Patents

Literature

160results about How to "Shorten coating time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature curing powder coating for coating medium-density fiber board and preparation method for coating

InactiveCN102898923AImprove electrical conductivityImprove powder feeding efficiencyPowdery paintsEpoxy resin coatingsMedium density fiberboardFiber

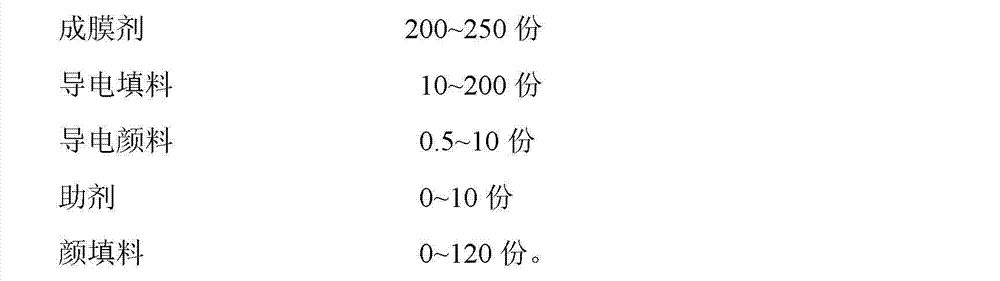

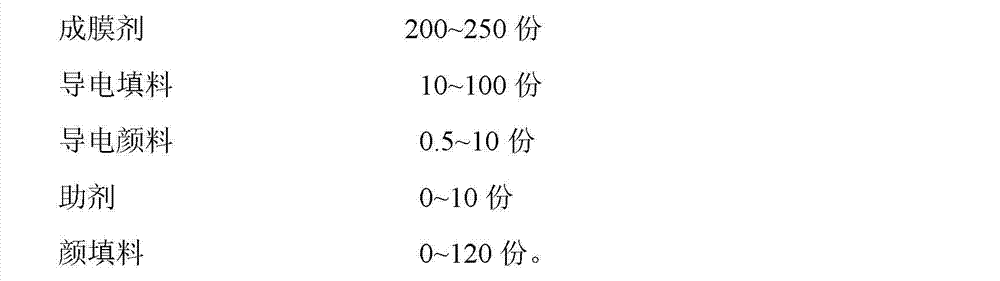

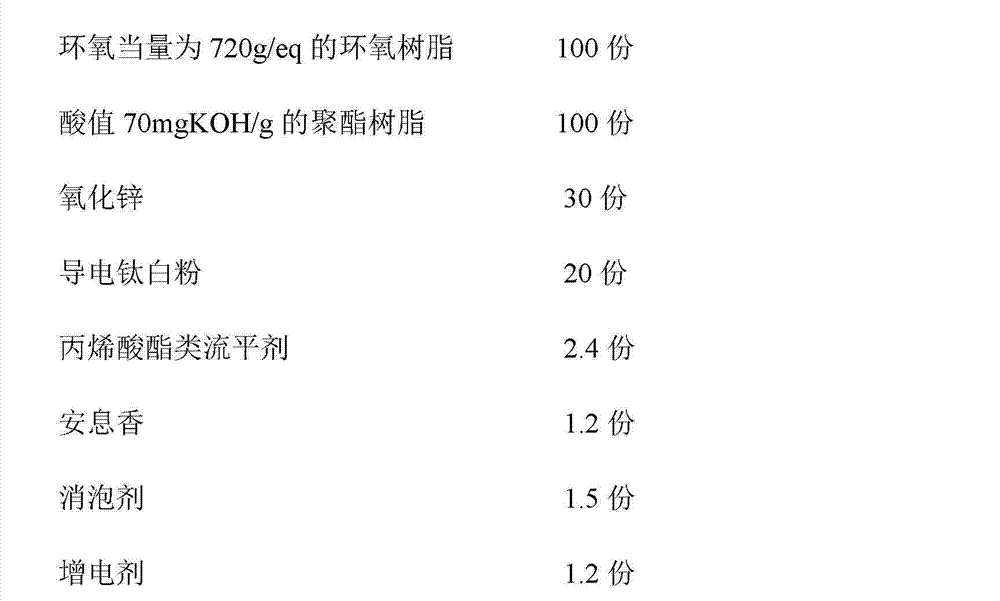

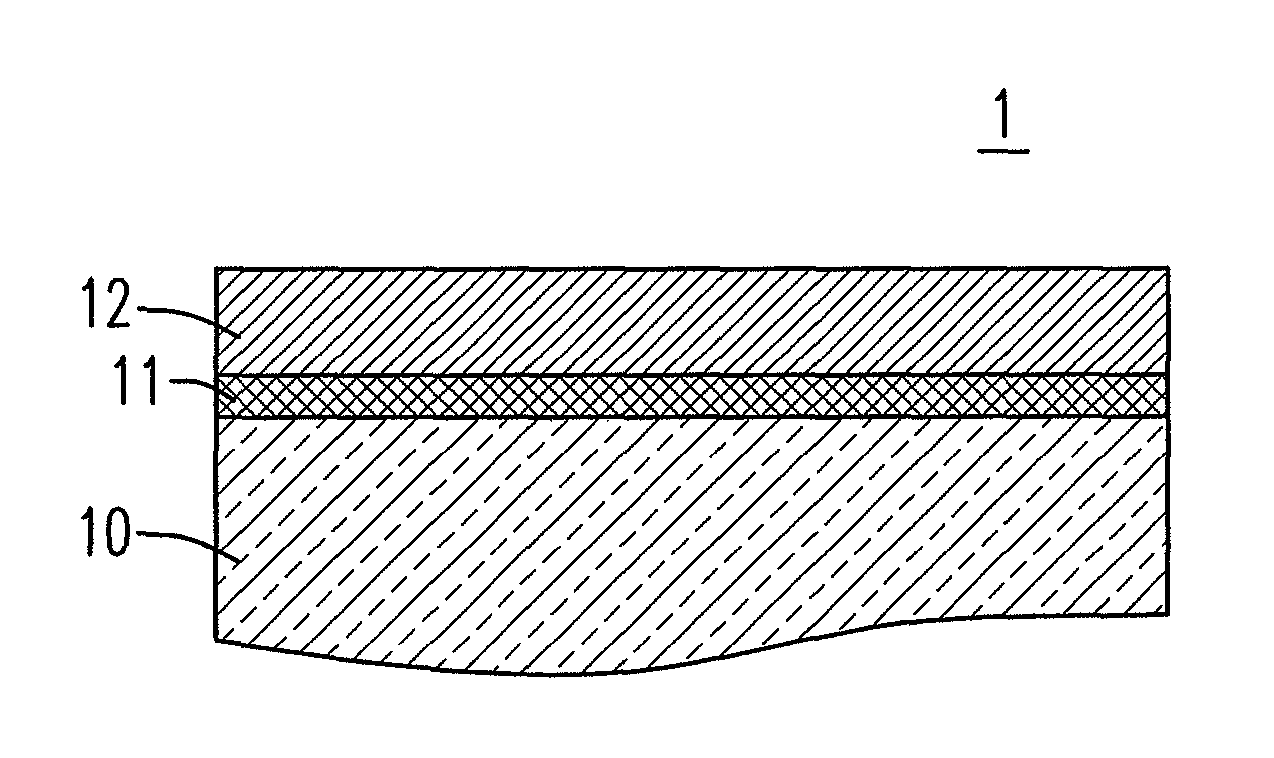

The invention discloses a low-temperature curing powder coating for coating a medium-density fiber board. The coating comprises 200 to 400 parts of conventional medium-density fiber board powder coating, 10 to 200 parts of conductive filler, and conductive pigment. The invention also discloses a preparation method for the powder coating. The powder coating for electrostatic coating can effectively overcome the defect that the conventional medium-density fiber board powder coating for electrostatic coating of the medium-density fiber board is difficult to coat.

Owner:CHINA NAT ELECTRIC APP RES INST +1

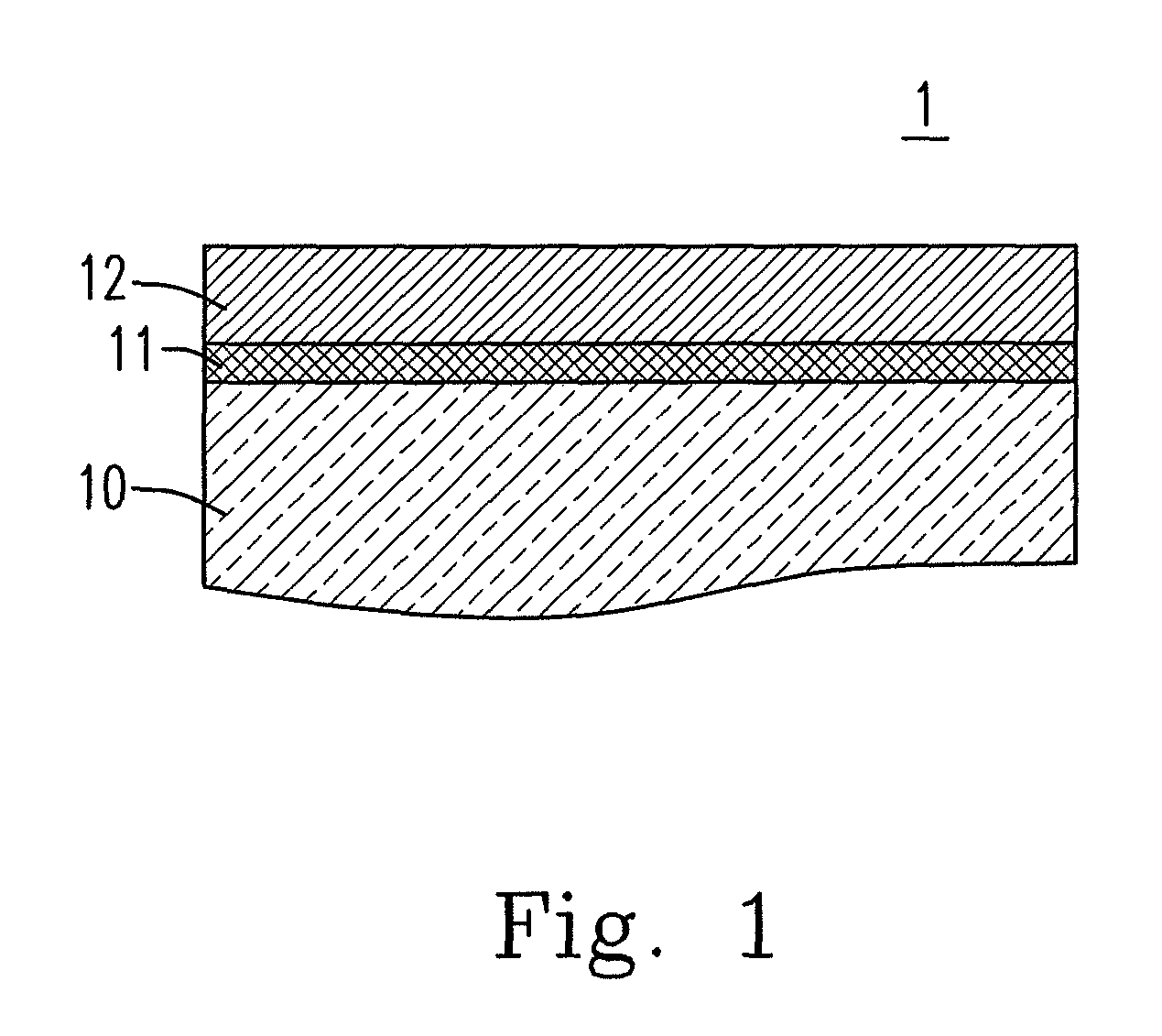

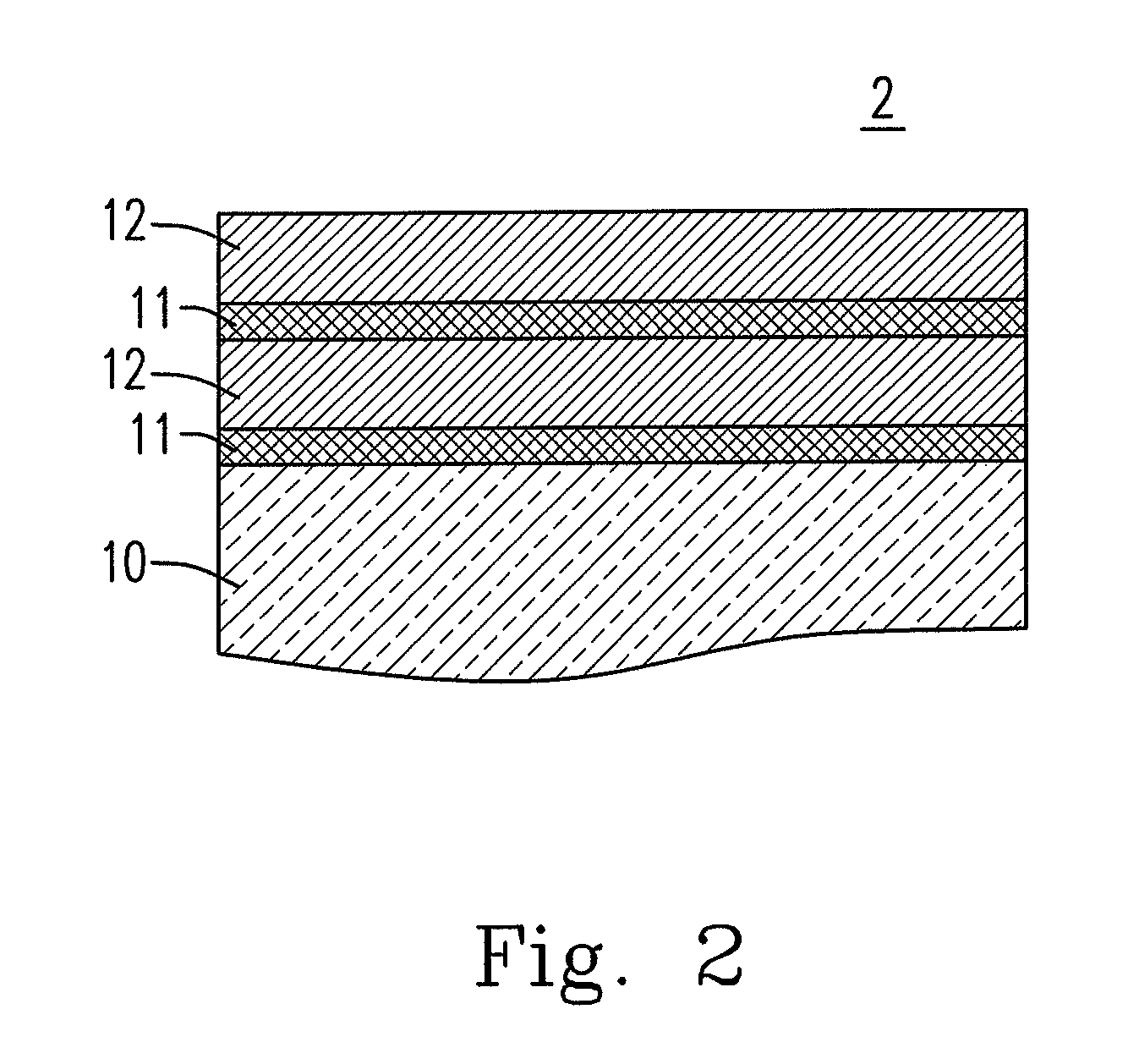

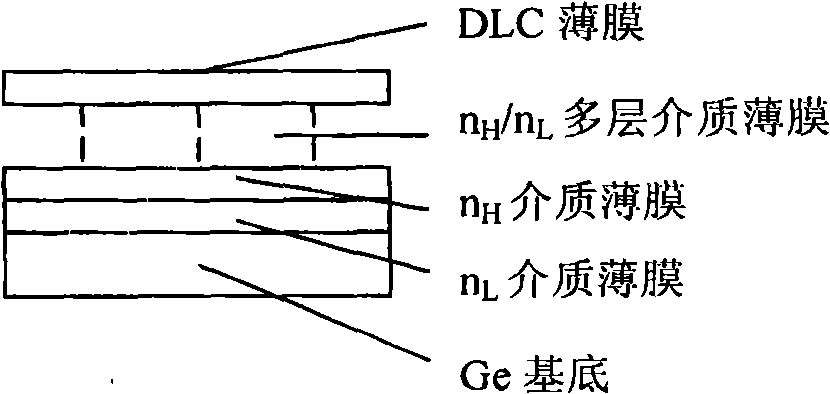

Antireflection structure and manufacturing method thereof

ActiveUS8236433B2Good effectShorten coating timeLiquid surface applicatorsVacuum evaporation coatingRefractive indexInorganic layer

Owner:NAT APPLIED RES LAB

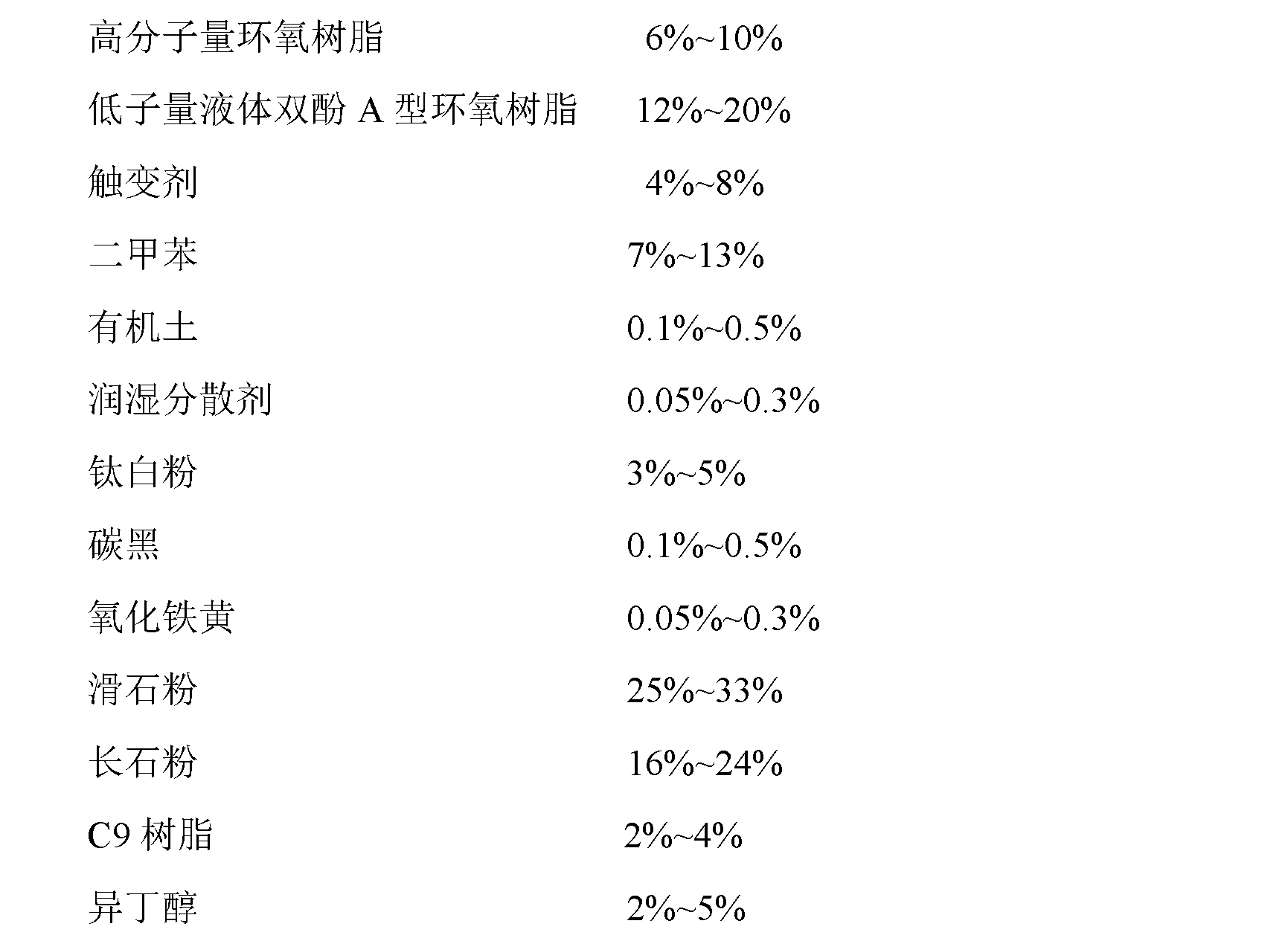

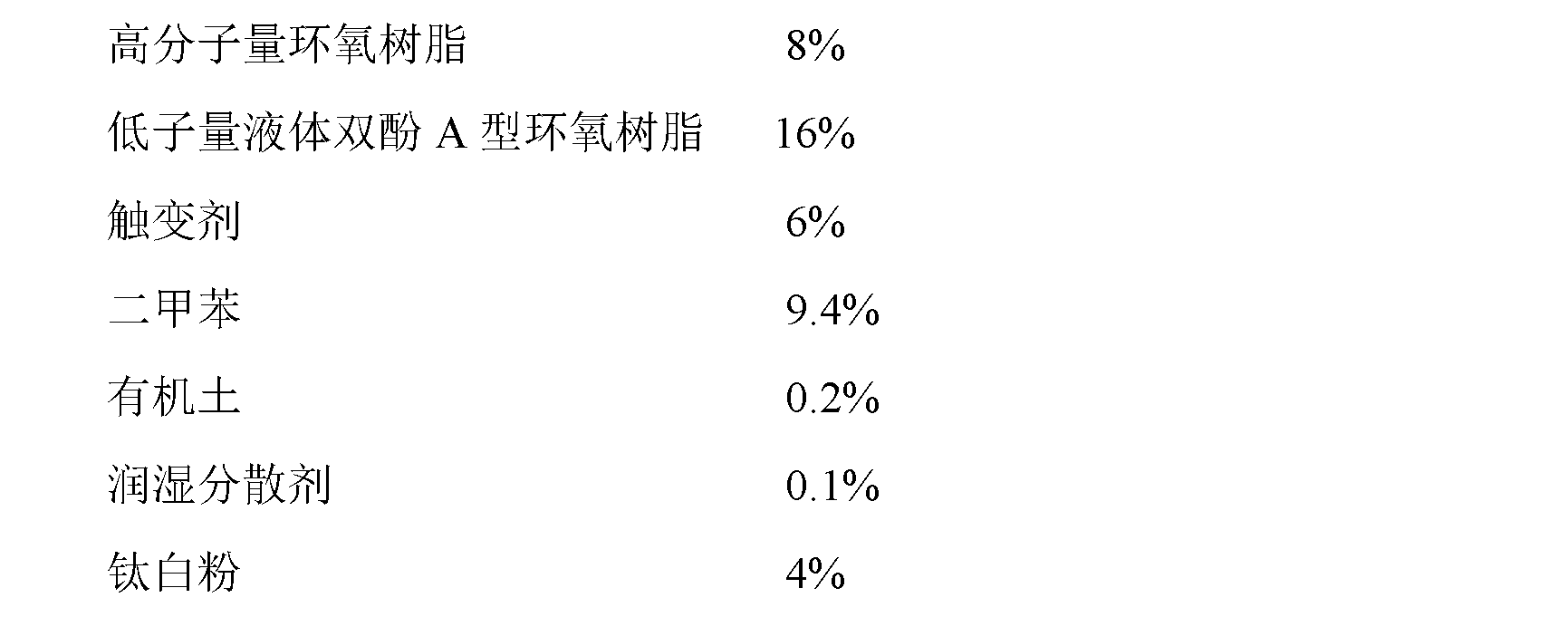

Epoxy universal primer for ships and preparation method thereof

ActiveCN103013276AShorten coating timeEasy constructionAnti-corrosive paintsEpoxy resin coatingsSilanesIsobutyl alcohol

The invention discloses an epoxy universal primer for ships and a preparation method thereof. The epoxy universal primer for the ships comprises components A and components B, wherein the components A comprise the following components in percentage by weight: high molecular weight epoxy resin, low molecular weight liquid bisphenol A epoxy resin, thixotropic agent, dimethylbenzene, organic soil, wetting dispersant, titanium dioxide, carbon black, iron oxide yellow, talcum powder, feldspar powder, C9 resin, isobutyl alcohol and silane auxiliaries; the components B comprise the following components in percentage by weight: polyamide curing agent and epoxy curing accelerator; in a using process, the mixing mass ratio of the components A to the components B is (6-7) to 1. The epoxy universal primer for the ships provided by the invention can be coated to 400 microns by one step without sagging, saves coating time, can be directly matched with the original coating without a transitional layer, is simple to construct, easy to grasp, and time-saving and labour-saving.

Owner:WUXI HUHUANG PAINT

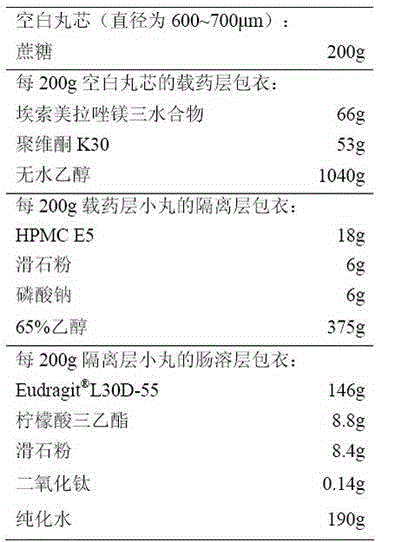

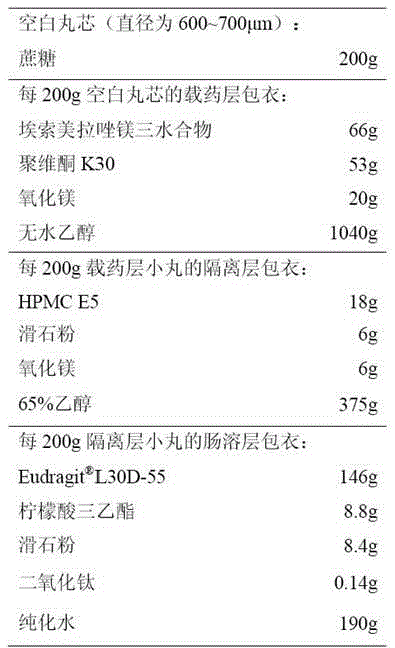

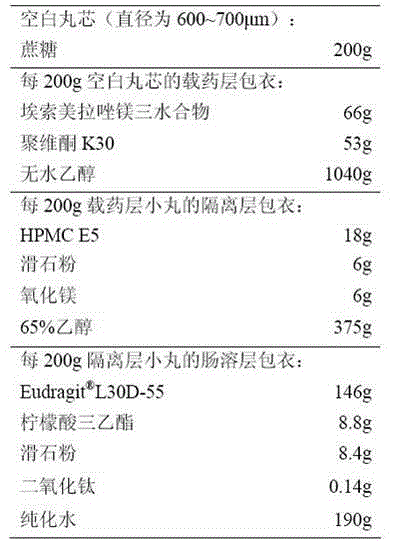

Esomeprazole enteric coated pellet preparation and preparation method thereof

ActiveCN104606146AImprove coating efficiencyShorten coating timeOrganic active ingredientsDigestive systemSolventPlasticizer

The invention discloses an esomeprazole enteric coated pellet preparation and a preparation method thereof. Particularly, the esomeprazole enteric coated pellet preparation is prepared from the following parts including a hollow pellet core, a drug loading layer, an isolation layer and an enteric coated layer, wherein the drug loading layer is prepared from the following raw materials including esomeprazole trihydrate, an adhesive and a drug loading layer solvent; the isolation layer is prepared from the following raw materials including a polymer material, a lubricant, an acid and alkali regulator and a drug loading layer solvent; the enteric coated layer is prepared from the following raw materials including a film forming agent, a plasticizer, a lubricant, a sunscreen and a drug loading layer solvent. The preparation method of the esomeprazole enteric coated pellet preparation sequentially comprises the following steps: 1) coating the drug loading layer; 2) coating the isolation layer; and 3) coating the enteric coated layer. With the optimization of a formula and a technology, the preparation method is capable of improving the coating efficiency, reducing the coating time and preventing the manpower and material resource waste. The prepared enteric coated pellet preparation is capable of improving the stability of a medicament and the medicine taking compliance of a patient, is more suitable for the patient to use and can be further processed into an oral preparation such as a capsule or a tablet.

Owner:SUZHOU UNIV

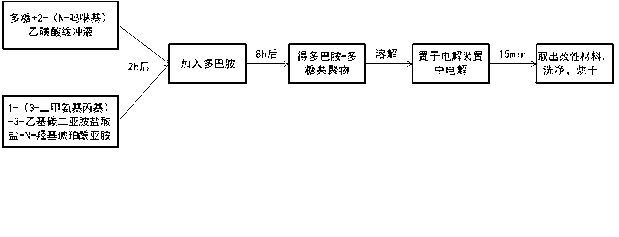

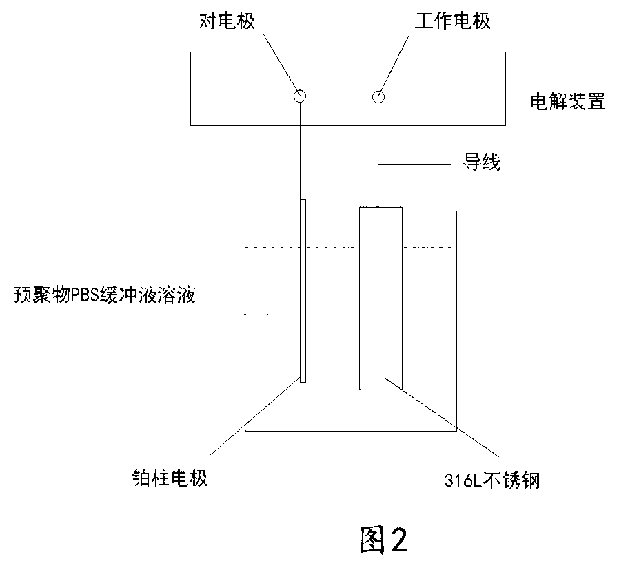

Method for quickly coating polysaccharide polymer on metal material surface

InactiveCN103255456AReduce coating timeUniform coatingElectrolytic organic material coatingChemistryElectrochemical response

The invention aims to provide a method for quickly coating a polysaccharide polymer on a metal material surface. The method comprises the following steps of: preparing a dopamine derivative modified polysaccharide polymer; soaking a material to be modified into a prepared alkaline buffer solution; and adopting a three-electrode system to carry out the electrochemical reaction of anodes in an electrolytic tank, and electrochemically modifying the material through a medium in the solution so as to obtain a metal material with excellent biocompatibility. Compared with the defects such as long modification time, poor coating adhesive force and uneven surface of a conventional coating modification technology, the method can be used for greatly shortening the coating time, and an obtained coating is uniform and dense and has strong adhesive force.

