Solar battery and method for manufacturing the same

A solar cell and electrode technology, which is applied in the field of solar cells, can solve problems such as insufficient sunlight absorption and negative effects on efficiency, and achieve the effects of improving optical absorption properties, reducing the minimum, and improving the photodegradation of amorphous silicon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

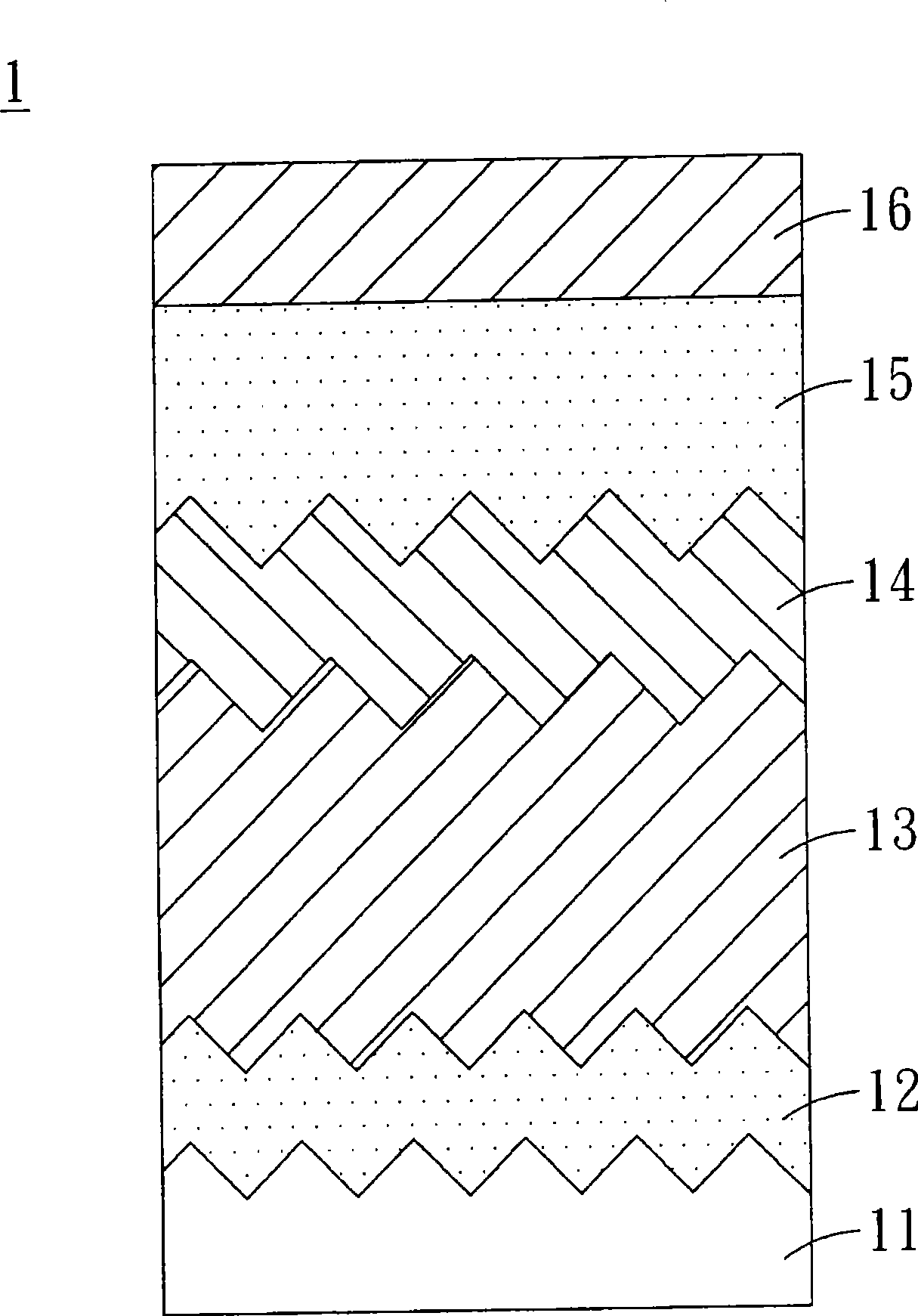

[0032] A solar cell and a manufacturing method thereof according to preferred embodiments of the present invention will be described below with reference to related drawings.

