Solvent-free epoxy anticorrosion paint with corrosion restoration function and preparation method thereof

An epoxy anti-corrosion coating, solvent-free technology, applied in the field of coatings, can solve problems affecting coating performance, short plate effect, performance deterioration, etc., achieve excellent anti-corrosion performance, improve corrosion resistance, and reduce the number of coatings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Prepare the restorative composite filler as follows:

[0057] (a) Prepare a mixed aqueous solution of phosphoric acid and dodecylbenzenesulfonic acid: wherein the phosphoric acid is 1M, and the dodecylbenzenesulfonic acid is 0.5M.

[0058] (b) Prepare ammonium persulfate aqueous solution: ammonium persulfate is 2M.

[0059] (c) Add aniline to (a) mixed acid solution, the concentration of aniline is 3M. Stir well.

[0060] (d) Take 1000ml of (c), add 200g of zinc phosphate and 100g of montmorillonite into it, and stir evenly at 5°C.

[0061] (e) Gradually add 1000ml of (b) into (d), keep stirring, and control the temperature at 5°C for 4h. The reaction product was filtered, washed with distilled water until the pH of the solution was 4-5, and then filtered.

[0062] (f) Add the filtered product obtained in (e) to KH560 silane coupling agent methanol aqueous solution (methanol: water: coupling agent = 10:1:1) 1000ml, continue stirring for 48h, filter, and dry at 80°C....

Embodiment 2

[0067] Prepare the restorative composite filler as follows:

[0068] (a) Prepare a mixed aqueous solution of phosphoric acid and dodecylbenzenesulfonic acid: wherein the phosphoric acid is 0.5M, and the dodecylbenzenesulfonic acid is 2M.

[0069] (b) Prepare ammonium persulfate aqueous solution: ammonium persulfate is 3M.

[0070] (c) Add aniline to (a) mixed acid solution, the concentration of aniline is 2M. Stir well.

[0071] (d) Take 1000ml of (c), add 100g of zinc phosphate and 100g of montmorillonite into it, and stir evenly at 0°C.

[0072] (e) Gradually add 1000ml of (b) into (d), keep stirring, and control the temperature at 0°C for 4h. The reaction product was filtered, washed with distilled water until the pH of the solution was 4-5, and then filtered.

[0073] (f) Mix the filtered product obtained in (e) with 5ml of JN14 titanate coupling agent, place it for 48 hours, filter, dry at 100°C, and grind it finely to obtain the polyaniline modified polyaniline treat...

Embodiment 3

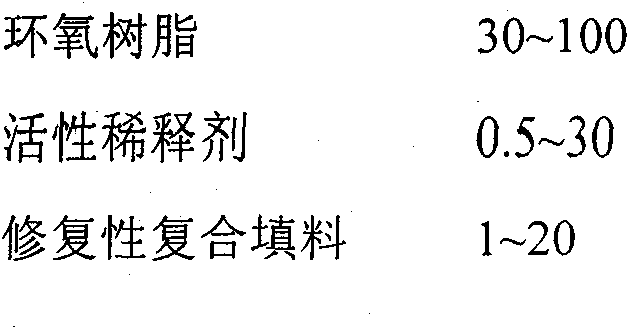

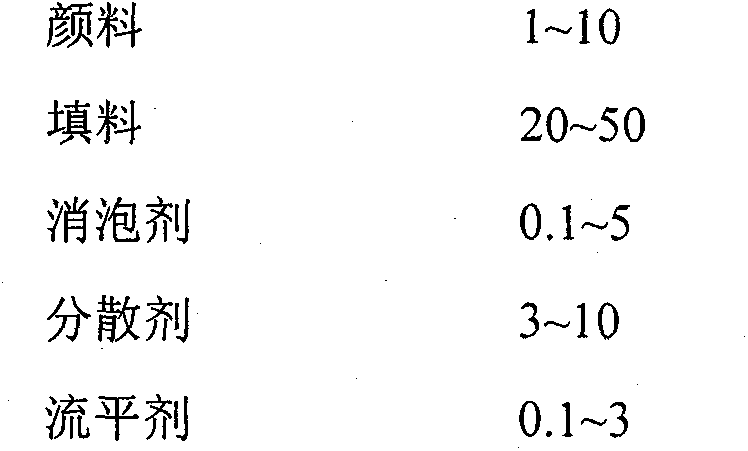

[0078] 1) Mix 10 parts of reactive diluent (6690), 0.5 parts of defoamer (Defom5300), 5 parts of dispersant (Disperbyk163) and 100 parts of novolac epoxy resin (F51), and then add the ingredients in Example 2 in sequence. Prepared titanate coupling agent-treated polyaniline modified zinc phosphate and montmorillonite composite filler 20 parts, titanium dioxide 10 parts, filler (mica iron oxide) 50 parts, leveling agent (BYK354) 3 parts, in Disperse in a high-speed disperser for 60 minutes to make component A.

