Device for preparing polyelectrolyte multilayer film by utilizing automatic layer upon layer dip plating method and control method thereof

A technology of polyelectrolyte and control method, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of inconsistent processing quality and low working efficiency of polyelectrolyte multi-layer film technology, so as to shorten the coating time and ensure consistency performance, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

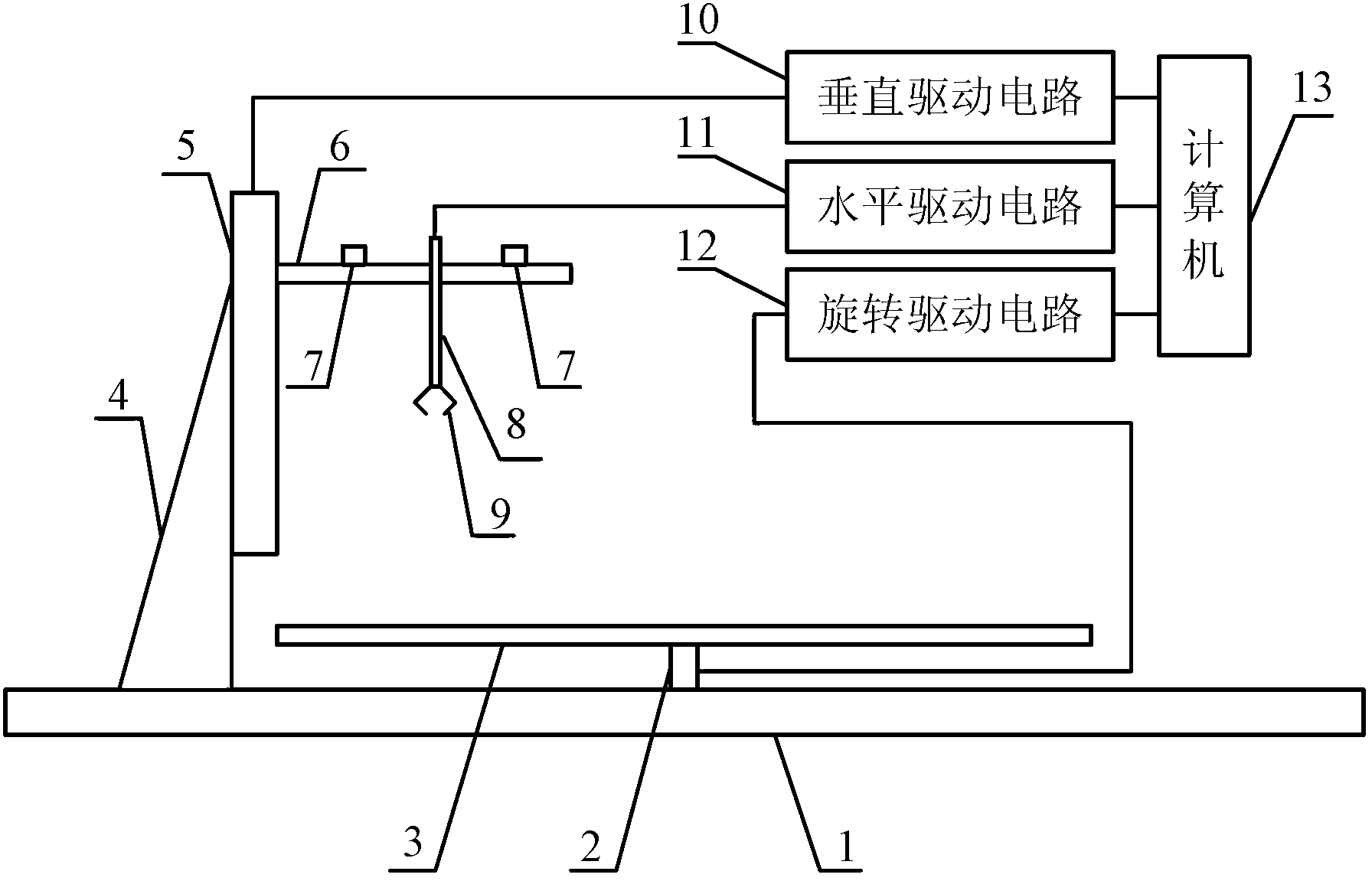

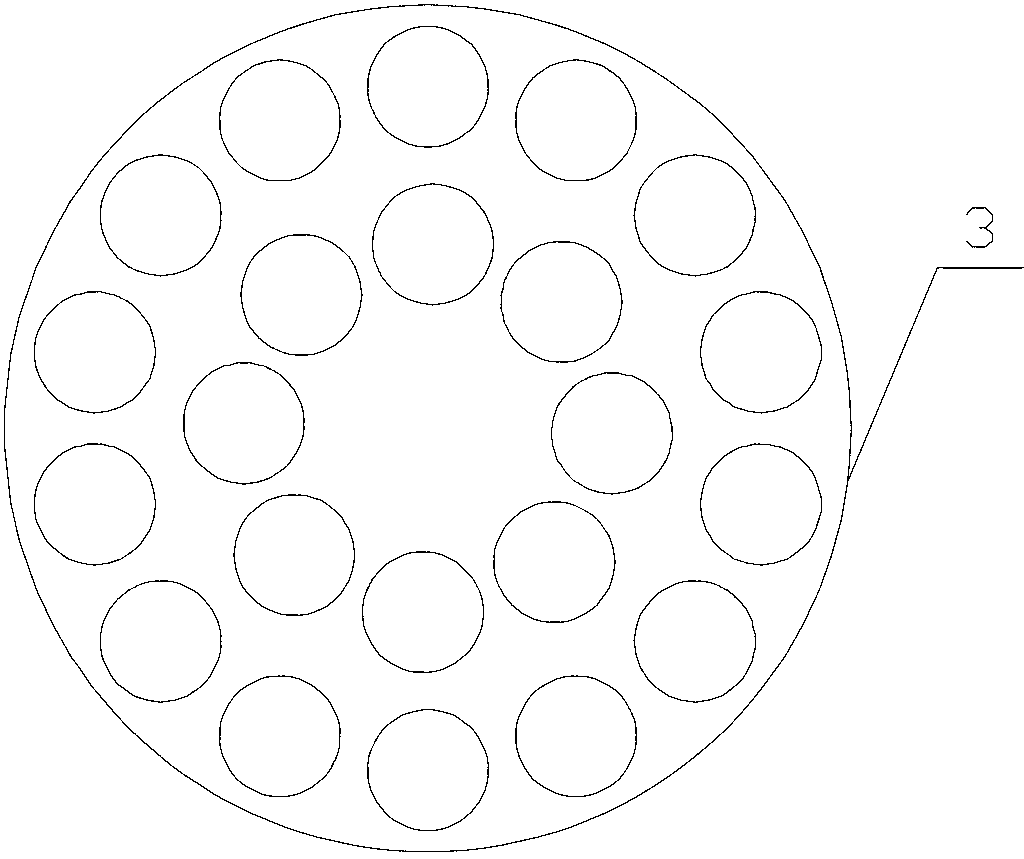

[0024] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, the device for preparing a polyelectrolyte multilayer film by the automated layer-by-layer immersion plating method described in this embodiment includes a bottom plate 1, a rotary actuator 2, a rotary plate 3, a tripod 4, a vertical actuator 5, and a horizontal guide rail 6 , two stoppers 7, a horizontal actuator 8, a sample holder 9, a vertical drive circuit 10, a horizontal drive circuit 11, a rotary drive circuit 12 and a computer 13, the rotating plate 3, the tripod 4, the vertical actuator 5 , a horizontal guide rail 6, two stoppers 7, a horizontal actuator 8 and a sample holder 9 constitute a two-dimensional moving device, the rotating plate 3 is a circular flat plate, and the rotating plate 3 is connected to the rotating actuator 2 and The bottom plate 1 is connected, the rotary actuator 2 is located at the center of the rotary plate 3, one right-angled side of the t...