Owner:SHANGHAI UNIV

Method for preparing titanium oxide crystal

ActiveCN103806099AHigh purityQuality improvementPolycrystalline material growthVacuum evaporation coatingTitanium powderTitanium oxide

The invention discloses a method for preparing titanium oxide crystal. The method comprises the following steps: evenly mixing titanium powder and titanium oxide in a sintering mold, spreading flat and compacting; putting in a vacuum sintering furnace and vacuumizing; sintering by stages; finally cooling to obtain the product, wherein a sintering curve is as follows: the heating rate is 6-8 DEG C / min between normal temperature to 1200 DEG C; the heating rate is 3-5 DEG C / min between 1200 DEG C and 1670 DEG C; the heating rate is 1.5-2.5 DEG C / min between 1670 DEG C and 1770 DEG C; the heating rate is 1-2 DEG C / min between 1770 DEG C and 1805 DEG C; cooling after keeping the temperature at 1805 DEG C for 4-8 hours. The flaky titanium oxide crystal can be prepared by the method; the premelting time can be shortened by the flaky Ti3O5 crystal, or even the premelting procedure can be omitted, the coating time can be greatly shortened, and by adopting the coating layer product prepared by the flaky Ti3O5 crystal, the purity and the quality are effectively improved.

Owner:FUJIAN ACETRON NEW MATERIALS CO LTD

Poly urethane (PU) polyurethane paint

The invention discloses poly urethane (PU) polyurethane paint capable of being forcedly dried and used for woodware big table-board coating and contains components by weight: 60-80 parts of alkyd resin, 5-20 parts of fillers, 15-25 parts of solvent, 0.1-0.3 part of defoaming agent, 0.1-0.3 part of flatting agent, 0.5-1 part of anti-settling agent, 35-45 parts of toluene diisocynate (TDI) affixture, 45-55 parts of TDI trimer and 5-10 parts of polyurethane -level solvent. The PU polyurethane paint capable of being forcedly dried can be forcedly dried at the temperature of 50 DEG C without having prickly heat and hidden bubbles easily, and greatly improves coating efficiency and effect of the PU polyurethane paint.

Owner:展辰涂料集团股份有限公司

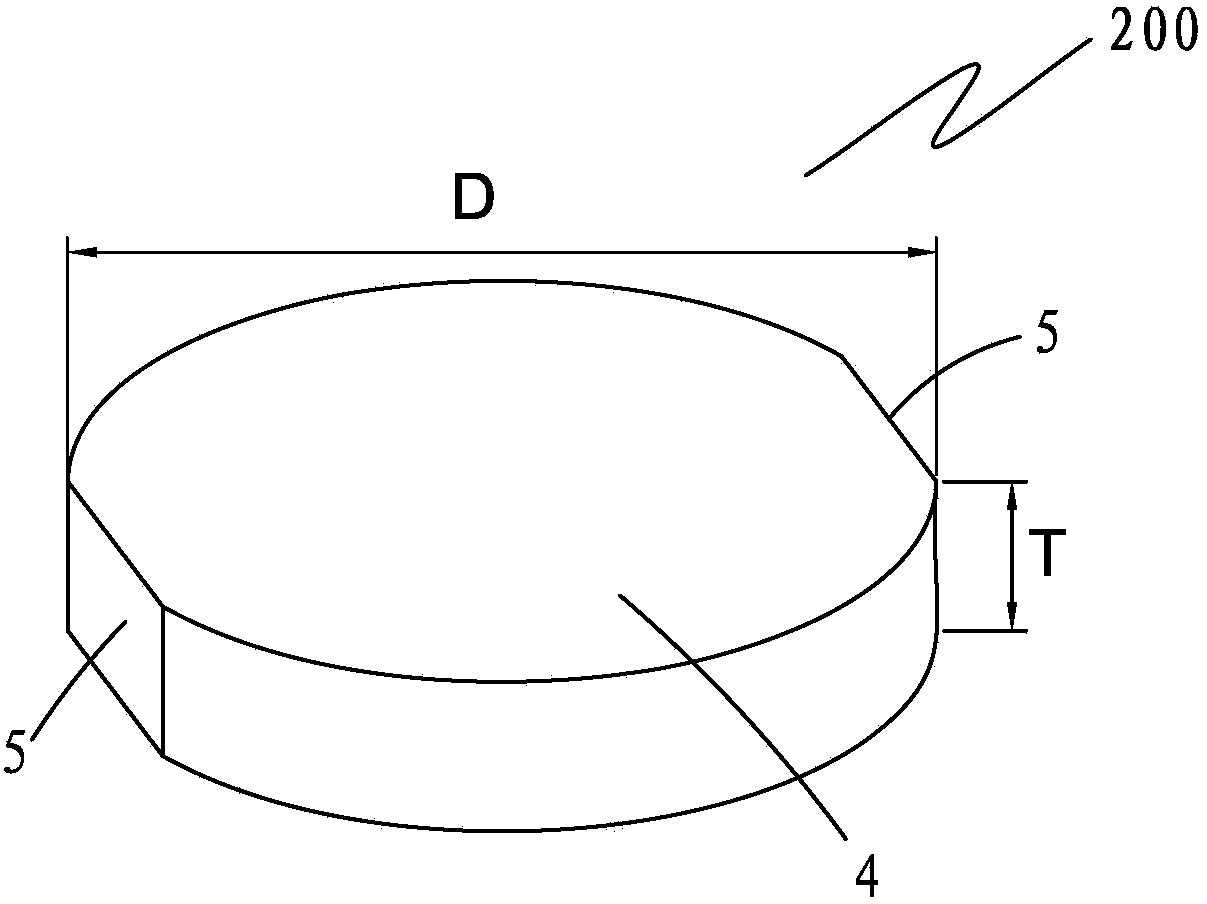

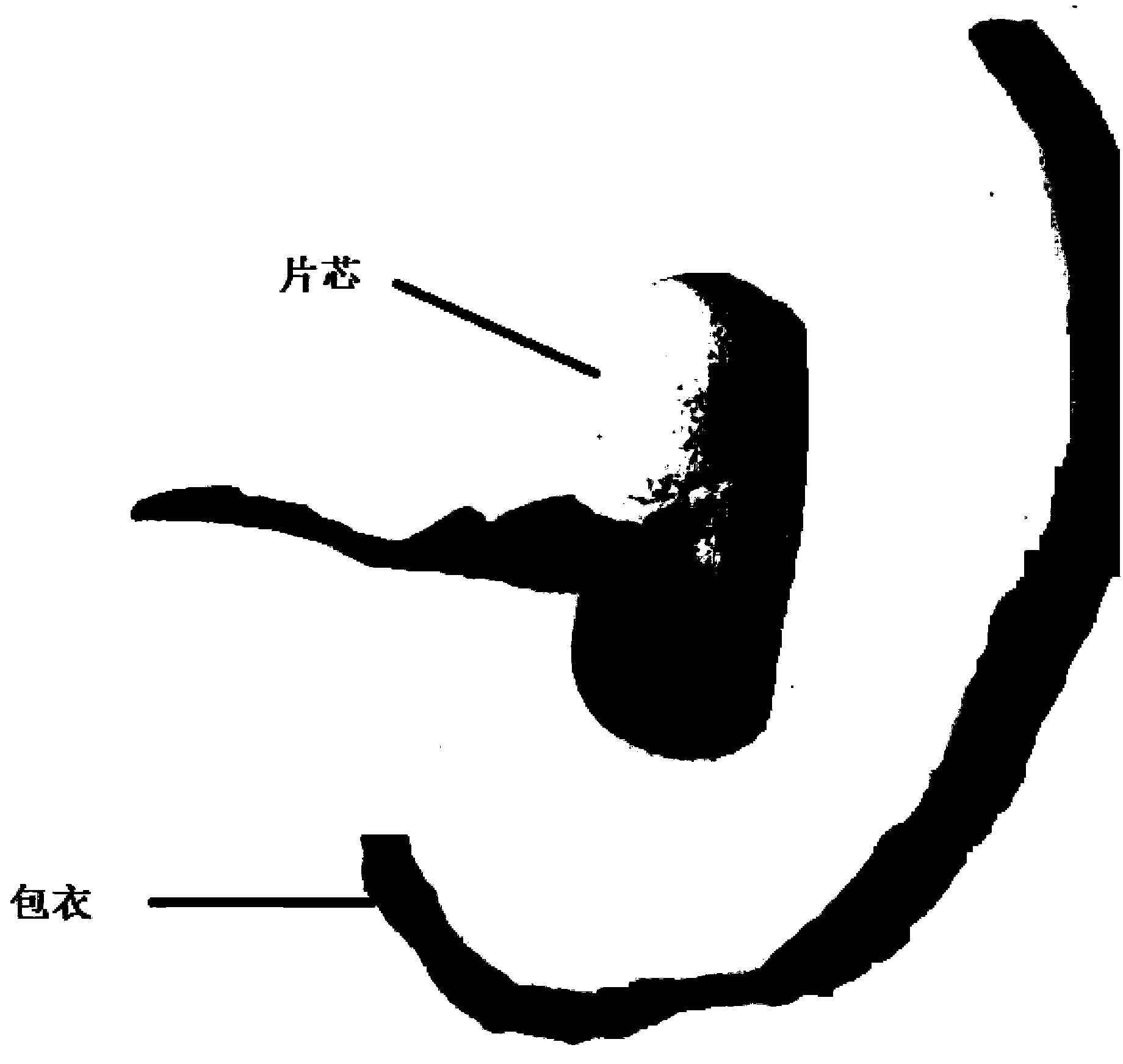

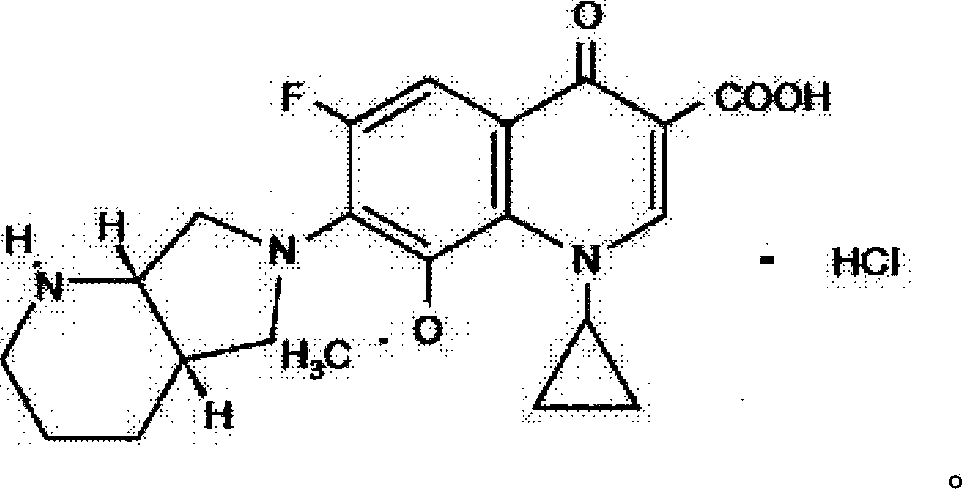

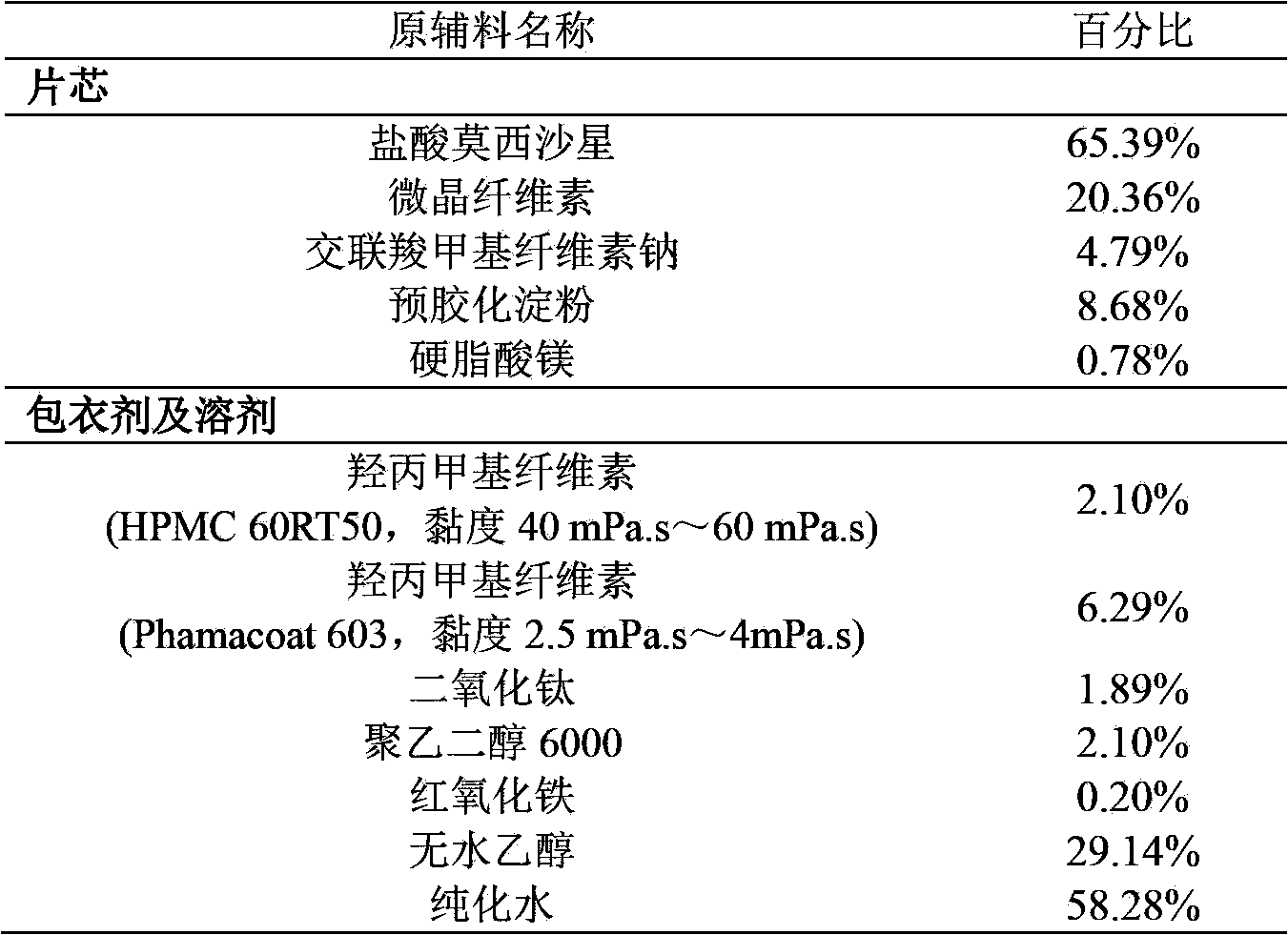

Moxifloxacin hydrochloride pharmaceutical composition and preparation method thereof

InactiveCN103768063ASave energySave costsAntibacterial agentsOrganic active ingredientsHypromelloseMoxifloxacin hydrochloride

The invention provides a moxifloxacin hydrochloride pharmaceutical composition and preparation method thereof. The invention is characterized in that: tablet core is prepared by moxifloxacin hydrochloride, more than one excipient and a coating material, wherein, the weight of moxifloxacin hydrochloride is 60-70% of that of the tablet core, and the weight of excipients is 30-40% of that of the tablet core, and the weight of the coating material which is used for coating the tablet core and is composed of hypromellose with two or more than two viscosities is 1.0-4.0% of that of the pharmaceutical composition tablet core, and the weight ratio between hypromellose with viscosity of 40-120mPa.s and hypromellose with viscosity of 2.5-1.8mPa.s is 1:5-1:2. The pharmaceutical composition has the advantages of good stability, simple preparation technology and easy reproduction; the preparation method is suitable for industrial production.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD

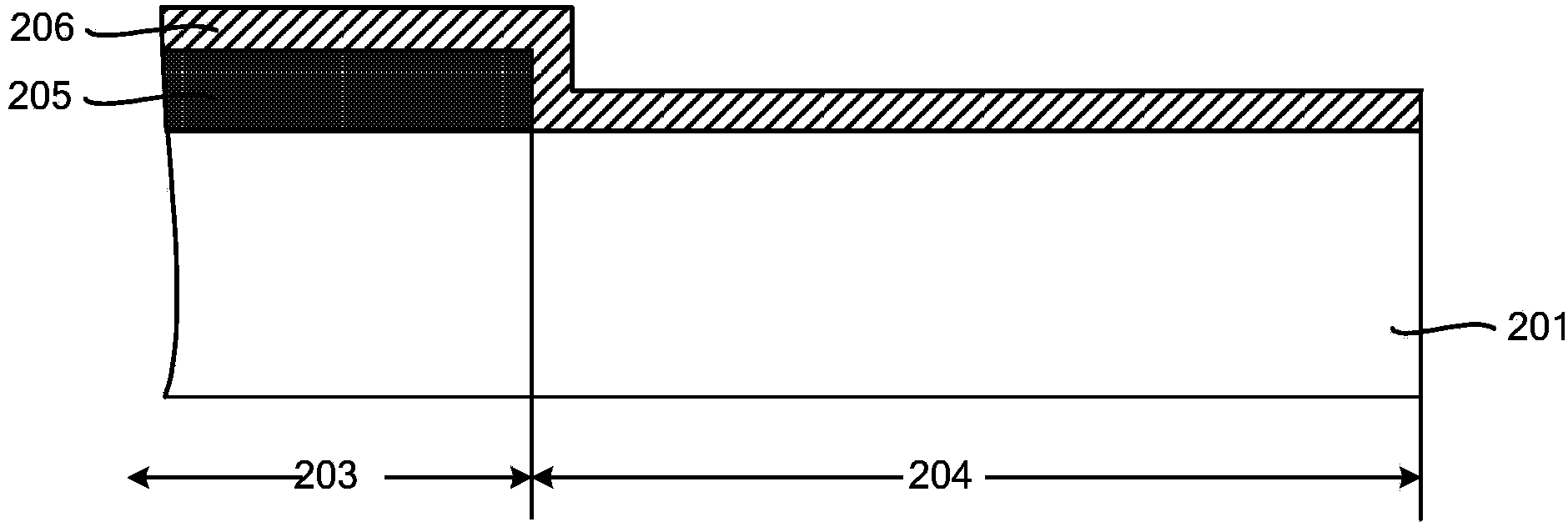

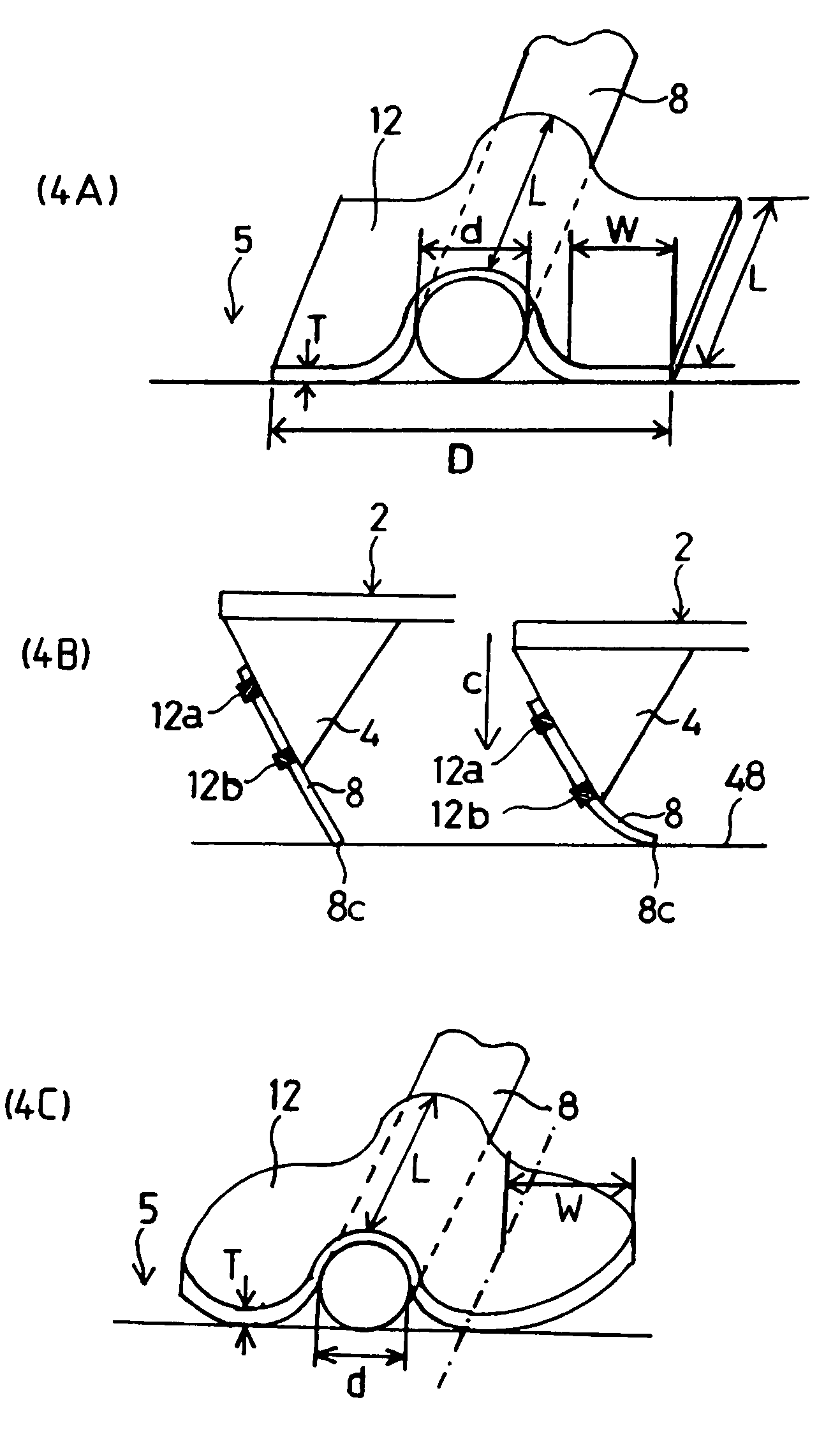

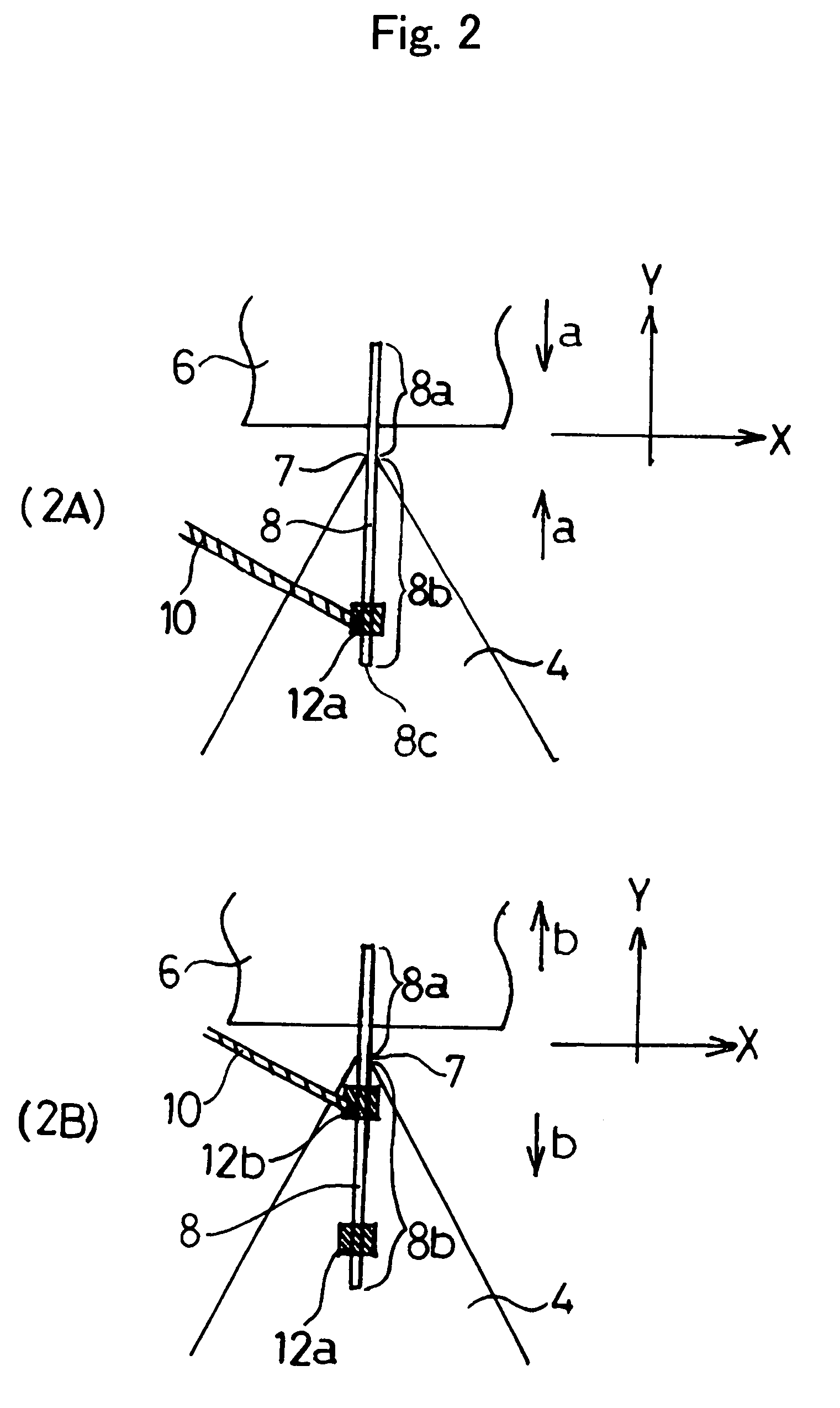

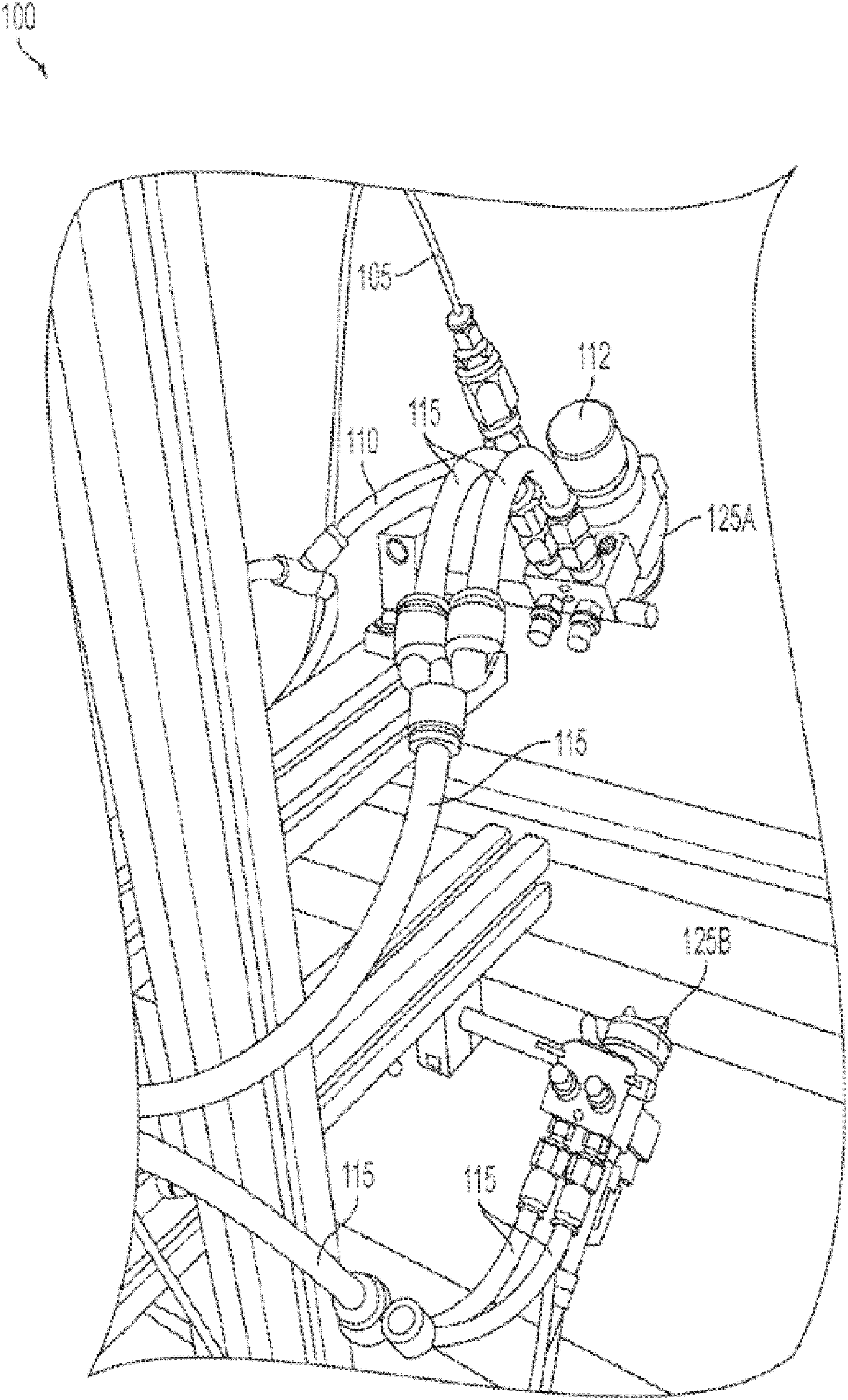

Nanotube probe and method for manufacturing the same

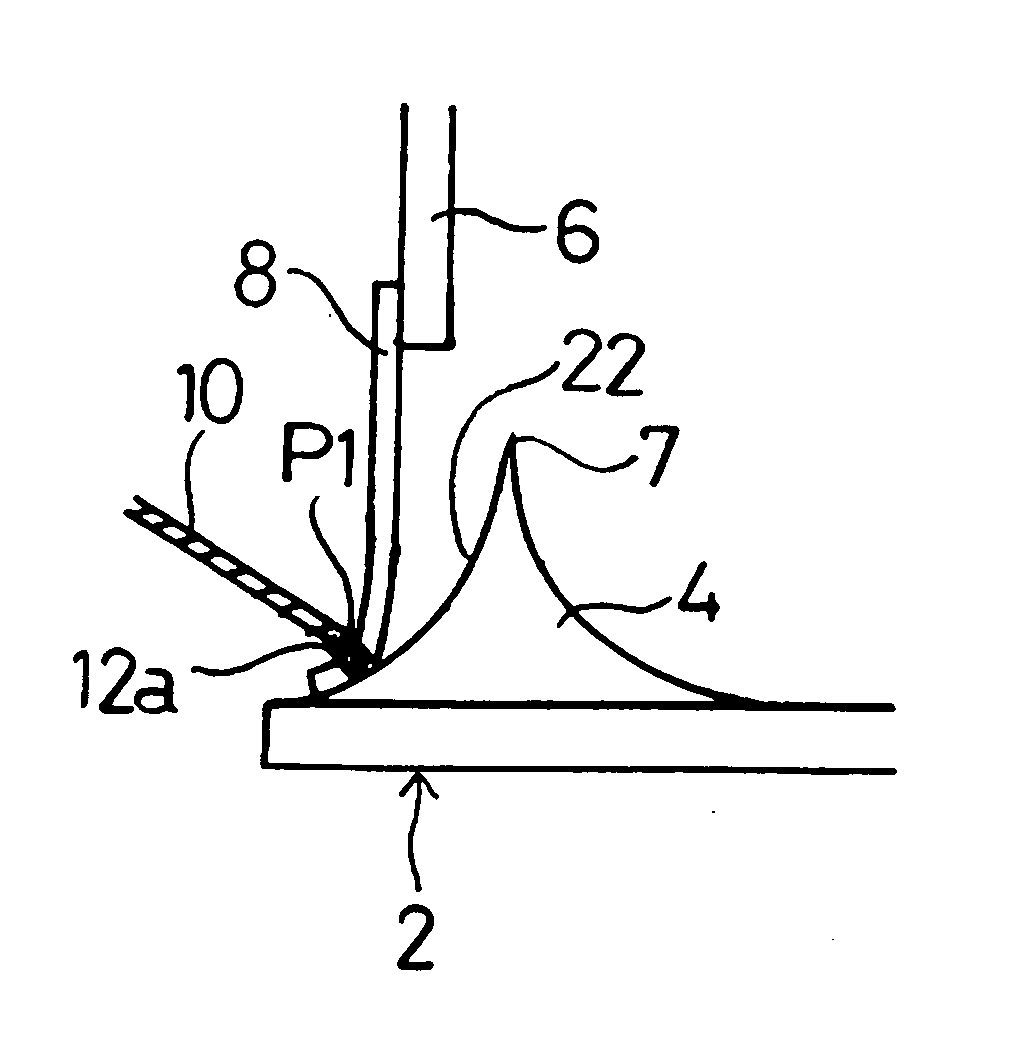

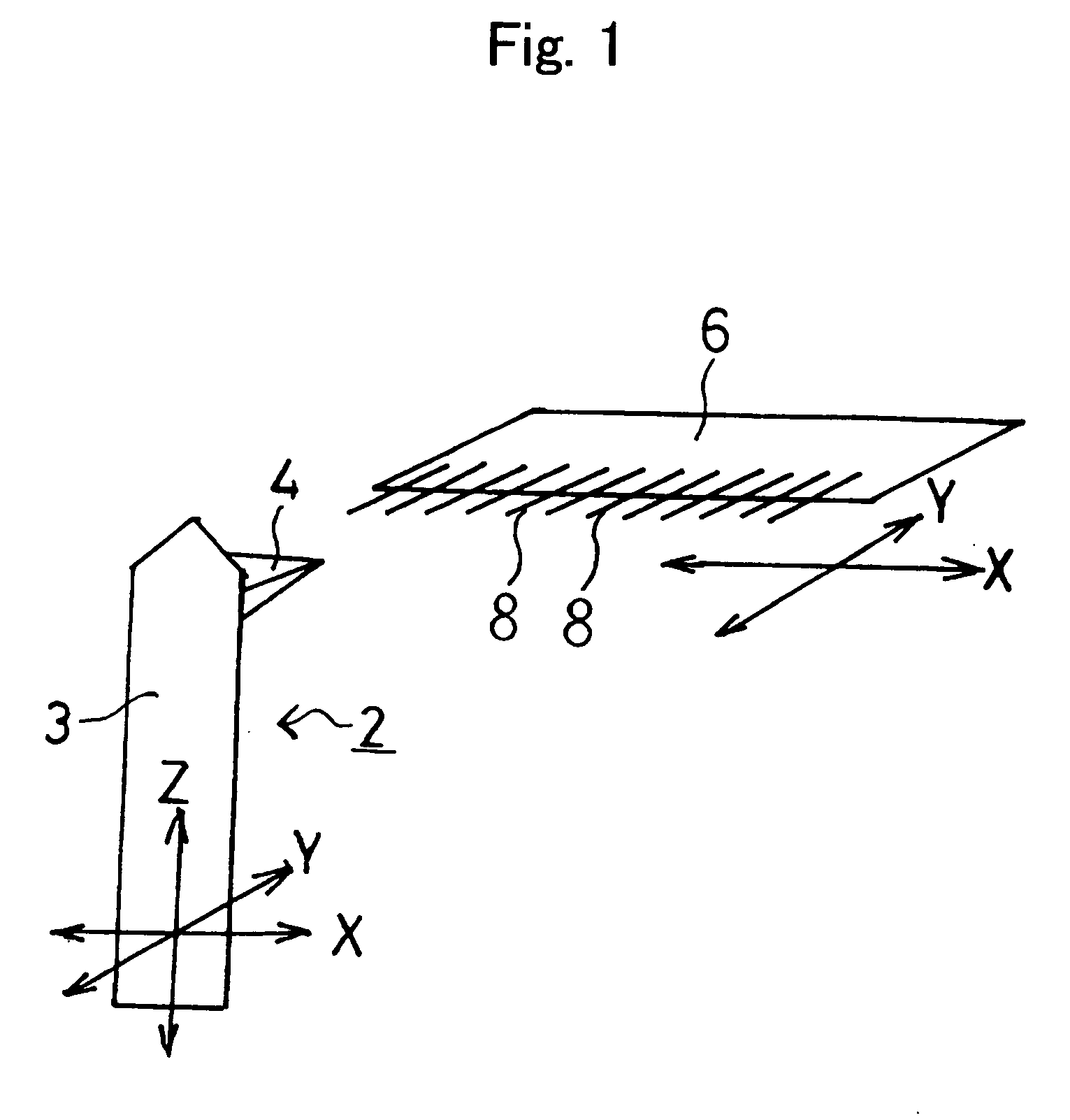

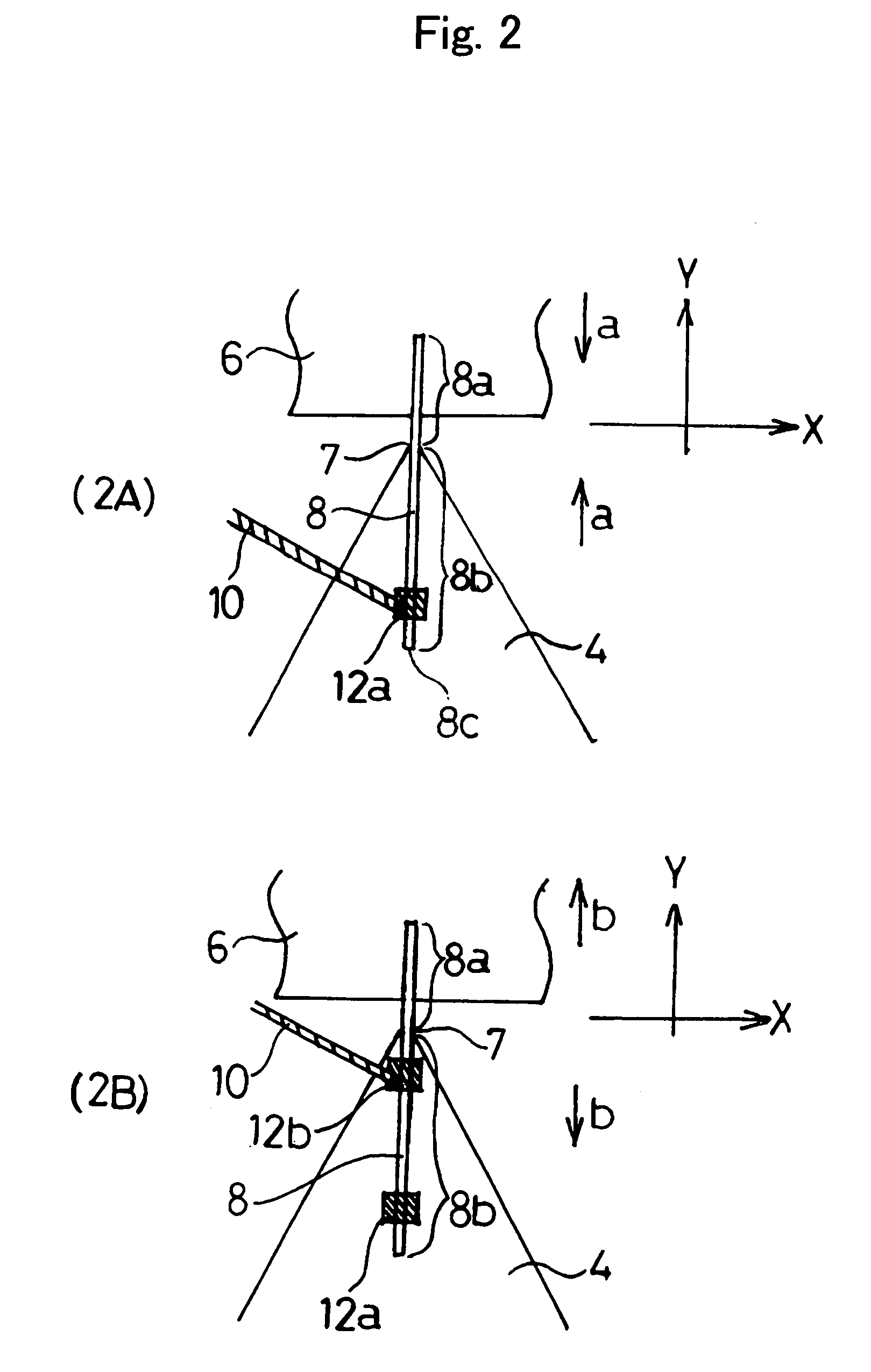

InactiveUS20070018098A1Improve practicalityShorten coating timeMaterial analysis using wave/particle radiationElectric discharge tubesBeam diameterCantilever

The present invention realizes a nanotube probe with high durability that can be manufactured in short time with less impurities adhered to the holder sustaining the nanotube. The nanotube probe according to this invention is constructed by fastening a nanotube 8 on the protruded portion 4 of a cantilever by way of at least two partial coating films 12a and 12b. One or more additional partial coating films may be formed in the intermediate area between these two partial coating films. Each partial coating film is formed by irradiating electron beam 10 on the position where the nanotube 8 is in contact with the protruded portion 4 of the cantilever. The partial coating films are separated not to overlap each other. By minimizing the size of partial coating film as well as by narrowing down the beam diameter, coating time may be further shortened. With the beam diameter narrowed down, excessive deposit of impurities can be put under control.

