Metal piece and preparing method thereof

A technology for metal parts and metal substrates, applied in the direction of metal layered products, chemical instruments and methods, metal material coating technology, etc., can solve the problems of lack of metallic luster, low hardness and poor toughness of the hard coating on the surface of stainless steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention also provides a method for preparing the above-mentioned metal parts, including:

[0030] S1, the metal substrate is fixed in the coating chamber of the magnetron sputtering ion coating machine, wherein the target is a composite target composed of chromium and silicon; in the composite target, the content ratio of chromium and silicon is 1:1;

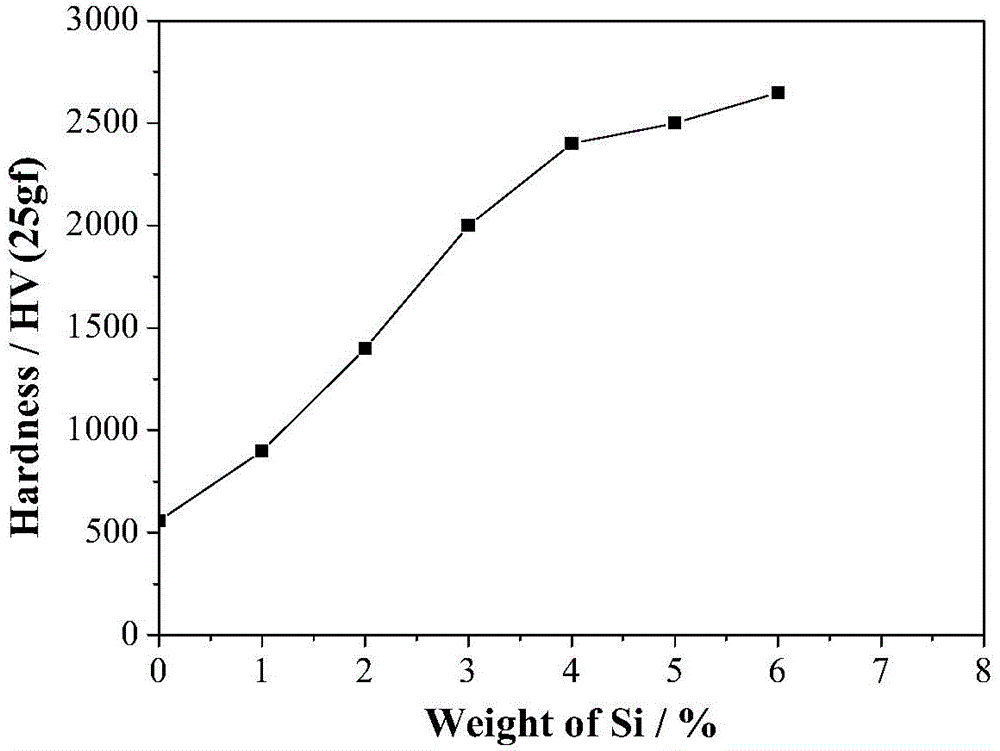

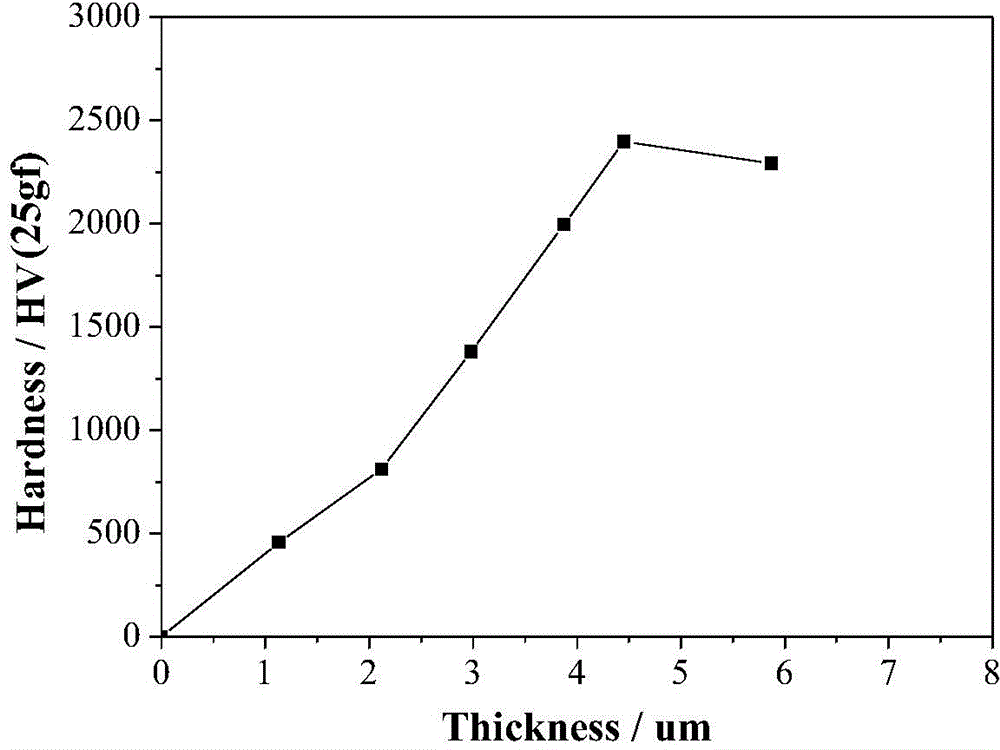

[0031] S2. Using argon as the working gas, perform magnetron sputtering to form a coating layer composed of silicon and chromium with a thickness of 2.5-5 μm on the surface of the metal substrate; the content of silicon in the coating layer is 3-5 wt%.

[0032] According to the present invention, the aforementioned metal substrate is preferably stainless steel, such as 316L stainless steel sheet. When forming the above-mentioned coating on the surface of the metal substrate, a magnetron sputtering method is used. Fix the metal substrate in the coating chamber of the magnetron sputtering ion coating machine....

Embodiment 1

[0042] This embodiment is used to illustrate the metal piece disclosed in the present invention and its preparation method.