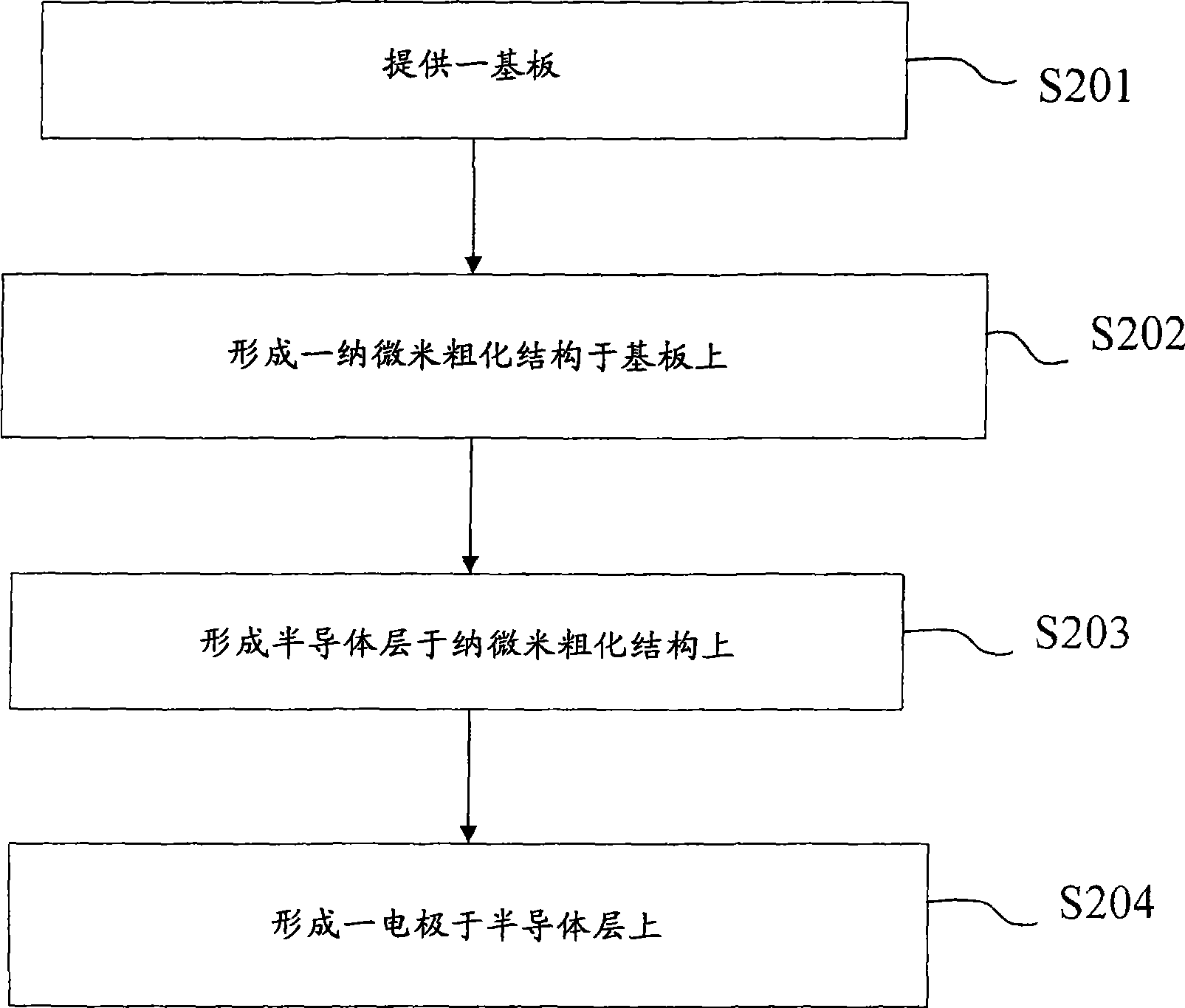

[0033] figure 2 It is a flowchart of a method for fabricating a solar cell according to an embodiment of the present invention. Figure 3A to Figure 3D for figure 2 Cross-section diagrams for each step.

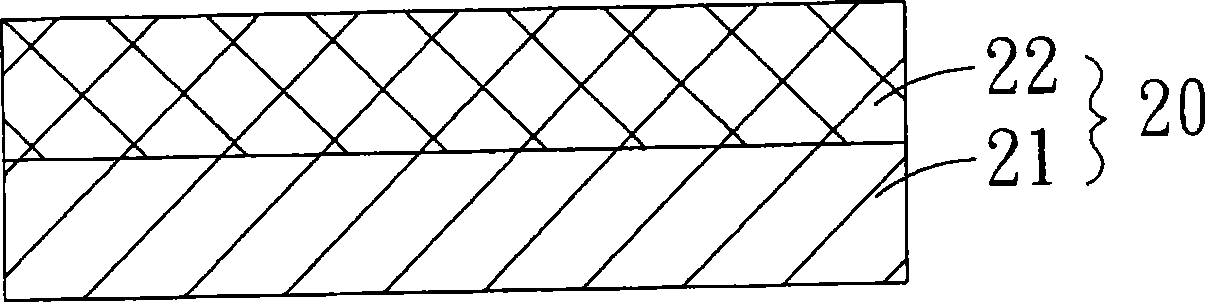

[0034] First, if Figure 3A As shown, a substrate 20 is provided, which is a transparent substrate 21 having a first transparent conductive layer 22 (step S201 ). The transparent substrate 21 can be a glass substrate, but not limited thereto. The first transparent conductive layer 22 is a transparent conductive oxide film (Transparent Conductive Oxide, TCO), such as indium tin oxide (Indium Tin Oxide, ITO), but This is not the limit. In addition, the surface of the first transparent conductive layer 22 has a rough (textured) or smooth (smooth) surface structure.

[0035] Next, if Figure 3B As...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com