Owner:NAKAYAMA YOSHIKAZU +1

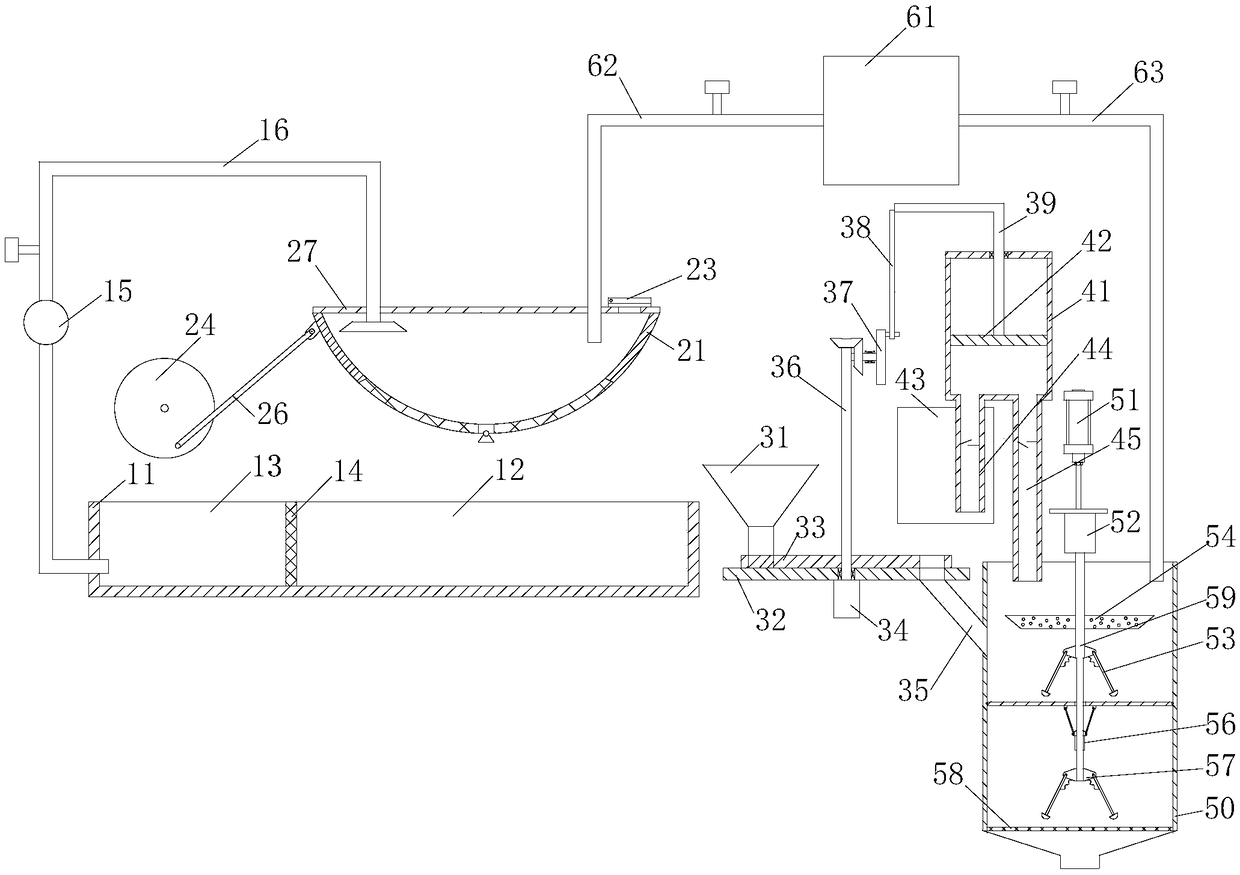

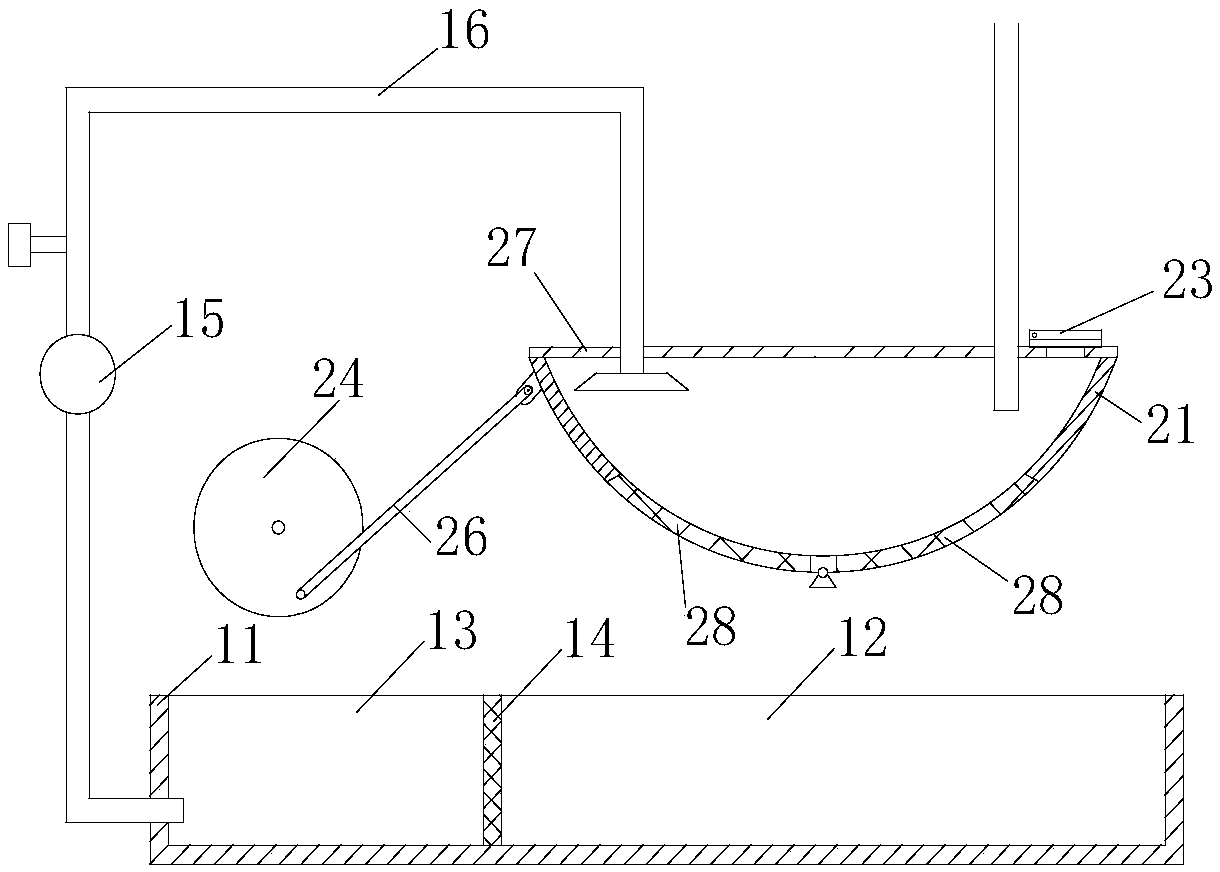

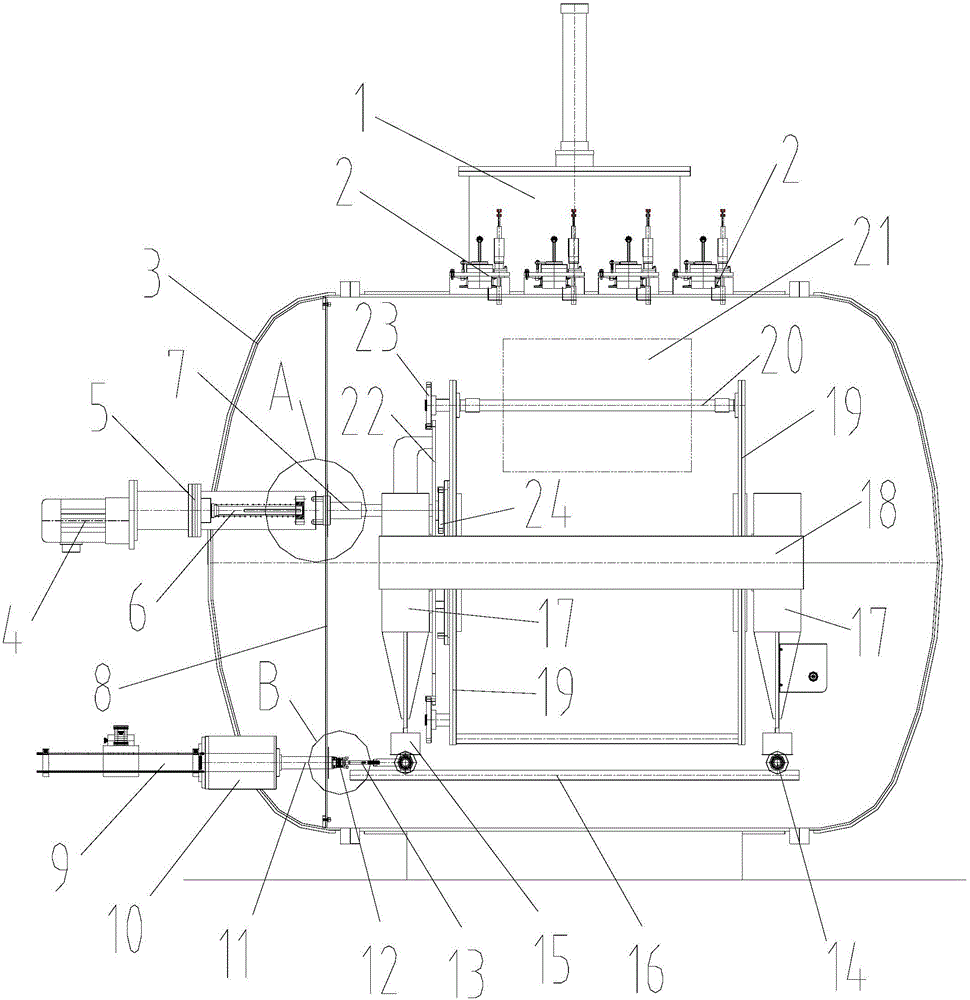

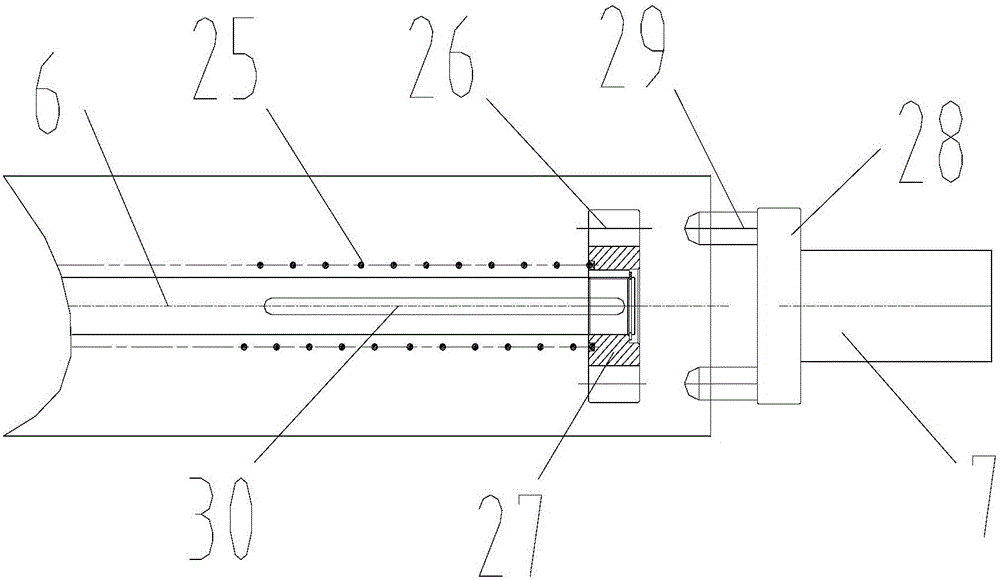

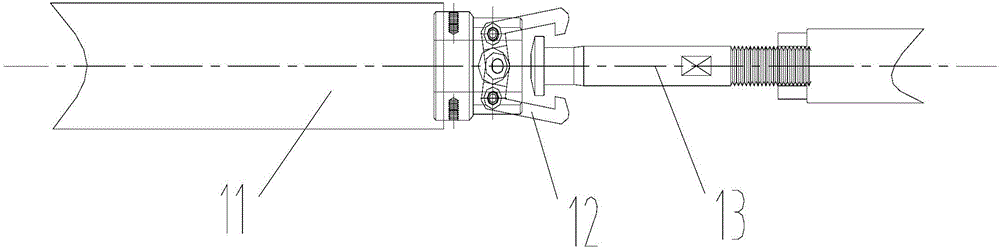

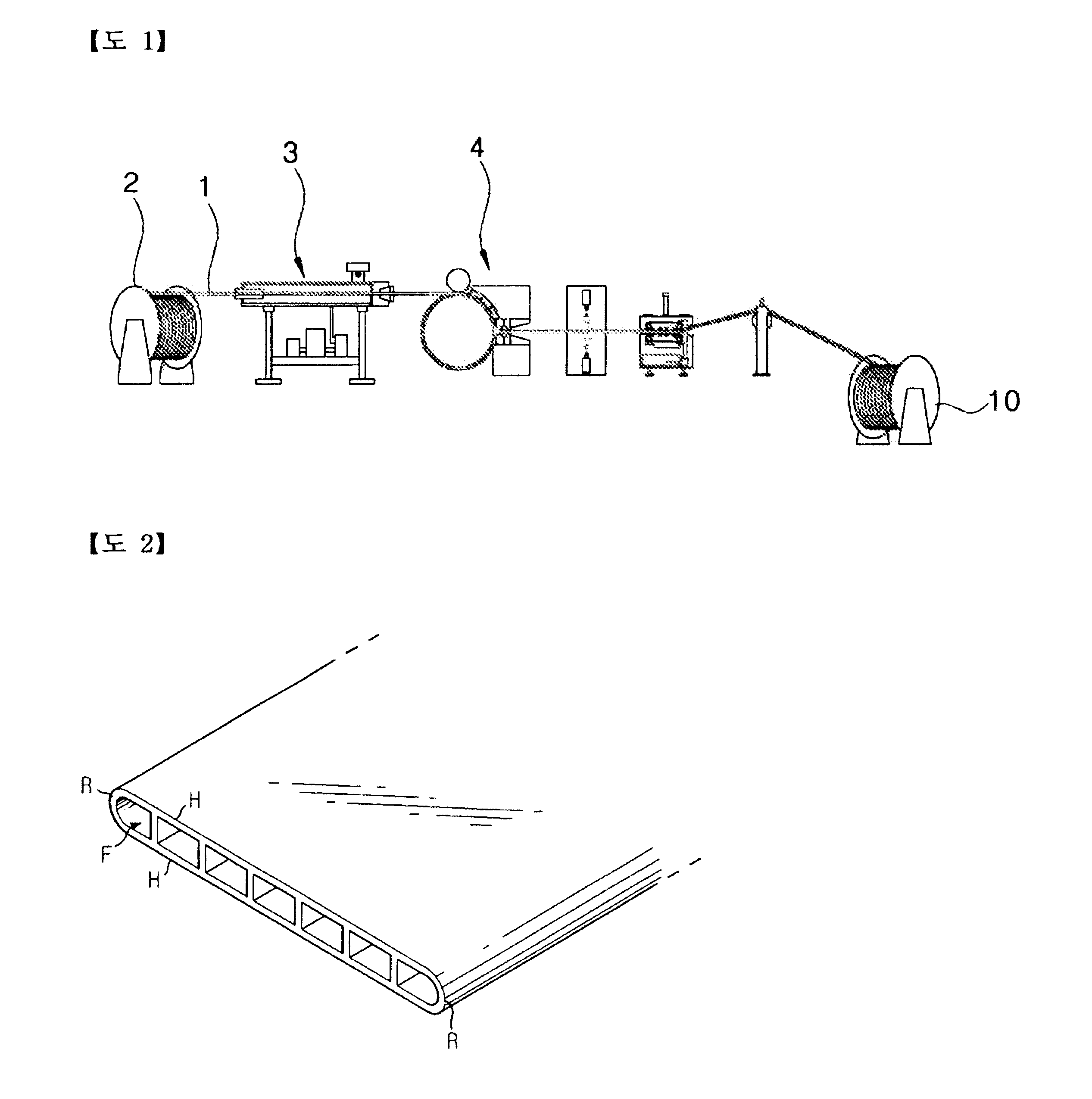

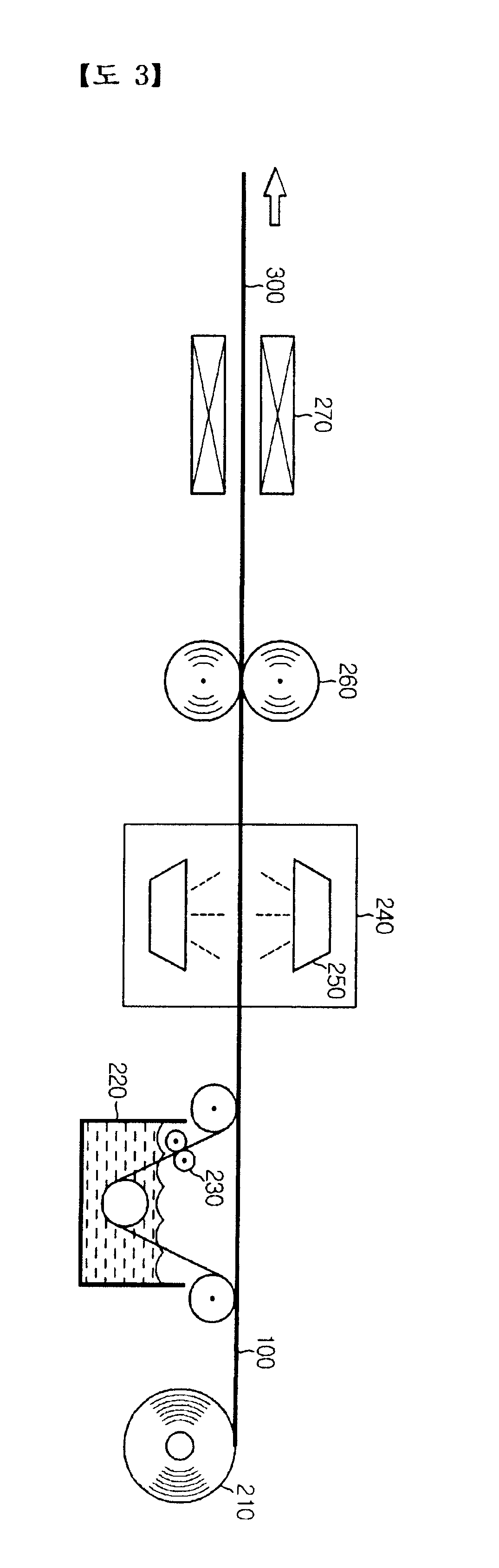

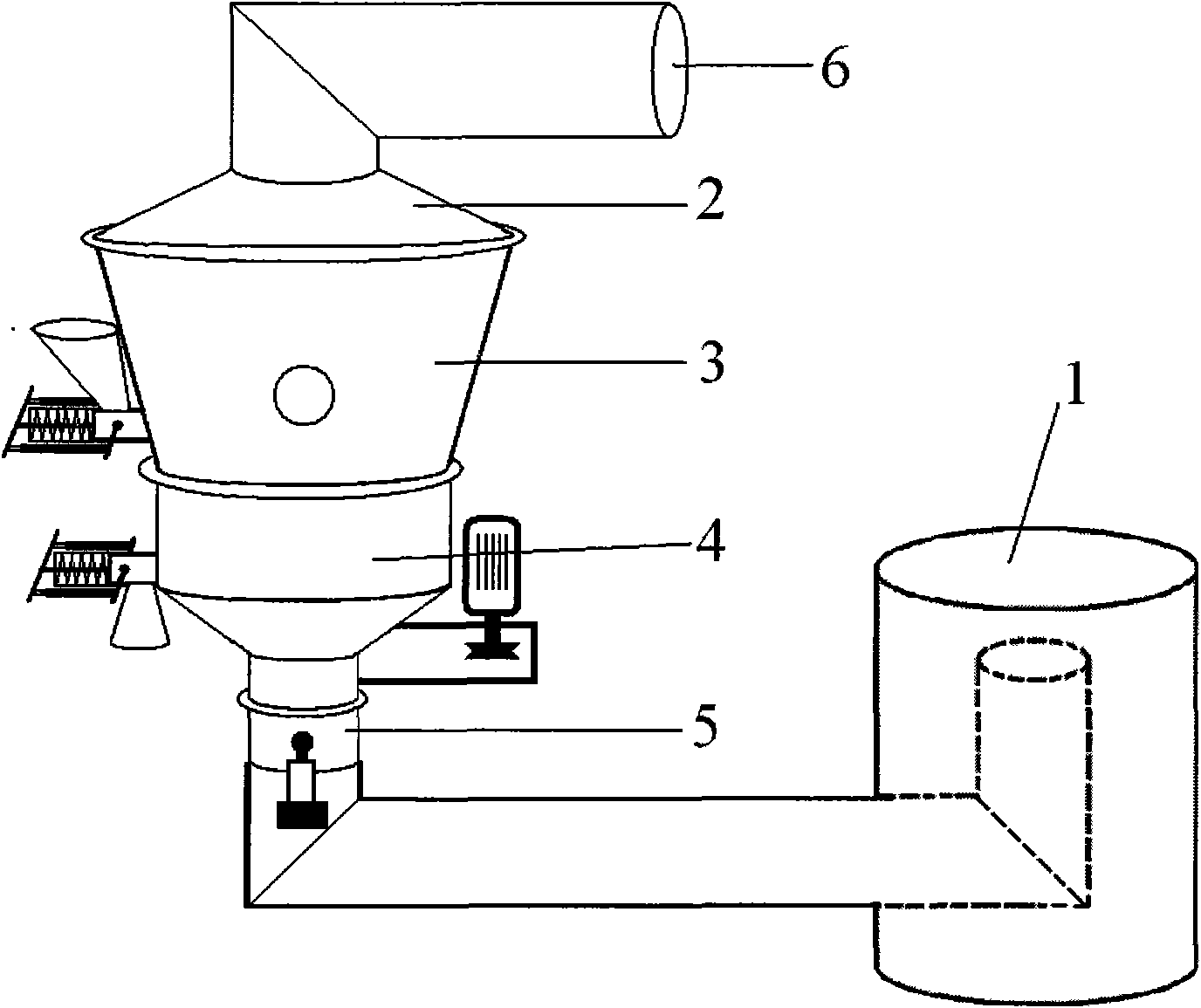

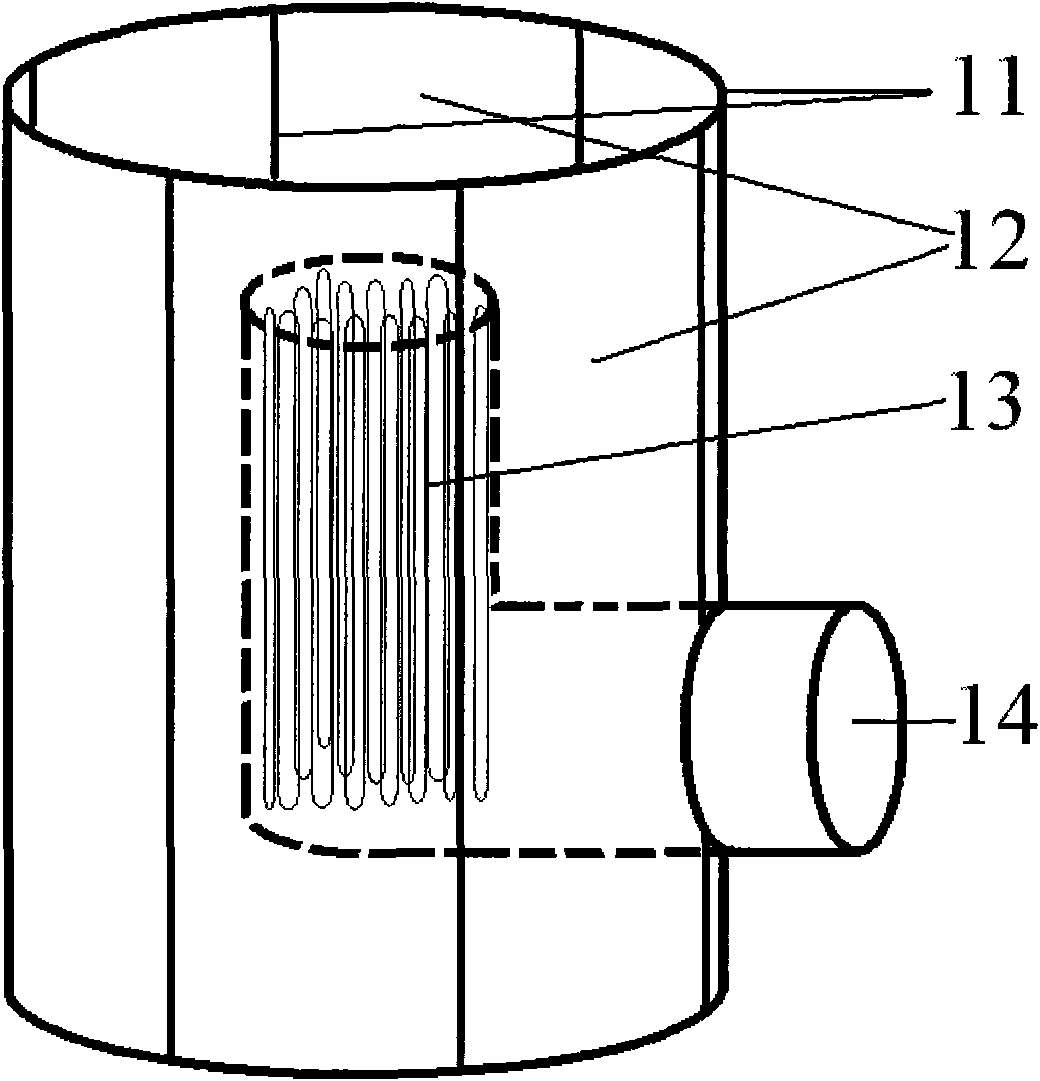

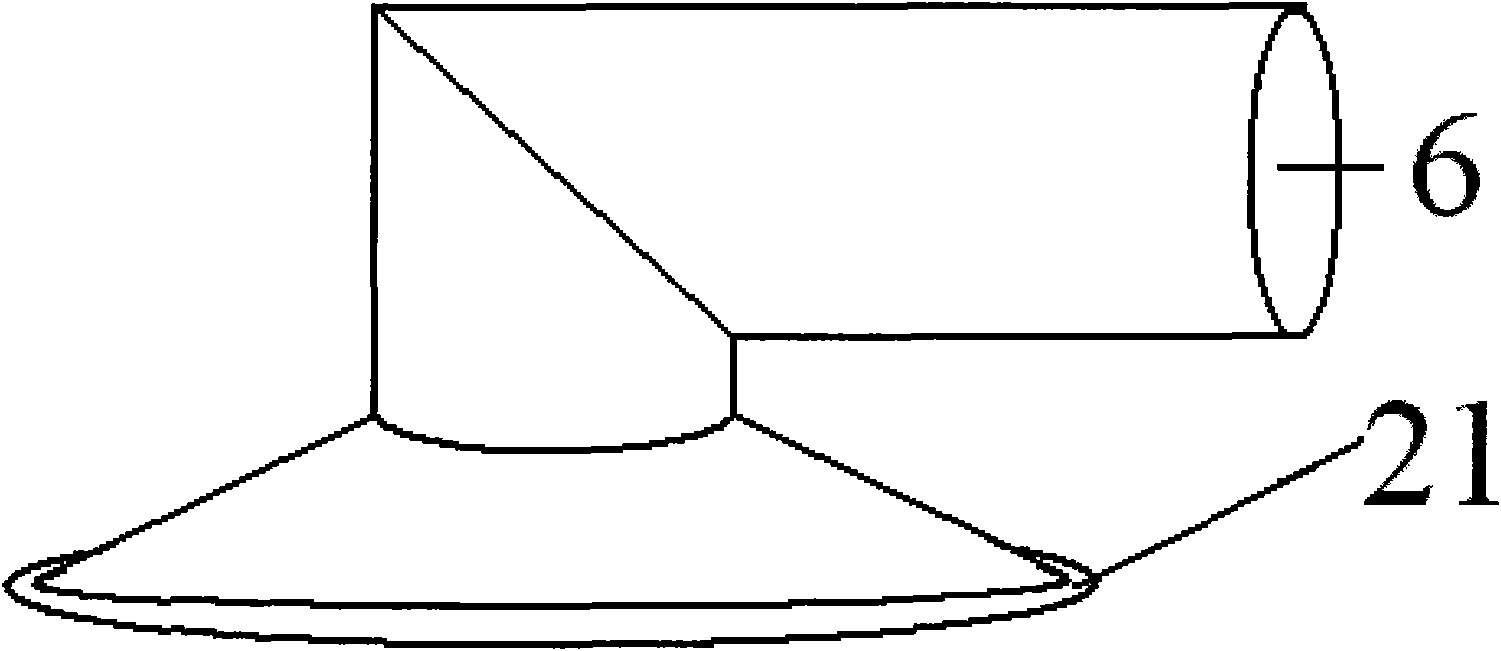

Seed coating device

InactiveCN108207175ASolve the problem of insufficient coatingReduce moistureSeed coating/dressingCoating systemEngineering

The invention relates to a seed coating device, which comprises a pretreatment system, a feeding system and a coating system arranged in order from the first to the last in a process sequence, and thepretreatment system is used for removing impurities, cleaning dust and drying seeds. The coating system comprises a coating box, the feeding system comprises a seed quantitative conveying unit and aseed coating agent quantitative conveying unit, the seed quantitative conveying unit is configured to quantitatively feed the seeds after treated by the pre-treatment system into the coating box, andthe seed coating agent quantitative conveying unit is used to quantitatively feed a seed coating agent into the coating box. Since the amounts of the seeds and the seed coating agent entering the seedcoating system are basically constant, the ratio of the seeds and the seed coating agent is approximately equal to a preset matching ratio, the purpose of accurate feeding can be achieved, and the technical effects of simplification of operation steps and convenient operation can be achieved.

