Patents

Literature

67results about How to "Reduce the number of coats" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

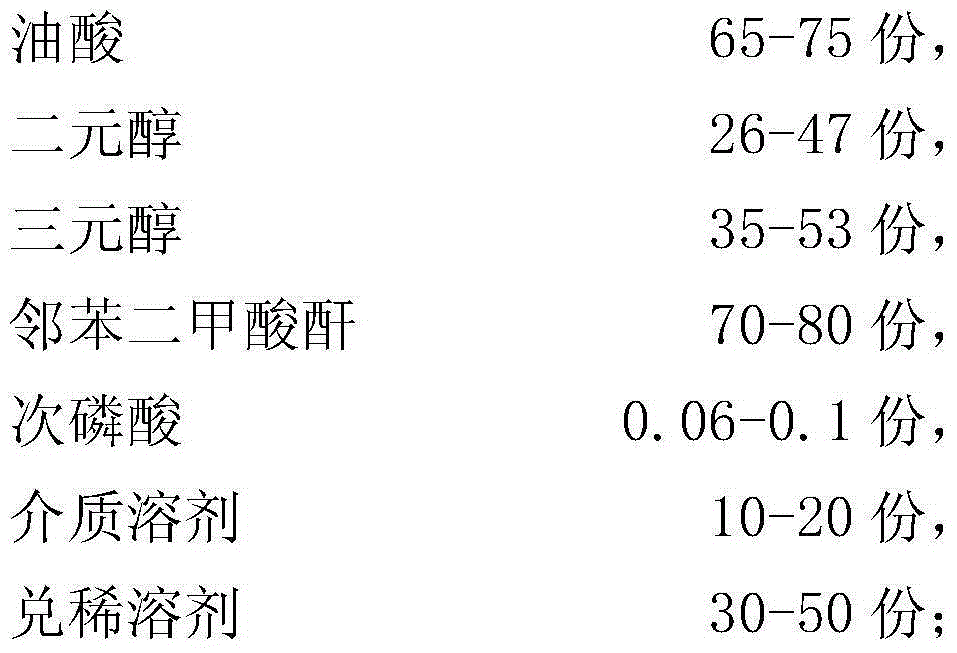

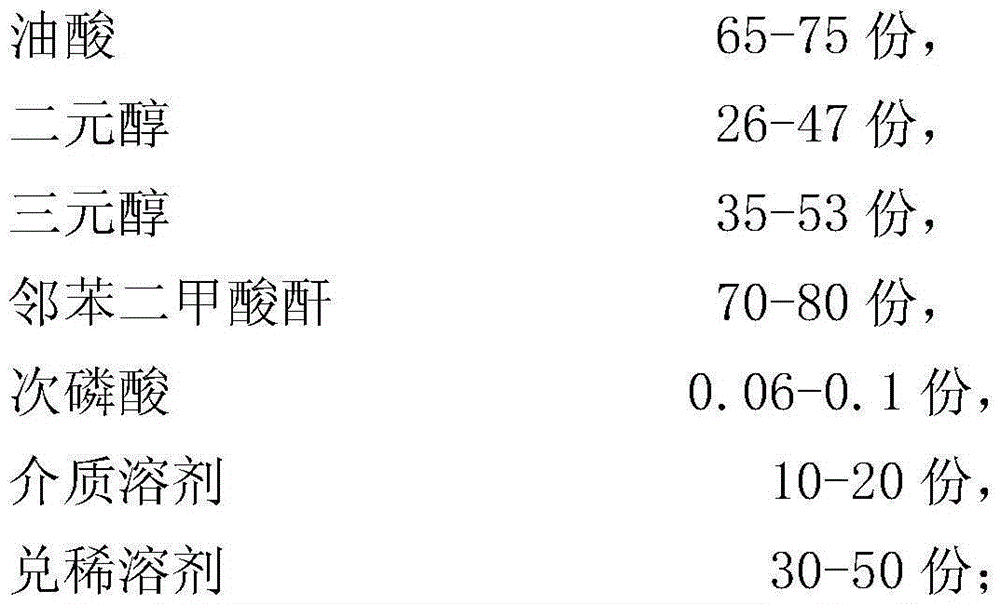

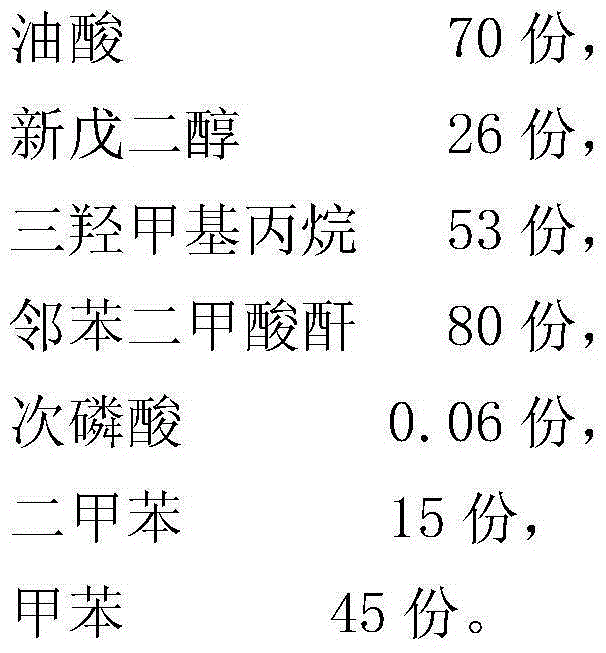

High-solid and low-viscosity short oil alkyd resin and preparation method therefor

The invention relates to alkyd resin, particularly high-solid and low-viscosity short oil alkyd resin and a preparation method therefor. The high-solid and low-viscosity short oil alkyd resin provided by the invention is prepared from the following components in parts by weight: 65-75 parts of oleic acid, 26-47 parts of dihydric alcohol, 35-53 parts of trihydric alcohol, 70-80 parts of phthalic anhydride, 0.06-0.1 part of hypophosphorous acid, 10-20 parts of a medium solvent, and 30-50 parts of a diluting solvent. The short oil alkyd resin prepared by the invention is high in solid content and low in viscosity, can be used in light or matte polyurethane wood lacquer at the same time, remarkably reduces the content of VOC in paint, and has a good film effect.

