Low-temperature curing powder coating for coating medium-density fiber board and preparation method for coating

A powder coating and fiberboard technology, applied in powder coatings, conductive coatings, polyester coatings, etc., can solve the problems of difficulty in popularization and application, cumbersomeness, etc., and achieve the effects of shortening coating time, high powdering efficiency, and improving spraying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

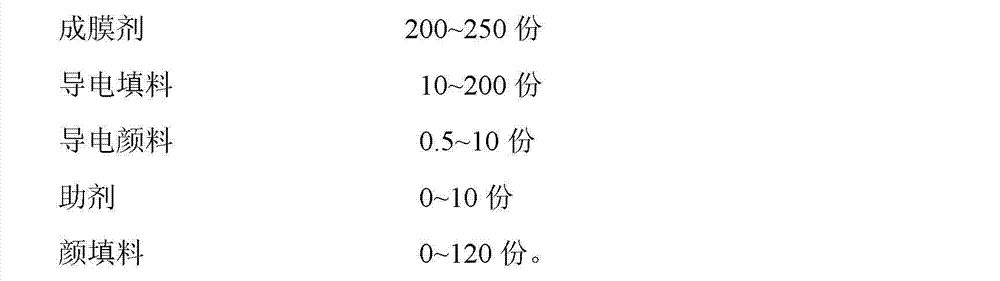

[0029]

[0030] Preparation:

[0031] (a) Weigh each component according to the proportion, place it in the mixing tank, mix thoroughly and crush for 1-20 minutes;

[0032] (b) The crushed material enters the twin or single screw extruder for extrusion; the heating temperature of the extruder is controlled at 70~90°C;

[0033] (c) The extruded material is compressed into tablets, cooled, pulverized into a powder with a particle size (equivalent particle size D50) of 50 microns, and then sieved and packaged.

Embodiment 2

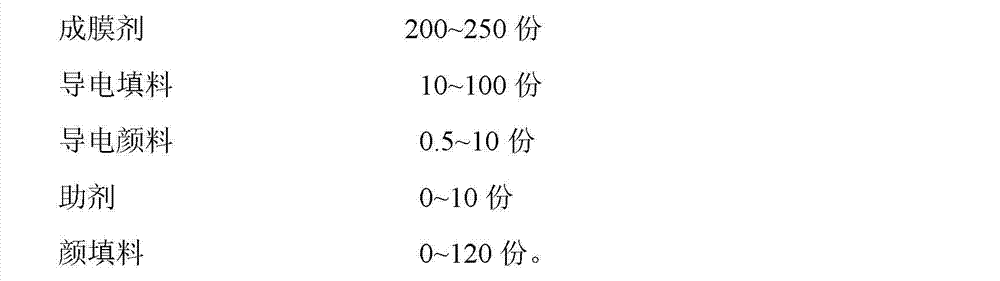

[0035]

[0036]

[0037] Preparation:

[0038] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0039] (b) The crushed material is extruded into a twin or single screw extruder; the heating temperature of the extruder is controlled at 80°C;

[0040] (c) The extruded material is compressed into tablets, cooled, pulverized into a powder with a particle size (equivalent particle size D50) of 50 microns, and then sieved and packaged.

Embodiment 3

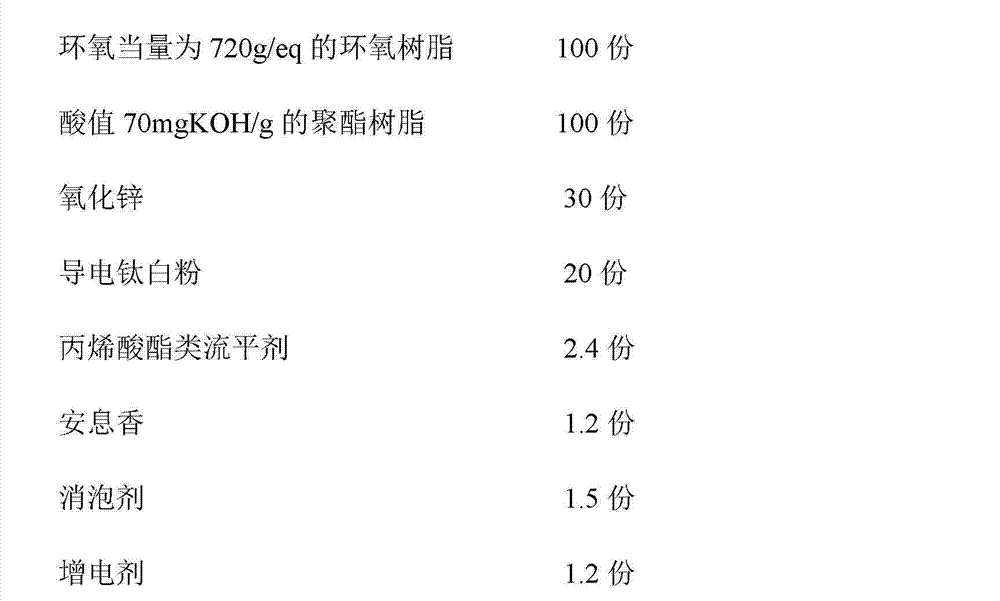

[0042]

[0043] Preparation:

[0044] (a) Weigh each component according to the proportion, place it in the mixing tank, fully mix and crush for 5 minutes;

[0045] (b) The crushed material is extruded into a twin or single screw extruder; the heating temperature of the extruder is controlled at 80°C;

[0046] (c) The extruded material is compressed into tablets, cooled, pulverized into a powder with a particle size (equivalent particle size D50) of 50 microns, and then sieved and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com