Coating raw material containing device

A technology for containing devices and raw materials, applied in sputtering coating, ion implantation coating, vacuum evaporation coating and other directions, can solve the problems of long time consumption, discontinuous coating process, cumbersome steps, etc., and achieve easy access and coating. effect of time reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below in conjunction with the accompanying drawings.

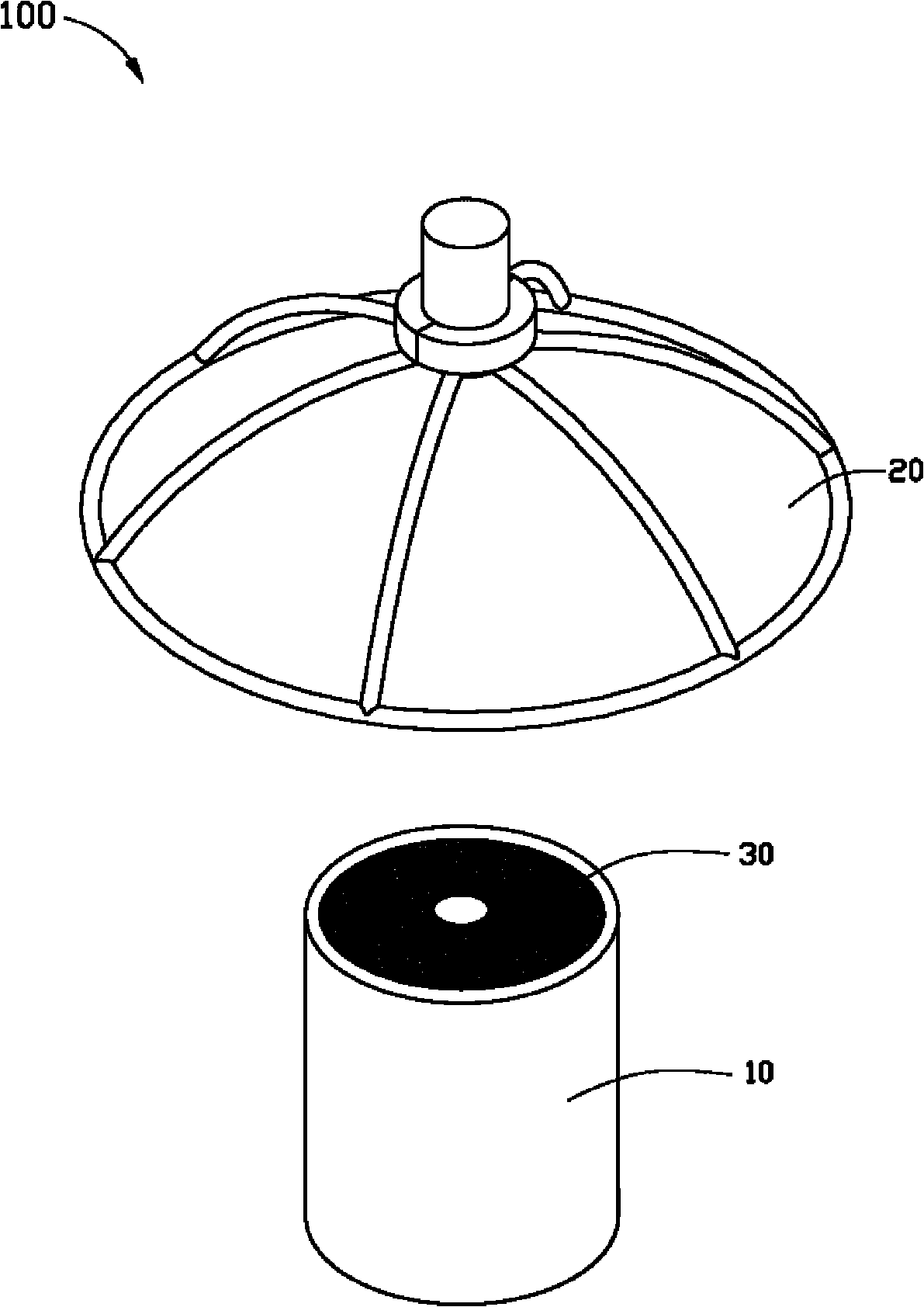

[0011] see figure 1 , is a coating raw material storage device 10 provided in an embodiment of the present invention, which is used in a coating device 100 . The coating device 100 includes the coating material storage device 10 and a coating umbrella 20 . The coating raw material storage device 10 is used for accommodating the coating raw material 30, which is fixed on a fixed platform (not shown). The coating raw material 30 in the coating raw material storage device 10 can cover the component to be coated (not shown) of the coating umbrella 20 to form a film after being evaporated.