Owner:SKSHU PAINT

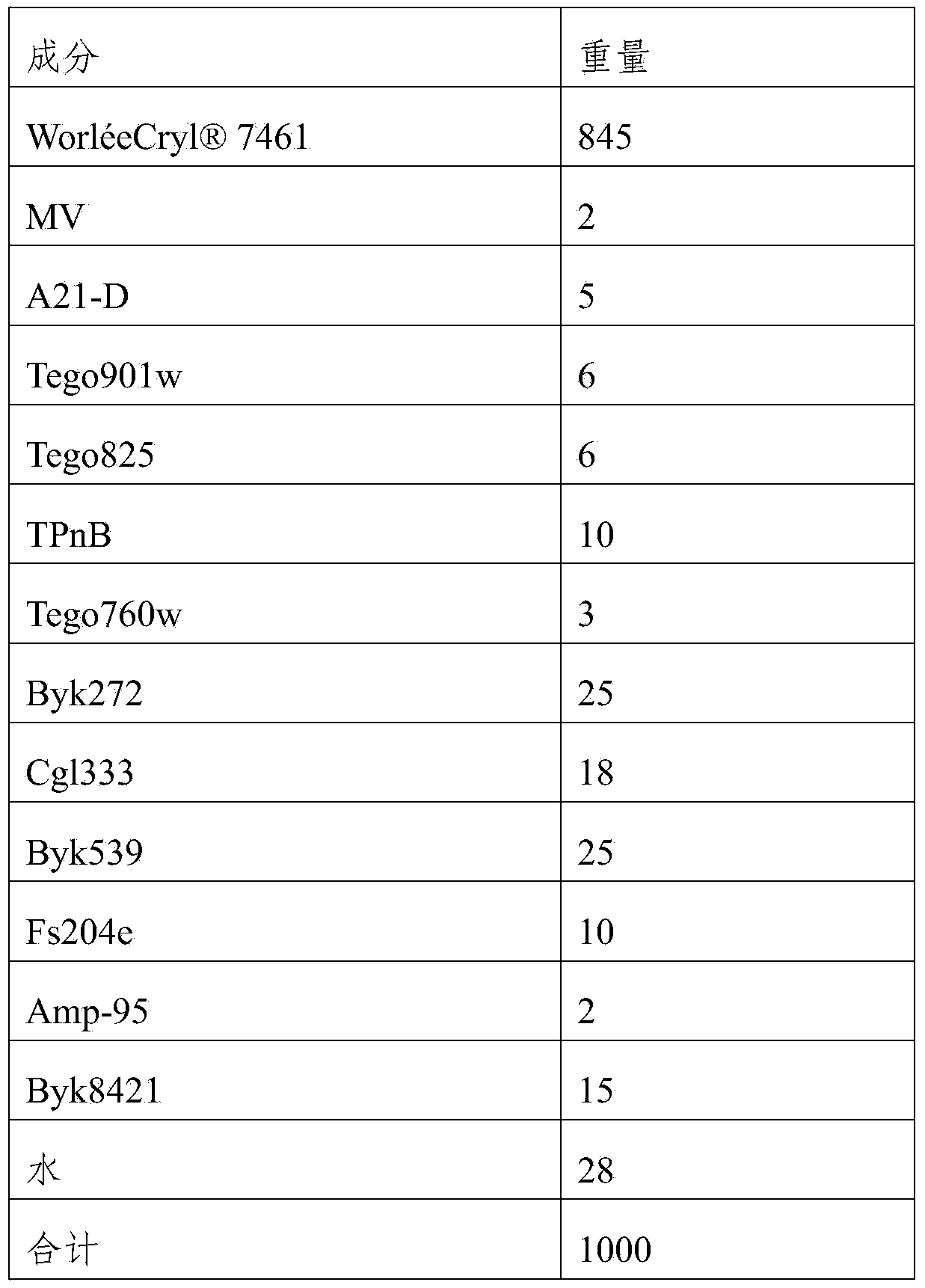

Water-based clear topcoat with high solid content and preparation method thereof

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

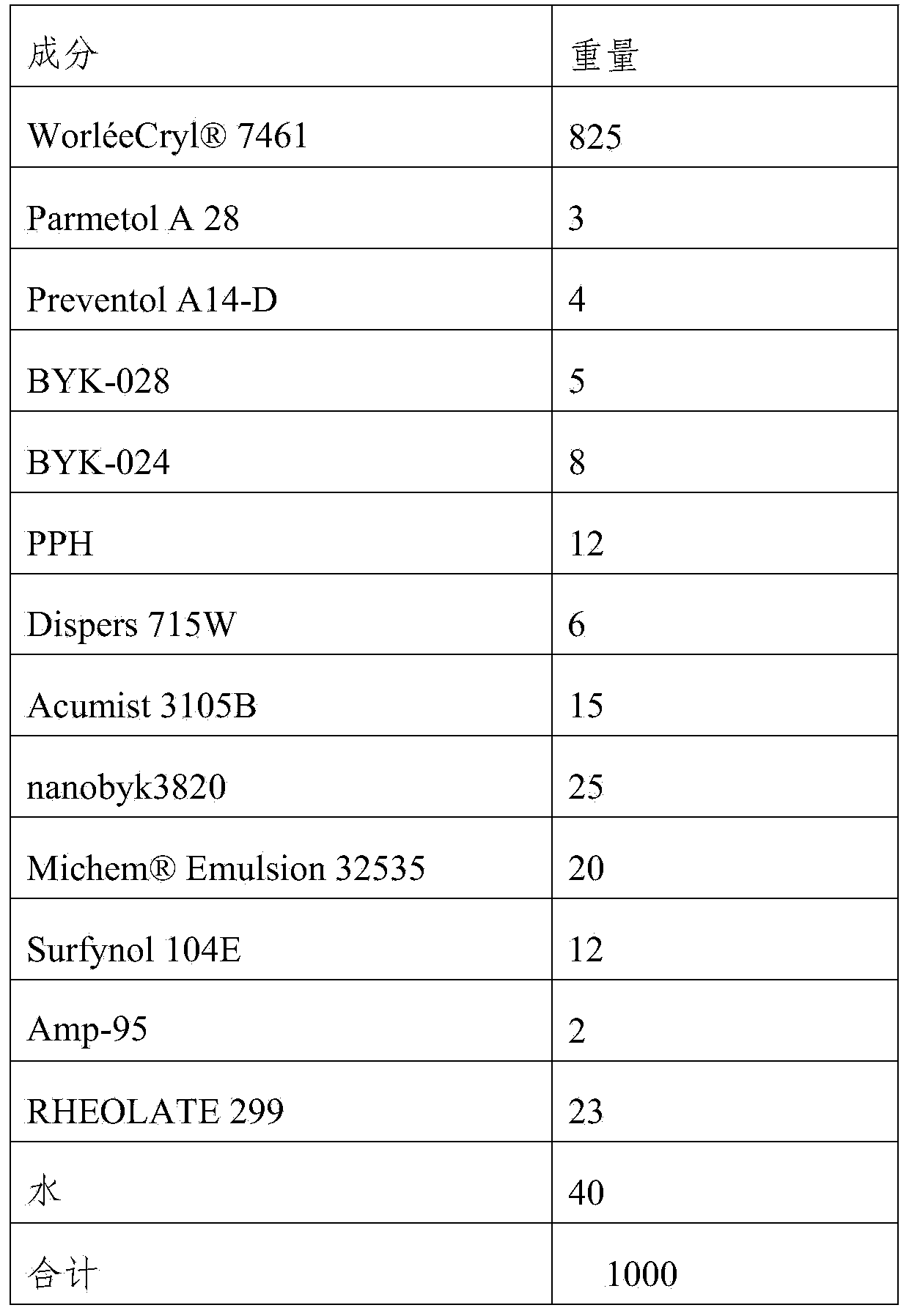

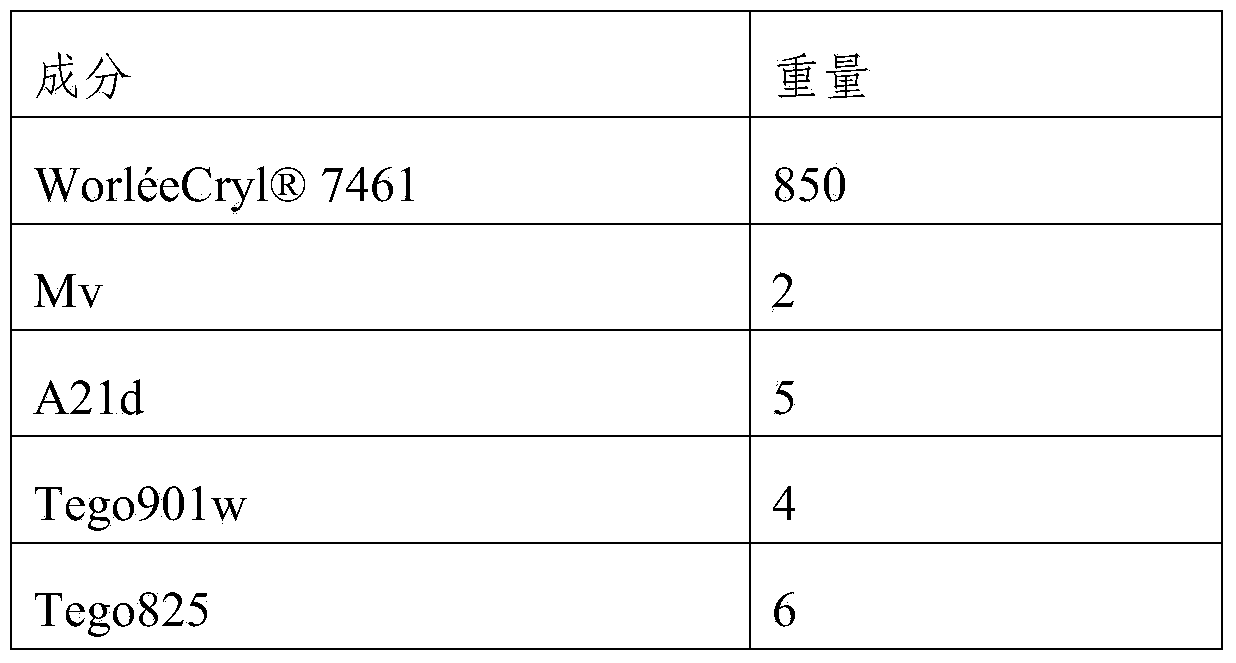

