Hydraulically driven low-tension energy-saving open-width rinsing bath

A technology of open-width water washing and hydraulic drive, which is applied in the fields of hydroelectric power generation, engine components, machines/engines, etc. It can solve the problems of difficult cleaning, easy accumulation of dirt in bottom pipes, and high energy consumption, so as to reduce scratches and save steam consumption Quantity, the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

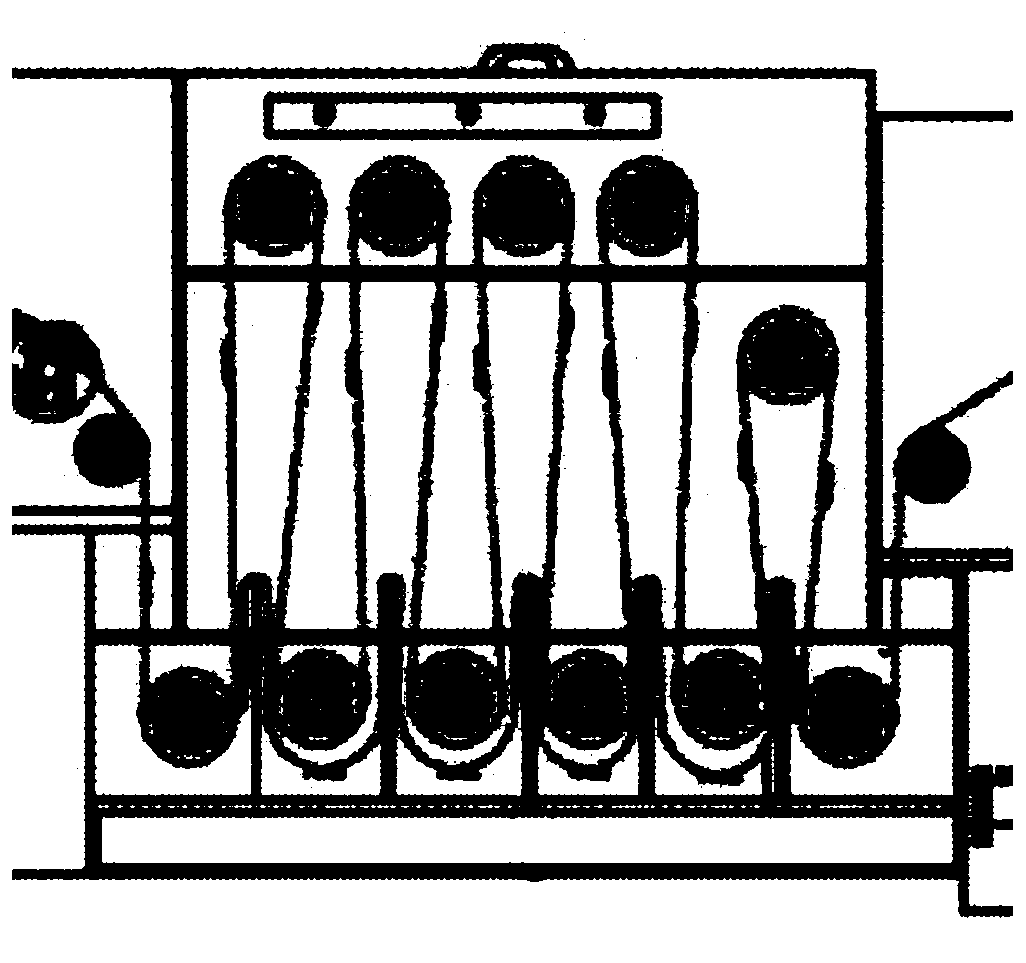

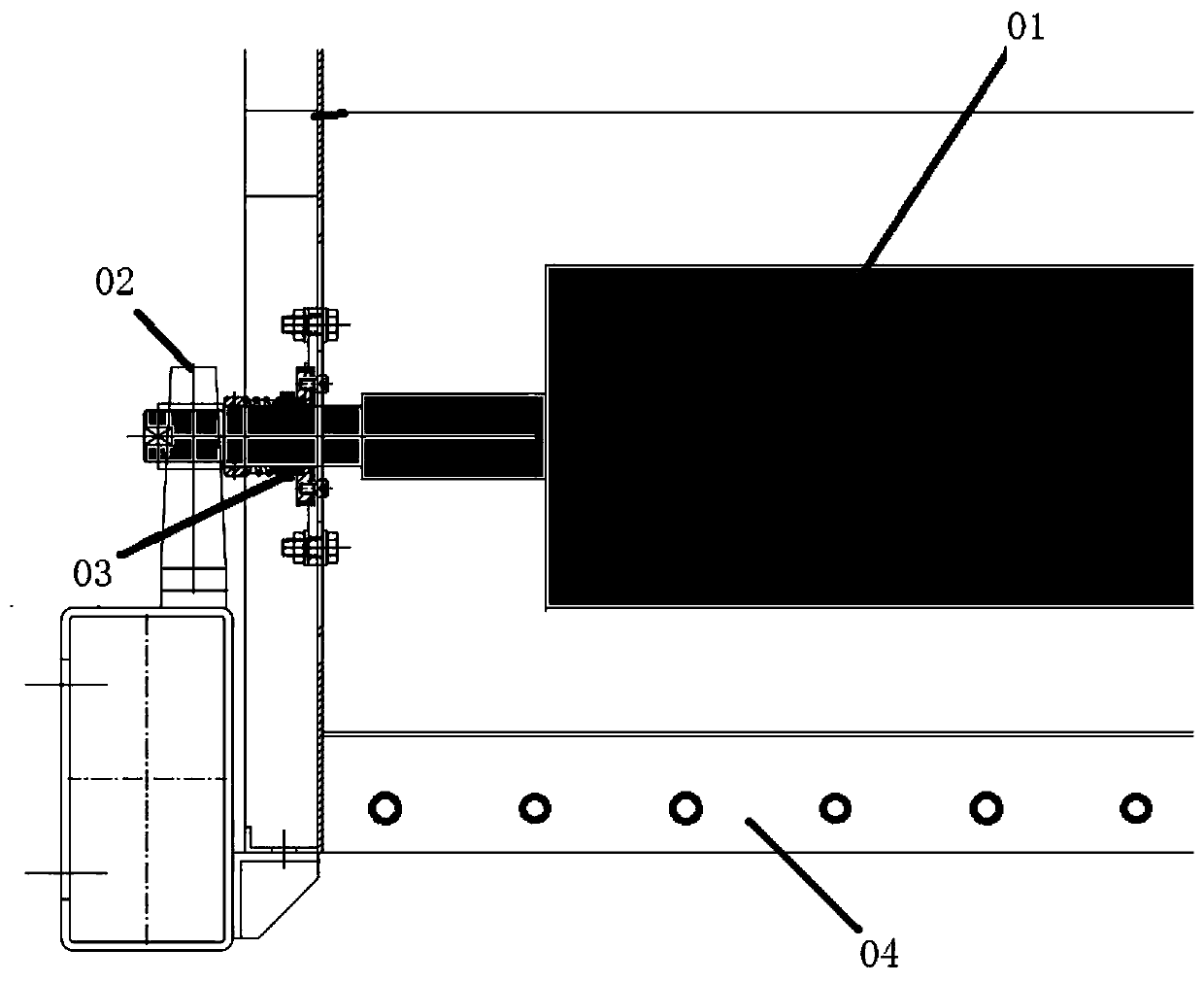

[0031] Such as Figure 1-2 As shown, it is a schematic diagram of the overall structure of the traditional washing tank and a schematic diagram of the assembly structure of the lower cloth guide roller in the traditional washing tank. The fabric passes through the upper and lower rows of cloth guide rollers. The cloth rollers are generally driven by motors, the lower cloth guide roller 01 is a free roller, the bearing 02 of the cloth guide roller is set outside the water tank, and the mechanical seal 03 is used to isolate the inside and outside of the water tank. The bottom of the washing tank is also provided with a steam heating coil 04 to heat the water tank.

