Method and appratus for applying a topcoat to a golf ball surface

A golf ball and surface coating technology, applied to balls, solid core balls, sports accessories, etc., can solve problems such as unevenness, easy filling of pits, and too thick coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

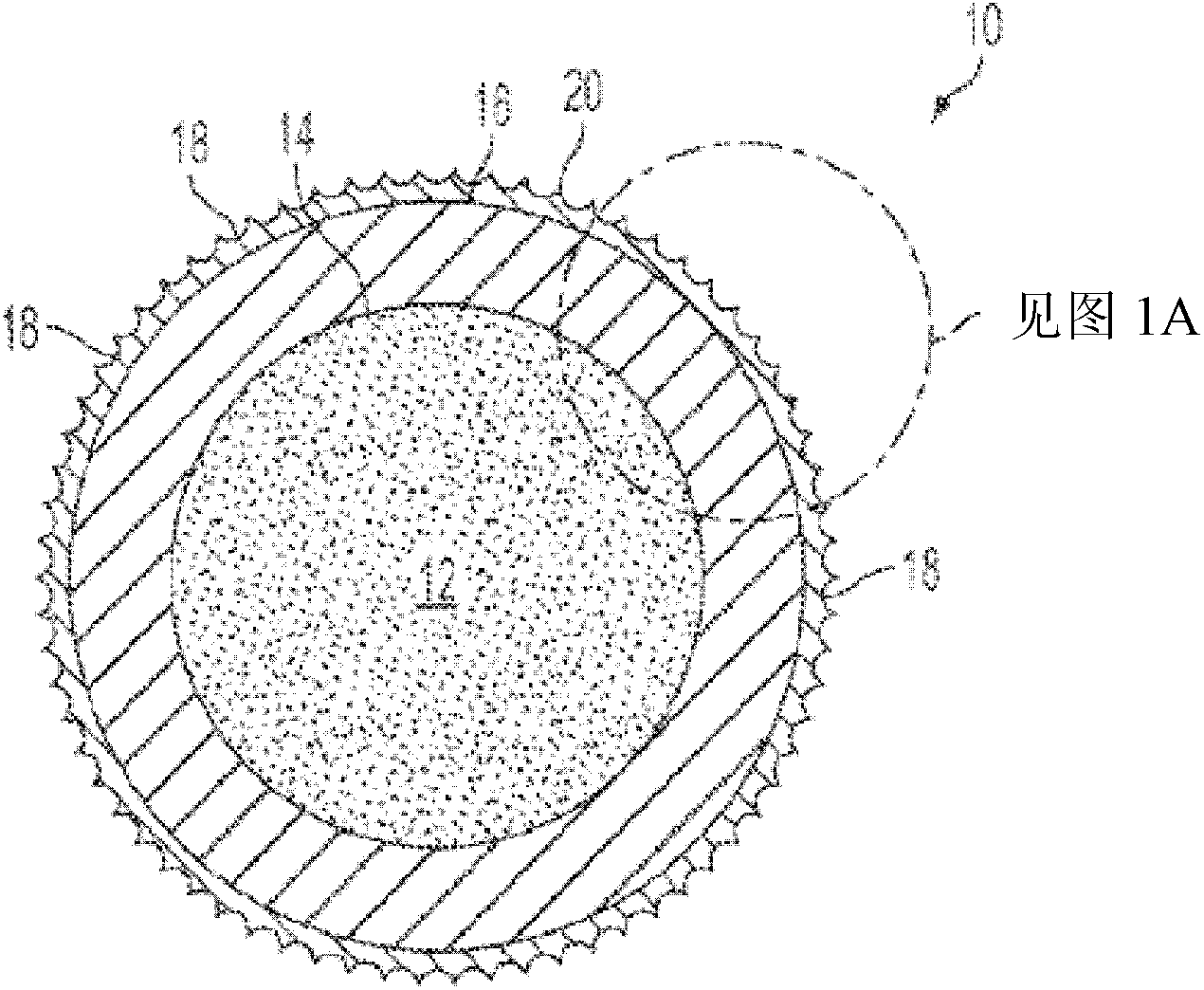

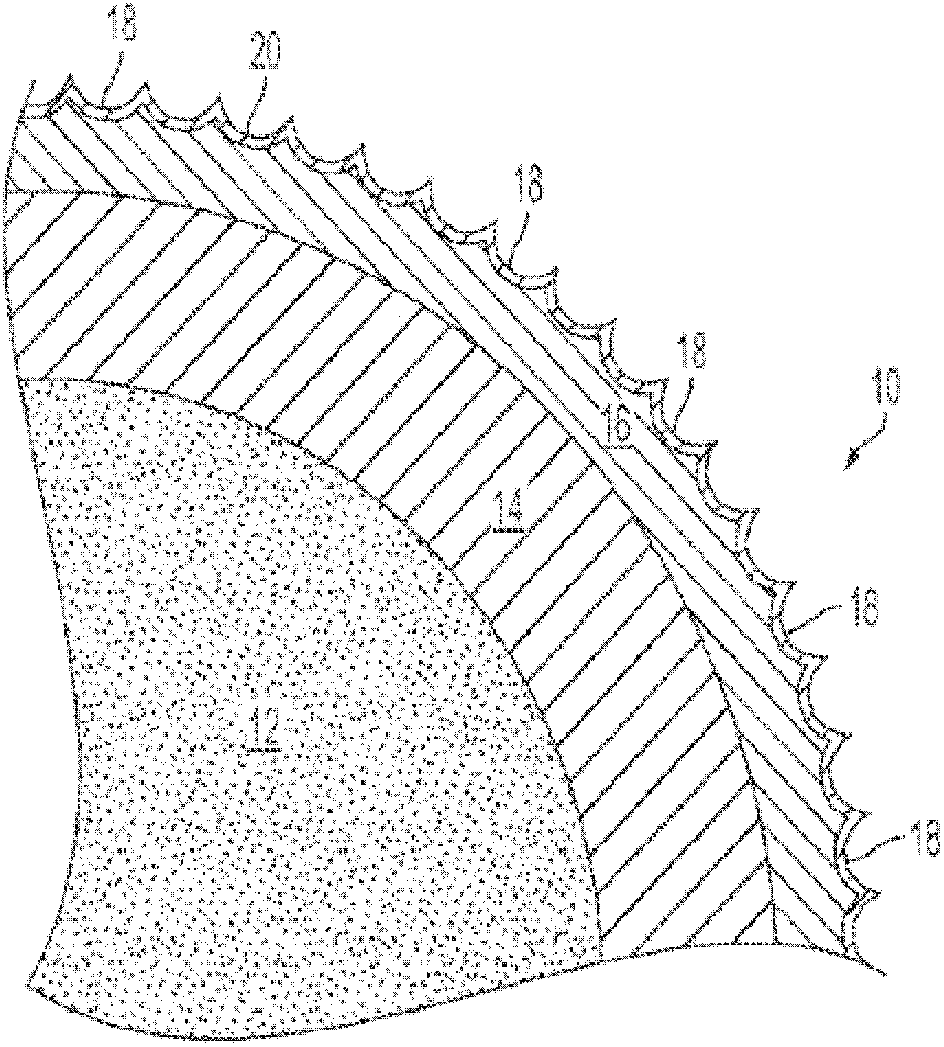

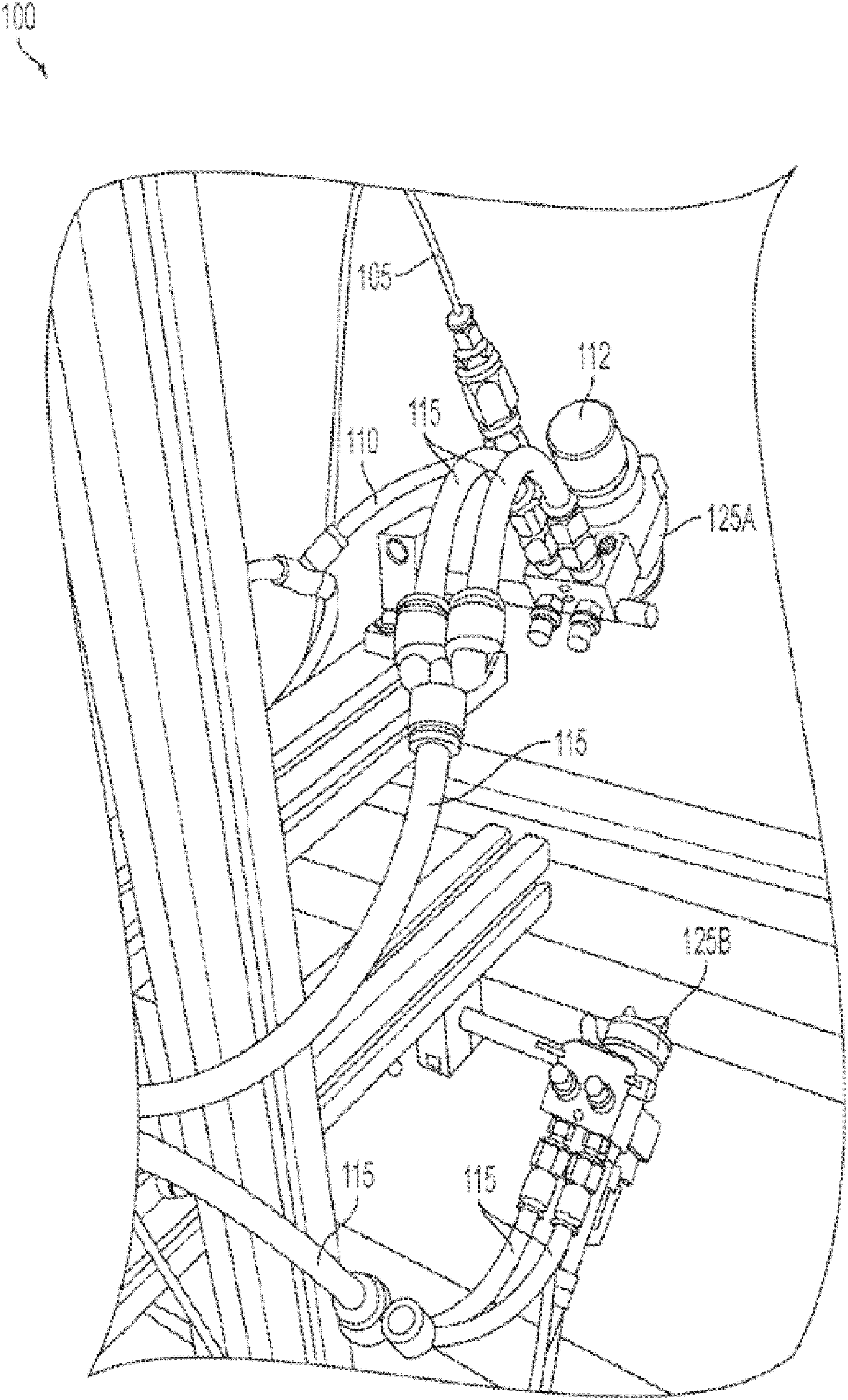

[0018] Various embodiment structures are described below with reference to the accompanying drawings, which form a part hereof, and illustrate various golf structure embodiments. In addition, it is to be understood that other specific arrangements of parts and structures may be utilized and structural and functional changes may be made without departing from the scope of the present invention. In addition, terms such as "top", "bottom", "front", "rear", "rear", "side", "bottom" and the like are used herein to describe various examples of the present invention. To describe specific features and elements, these terms are used herein for convenience, eg, based on the exemplary orientation shown in the drawings and / or the orientation of typical use. This description should not be read as requiring a specific three-dimensional or spatial orientation of the structures.

[0019] A. Overview of Golf Balls and Systems and Methods of Manufacturing

[0020] Golf balls can have a variet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com