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

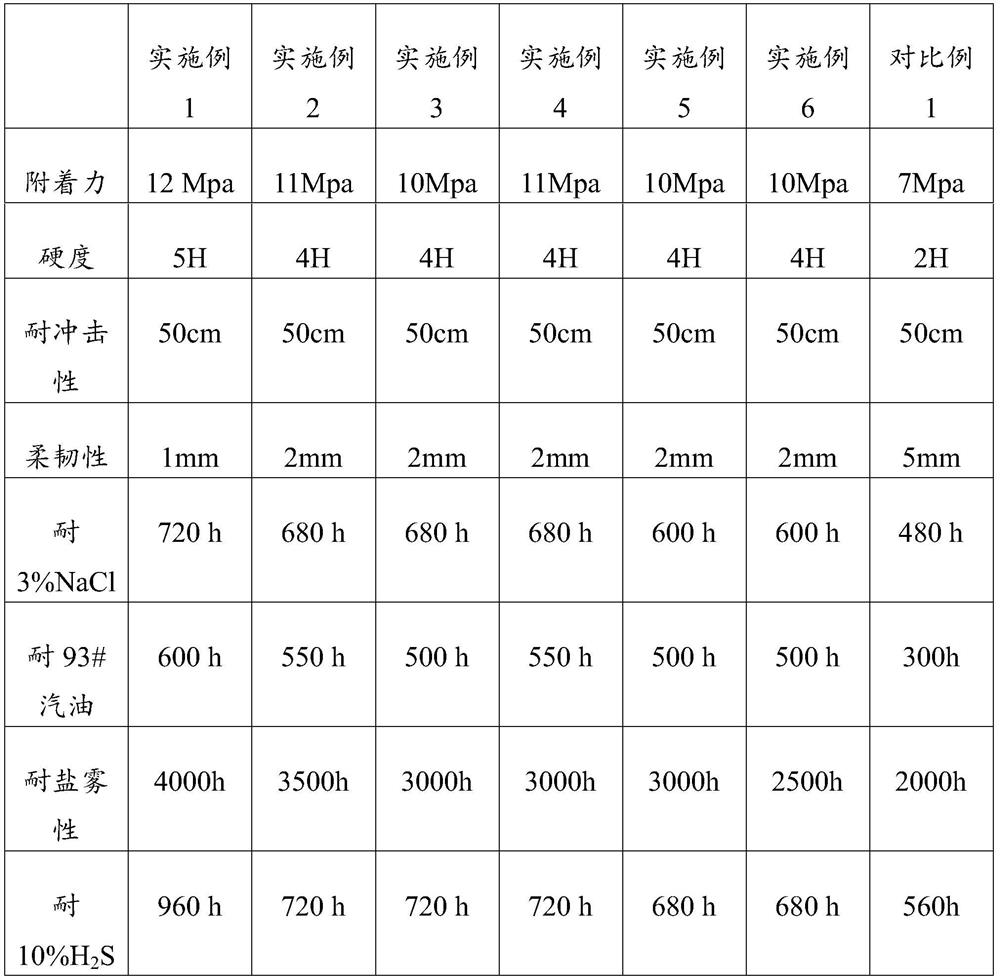

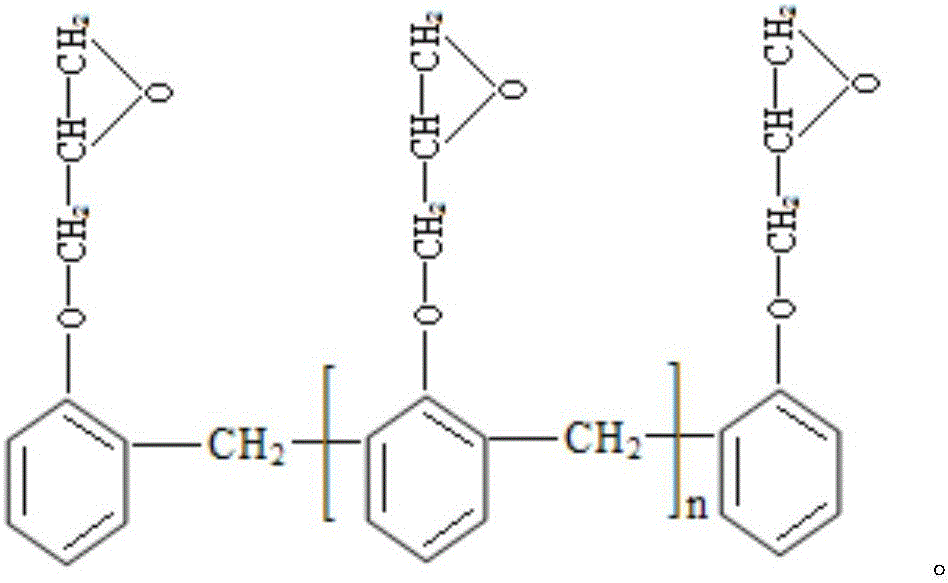

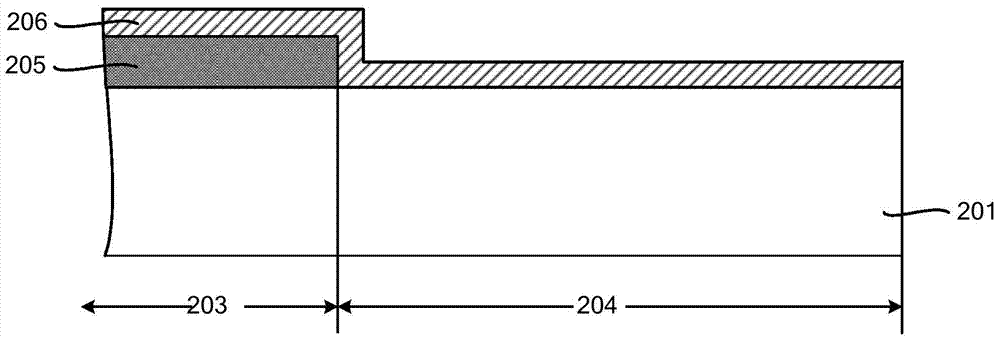

Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

InactiveCN109181477AGood chemical resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

