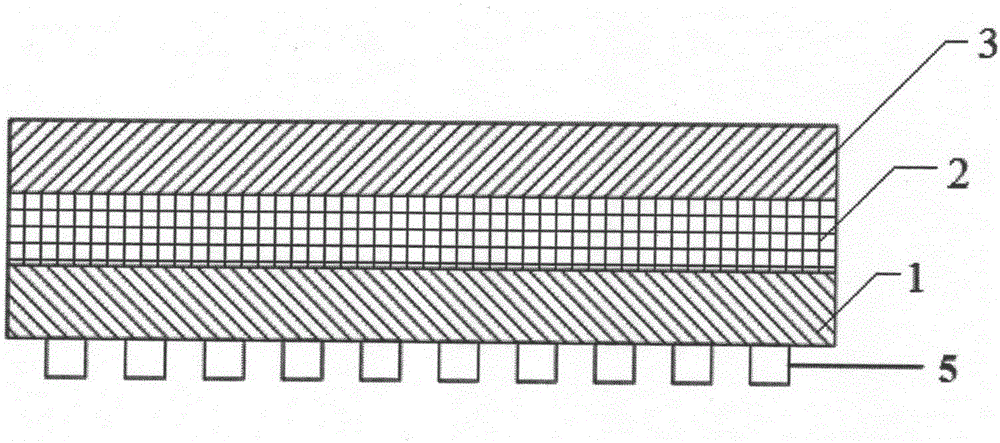

[0057] Example 3: Elastic stretchable electromagnetic shielding adhesive film

[0058] A method for preparing a flexible and stretchable electromagnetic shielding film, the specific steps are:

[0059] The first step: immerse the carbon nanotube film in the graphene suspension for 3 hours, immerse once, take it out, and dry it naturally at room temperature to obtain a flexible nano electromagnetic shielding composite film 2, and conduct electricity at both ends Silver glue adheres to copper wire electrodes;

[0060] The selected size of the carbon nanotube film is 20×30cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is made of multi-walled carbon nanotubes. The diameter of the carbon nanotubes is about 20nm, the film thickness is 20um, the porosity is 75%, and the tensile strength is about 200MPa, conductivity is about 1×10 5 S / m; the graphene suspension with the concentration of the graphene suspension of 2 mg / ml (Num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com