Owner:韩洪军 +6

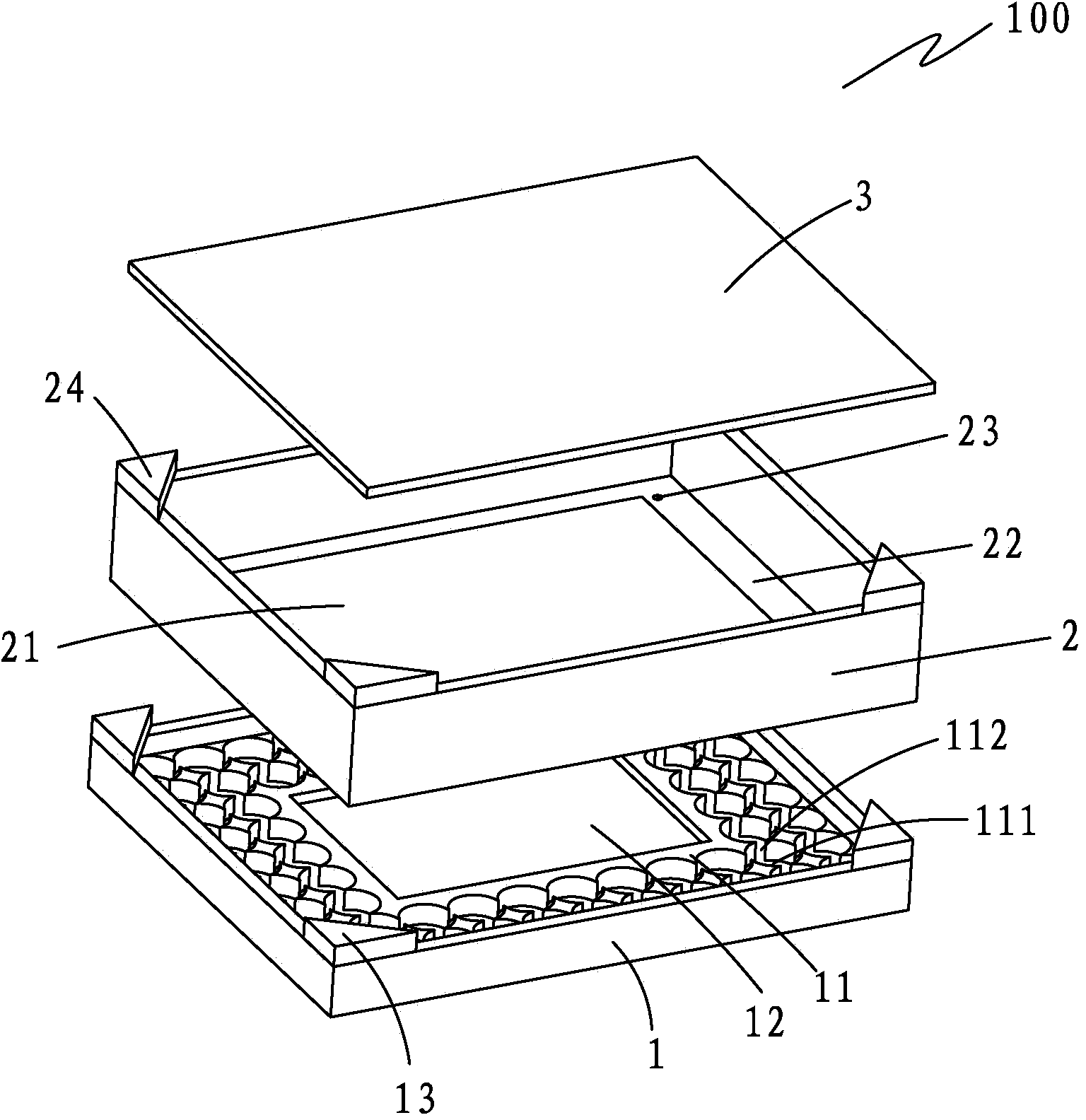

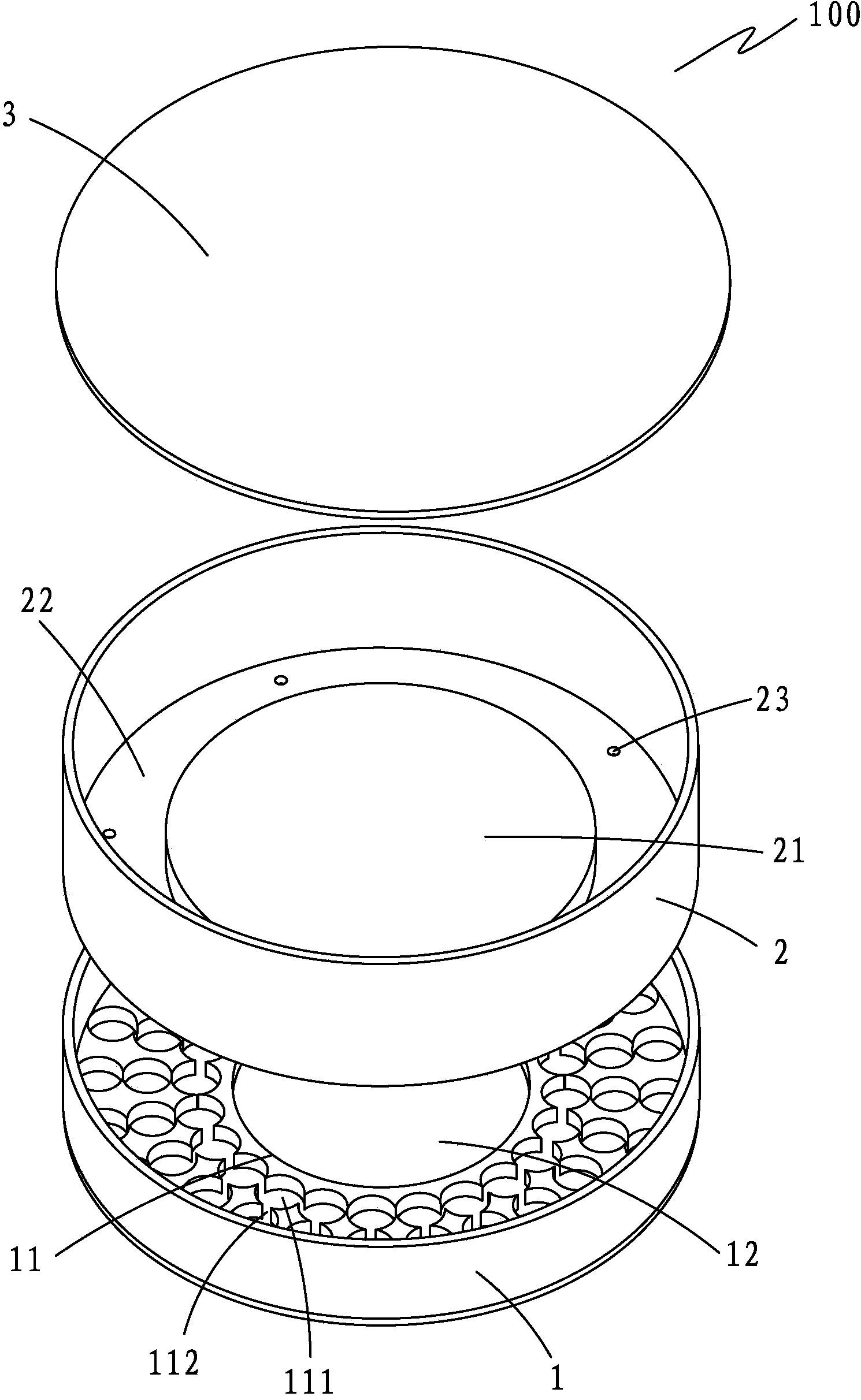

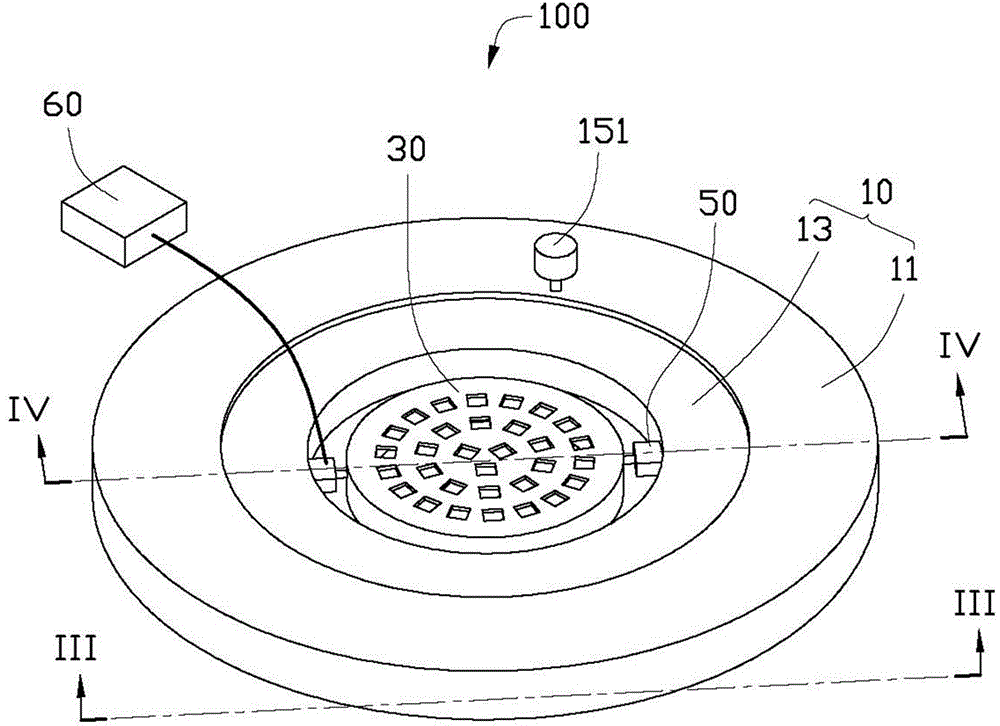

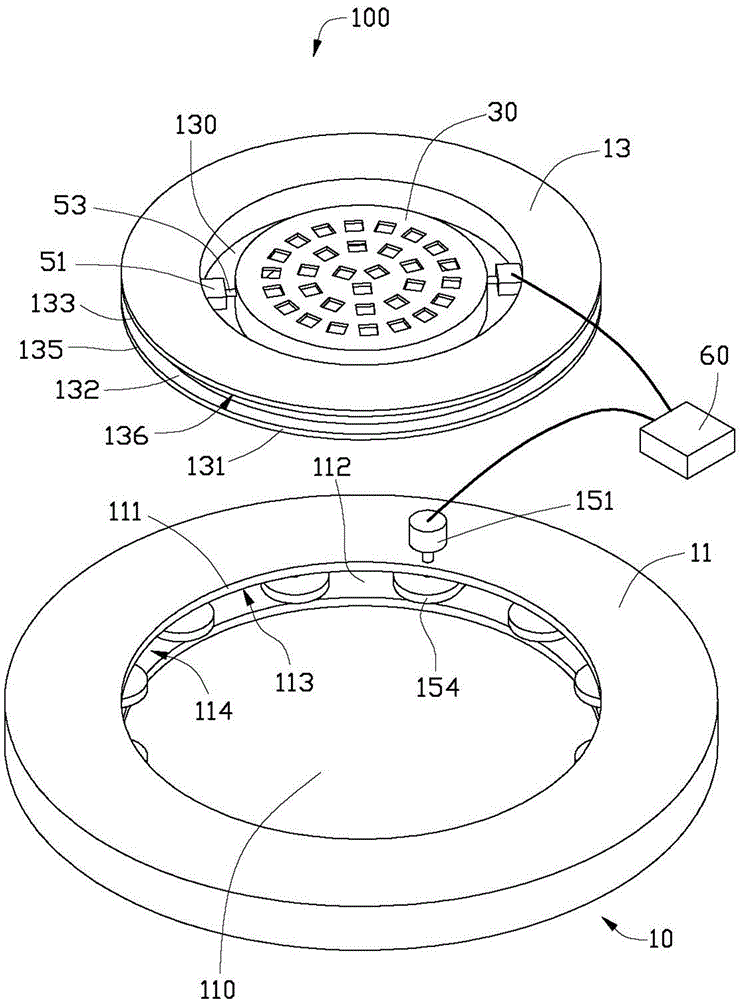

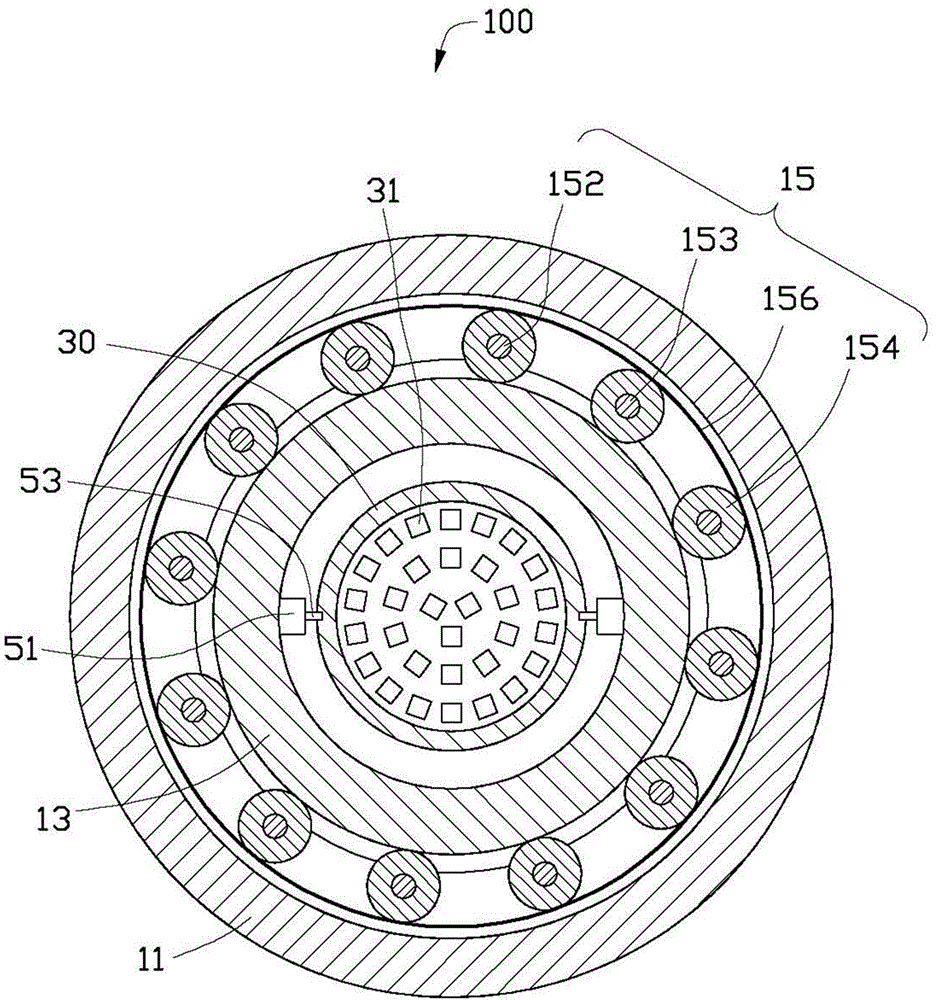

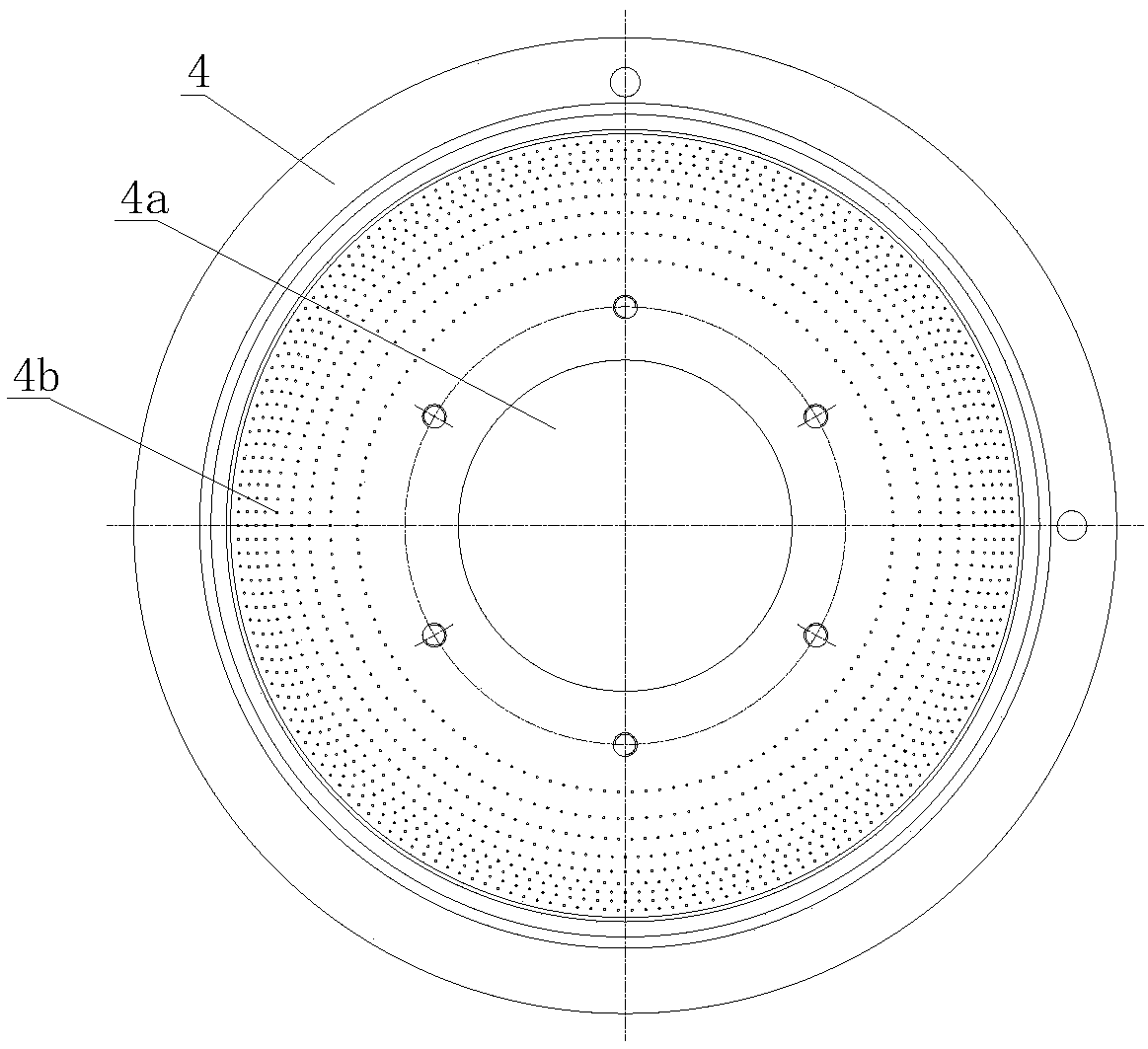

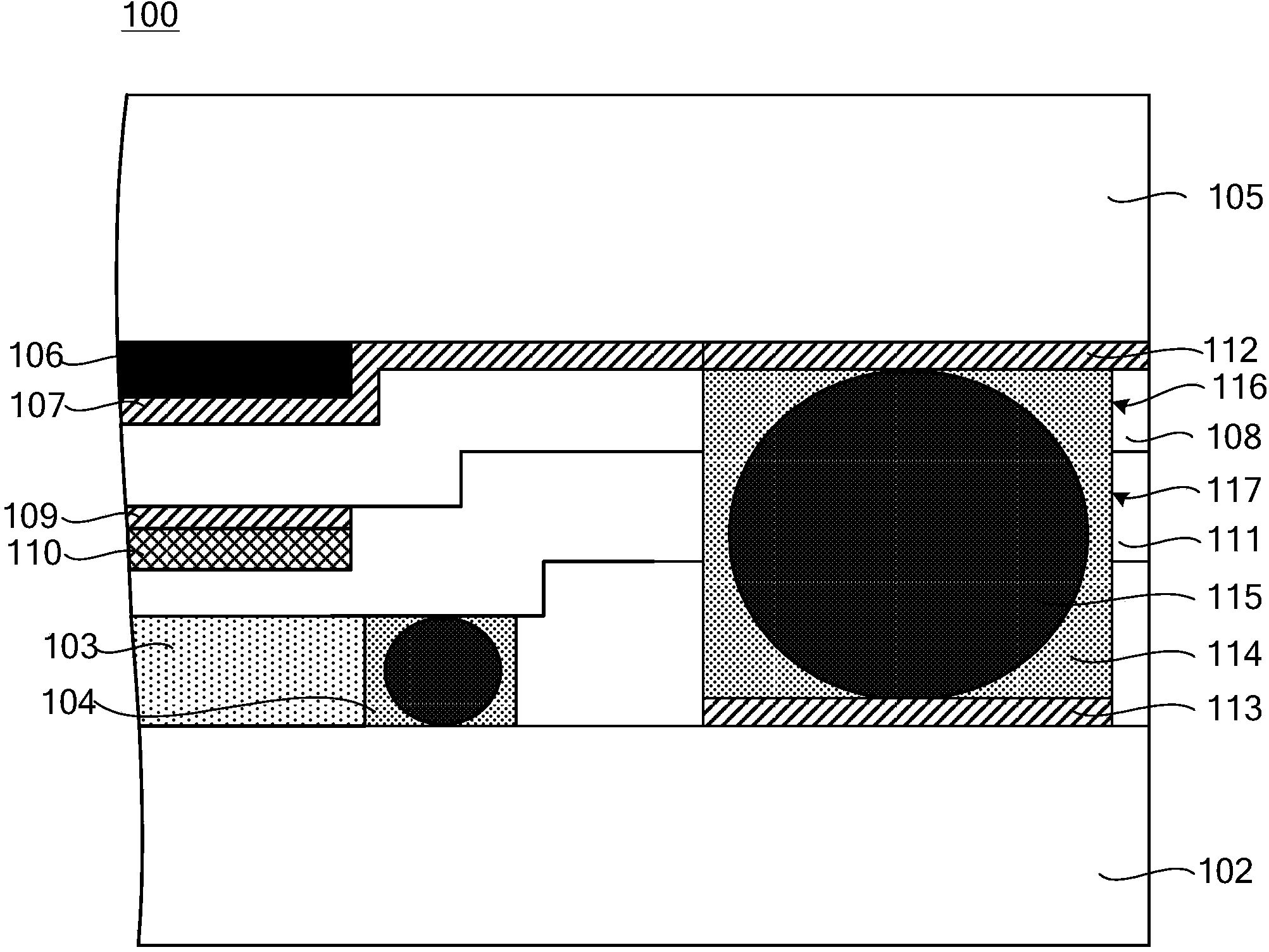

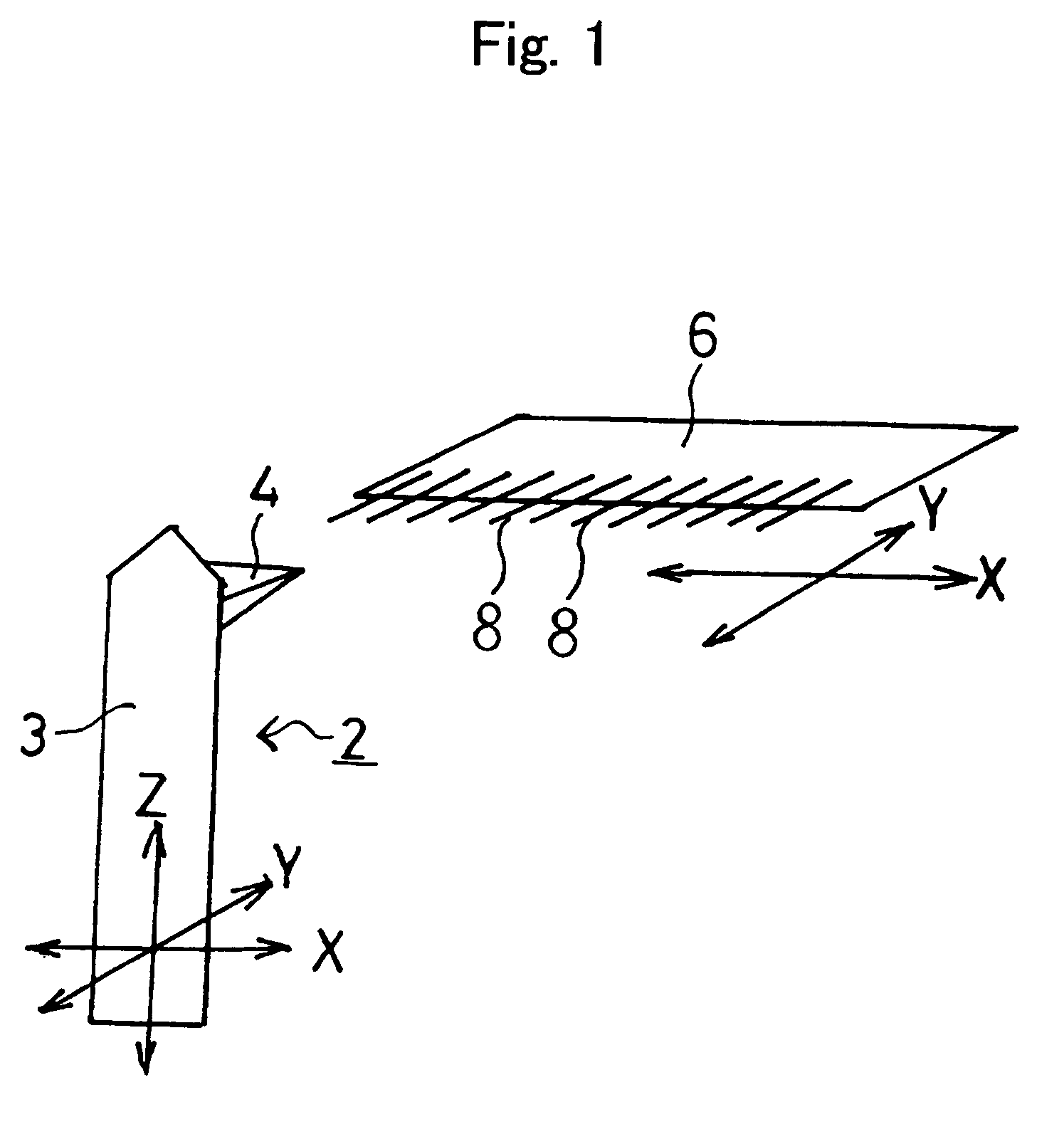

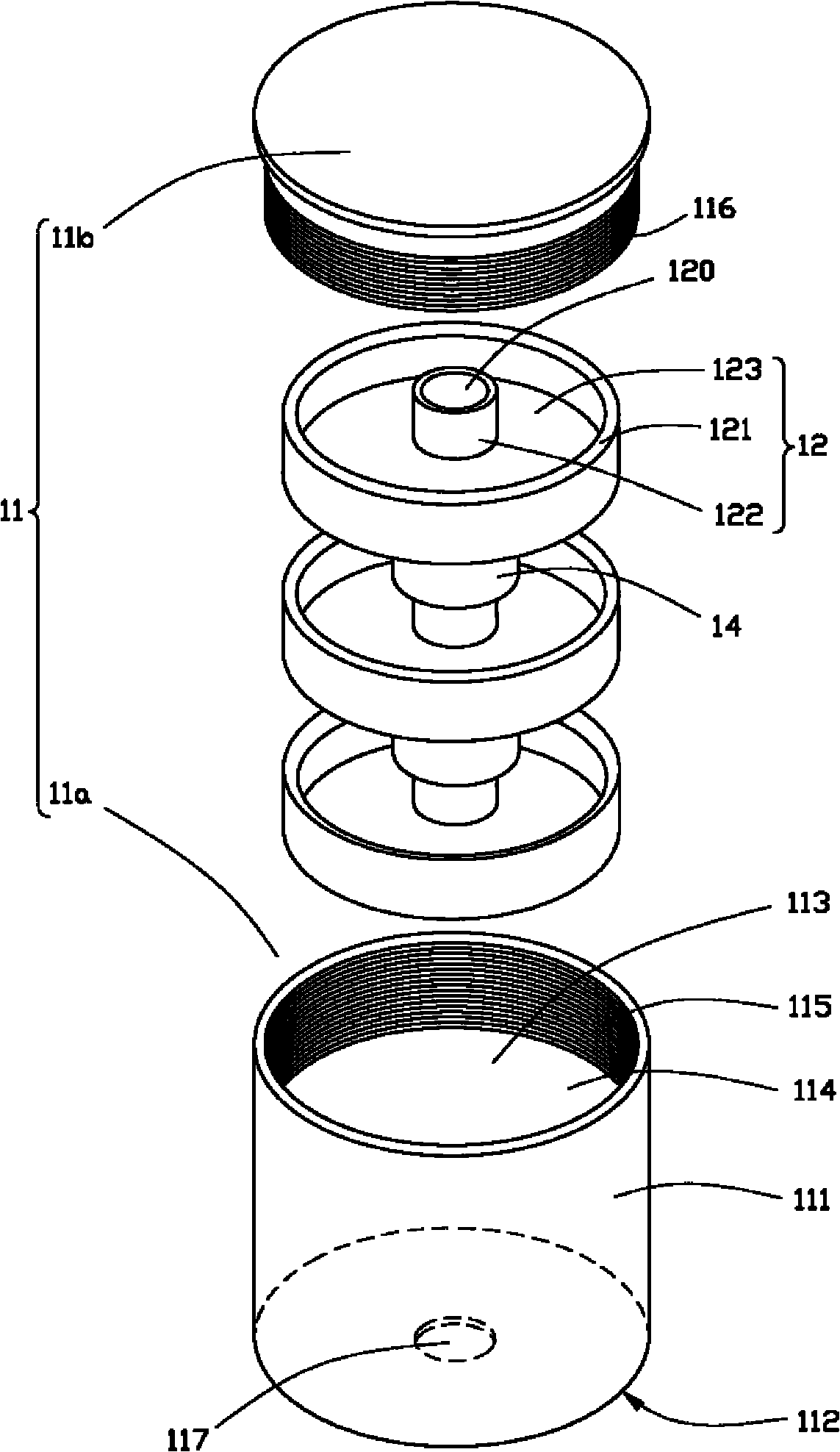

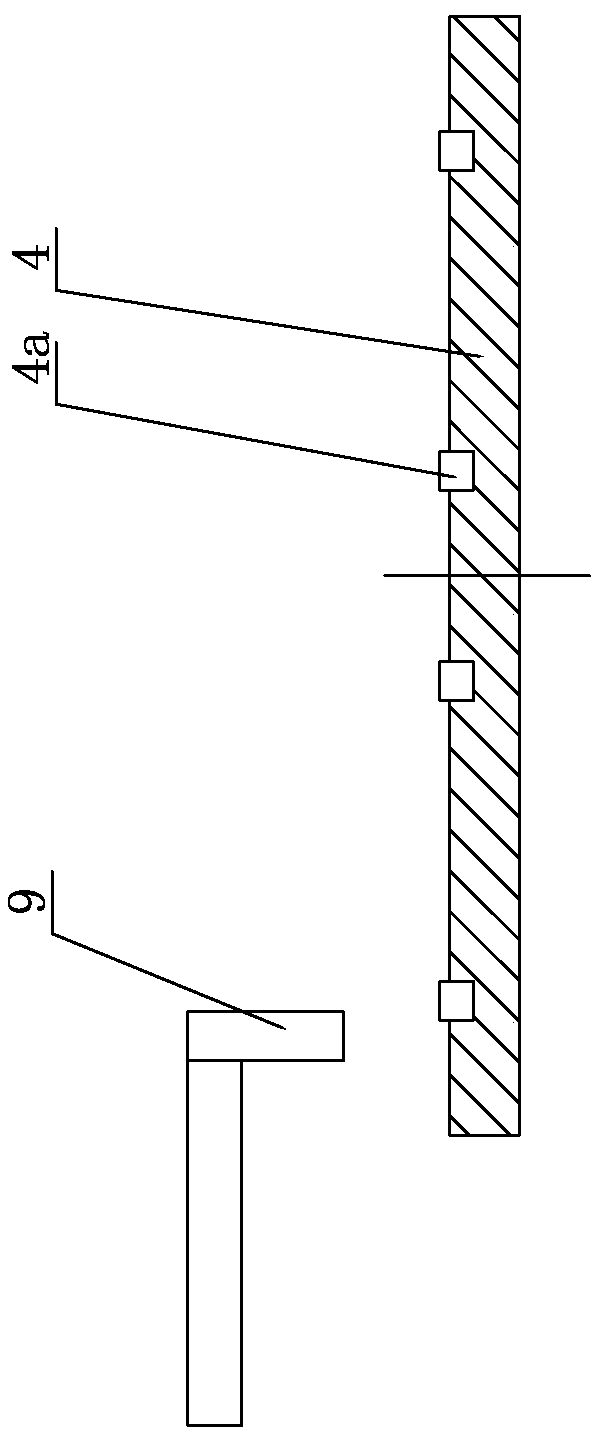

Film coating bearing frame

InactiveCN102796990AReduce heating and vacuuming timesShorten coating timeVacuum evaporation coatingSputtering coatingEngineeringFilm coating

The invention provides a film coating bearing frame, comprising a base, a carrying disc and an overturning assembly, wherein the base comprises an outer frame and a circular-disk-shaped inner frame which is rotatably arranged on the outer frame. The outer frame is provided with a first through hole. The inner frame is contained in the first through hole and is arranged coaxial with the first through hole. The carrying disc is reversibly arranged on the inner frame through the overturning assembly. The carrying disc is provided with a plurality of bearing through holes of bearing pieces to be coated. The overturning assembly comprises two overturning motors and two rotating shafts coupled with the corresponding overturning motors. The two overturning motors are fixedly arranged on the inner frame and are used for driving the corresponding rotating shafts to rotate. The two rotating shafts are oppositely arranged and are located on the same straight line. The opposite two ends of each rotating shaft are respectively fixed on the corresponding overturning motors and the carrying disc. The film coating bearing frame disclosed by the invention utilizes the overturning assembly to automatically overturn the pieces to be coated and the pieces to be coated can be subjected to double-faced film coating without opening a vacuum chamber.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

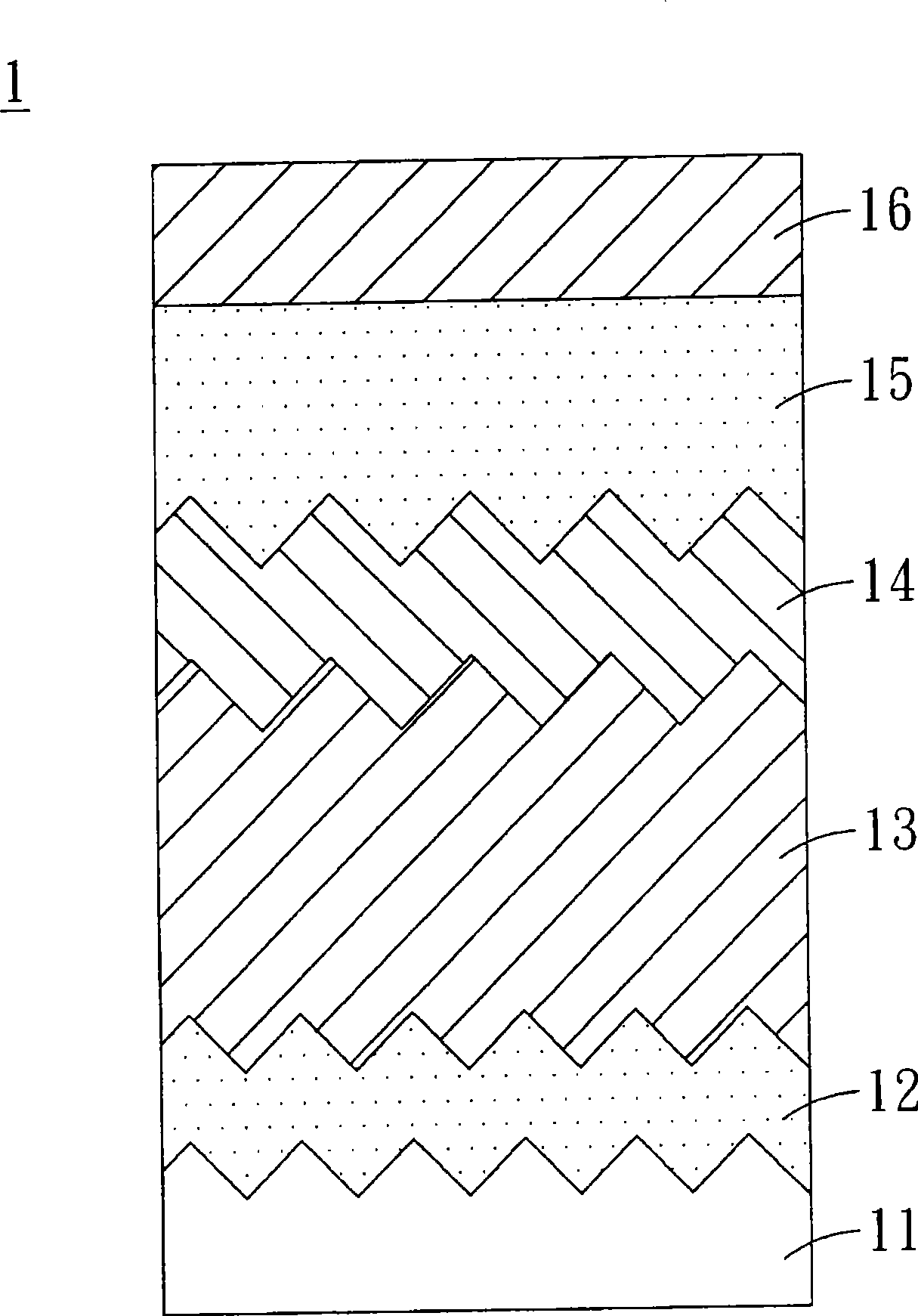

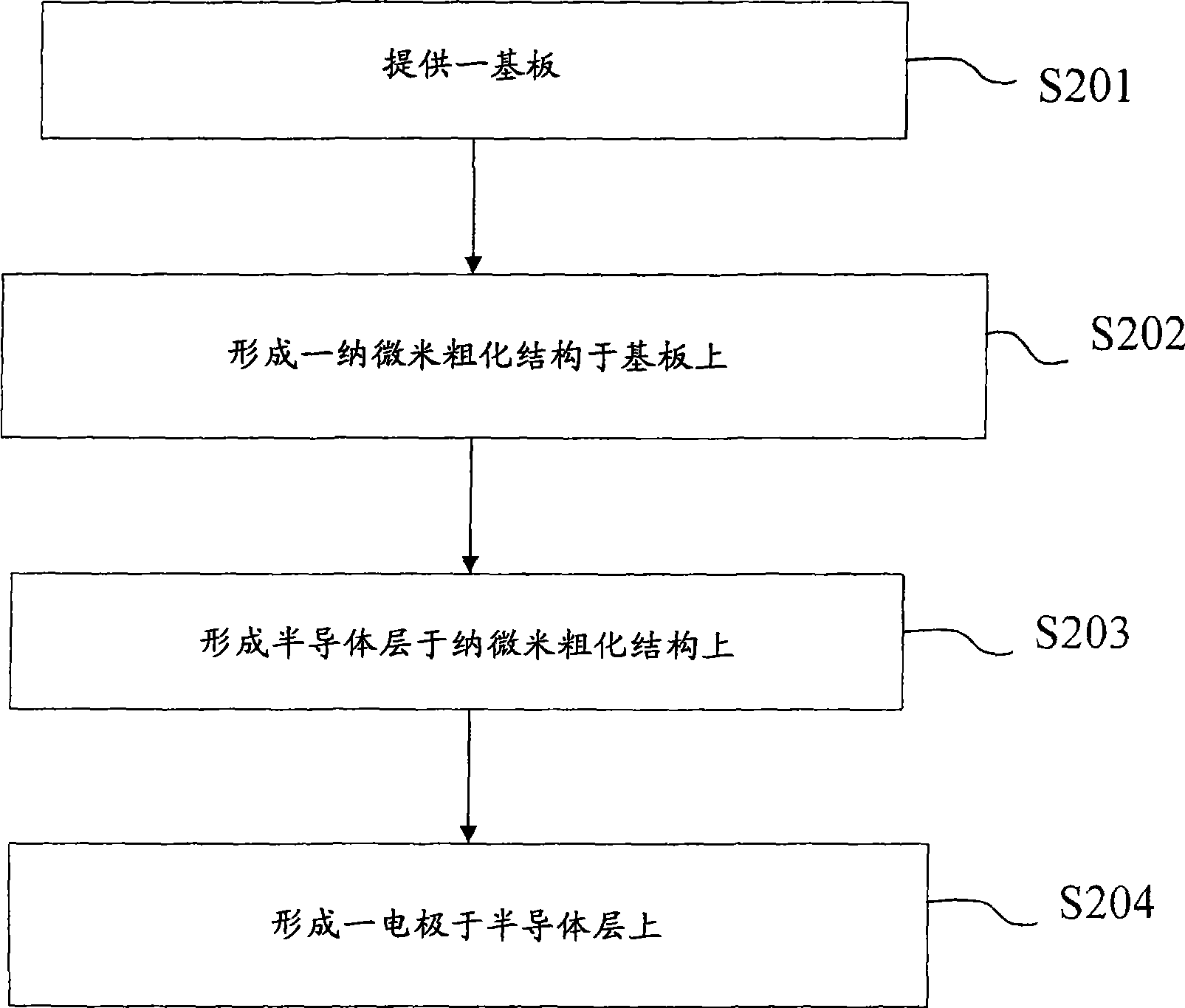

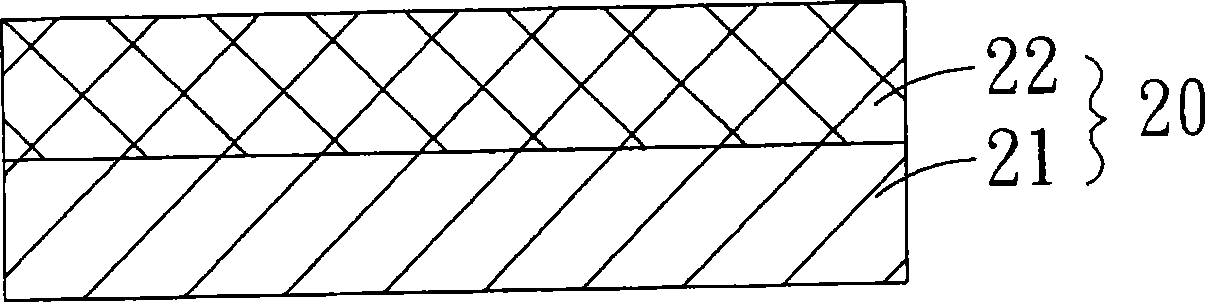

Solar battery and method for manufacturing the same

InactiveCN101459201AAdd Optical PathImprove optical absorption propertiesPhotovoltaic energy generationSemiconductor devicesEngineeringSolar battery

The invention provides a solar cell and a manufacturing method thereof, the solar cell comprises a substrate, a nano-micron coarsening structure and a semiconductor layer, wherein the substrate is provided a first transparent conducting layer, the nano-micron coarsening structure is formed on the first transparent conducting layer, and the semiconductor layer is formed on the nano-micron coarsening structure and is coated on the nano-micron coarsening structure.

Owner:DELTA ELECTRONICS INC +1

Uniformity multi-arc ion coating device

ActiveCN105986229AImprove uniformityReduce defects such as zebra stripesVacuum evaporation coatingSputtering coatingHydraulic cylinderEngineering

The invention relates to a uniformity multi-arc ion coating device, and belongs to the technical field of vacuum coating. The uniformity multi-arc ion coating device comprises multi-arc targets, a vacuum chamber, a path rail and a frame, wherein the path rail and the frame are arranged in the vacuum chamber. The frame is provided with a supporting piece, a center shaft and a rotation disc. The supporting piece used for supporting the frame is movably arranged on the path rail. The center shaft is sleeved with the rotation disc. The rotation disc is provided with a self-rotation shaft rotating relative to the rotation disc. The self-rotation shaft is provided with a clamp, and the multi-arc targets installed on the vacuum chamber face the clamp. The coating device further comprises a linear drive mechanism. The vacuum chamber is provided with a second sealing device, and the linear drive mechanism penetrates the second sealing device to be connected with the frame. A hydraulic cylinder penetrates the second sealing device to be connected to an extending-out arm. A grabbing claw used for grabbing the extending-out arm is arranged at the end portion of a piston rod of the hydraulic cylinder. According to the uniformity multi-arc ion coating device, correction of uniformity of workpiece coating can be achieved, and the overall quality of products is improved.

Owner:广东腾胜科技创新有限公司

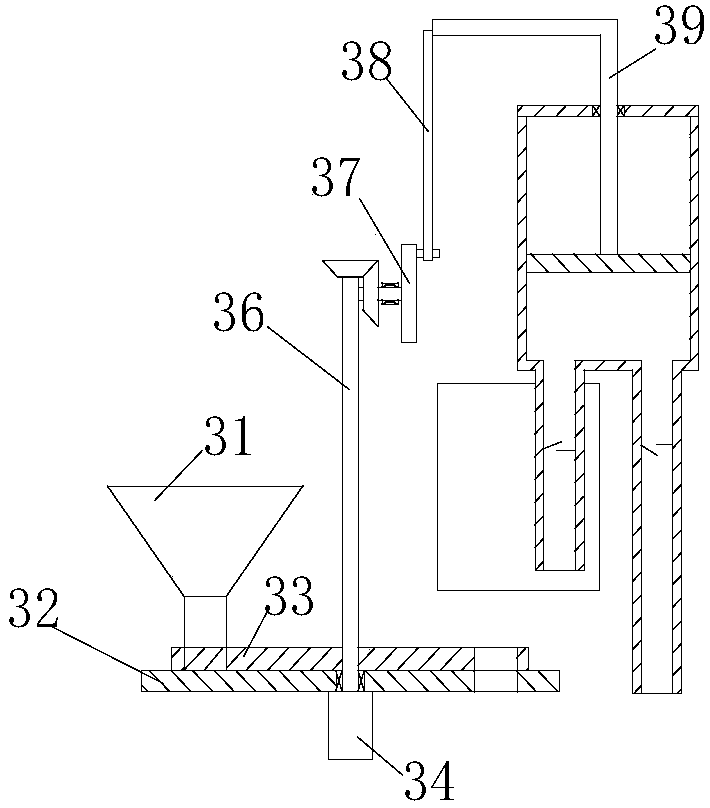

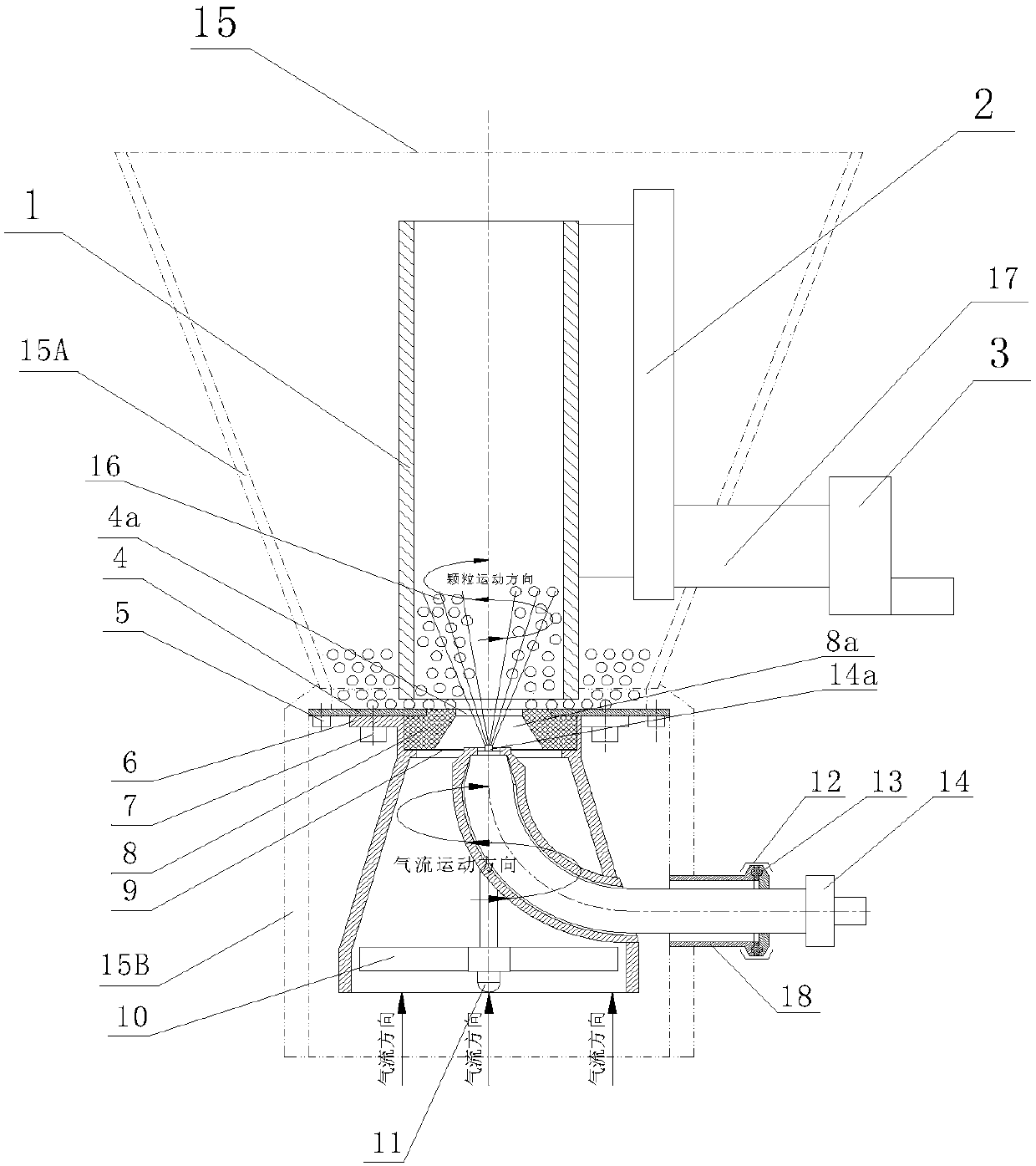

Fluidized bed bottom spraying coating device

PendingCN107638295ARun as usualRealize online gun clearingPharmaceutical product form changeFluidized bedSpray nozzle

A fluidized bed bottom spraying coating device comprises a fluidized bed body with a hollow cavity, and the fluidized bed body comprises an upper body part and a lower body part; the upper body part is provided with pharmaceutical granules and coaxially and vertically provided with a flow guide cylinder; a flow guide cylinder lifting mechanism is arranged on the axial outer side of the flow guidecylinder, and the flow guide cylinder lifting mechanism is indirectly connected with a hand wheel through a rotating shaft; an air flow distribution plate is arranged below the bottom of the flow guide cylinder, an air flow hole communicated with the inner cavity of the flow guide cylinder is formed in the middle of the air flow distribution plate; the air flow distribution plate is connected withthe lower body part; a spray gun mounting base is arranged in the cavity of the lower body part, the top of the spray gun mounting base is connected with the air flow distribution plate; the lower body part is provided with a spray gun base, and a coating spray gun is arranged on the spray gun base; a pressing block is arranged on the air flow distribution plate; a conical center hole is formed in the pressing block, and an intercepting net is arranged on the bottom surface of the pressing block; a nozzle of the spray gun directly faces the conical center hole of the pressing block and protrudes out of the top surface of the intercepting net. By means of the coating device, online gun cleaning is achieved, and operation is convenient; the granules move spirally, the coating effect is good, the coating time is short, and the coating efficiency is high.