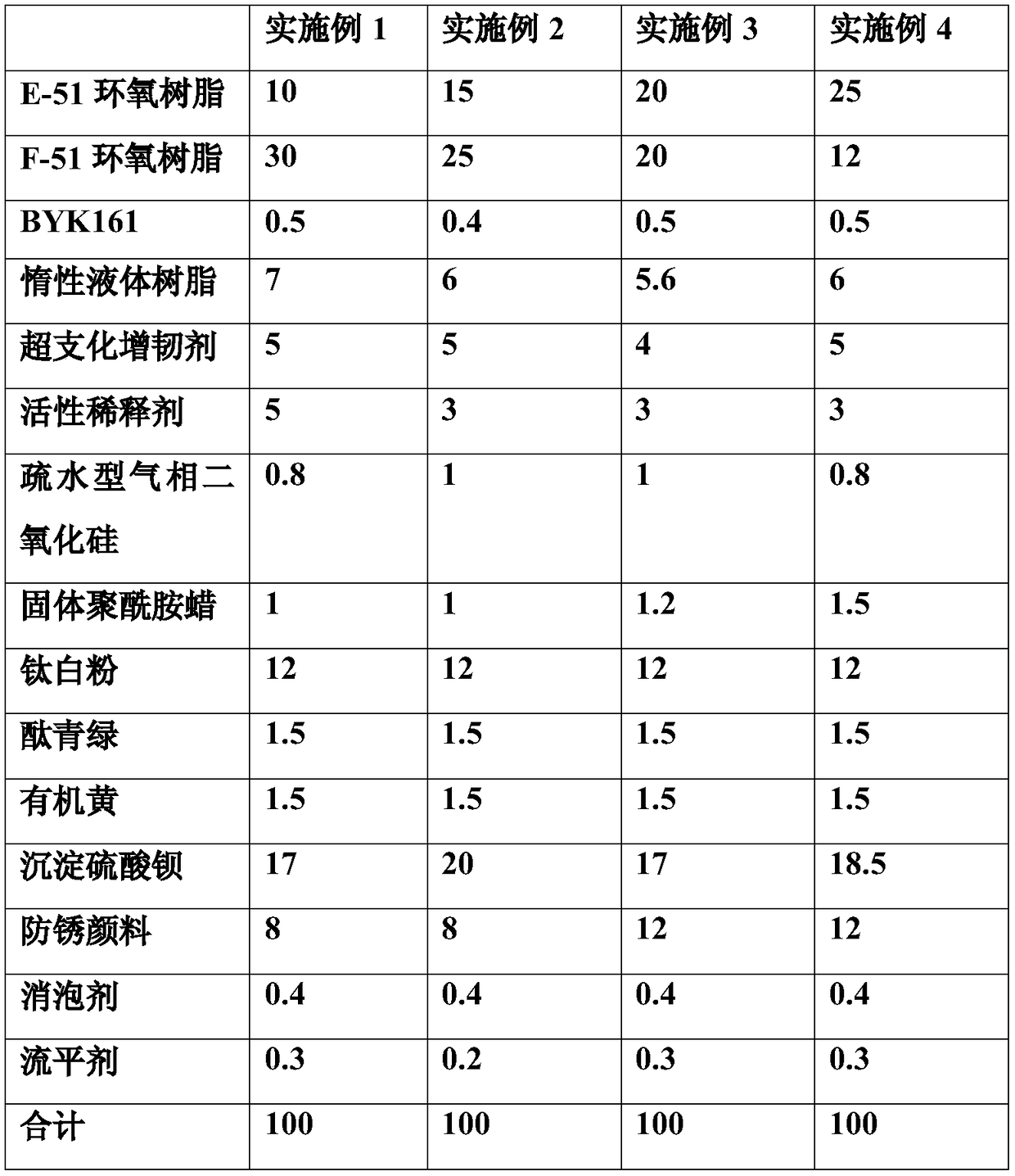

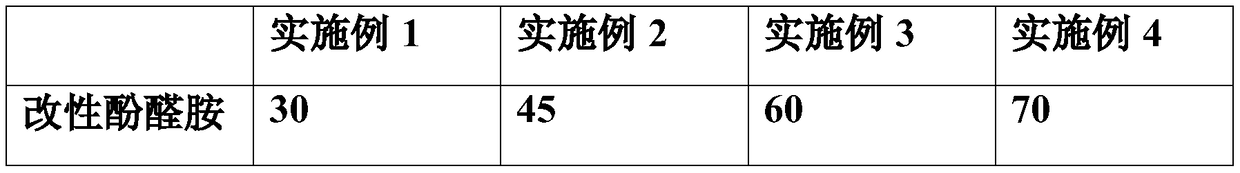

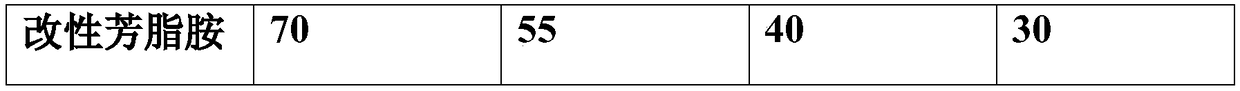

The invention discloses a solvent-free epoxy heavy anti-corrosion paint which is extruded and coated to the inner wall of a crude oil gathering pipeline. The paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-25 parts of E-51 epoxy resin, 12-30 parts of F-51 epoxy resin, 10-15 parts of titanium dioxide, 1-2 parts of phthalocyanine green, 1-2 parts of organic yellow, 1.5-3 parts of a thixotropic agent, 0.3-0.5 part of a wetting dispersant, 5-8 parts of inert liquid resin, 3-5 parts of an active diluting agent, 3-5 parts of a hyperbranched toughening agent, 15-20 parts of precipitated barium sulfate, 8-15 parts of anti-rust pigment, 0.3-0.5 part of a defoaming agent, 0.2-0.4 part of a flatting agent; the component B is prepared from 30-70 parts of modified phenolic amine curing agent and 70-30 parts of modified aromatic amine curing agent; and the mass ratio of the component A to the component B is(5-7):1. The solvent-free epoxy heavy anti-corrosion paint is applicable to gathering pipeline extruding and coating processes, the pipeline inner wall coating has excellent corrosion resistance and physical performance, the coating process can be reduced, the construction time can be saved, and the work efficiency can be improved.

Owner:石家庄市油漆厂

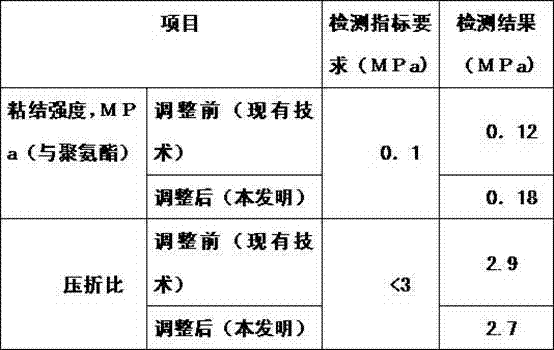

Surface mortar for outer wall external insulation system using sprayed rigid foam polyurethane

InactiveCN102351471AAvoid crackingGood flexibilitySolid waste managementCrack resistanceThermal insulation

The invention relates to a surface mortar for an outer wall external insulation system using sprayed rigid foam polyurethane. The surface motor is prepared by mixing the following materials in proportion (mass): 40 to 58% of cement, 20 to 35% of a lightweight insulation material, 0.1 to 0.2% of an anti-cracking agent, 0.4 to 1% of redispersible rubber powder, 0.2 to 0.3% of a water-retaining agent and 0 to 0.5% of slow-drying agent, with the balance being a filler. The surface mortar provided in the invention has good flexibility and crack resistance, can compensate for temperature strain caused by difference among expansion coefficients of materials and avoids the cracking of the external insulation system, thereby thoroughly overcoming the difficulty in leveling and the problem of proneness to cracking in the prior art. Simultaneously, a conventional process for leveling of insulation mortar and rendering of crack resistant mortar is simplified in the invention; the surface mortar provided in the invention has both the functions of leveling and rendering and has excellent leveling and filling performance and a light weight, providing reliable guarantee for the security of the system. Low cost and substantially reduced construction cost are achieved in the invention.

Owner:江苏百代节能建材有限公司

Solid thermoplastic acrylic resin special for PP (polypropylene) and preparation method thereof

The invention discloses a solid thermoplastic acrylic resin special for PP (polypropylene), comprising the following components in percentage by mass: 35-45% of styrene, 15-25% of methyl methacrylate, 14-23% of vinyl acetate, 10-20% of high chlorinated polypropylene, 3-5% of high chlorinated polyvinyl resin, 0.7-1.2% of dibenzoyl peroxide and 0.7-1.2% of crylic acid. The invention also discloses a preparation method of the acrylic resin, comprising the steps of: heating proper deionized water to 75 DEG C and adding mixing monomer for polymerization, carrying out polymerization after heating the mixture to 88-95 DEG C and applying pressure to 0.5-1kg, reacting for 60min, finishing the polymerization at 108-112 DEG C, cooling after keeping temperature for 45min, discharging, dehydrating and drying. The solid thermoplastic acrylic resin can be directly prepared into printing ink and painting, reduce the construction difficulty and painting time, and has time and labor saving, low cost, good film-forming property and adhesion and high gloss.