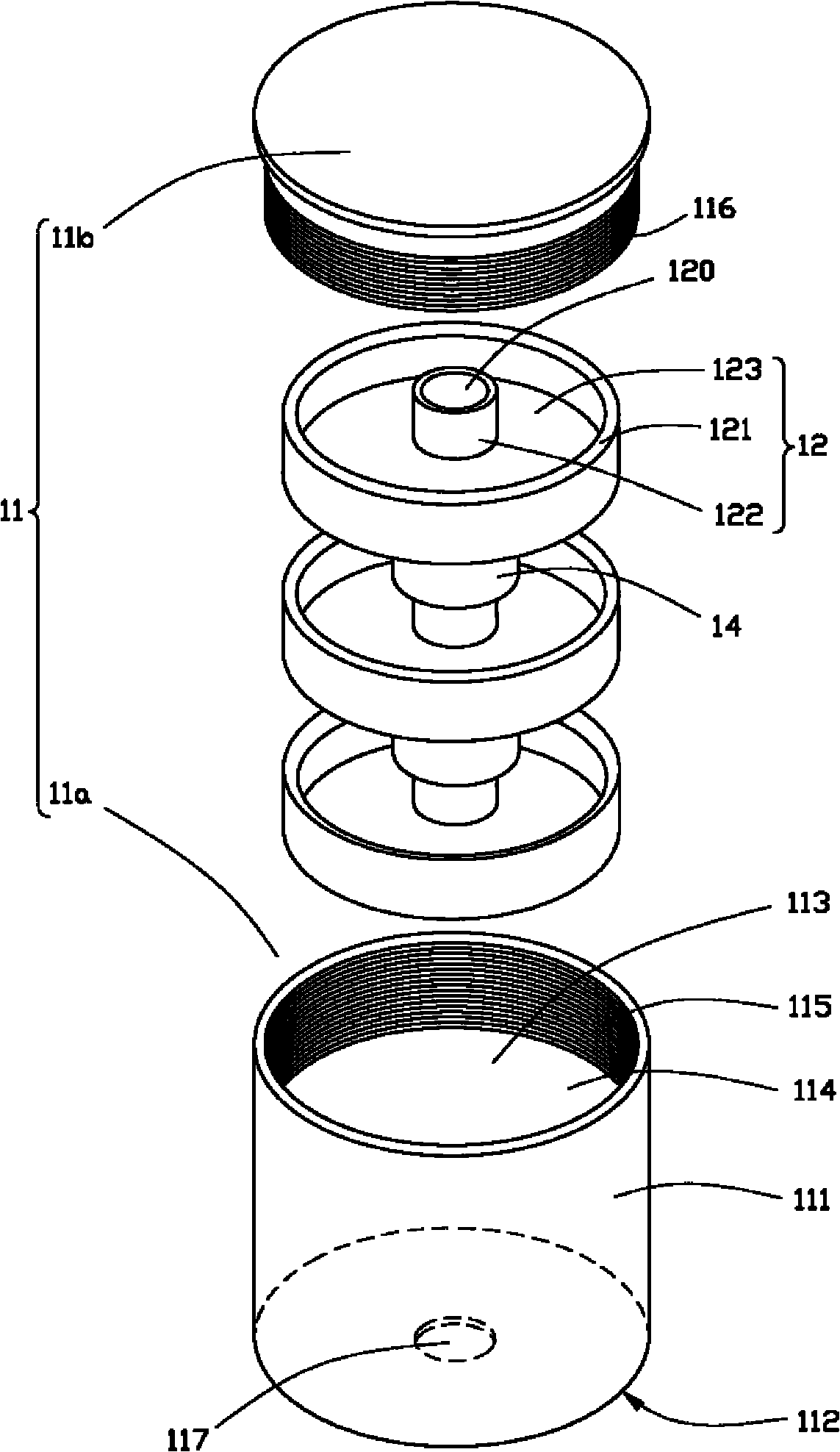

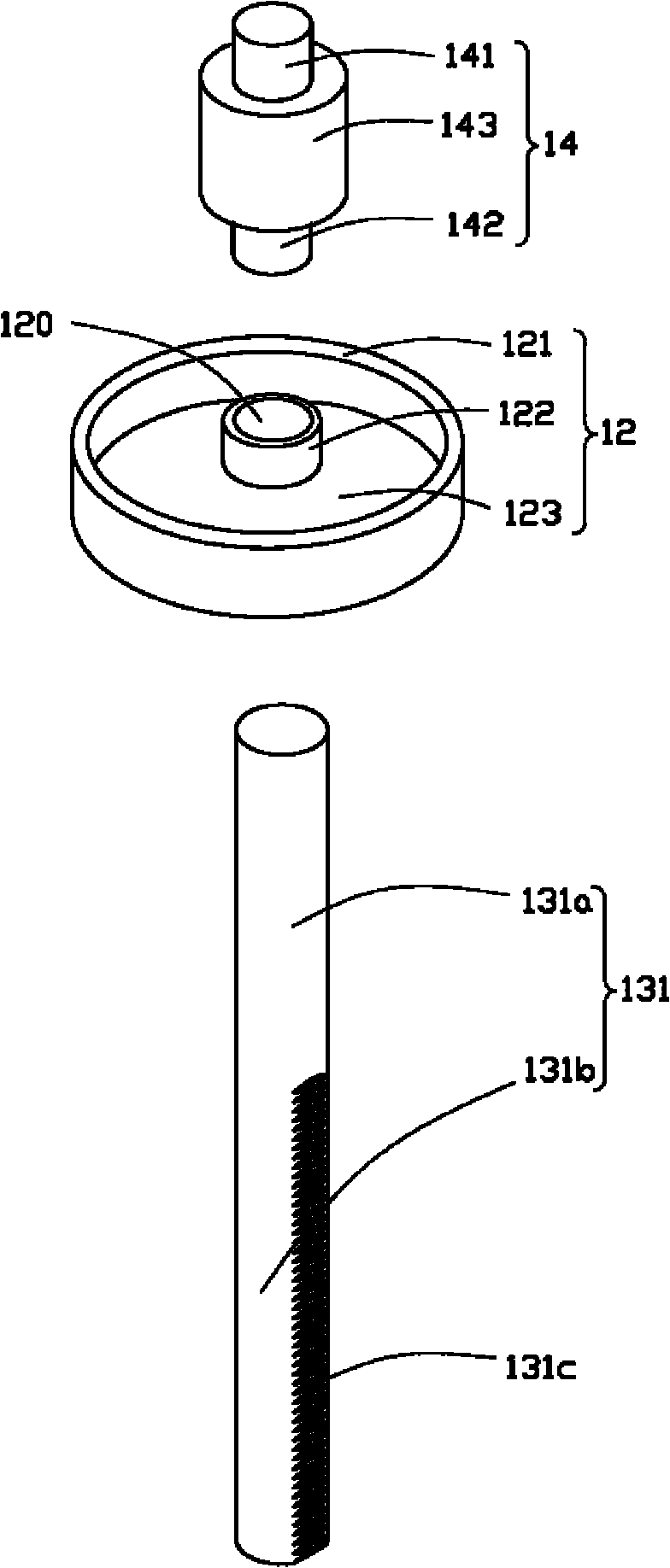

[0012] Please combine Figure 2 to Figure 4 , the coating raw material storage device 10 includes a bearing seat 11 , a plurality of crucibles 12 and a lifting mechanism 13 . The crucible 12 is fixed on the lifting mechanism 13 and accommodated in the bearing base 11 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com