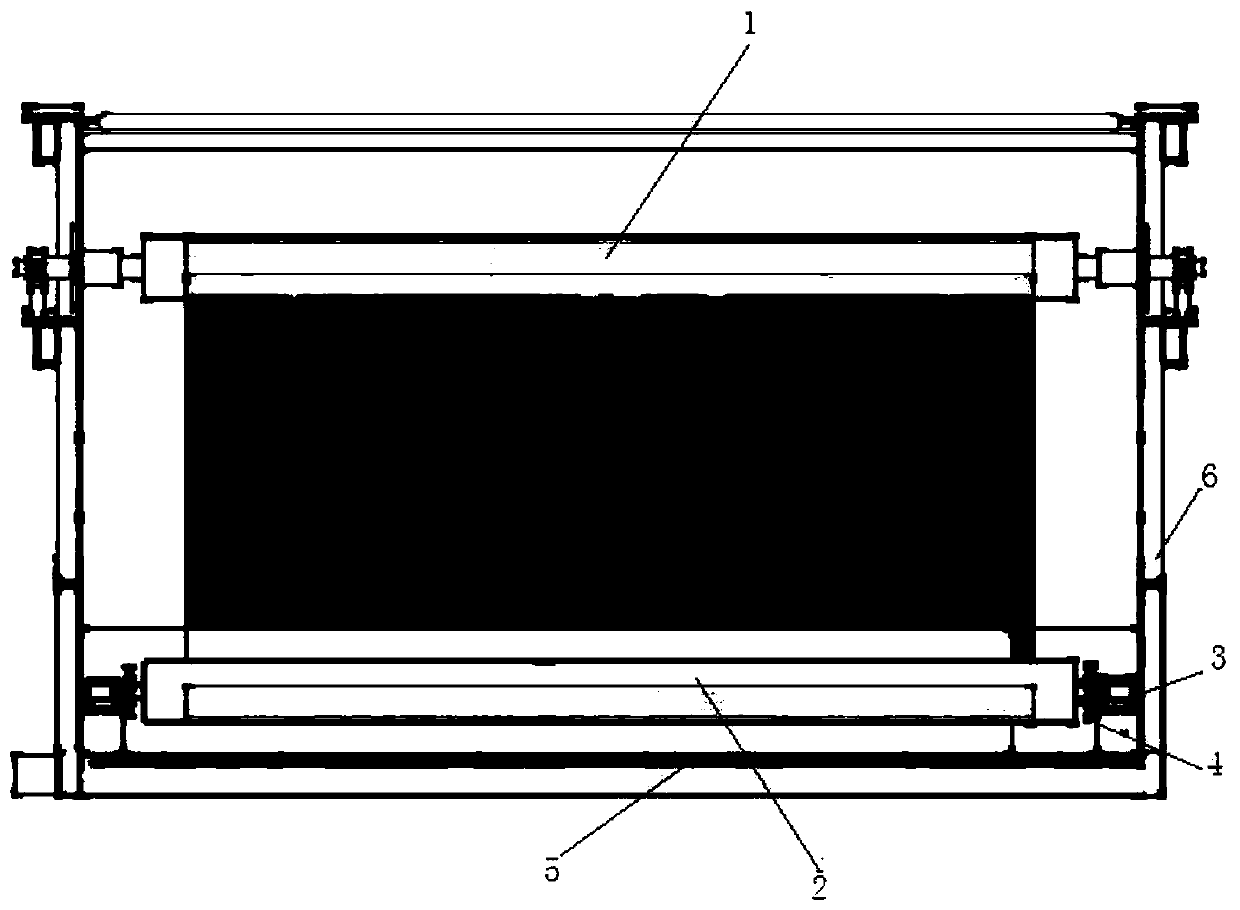

[0032] Such as Figure 3-6 As shown, the hydraulically driven low-tension energy-saving open-width washing tank of the present invention includes an upper rotary cloth guide roller 1, a bottom rotary cloth guide roller 2, a bearing 3, a cloth guide roller paddle 4, and a pillow-shaped flow channel heating plate 5. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com