Owner:YANGZHOU ZHENGXING RESIN

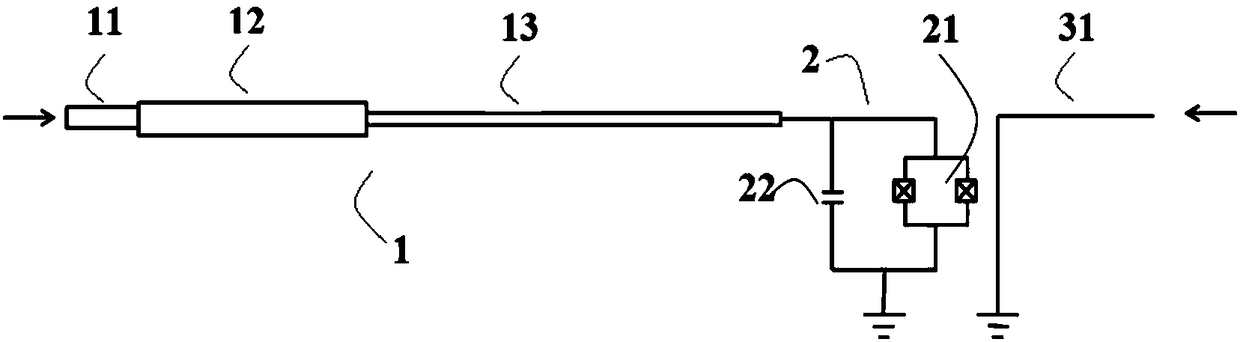

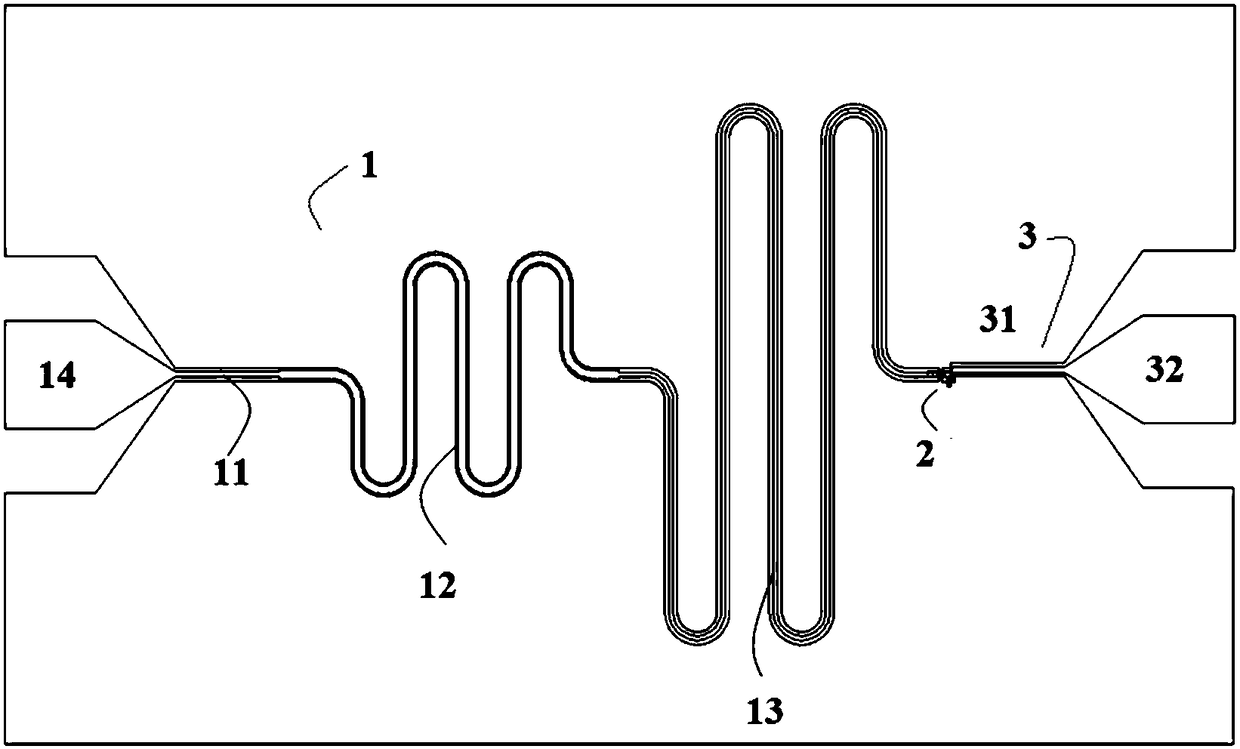

Impedance matching Joseph Sen parametric amplifier, manufacturing method thereof and a communication module

PendingCN108259014AGuaranteed reliabilitySimple manufacturing processVariable-capacitor element amplifiersImpedance transformerCapacitance

The invention discloses an impedance matching Joseph Sen parametric amplifier, a manufacturing method thereof and a communication module, belongs to the field of Joseph Sen parametric amplifiers, andaims to solve the problem that the impedance matching Joseph Sen parametric amplifier has larger signal attenuation and larger device size in the prior art. An impedance transformer, an anharmonic resonant cavity and a pump microwave circuit of the impedance matching Joseph Sen parametric amplifier are all integrated on a silicon substrate; and a second end of the impedance transformer is connected in series with the anharmonic resonant cavity through a superconducting material. Meanwhile, all components other than a supercapacitor insulating layer are made of the superconducting material, sothat the reflection and loss of signal microwaves of the manufactured amplifier are greatly reduced, and the attenuation constant is almost zero. The bandwidth of the amplifier can reach 1GHz or more,and the amplifier can work in a frequency range of 5GHz to 8GHz. Meanwhile, a preparation process is simplified, and the repeatability and yield of device manufacturing are improved.

Owner:HEFEI ORIGIN QUANTUM COMP TECH CO LTD

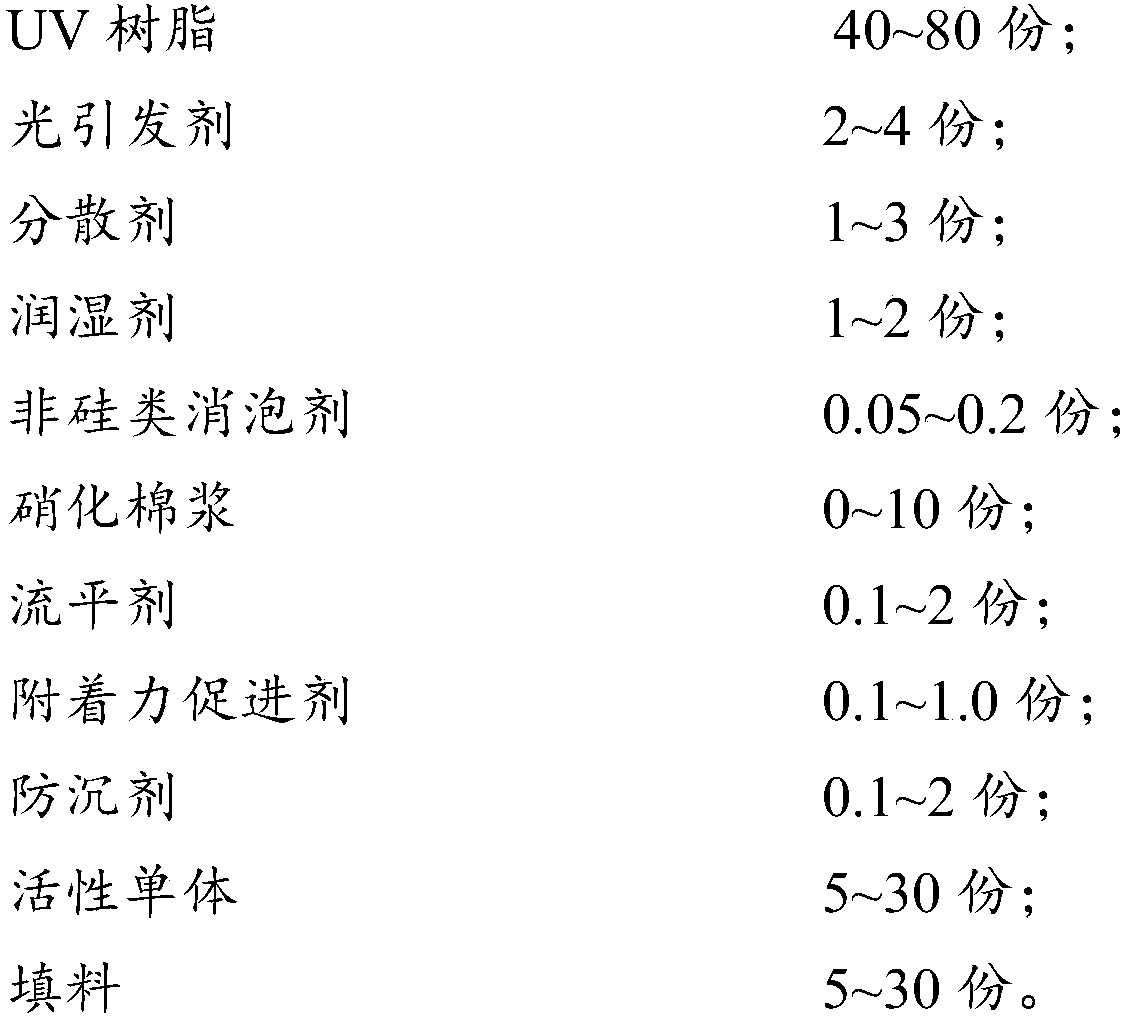

Ultraviolet curing primer for surface of wood and preparation method of ultraviolet curing primer