Owner:SHANGHAI HAN OU PHARMA EQUIP CO LTD

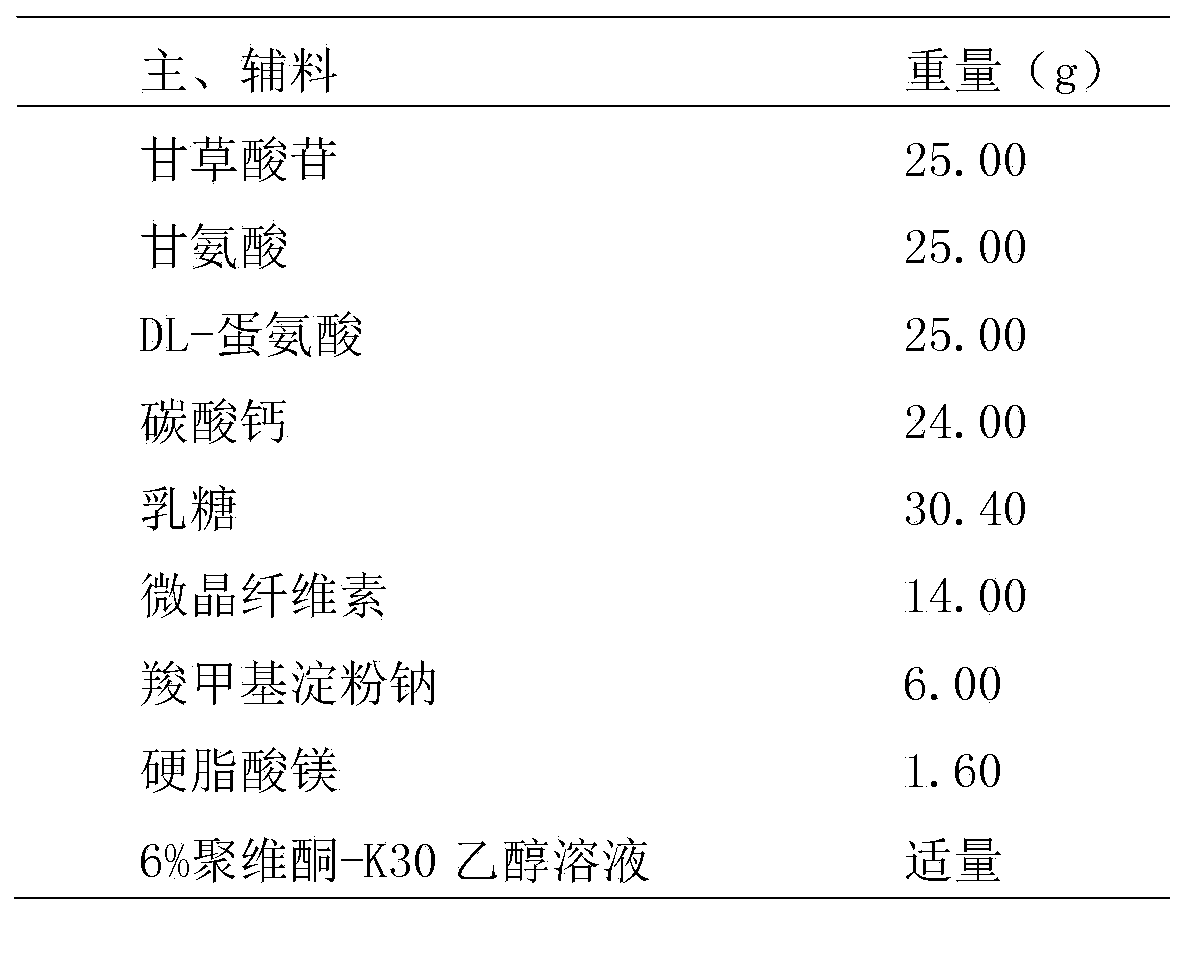

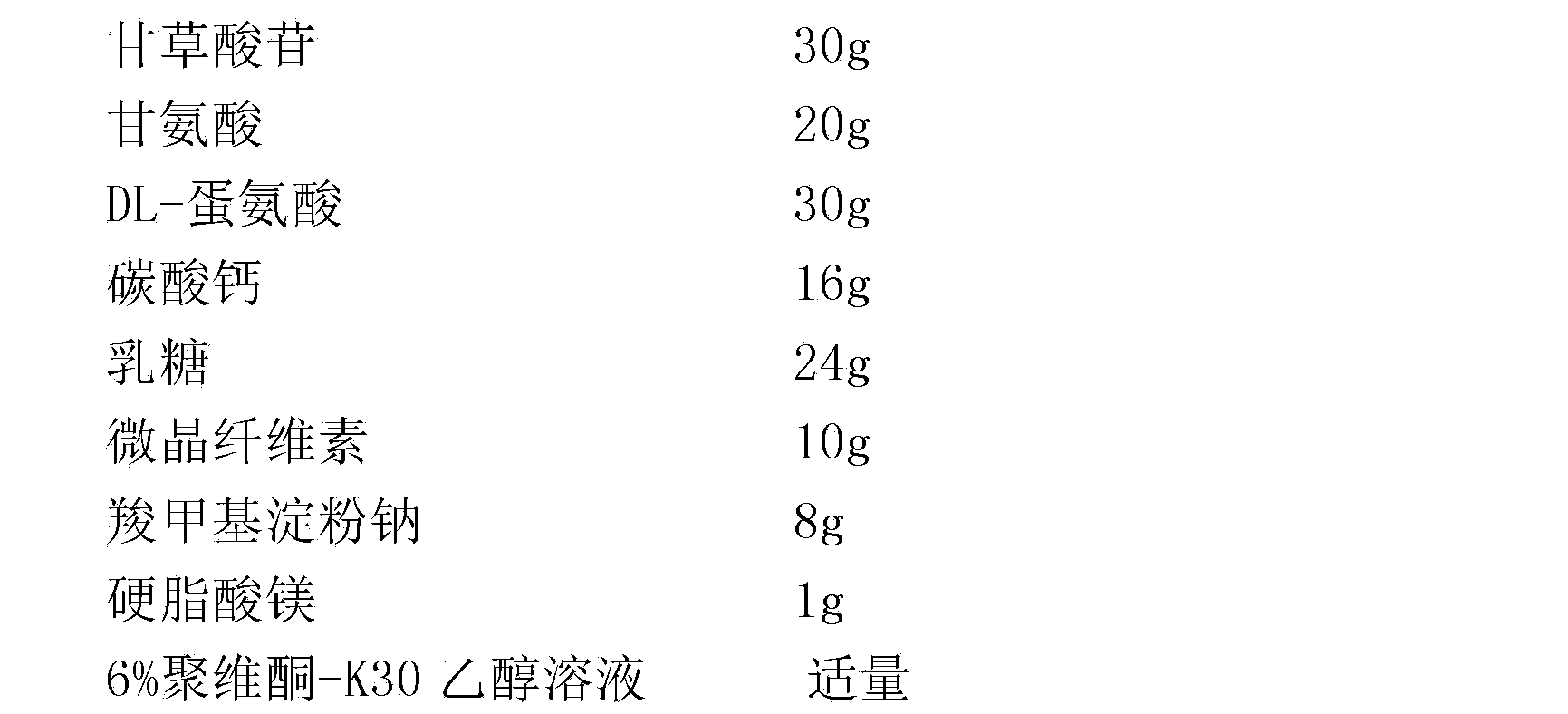

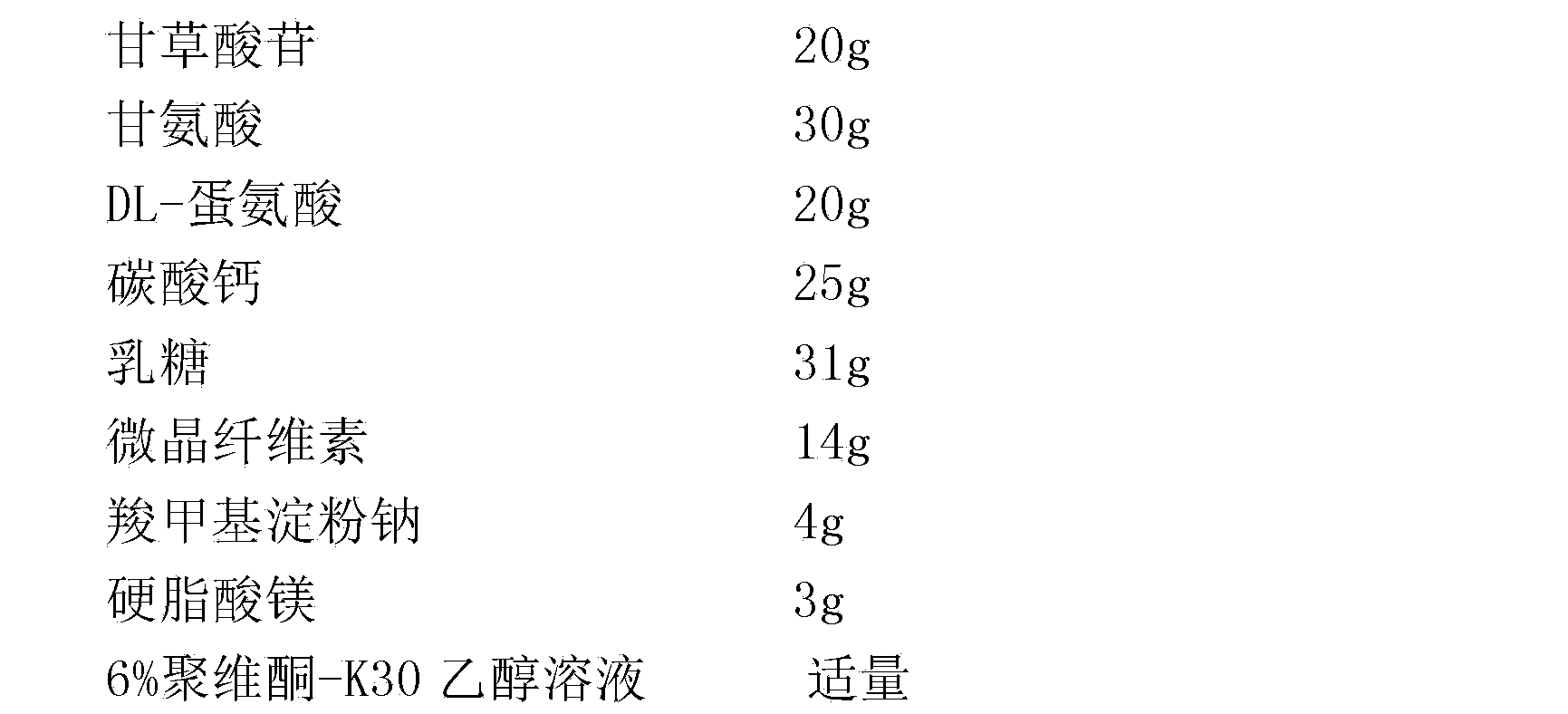

Compound glycyrrhizin tablet and preparation method thereof

InactiveCN103845350AReduce dosageShorten coating timeOrganic active ingredientsDigestive systemGlycineDL-methionine

The invention belongs to the field of medicines, and provides a compound glycyrrhizin tablet and a preparation method thereof. The compound glycyrrhizin tablet is composed of the following raw materials in parts by weight: 10-50 parts of glycyrrhizin, 10-50 parts of glycine, 10-50 parts of DL-methionine, 30-90 parts of a diluent, 1-20 parts of a disintegrating agent and 0.5-5 parts of a lubricant. The provided compound glycyrrhizin tablet has the advantages of good absorption, beautiful appearance, convenience in administration and carrying around, suitability for long-term administration, simple preparation method, industrial production applicability, and the like.

Owner:BEIJING INCREASEPHARM CORP LTD

Kit for detecting biomarker of Alzheimer's disease and detection method thereof

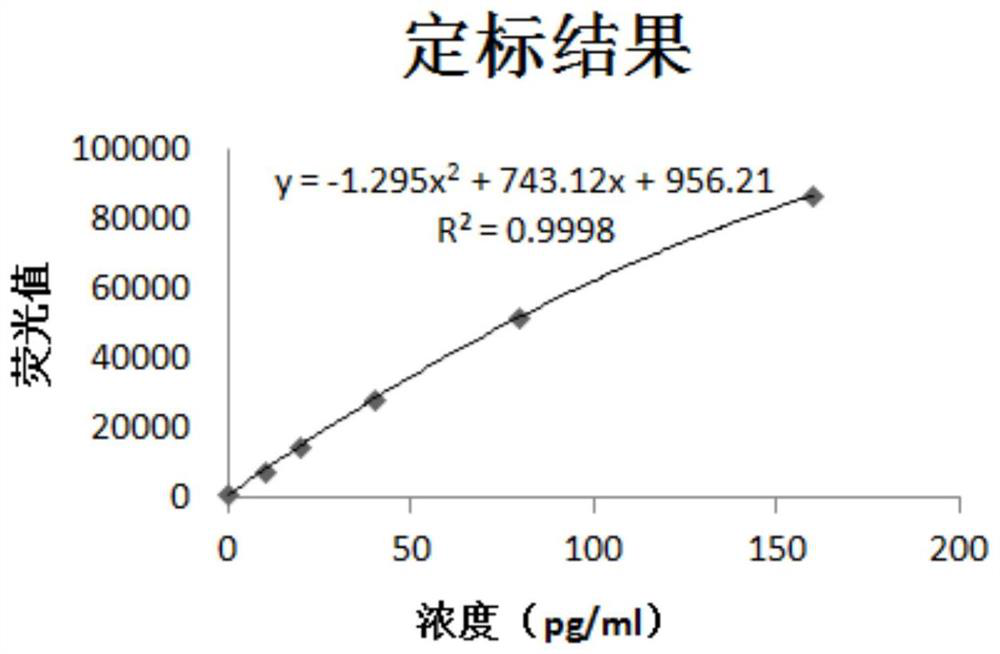

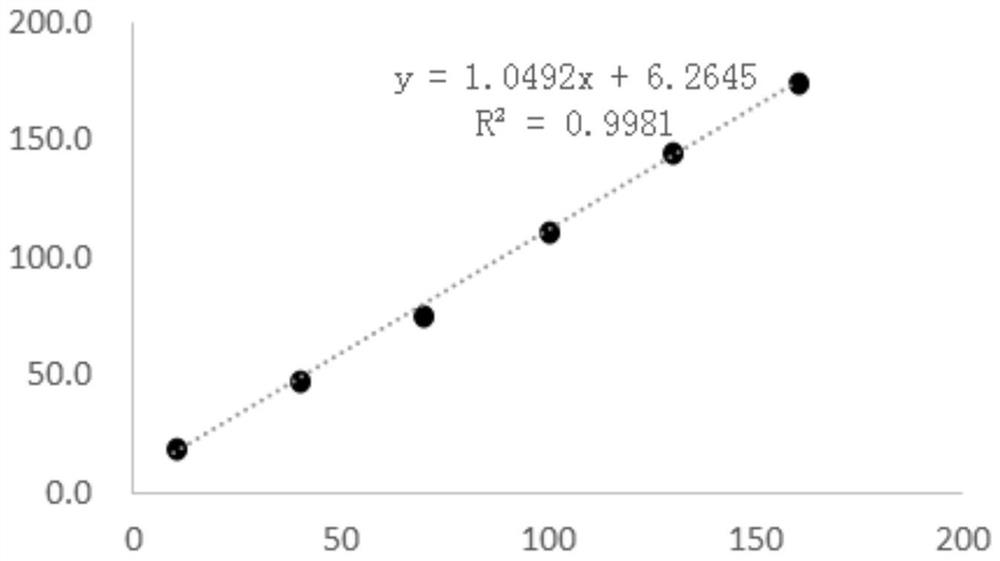

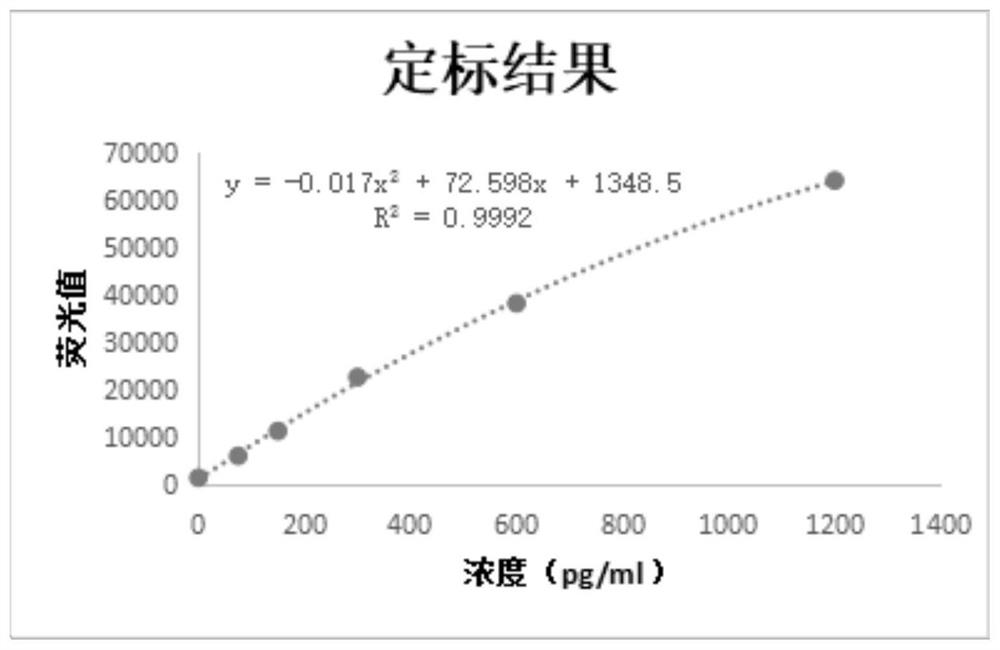

PendingCN112162101AImprove corrosion resistanceImprove the coating processDisease diagnosisBiological testingHorse-radishAntiendomysial antibodies

The invention discloses a kit for detecting a biomarker of an Alzheimer's disease, and relates to the technical field of in vitro diagnosis. The kit comprises a horse radish peroxidase labeled biomarker antibody solution, an anti-biomarker antibody coated elisa plate, a concentrated washing solution, a luminous substrate solution, a calibration product and a quality control product. The inventionfurther discloses a preparation method of the elisa plate coated with the anti-biomarker antibody. The kit has the beneficial effects that on the basis of chemiluminiscence immunoassay, the elisa plate coated with the anti-biomarker antibody is introduced, a coating process of the anti-biomarker antibody is improved, the reaction sensitivity is increased, a reagent production process is simplified, production time is shortened, and the detection kit which is high in quality, low in price, stable, reliable, good in repeatability, small in batch difference and high in accuracy is provided for the market.

Owner:NANJING LEADING BIOMEDICAL TECH CO LTD

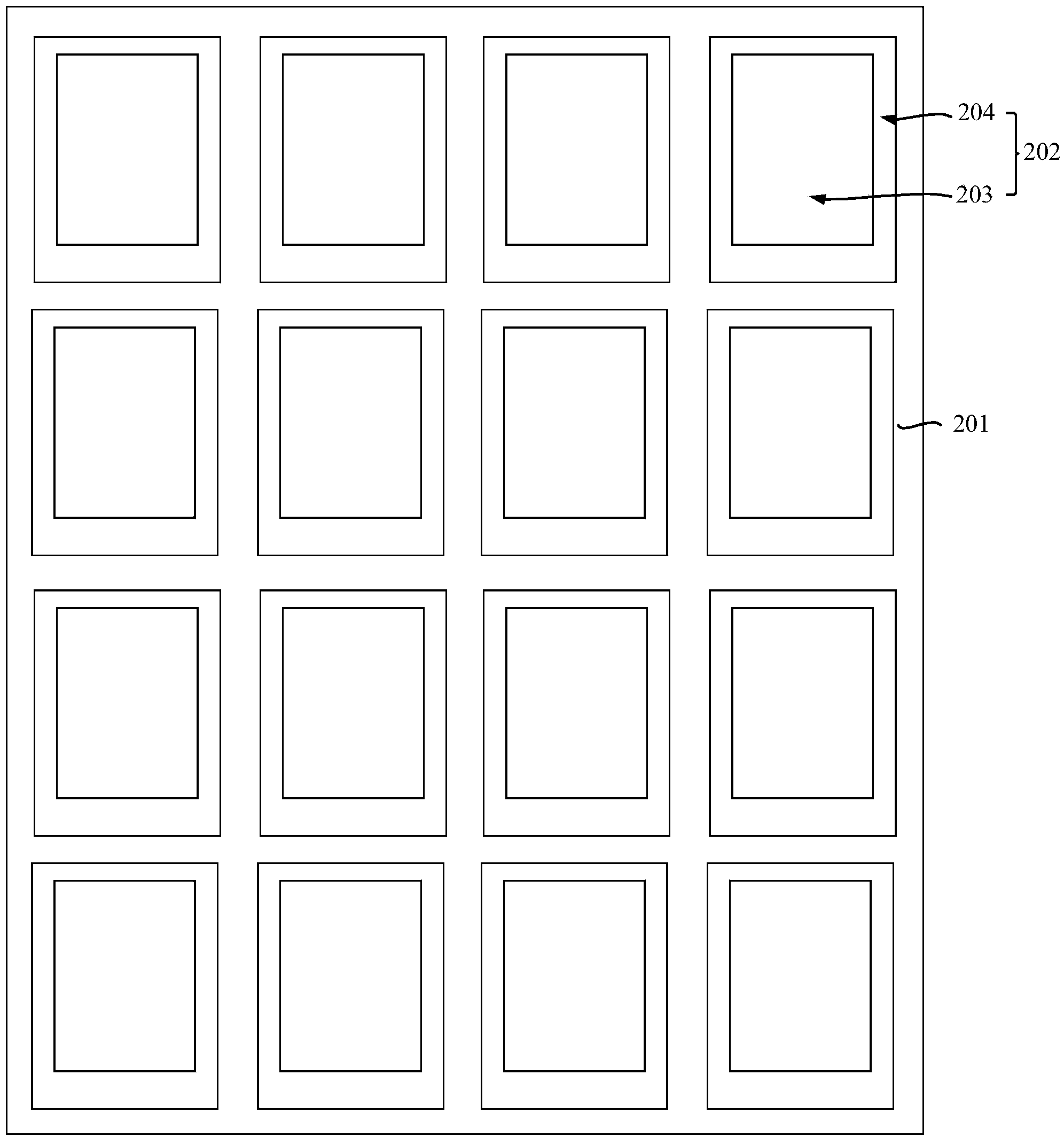

Embedded touch colour-film substrate and manufacturing method thereof

ActiveCN103984145AReduce the number of coatsShorten coating timeNon-linear opticsInput/output processes for data processingCushionOptoelectronics

The invention discloses an embedded touch colour-film substrate and a manufacturing method thereof. The embedded touch colour-film substrate comprises a substrate, first metal layers, first organic film layers, second metal layers and second organic film layers, wherein the substrate comprises multiple display areas and multiple nondisplay areas surrounding the display areas; the first metal layers, the first organic film layers, the second metal layers and the second organic film layers are formed on the substrate in sequence; each of the second metal layers comprises multiple electric conduction cushions arranged in the nondisplay areas; multiple through holes or through grooves are formed in each of the first organic film layers in the nondisplay areas; the electric conduction cushions are respectively and electrically connected with the first metal layers through the through holes or the through grooves; moreover, the electric conduction cushions are respectively exposed outside the second organic film layers. By applying the embedded touch colour-film substrate provided by the invention, the time on coating a frame sealing glue can be effectively shortened, so that the production efficiency can be improved greatly.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Nanotube probe and a method for manufacturing the same

InactiveUS7511270B2Improve practicalityShorten coating timeMaterial analysis using wave/particle radiationNanosensorsBeam diameterCantilever

The present invention realizes a nanotube probe with high durability that can be manufactured in short time with less impurities adhered to the holder sustaining the nanotube. The nanotube probe according to this invention is constructed by fastening a nanotube 8 on the protruded portion 4 of a cantilever by way of at least two partial coating films 12a and 12b. One or more additional partial coating films may be formed in the intermediate area between these two partial coating films. Each partial coating film is formed by irradiating electron beam 10 on the position where the nanotube 8 is in contact with the protruded portion 4 of the cantilever. The partial coating films are separated not to overlap each other. By minimizing the size of partial coating film as well as by narrowing down the beam diameter, coating time may be further shortened. With the beam diameter narrowed down, excessive deposit of impurities can be put under control.

Owner:NAKAYAMA YOSHIKAZU +1

Antique paint spraying technology for high-quality furniture

InactiveCN106216210ASimplify the production processReduce material usagePretreated surfacesCoatingsMachining processMaterials science

The invention discloses an antique paint spraying technology for high-quality furniture. The antique paint spraying technology is characterized by comprising the following processes of (1), the white blank polishing process, (2), the antique agent spraying process, (3), the primer spraying process, (4), the sand removal process, (5), the embellishing process, (6), the finishing coat spraying process, (7), the drying process and (8), the finishing and polishing process. The antique paint spraying technology solves the problems that an existing antique furniture spraying technology is complex in operation process, cumbersome in processing process and poor in spraying quality.

Owner:成都四通瑞坤科技有限公司

Paint archaized coating process for furniture

The invention discloses a paint archaized coating process for furniture. The paint archaized coating process is characterized by comprising the following steps of: polishing a white blank, namely polishing the surface of the furniture, so that the surface is smooth; spraying an archaizing agent, namely spraying the archaizing agent on the surface and then drying; spraying primer, namely uniformly spraying the primer after the archaizing agent is dried; and trimming and polishing, namely polishing the surface of the paint, so that the surface is smooth. Compared with the traditional process, the process has the advantages that procedures of applying oil stain, coating a first layer of primer, performing secondary polishing and coating glaze are eliminated, so that the production procedures are simplified, using materials are reduced, the production cost is saved, the paint coating time is shortened, and the production efficiency is improved; and the primary polishing process is eliminated, so that dust generated during polishing is reduced, and the environmental pollution is reduced.