specific Embodiment approach 2

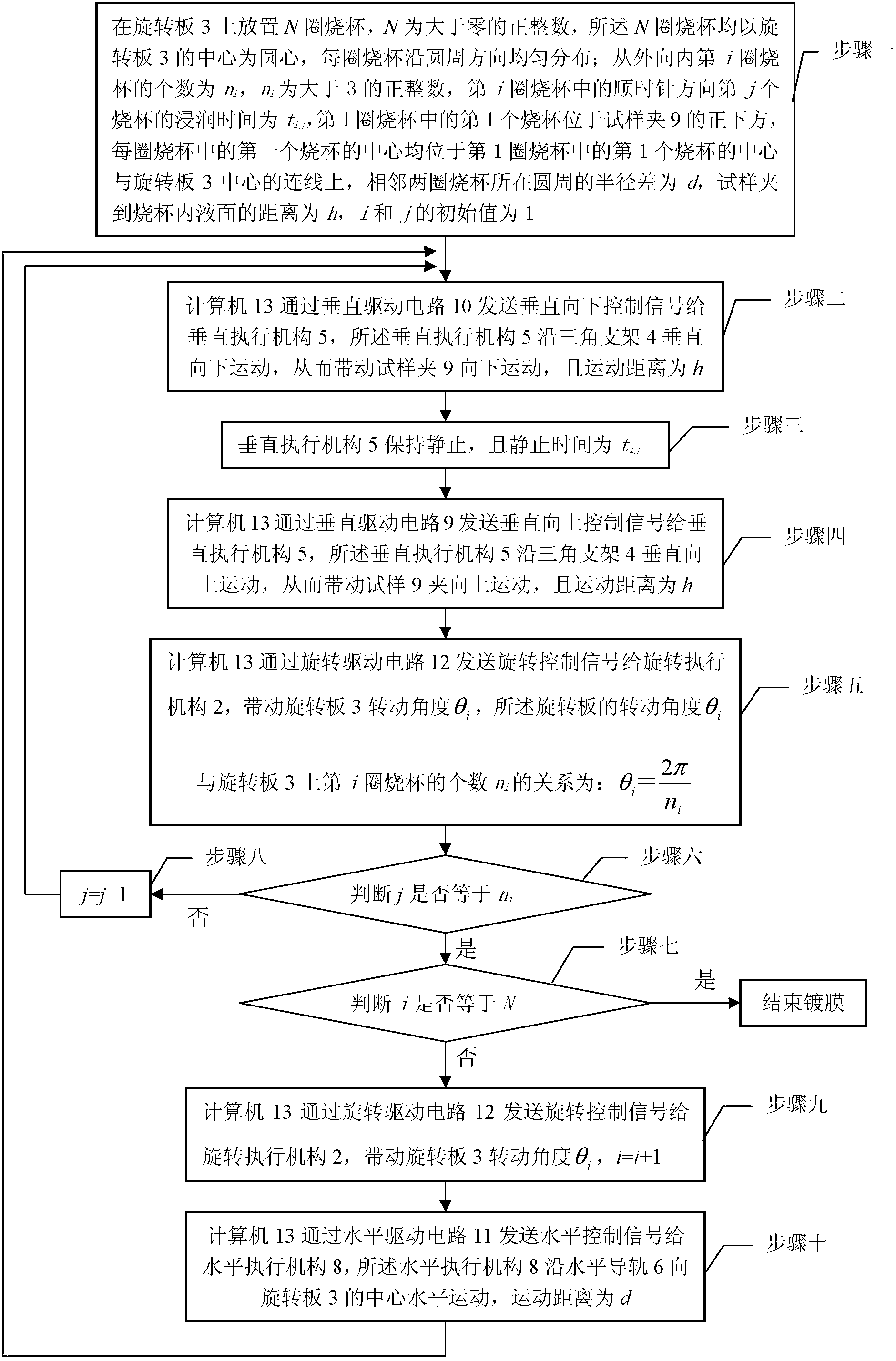

[0028] Specific implementation mode two: combination image 3 This embodiment is described. This embodiment is a control method for the device for preparing a polyelectrolyte multilayer film by the automatic layer-by-layer immersion plating method described in the first embodiment. The control method is realized by the following steps:

[0029] Step 1. Place N circles of beakers on the rotating plate 3, where N is a positive integer greater than zero. The N circles of beakers are all centered on the center of the rotating plate 3, and each circle of beakers is evenly distributed along the circumferential direction; from the outside to the inside The number of ring beakers is n i , n i is a positive integer greater than 3, the infiltration time of the jth beaker clockwise in the i-th circle of beakers is t ij , the first beaker in the first circle of beakers is located directly below the sample holder 9, and the center of the first beaker in each circle of beakers is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com