ActiveCN109609002AImprove filling efficiencyImprove hole penetrationPolyester coatingsUltraviolet lightsEconomic benefits

The invention belongs to the technical field of coatings, and particularly relates to an ultraviolet curing primer for the surface of wood and a preparation method of the ultraviolet curing primer. Based on 100 parts of the total weight, the ultraviolet curing primer provided by the invention comprises the following components in parts by weight: 40-80 parts of ultraviolet (UV) resin, 2-4 parts ofa photoinitiator, 1-3 parts of a dispersing agent, 1-2 parts of a wetting agent, 0.05-0.2 part of a non-silicon deforming agent, 0-10 parts of nitrocotton pulp, 0.1-2 parts of a flatting agent, 0.1-1.0 part of an adhesion promoter, 0.1-2 parts of an anti-settling agent, 5-30 parts of active monomers and 5-30 parts of filler. Compared with the prior art, the ultraviolet light curing primer provided by the invention has good pore entering performance when the wood is sprayed and coated, filling efficiency of the primer is improved, coating times are reduced, and economic benefits are improved.In addition, a coating film formed by the primer has the characteristics of good filling, good polishing, high transparency and the like.

Owner:珠海展辰新材料股份有限公司

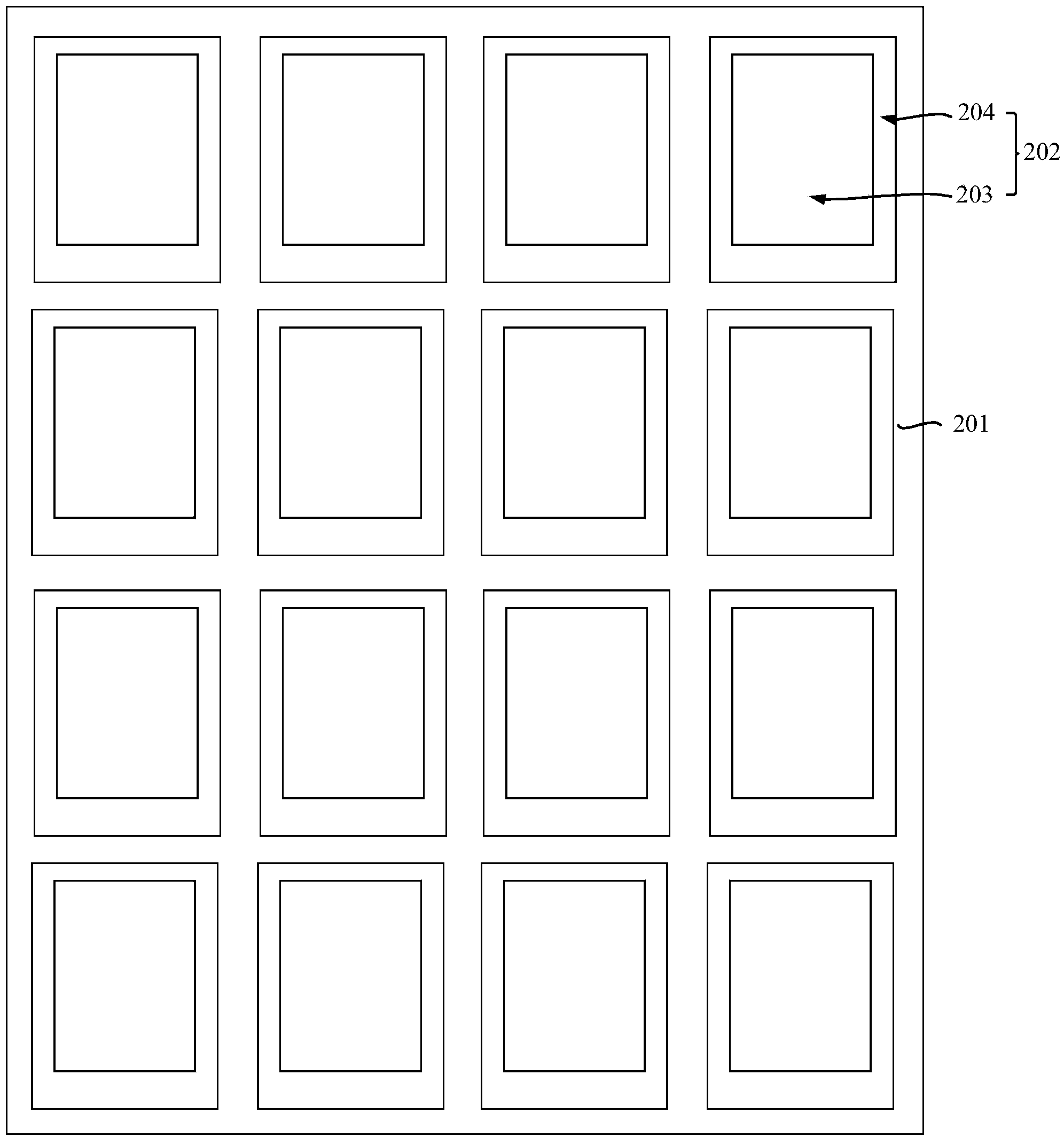

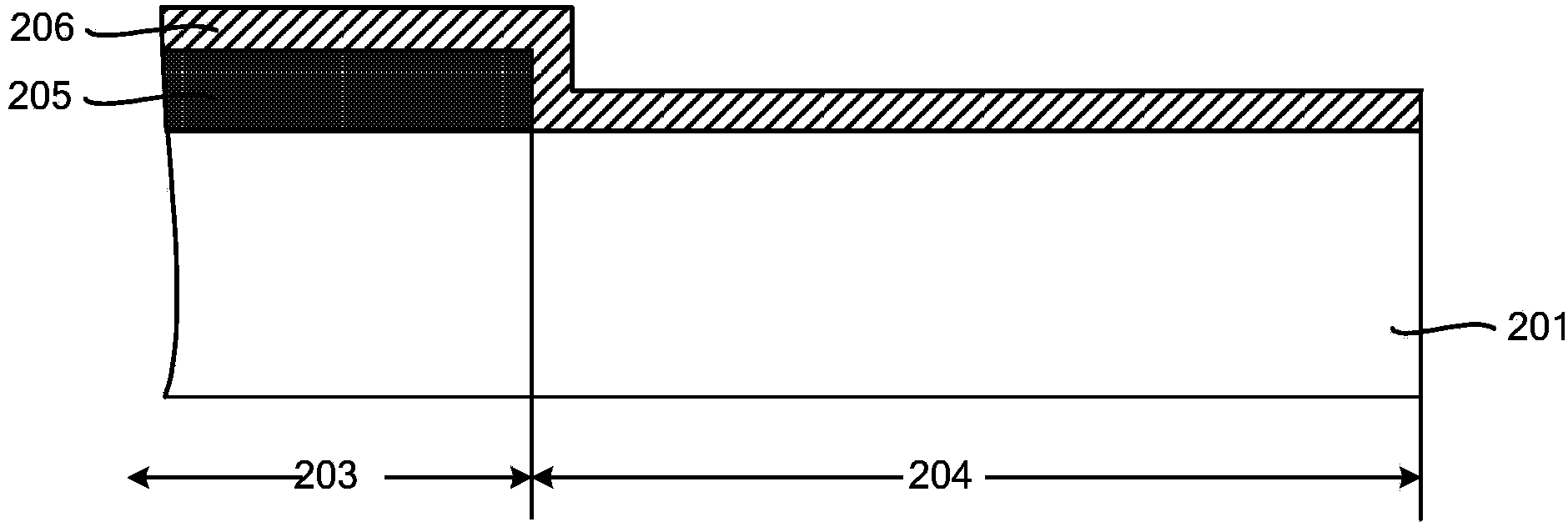

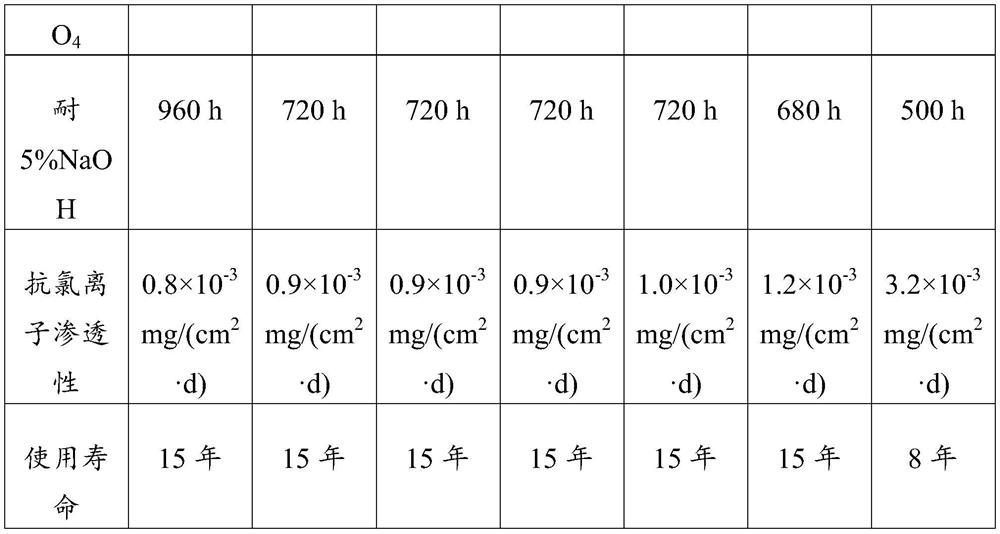

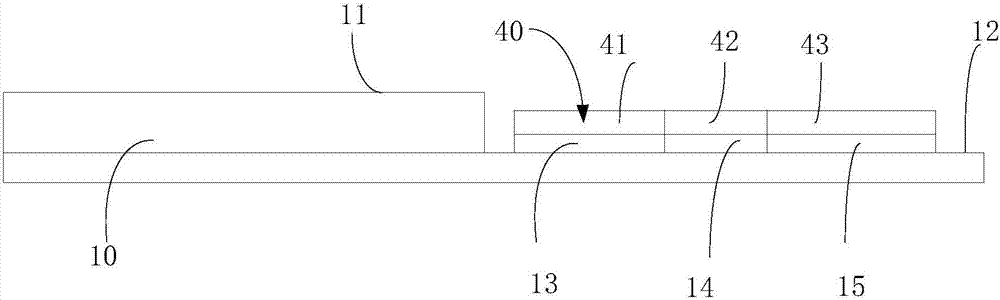

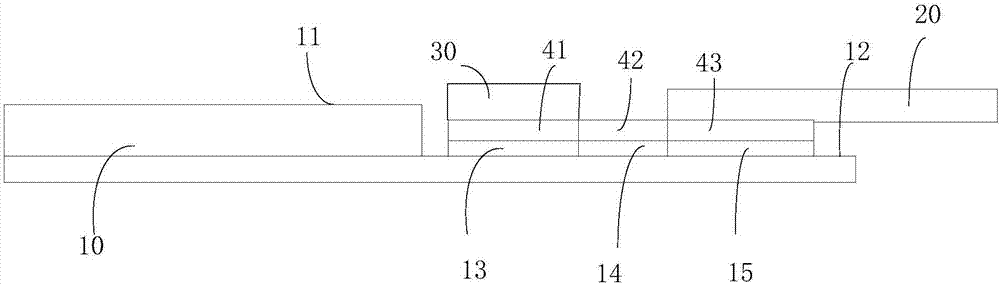

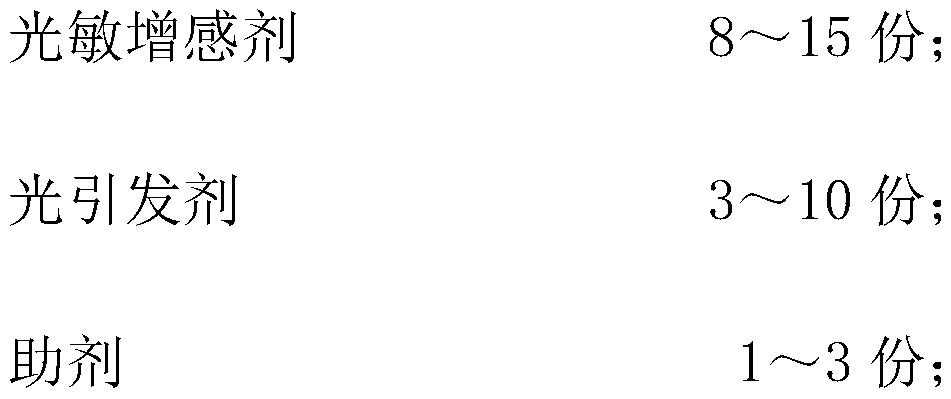

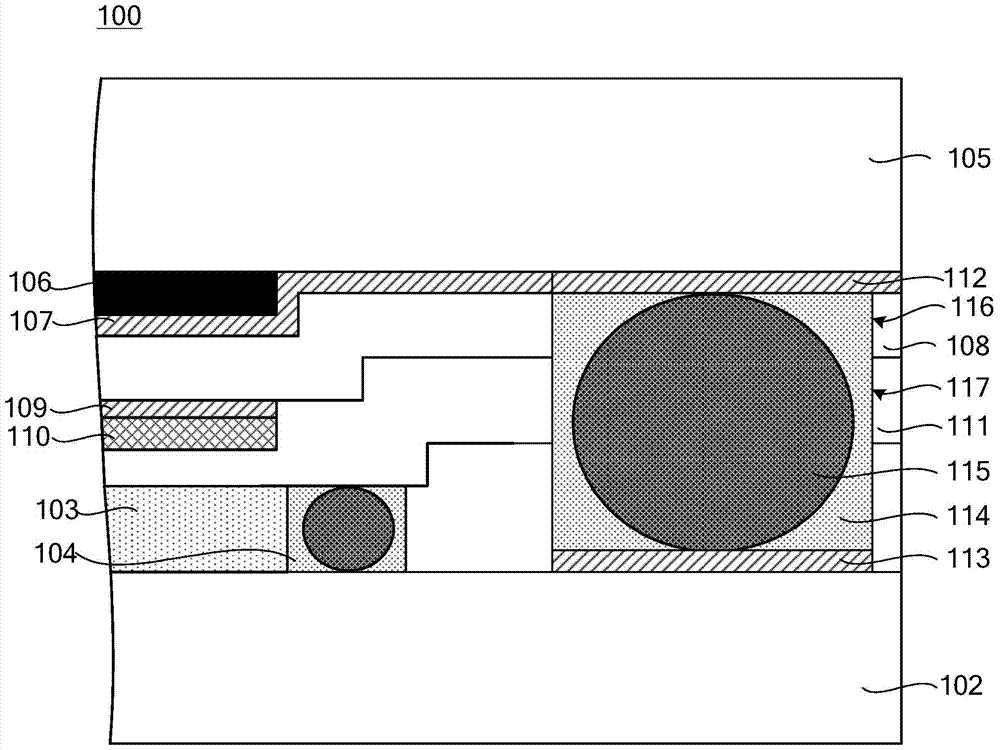

Embedded touch colour-film substrate and manufacturing method thereof

ActiveCN103984145AReduce the number of coatsShorten coating timeNon-linear opticsInput/output processes for data processingCushionOptoelectronics