[0043] The polished 316L stainless steel sheet (12mm×24mm)×3 pieces (the color measurement experiment has been carried out) is subjected to (85°C) high temperature dewaxing, degreasing and other pre-coating processes, hung up and dried, and then put into the medium frequency magnetron sputtering In the ion coating machine, the silicon-embedded chromium and silicon composite twin target (the content ratio of chromium and silicon is 1:1) is used as the target material. After cleaning by ion sputtering, pump the coating chamber to a background vacuum of 4-6×10 -3 After Pa, pass a certain amount of working gas argon (purity 99.99%) to maintain the vacuum at 0.12-1.2Pa. Turn on the power and carry out intermediate frequency magnetron sputtering. A silicon-doped chromium hard coating with a thickness of 4.5 μm is formed on the surface of the stainless steel...

Embodiment 2

[0060] This embodiment is used to illustrate the metal piece disclosed in the present invention and its preparation method.

[0061] The polished 316L stainless steel sheet (12mm×24mm)×3 pieces (the color measurement experiment has been carried out) is subjected to (85°C) high temperature dewaxing, degreasing and other pre-coating processes, hung up and dried, and then put into the medium frequency magnetron sputtering In the ion coating machine, the silicon-embedded chromium and silicon composite twin target (the content ratio of chromium and silicon is 1:1) is used as the target material. After cleaning by ion sputtering, pump the coating chamber to a background vacuum of 4-6×10 -3 After Pa, pass a certain amount of working gas argon (purity 99.99%) to maintain the vacuum at 0.12-1.2Pa. Turn on the power and carry out intermediate frequency magnetron sputtering. A silicon-doped chromium hard coating with a thickness of 4.5 μm is formed on the surface of the stainless steel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Surface hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com