Owner:A ZENITH HOME FURNISHINGS CO LTD

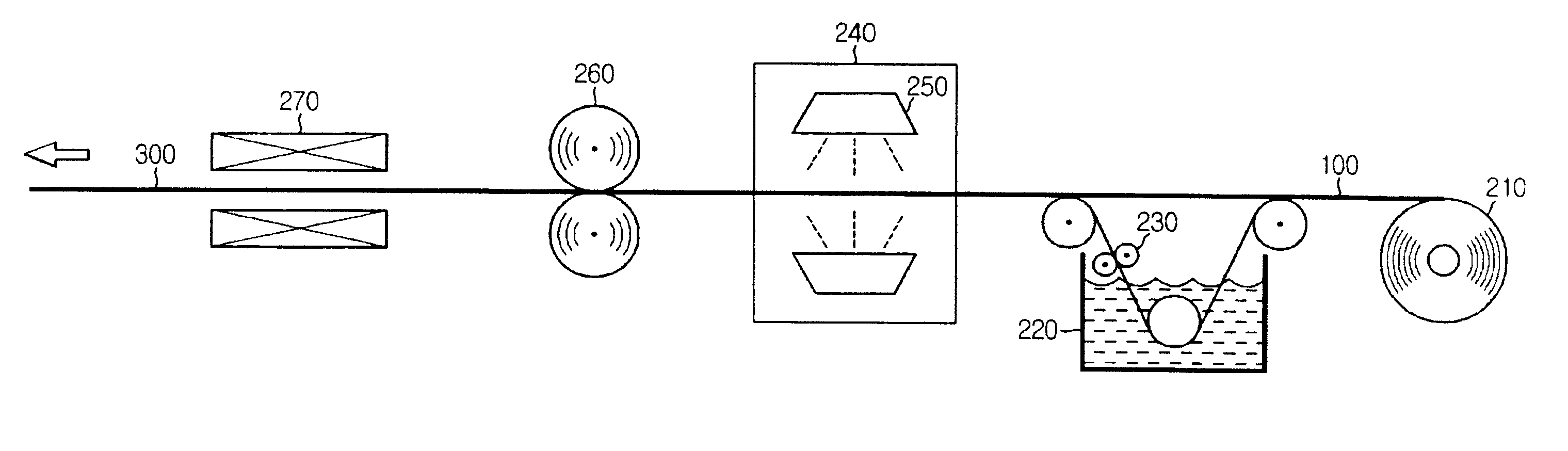

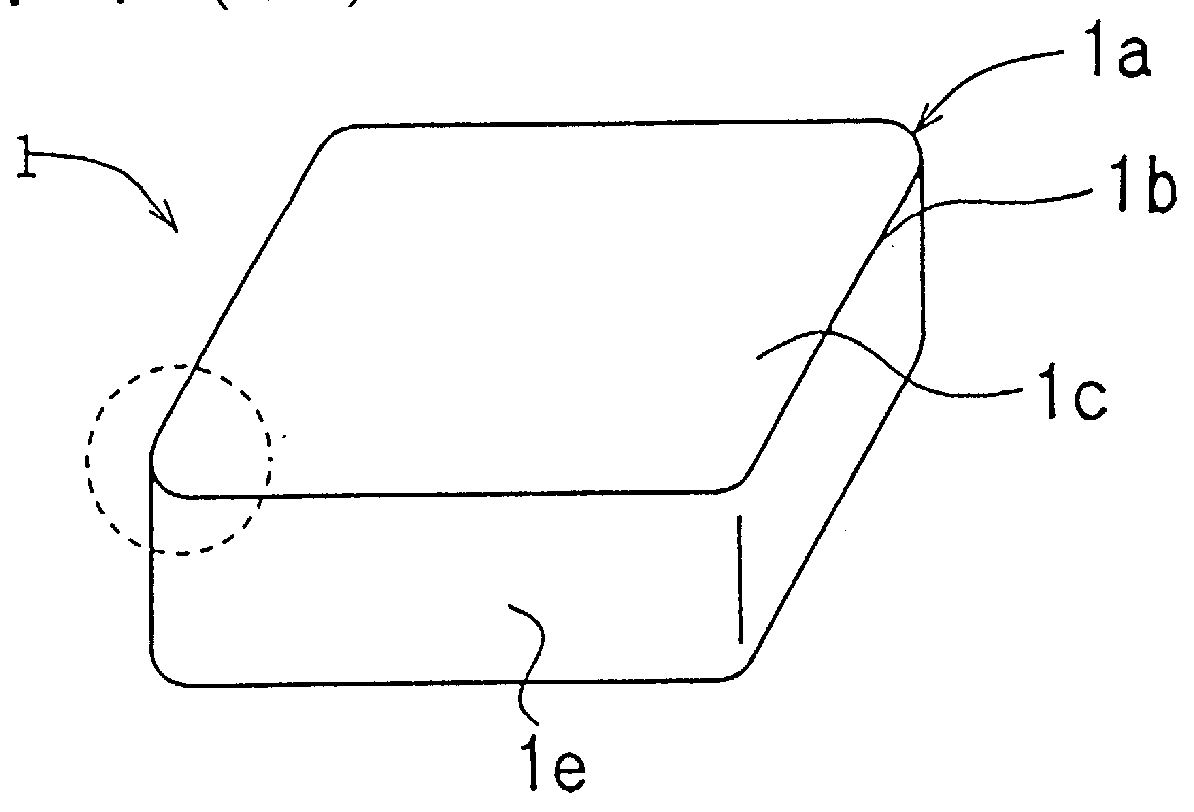

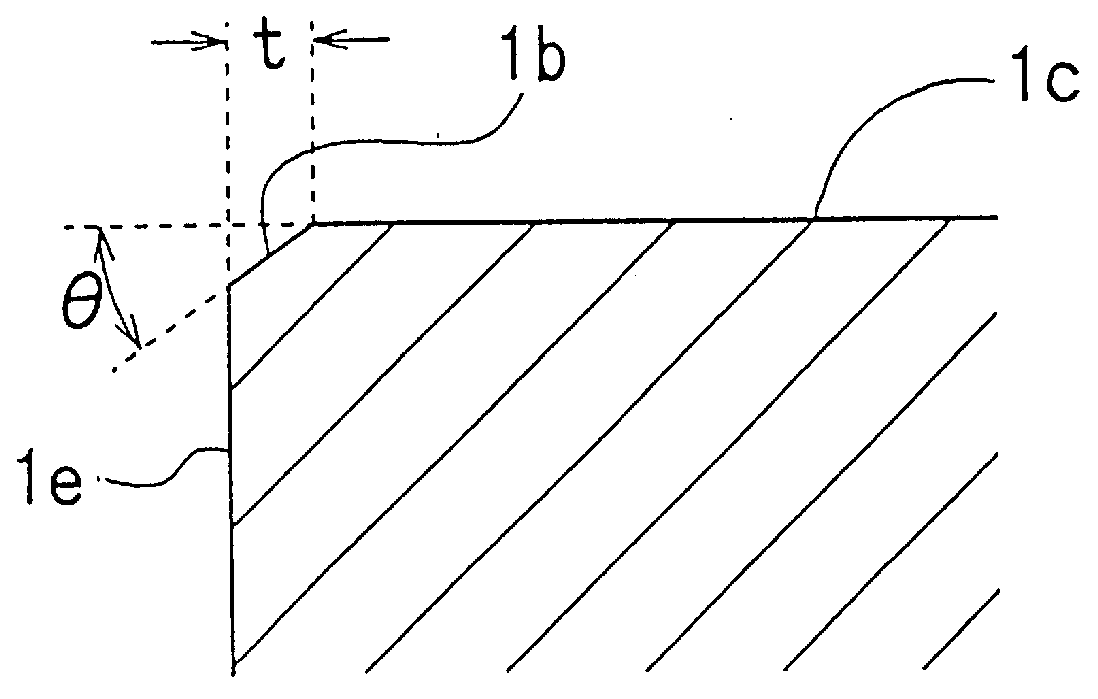

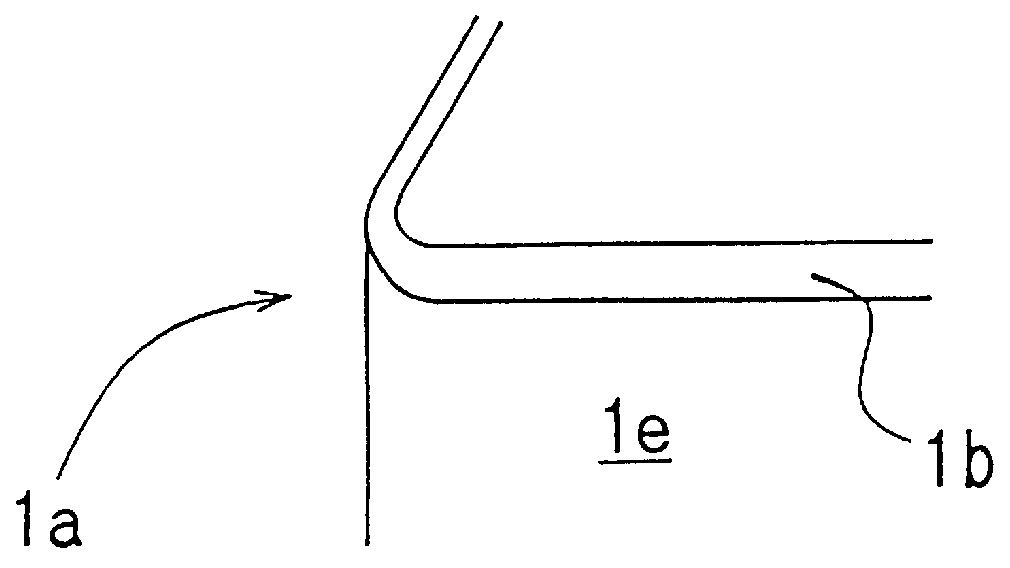

Method and apparatus for flux coating of heat exchanger tube

InactiveUS20080069947A1Reduce coatingShorten coating timePretreated surfacesCoatingsMetallurgySolvent

For flux coating of a heat exchanger tube made of aluminum, firstly, the heat exchanger tube is dipped in a storage tank containing a mixture of binder and solvent to coat the mixture on a surface of the heat exchanger tube, thereby forming a first coating layer on the surface of the heat exchanger tube. Then, flux powder is sprayed to the surface of the heat exchanger tube on which the first coating layer is formed, thereby forming a second coating layer. After that, a thickness of the heat exchanger tube on which the second coating layer is formed is controlled. Then, the thickness-controlled heat exchanger tube is heated to 150° C. or below so as to remove the solvent from the second coating layer.

Owner:LG CABLE LTD (KR)

Titanium carbo-nitride complex silicon nitride tool

InactiveUS6010777ANecessary strengthEfficient productionPigmenting treatmentOther chemical processesTitaniumHardness

Titanium carbo-nitride complex silicon nitride tool is composed mainly of titanium carbo-nitride and silicon nitride and contains 10 to 56 wt % of Ti, 11.6 to 51 wt % of Si and 1 to 21 wt % in total of one or two or more of Ce, Y, Yb and Dy. The tool is mainly composed of Si3N4 superior in both strength and resistance against thermal shock and TiCN superior in the effect of suppressing reactivity of Si3N4 with Fe and exhibiting high hardness. By using oxides CeO2, Y2O3, Yb2O3 and Dy2O3 as sintering aid so that the sum of the amounts of Ce, Y, Yb and Dy will be in the above range, both the resistance against flank notch (wear) of the end edge and resistance against thermal shock are improved resulting in improved durability as compared to the conventional silicon nitride cutting tool.

Owner:NGK SPARK PLUG CO LTD

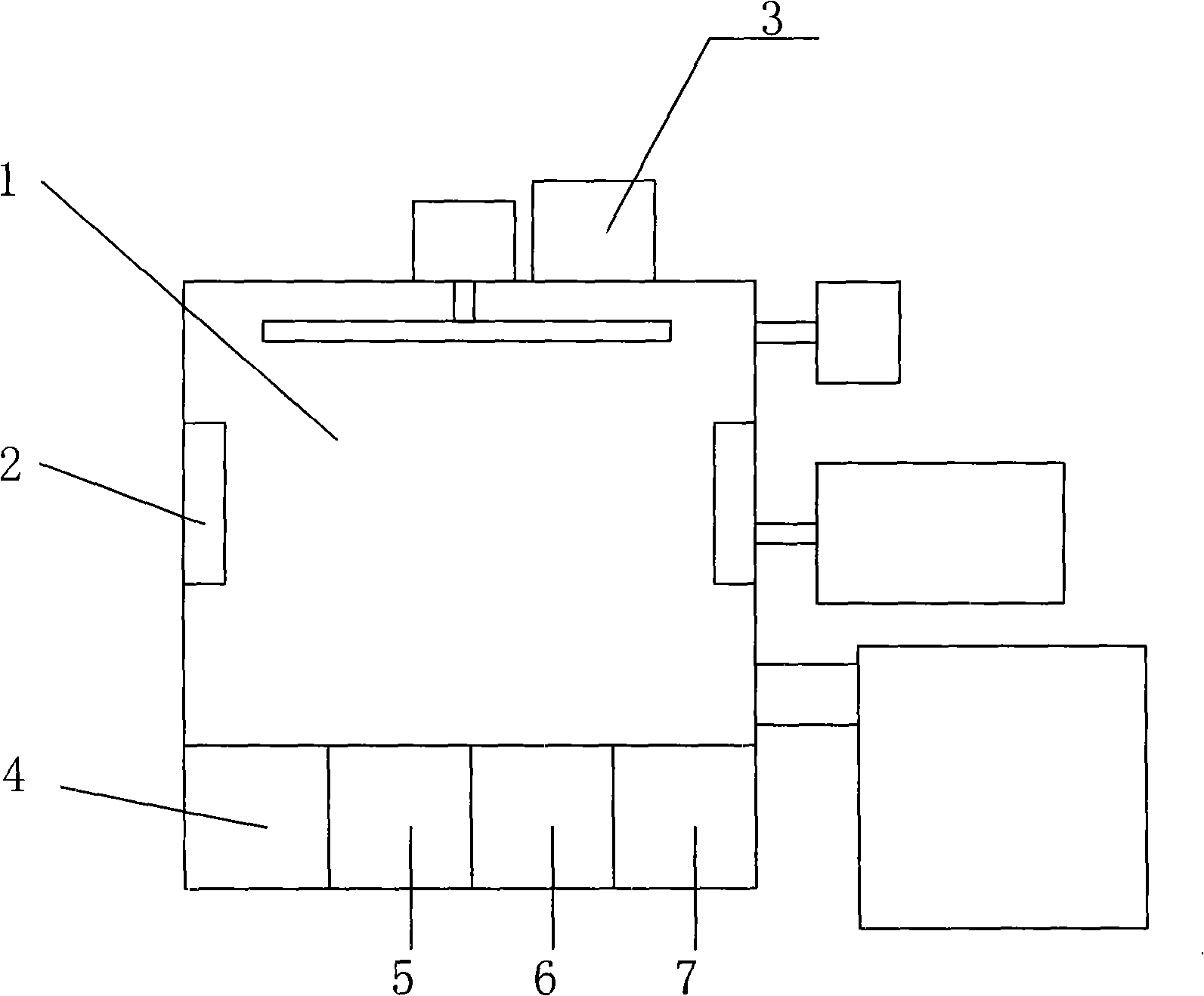

Optical coating method and optical film coater using the method

InactiveCN101359061ATo meet preparation needsAvoid the problems of decreased adhesion and even strippingVacuum evaporation coatingSputtering coatingTemperature controlOptical coating

The invention relates to the technical field of optical manufacturing and photoelectric component production equipment, in particular to an optical coating method and an optical coating machine which uses the optical coating method. The invention aims to solve the problems that the prior art can not meet the demands of the preparation of various optical films, optoelectronic functional multi-layer films, as well as photoelectric micro-systems, and the equipment investment is high. To solve the problems in the prior art, the following technical proposal is provided: an optical coating method combines the vacuum cathodic arc coating technology, the magnetron sputtering coating technology and the thermal evaporation coating technology in accordance with the types of the films; during the using process, the plated piece is maintained in a vacuum state and carries out rapid conversion of the evaporation source in a real-time way. At the same time, the invention provides an optical coating machine which comprises a vacuum coating chamber, a temperature control system, a film thickness control system, a gas flow providing and control system, as well as a thin-film evaporation system; and the thin-film evaporation system comprises a cathodic vacuum arc generator, a magnetron sputtering device and a thermal evaporation device.

Owner:XIAN TECH UNIV

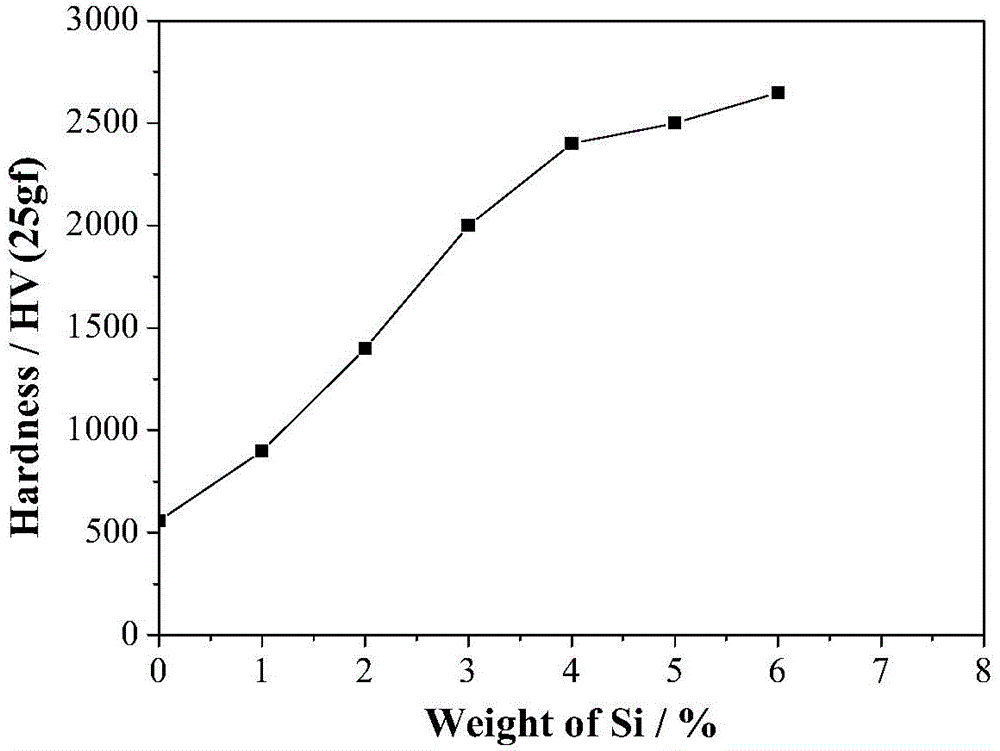

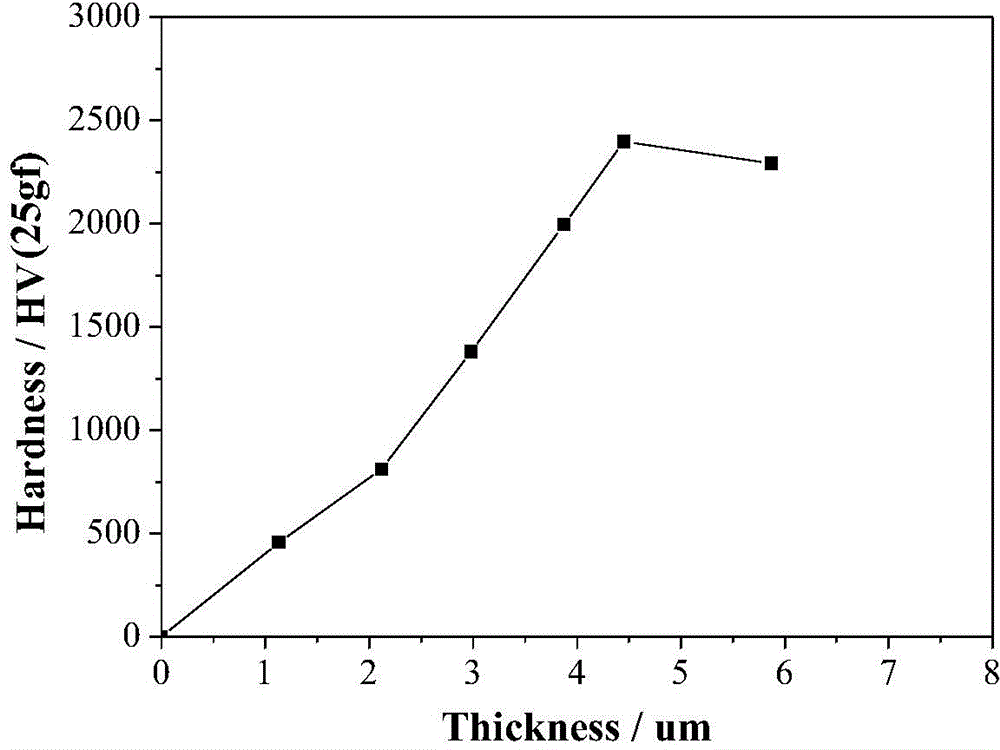

Metal piece and preparing method thereof

ActiveCN105586575AShorten coating timeVacuum evaporation coatingSputtering coatingMicrometerChromium

The invention provides a metal piece. By the adoption of the metal piece, the problems that in the prior art, a hard coating on the surface of stainless steel is low in hardness and poor in tenacity and has no metallic luster are solved. The metal piece comprises a metal base and a coating adhering to the surface of the metal base. The coating is prepared from, by weight, 3%-5% of silicon and the balance chromium. The thickness of the coating is 2.5-5 micrometers. Meanwhile, the invention discloses a preparing method of the metal piece. The coating on the surface of the metal piece has extremely high hardness and is good in tenacity and not prone to peeling; meanwhile, the coating has metallic luster.

Owner:SHENZHEN SENTAI METAL TECH CO LTD

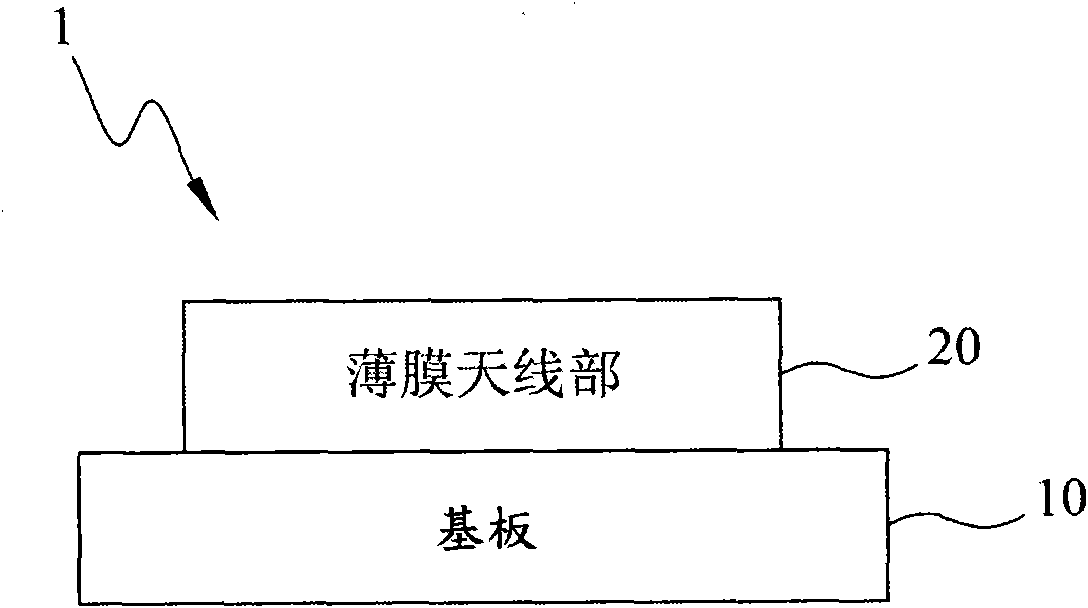

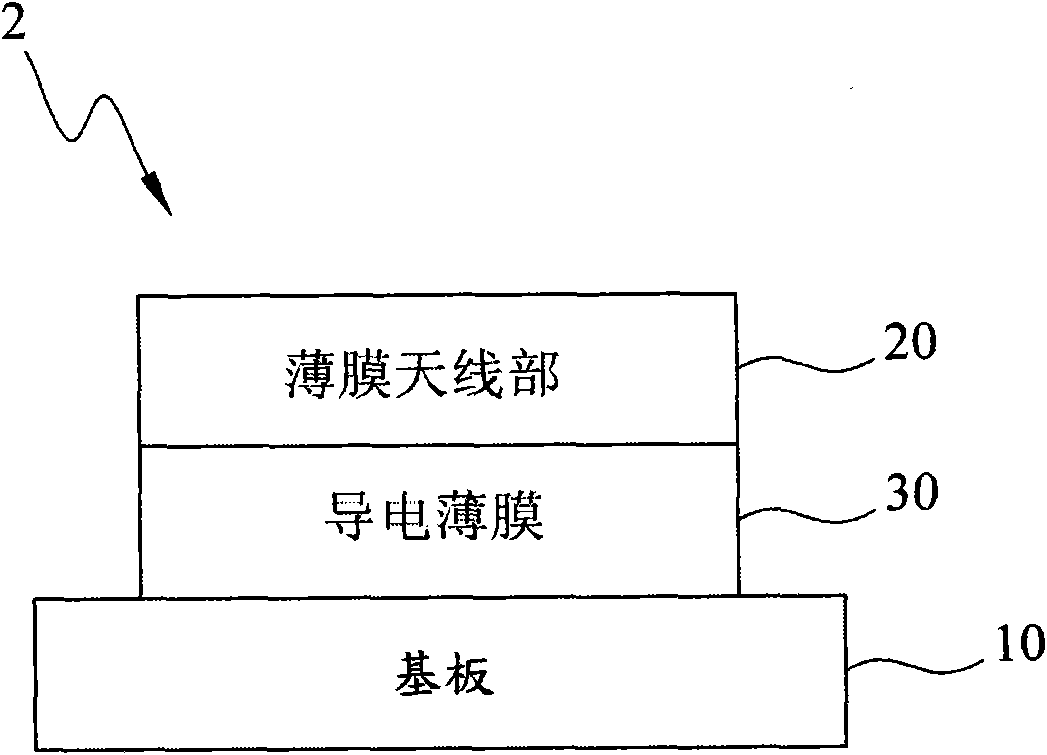

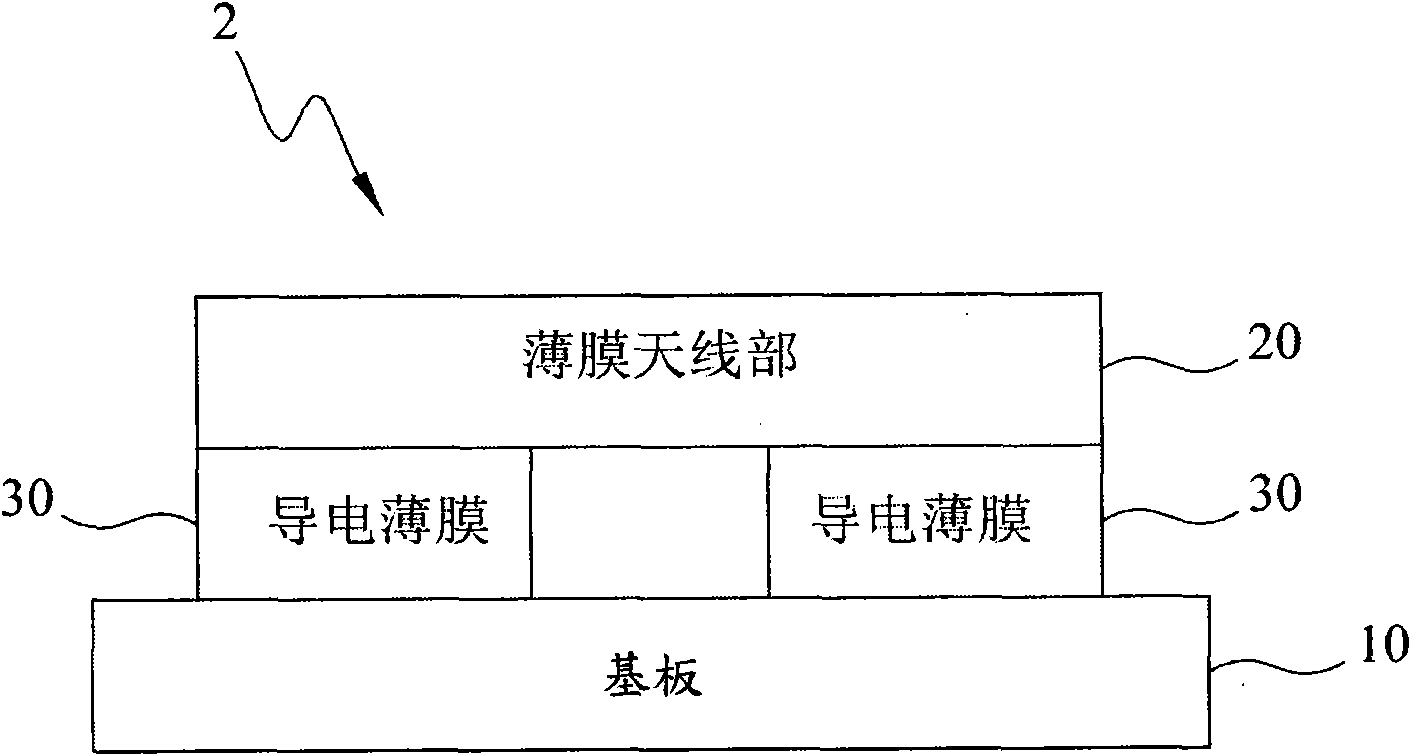

Flexible thin antenna and manufacturing method thereof

InactiveCN102055056AGood adhesionReduce thicknessAntenna supports/mountingsEngineeringElectrical and Electronics engineering

The invention discloses a flexible thin antenna and a manufacturing method thereof. The flexible thin antenna comprises a base plate, a thin-film antenna part and a thin conducting film, wherein the base plate is made of insulation material; the thin-film antenna part is provided with an antenna pattern and a transmitting / receiving module, and is used for transmitting and receiving signals; and the thin conducting film is arranged on the base plate, is wholly or partially connected with the thin-film antenna part and is flexible. In the invention, mainly the thin conducting film arranged between the base plate and the thin-film antenna part is used for improving the adhesiveness between the base plate and the thin-film antenna part under the action of an external force or expansion and contraction caused by temperature change, lowering the resistance and improving the defect that the resistance of the thin-film antenna part can be greatly increased under the action of an external force. Further, the thin conducting film can lower the resistance, and the thickness of the thin-film antenna part can be reduced, thereby shortening the coating time and simultaneously lowering the manufacturing cost.