The invention discloses an embedded touch colour-film substrate and a manufacturing method thereof. The embedded touch colour-film substrate comprises a substrate, first metal layers, first organic film layers, second metal layers and second organic film layers, wherein the substrate comprises multiple display areas and multiple nondisplay areas surrounding the display areas; the first metal layers, the first organic film layers, the second metal layers and the second organic film layers are formed on the substrate in sequence; each of the second metal layers comprises multiple electric conduction cushions arranged in the nondisplay areas; multiple through holes or through grooves are formed in each of the first organic film layers in the nondisplay areas; the electric conduction cushions are respectively and electrically connected with the first metal layers through the through holes or the through grooves; moreover, the electric conduction cushions are respectively exposed outside the second organic film layers. By applying the embedded touch colour-film substrate provided by the invention, the time on coating a frame sealing glue can be effectively shortened, so that the production efficiency can be improved greatly.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

Woodware filler

The invention provides a wood filling agent, which comprises components in weight portion as follows: 6 to 10 portions of polyethylene resin, 20 to 30 portions of solvent, 1 to 2 portions of anti-settling agent, 60 to 70 portions of filler and 1 to 5 portions of linseed oil. The wood filling agent has excellent interlayer adhesion and good filling performance, and can save 1 or 2 times of coating polyurethane (PU) with quick drying; and the wood with the wood filling agent can be polished after 15 minutes at a normal temperature of 25 DEG C. With excellent large-scale operation, the wood filling agent can adopt a plurality of construction ways such as rubbing or scrapping and has even wood coloring, thereby greatly improving labor productivity.

