Embedded touch colour-film substrate and manufacturing method thereof

A technology of color film substrate and manufacturing method, applied in the field of flat panel display, capable of solving problems such as long coating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0063] see Figure 2-Figure 12 The first embodiment of the present invention will be specifically described.

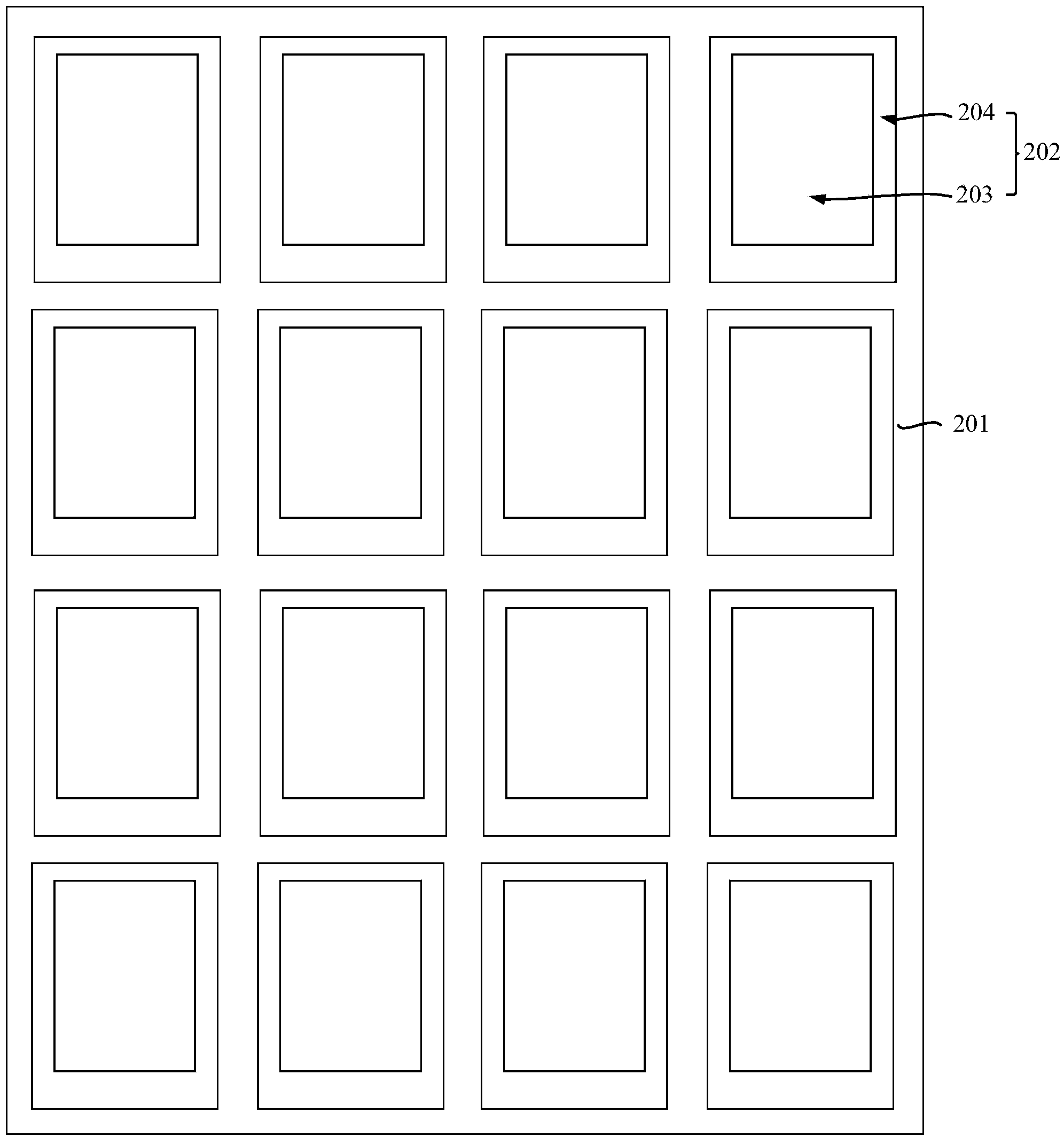

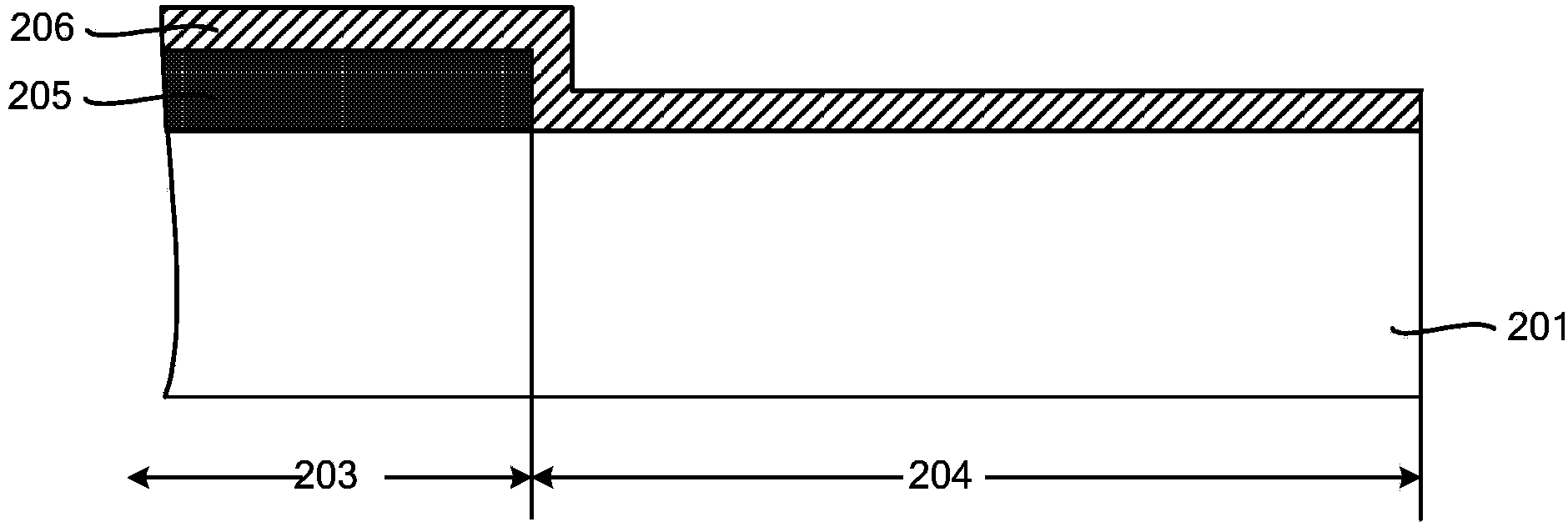

[0064] First, if figure 2 As shown, a substrate 201 is provided, and the substrate 201 includes a plurality of display units 202 , and each display unit 202 includes a display area 203 and a plurality of non-display areas 204 surrounding the display area 203 . Each of the display units 202 corresponds to a subsequent embedded touch display screen. For the convenience of description, one display unit is used as an example for illustration below.