[0079] 2) Add 20 parts of polyamide 651# to 5 g of reactive diluent 6690 and mix evenly to prepare component B.

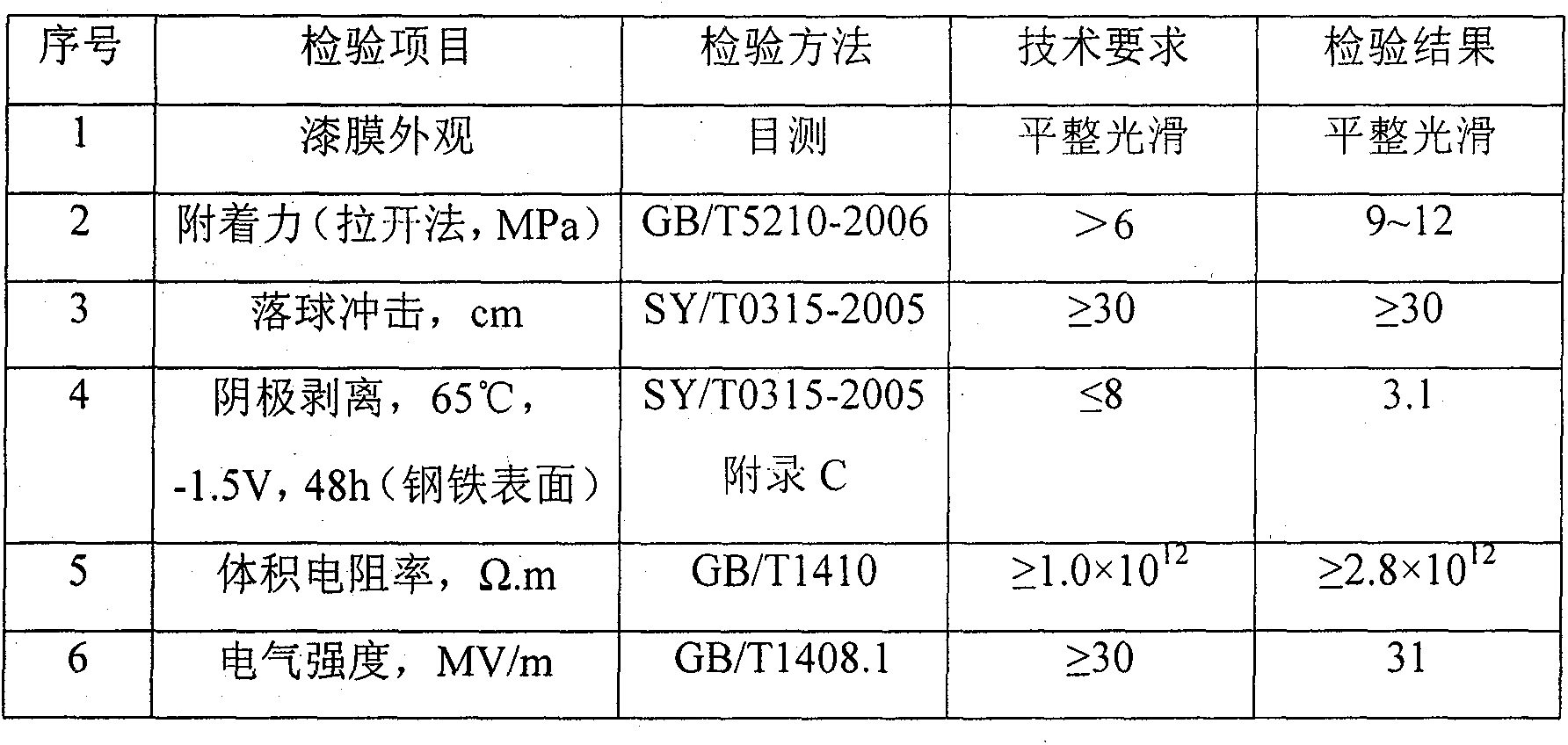

[0080] 3) According to component A: component B = 2:1, mix components A and B evenly, and apply the coating on the AZ91D magnesium alloy test piece with a surface roughness of Sa2.5, and cure it at room temperature for 7 days before coating. Layer performance testing. The coating thickness is 120±10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com