Owner:PARAGON TECH

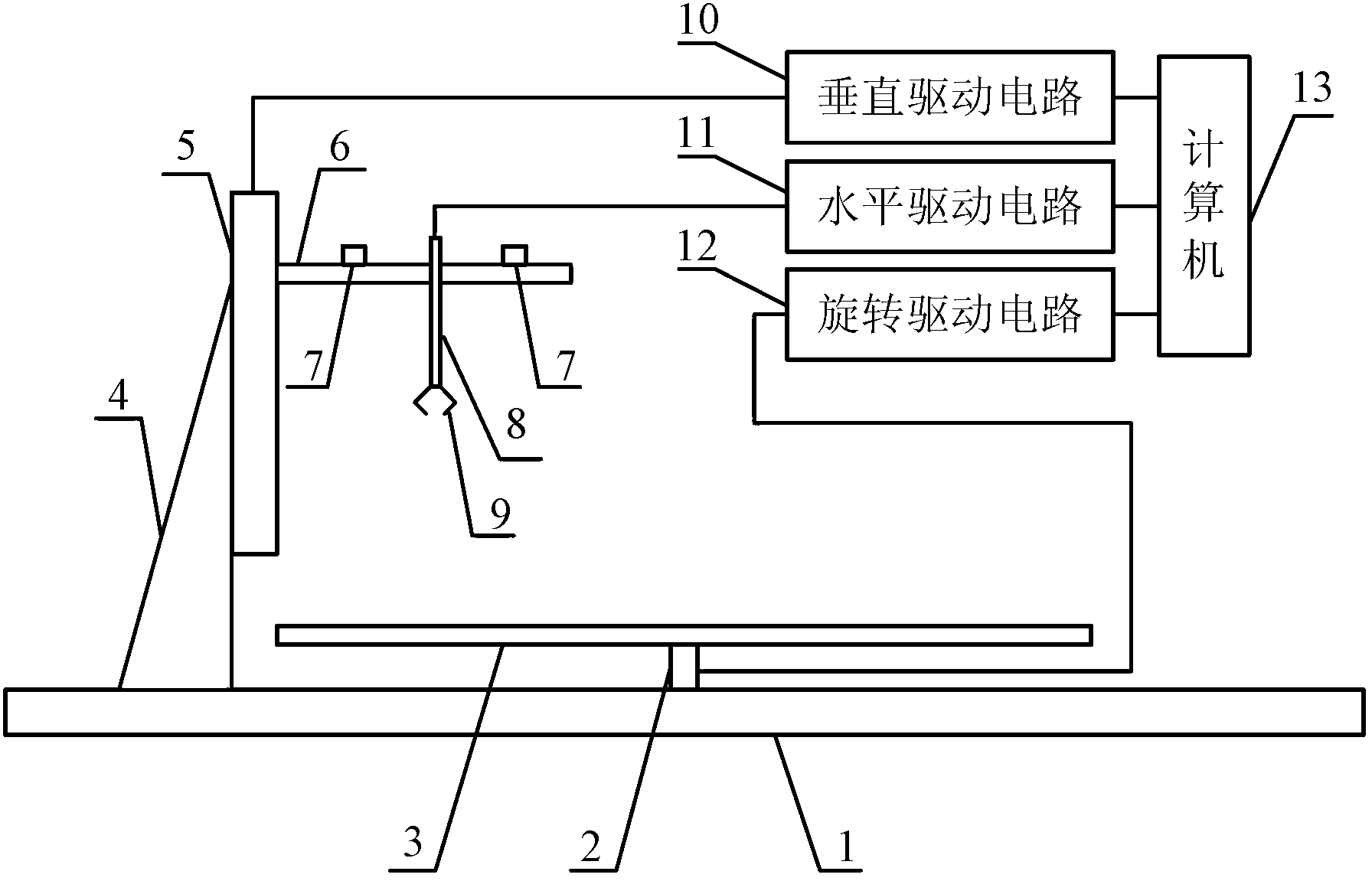

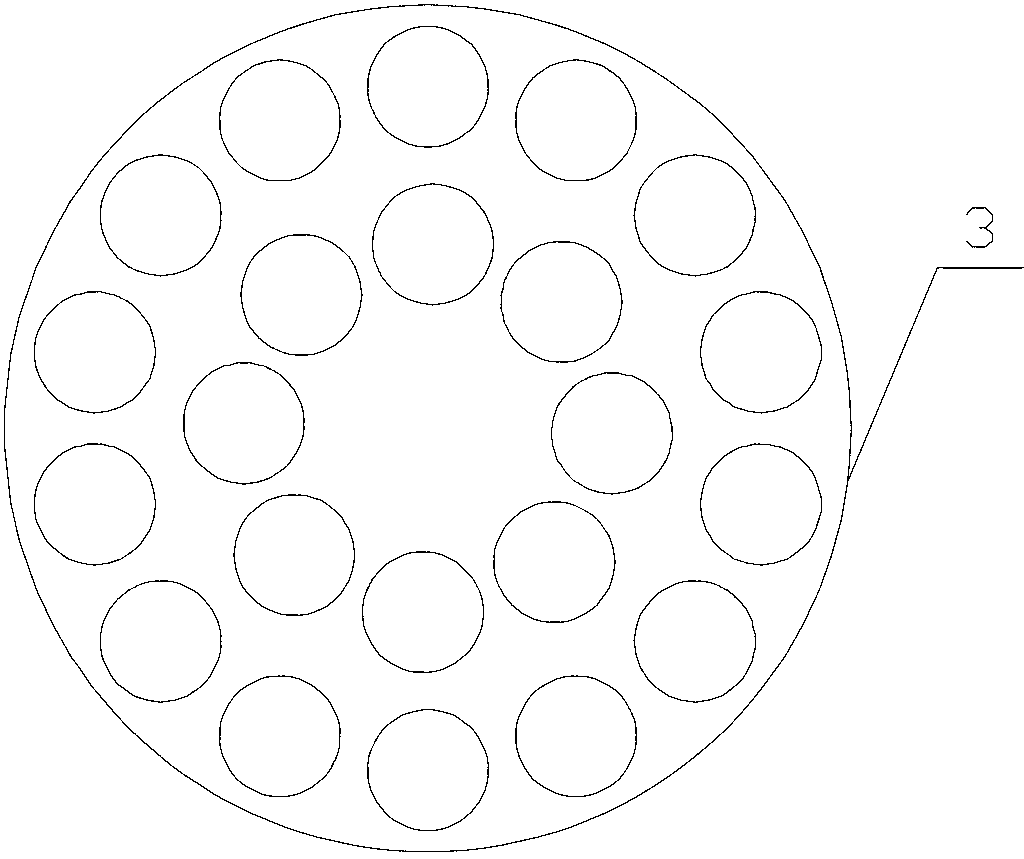

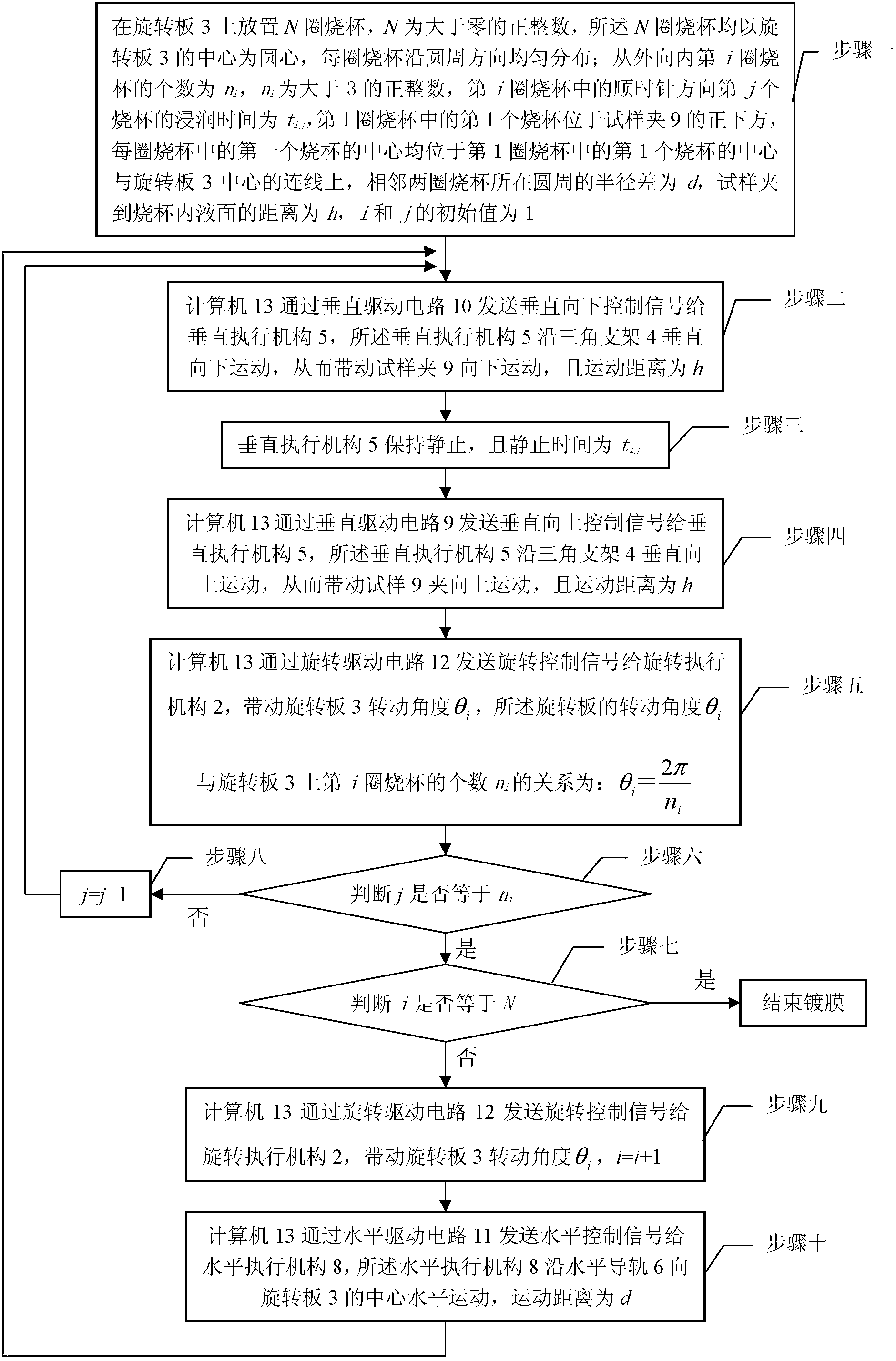

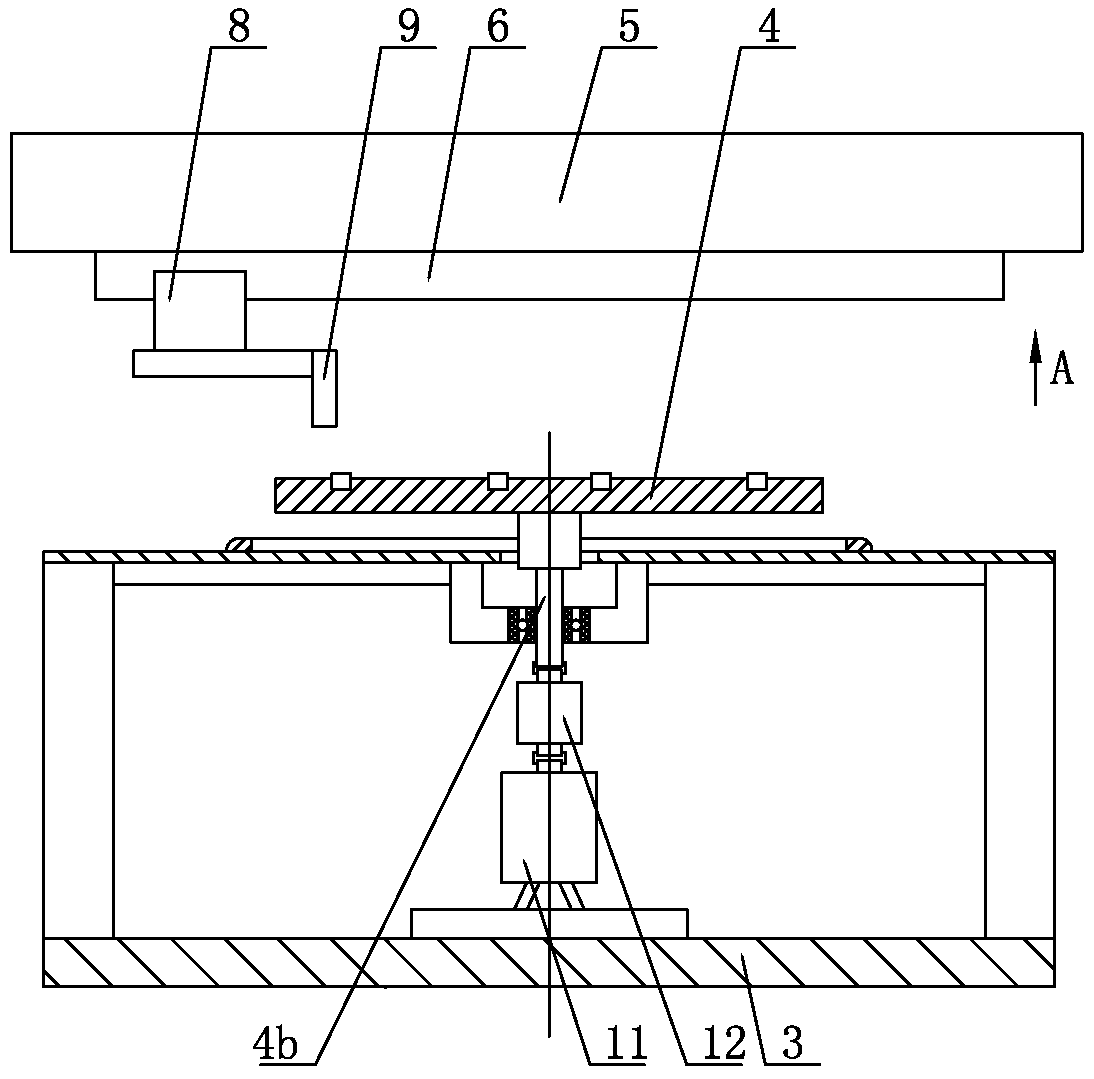

Device for preparing polyelectrolyte multilayer film by utilizing automatic layer upon layer dip plating method and control method thereof

InactiveCN103230857AShorten coating timeImprove work efficiencyLiquid surface applicatorsCoatingsPolyelectrolyteEngineering

The invention discloses a device for preparing a polyelectrolyte multilayer film by utilizing an automatic layer upon layer dip plating method and a control method thereof, and relates to a technology for preparing the polyelectrolyte multilayer film by utilizing a layer upon layer dip plating method. The device solves the problem that the manual operation of the polyelectrolyte multilayer film prepared by the existing layer upon layer dip plating method is slow, and the processing quality is inconsistent. The device provided by the invention comprises a bottom plate, a revolution actuating mechanism, a rotating plate, a triangle support, a vertical actuating mechanism, a horizontal guide rail, two limiting stoppers, a horizontal actuating mechanism, a sample holder, a perpendicular driving circuit, a horizontal driving circuit, a revolution driving circuit and a computer, wherein the revolution actuating mechanism is connected with the computer through the revolution driving circuit; and the vertical actuating mechanism is connected with the computer through the perpendicular driving circuit, the horizontal actuating mechanism is connected with the computer through the horizontal driving circuit, and the film coating is finished by controlling a sample holder to move through computer software. The device and the control method provided by the invention have the advantages that the efficiency is high, the processing quality is consistent. The device and the control method provided by the invention are suitable for the technical field of preparation of the polyelectrolyte multilayer film by utilizing the layer upon layer dip plating method.

Owner:HARBIN INST OF TECH

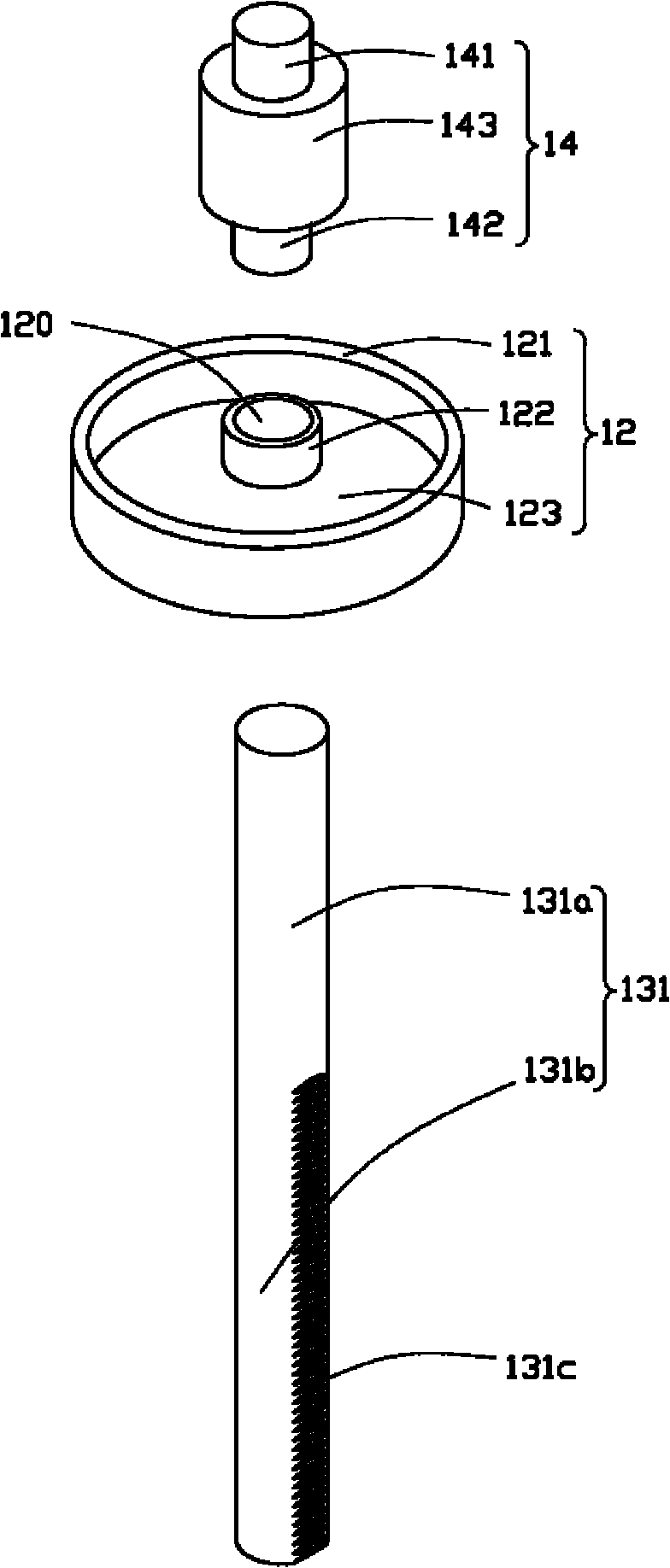

Coating raw material containing device

InactiveCN101871090AEasy accessShorten coating timeVacuum evaporation coatingSputtering coatingCrucibleEngineering

The invention relates to a coating raw material containing device which comprises a bearing seat, a plurality of crucibles and a lifting mechanism, wherein the plurality of crucibles are superposed, are mutually fixed and are used for containing coating raw materials, the bearing seat is provided with a containing cavity; the crucibles are fixed on the lifting mechanism and are contained in the containing cavity; the bearing seat is provided with an opening, and the opening is aligned with the crucibles; the lifting mechanism comprises a support shaft, and one end of the support shaft is fixedly connected with the crucibles; and the lifting mechanism can drive the crucibles to move up and down relative to the bearing seat. The coating raw material containing device can move an empty crucible in the bearing seat to the opening through the lifting mechanism to enable the crucible to be conveniently taken, thereby saving the step of resetting the crucible, reducing the coating time, and coherently carrying out the coating process.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

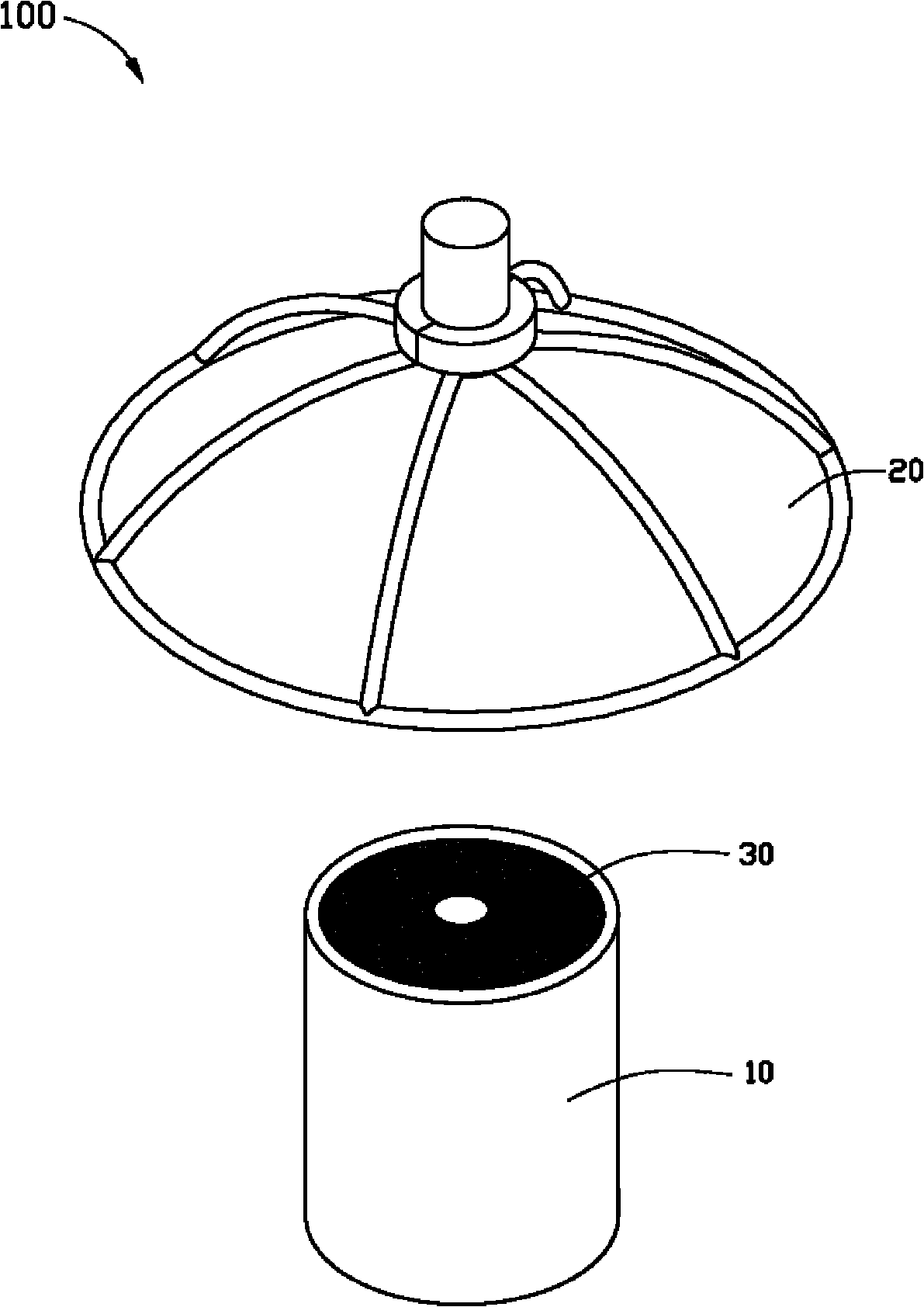

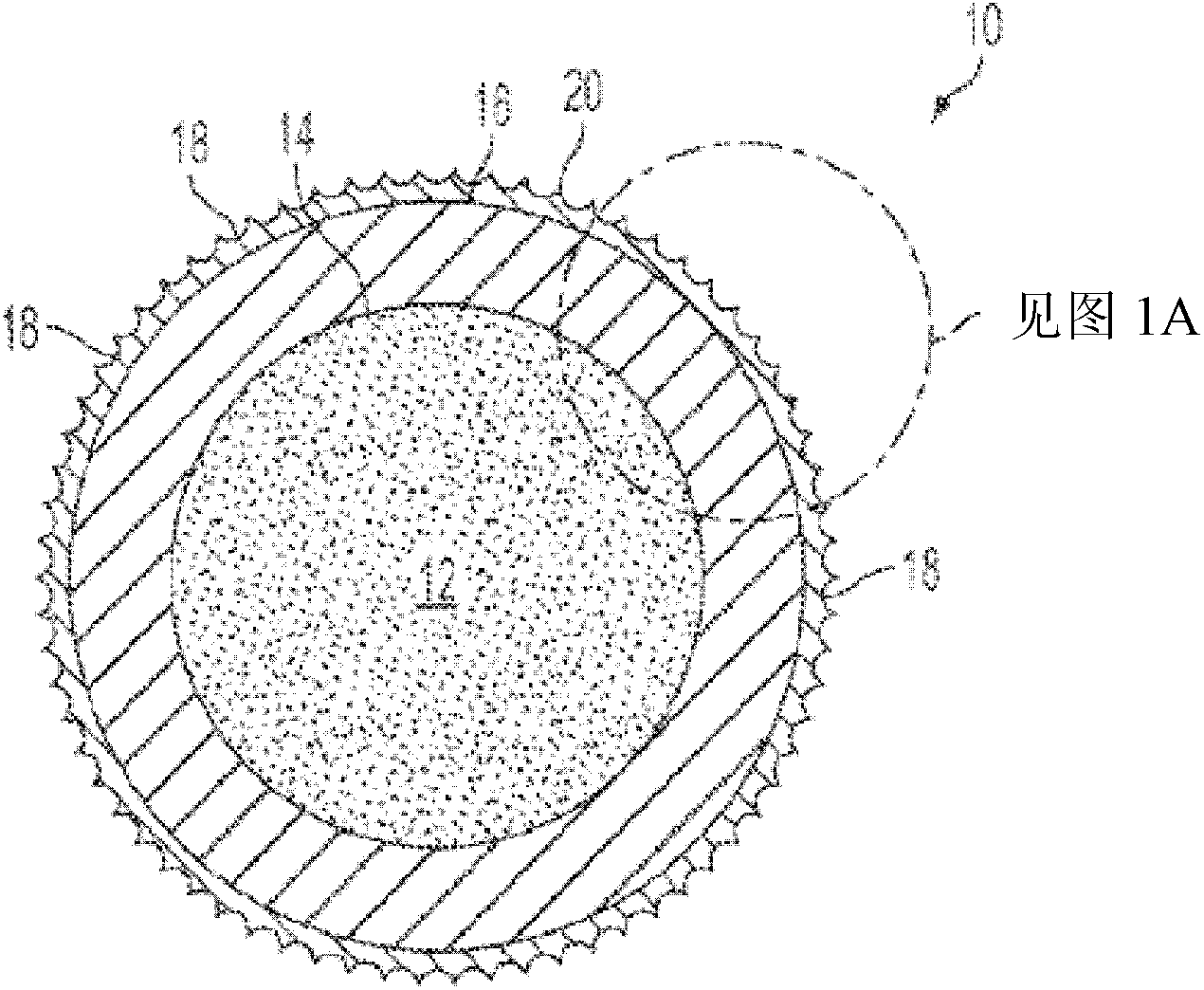

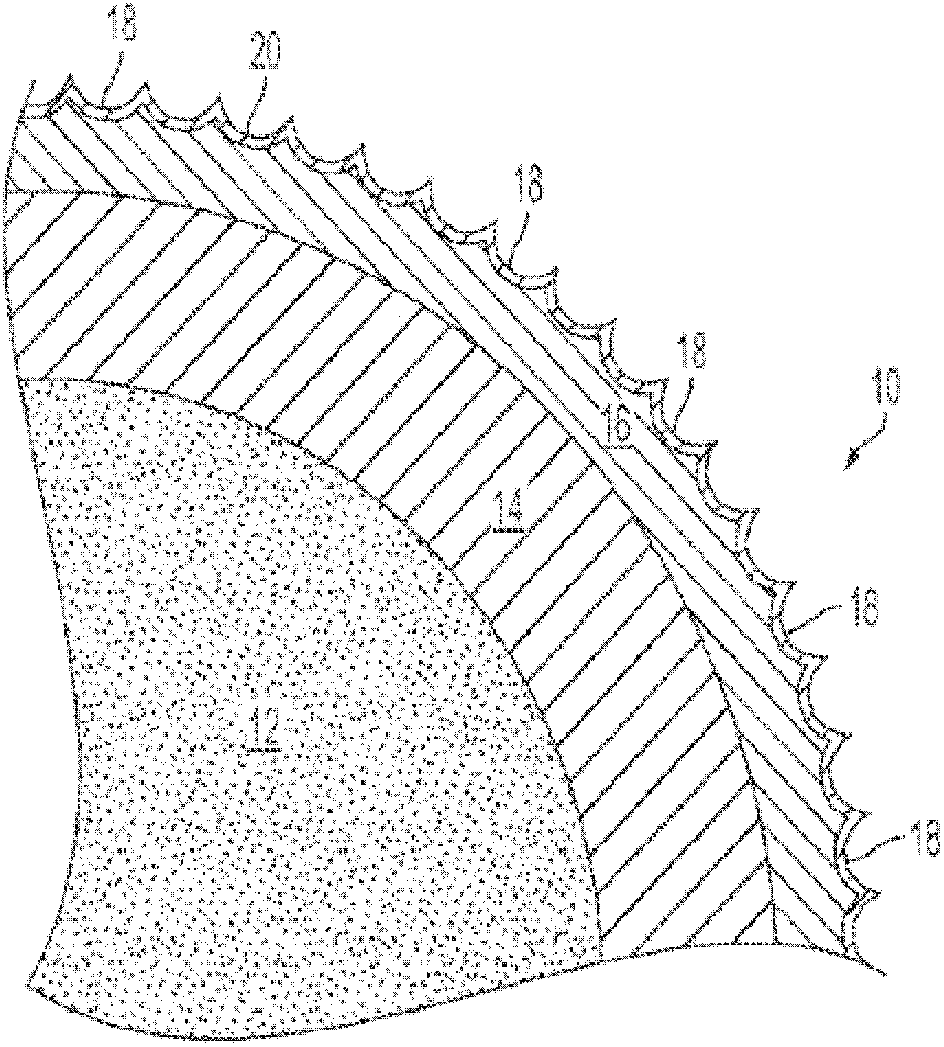

Method and appratus for applying a topcoat to a golf ball surface

InactiveCN102438707AReduce Density VariationsIncrease attractivenessSolid ballsNitrogenCarrier fluid

A topcoat is applied to a surface of a golf ball using a carrier fluid comprising nitrogen gas or nitrogen-enriched air. The carrier fluid typically has air enriched to about 90-99.5% nitrogen. A mixture of carrier fluid and coating material may be sprayed onto the exterior of the golf ball. Nitrogen-enriched air delivery provides a number of benefits over compressed air delivery, such as reduced coating thickness, reduced variance in the coating thickness and average thickness, reduced pooling in dimple center, edge ratio closer to 1.0, faster cure times, reduced viscosity, less material usage, reduced material flow rate, reduced atomization air pressure, and decreased drying time.

Owner:NIKE INNOVATE CV

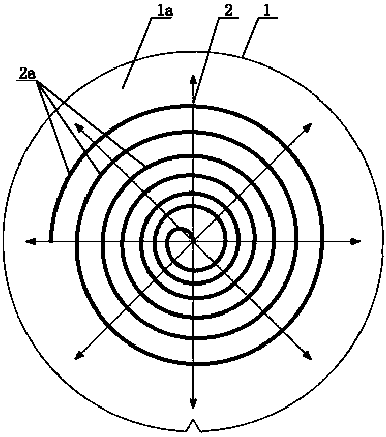

Spiral photoresist coating structure and preparation device and method thereof

PendingCN109663693AReduce photoresist viscosityReduce height differenceSpraying apparatusSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The invention discloses a spiral photoresist coating structure and a preparation device and method thereof and belongs to the field of semiconductor packaging manufacturing. The spiral photoresist coating structure comprises a wafer; the surface of the wafer is covered with a processing solvent layer and a photoresist layer; the photoresist layer is spiral. The device comprises a machine body; a circular rotating table is rotationally arranged on the upper side of the machine body; a rotating driving mechanism is arranged in the machine body; and a moving glue coating mechanism is arranged onthe upper portion of the rotating table. The preparation method comprises the following steps that the wafer is placed in the center of the rotating table at first and tightly sucked through a vacuumsuction cup, the wafer is sprayed with a processing solvent through a glue spraying arm, then the rotation table is controlled to keep rotating, the glue spraying arm moves to the edge of the wafer tostart spraying photoresist, radially move to the center of the wafer until the glue spraying arm moves to the position above the center of the wafer, and stops spraying photoresist. The use amount ofphotoresist can be reduced, the photoresist coating time can be shortened, thus, the photoresist is distributed on the surface of the wafer more properly, and the cost is reduced.

Owner:JIANGSU UNION SEMICON

Rotary plate-type fluidization coating equipment

InactiveCN102107126ASpraying speed is fastGood sustained release effectGranulation by powder suspensionEngineeringViscosity

The invention relates to rotary plate-type fluidization coating equipment which is characterized in that: the effective air intake area of a heat source air inlet of the fluidization coating equipment is increased, so that the intensity of a fluidizing air flow of the fluidization coating equipment is increased; and the driving force of a rotary plate on coated particles is enhanced and simultaneously the impact force of a wall of a coating chamber on the coated particles is enhanced, so as to reduce the adhesion between the coated particles, as a result, although the viscosity of a coating liquid is high, the coating quality of the coated particles is guaranteed. The adaptation of the fluidization coating equipment to the coating liquids with different performances can be maximally improved; and the coatings of the coated particles are intact and have good slow release properties, which can effectively increase the coating efficiency.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com