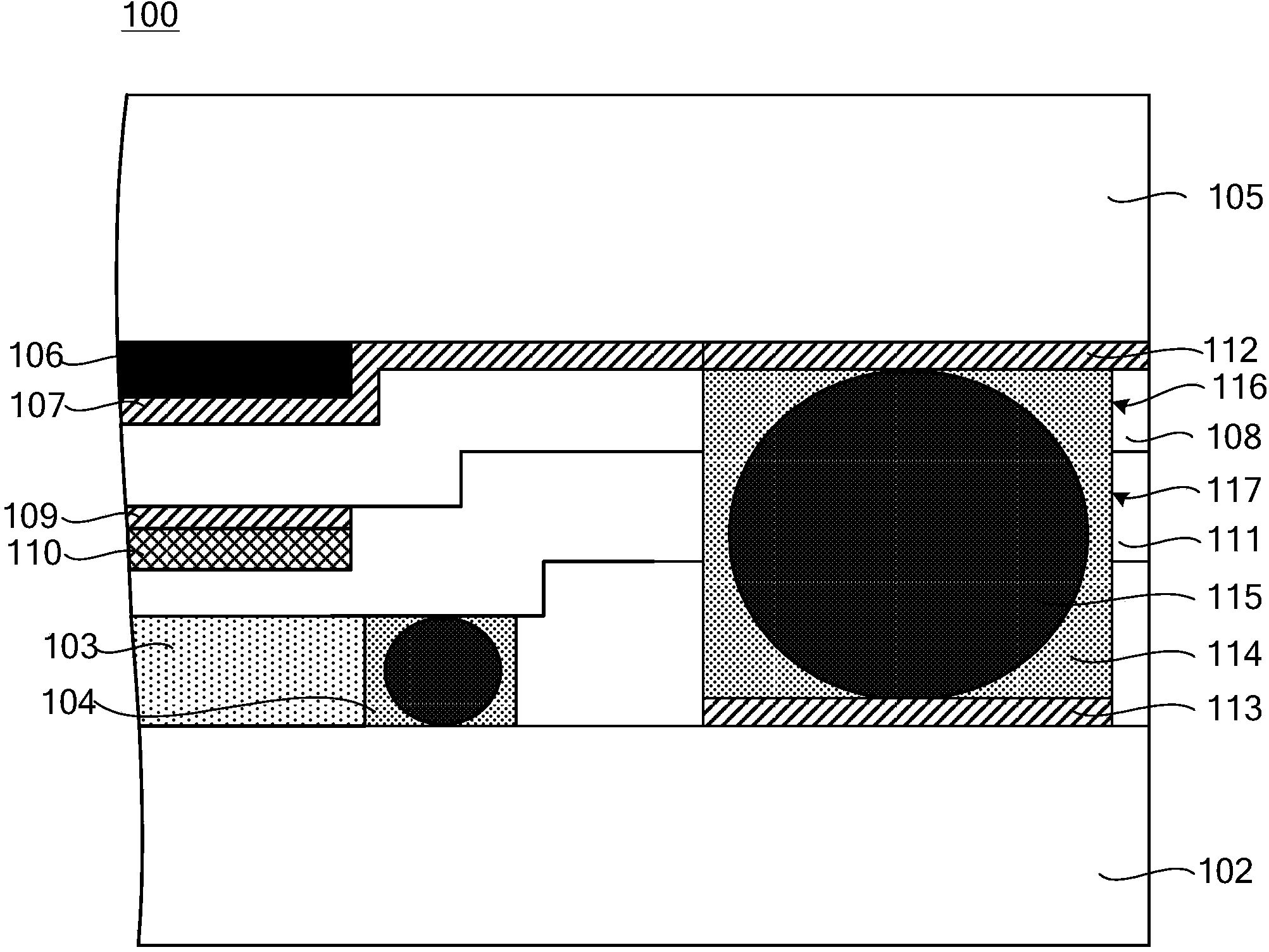

[0065] Such as image 3 As shown, a black matrix 205 and a first metal layer 206 are sequentially formed on the substrate 201 , and the black matrix 205 is only formed in the display area 203 . In the present invention, the first metal layer 206 is used as a driving electrode or a scanning electrode to complete the touch function, and the first metal layer 206 located in the display area 203 is a mesh structure formed on ...

no. 2 example

[0078] see Figure 13-Figure 16 , Figure 13 It is a schematic structural diagram of the display unit in the embedded touch screen according to the second embodiment of the present invention; Figure 14 for Figure 13 Partial sectional view along line AA'; Figure 15 It is a schematic diagram of the structure of the pad area in Embodiment 2 of the present invention; Figure 16 It is a cross-sectional view of the in-cell touch color filter substrate after the application of the frame sealant in the second embodiment of the present invention. exist Figure 13-Figure 16 , the reference numerals indicate the same Figure 2-Figure 12 The same expressions are the same components as those of the first embodiment. The in-cell touch color filter substrate 600 of the second embodiment is basically the same as the in-cell touch color filter substrate 200 of the first embodiment, the difference is that there are several pad areas in the non-display area, There are several conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com