Owner:上海展辰涂料有限公司 +1

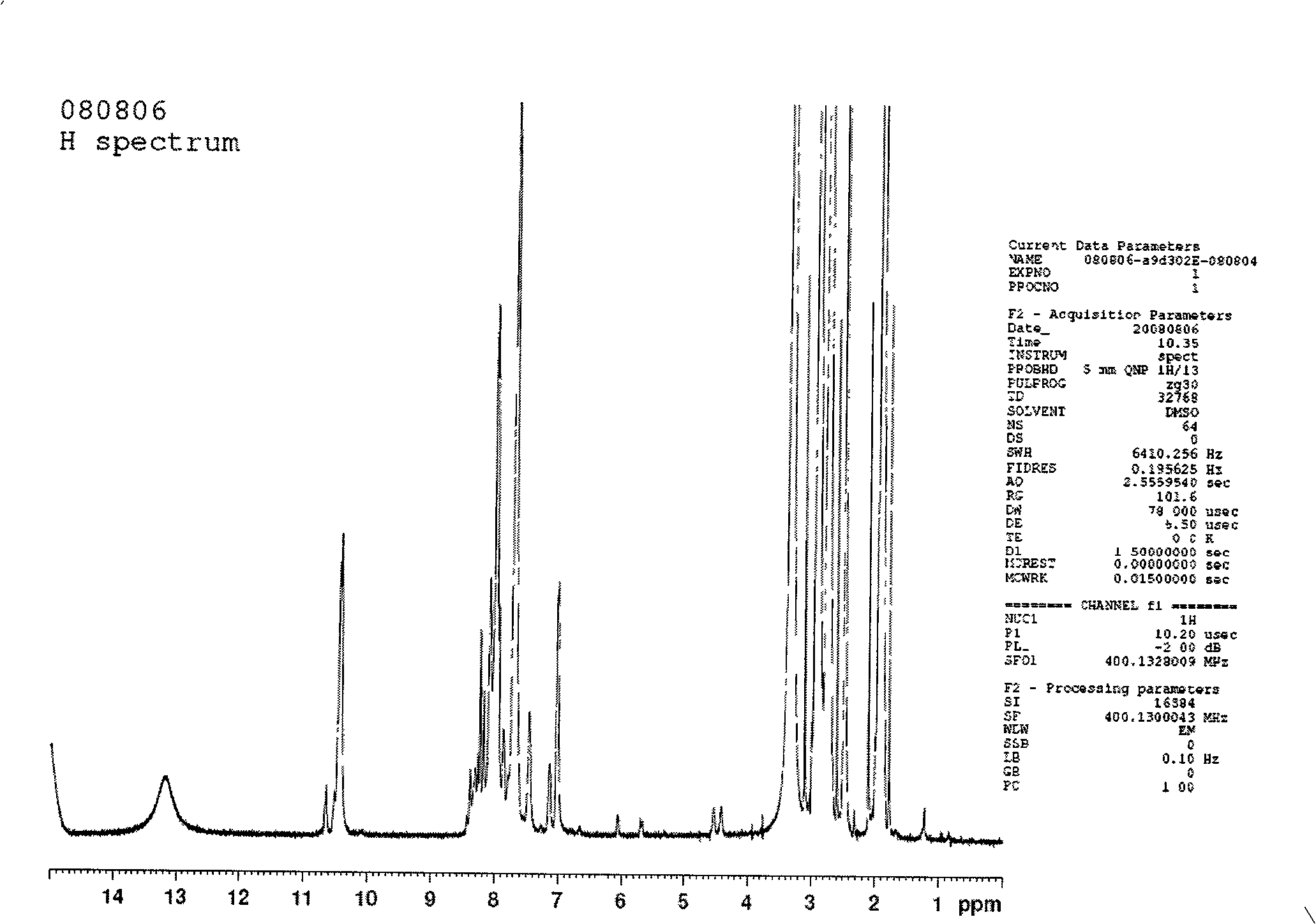

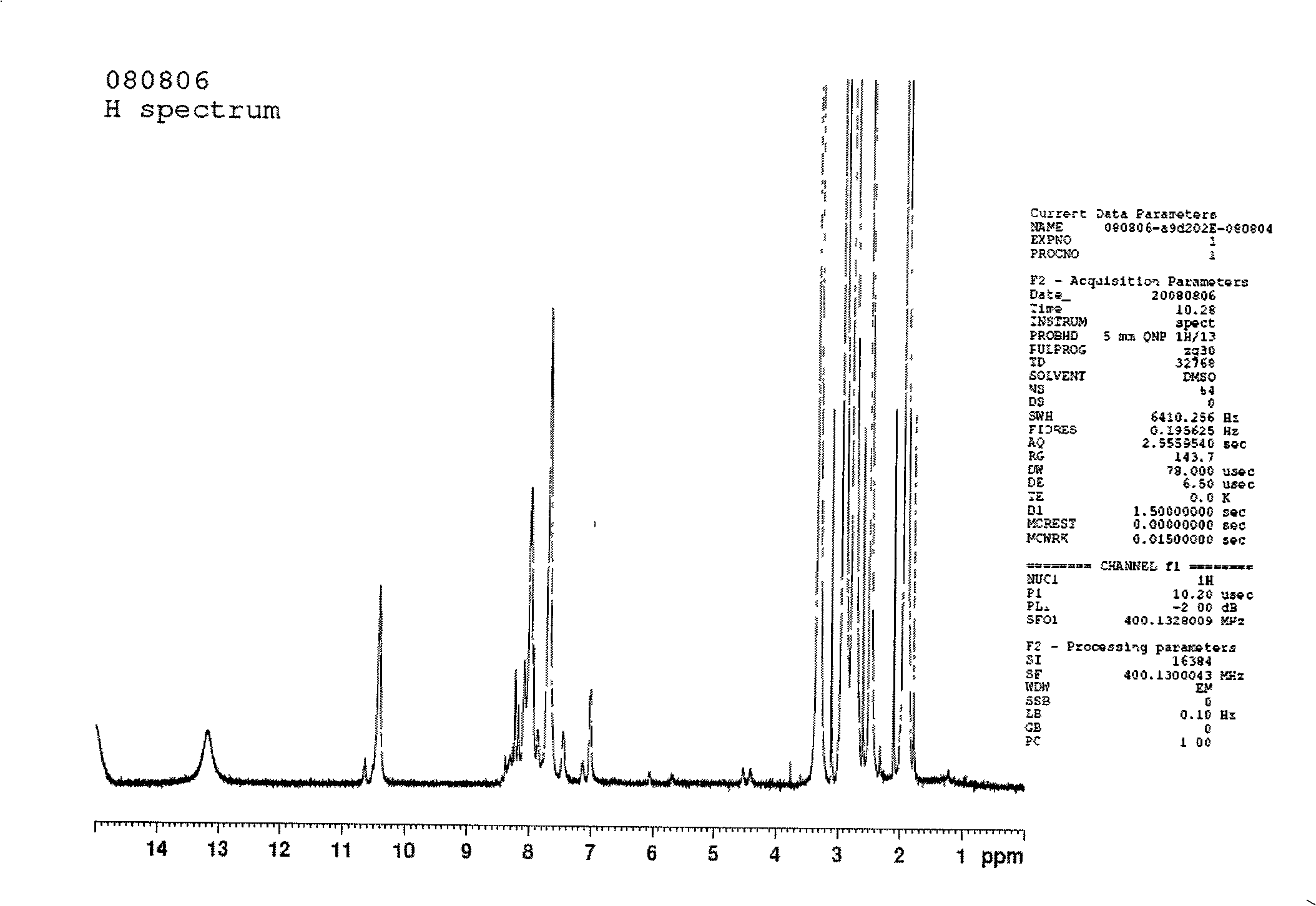

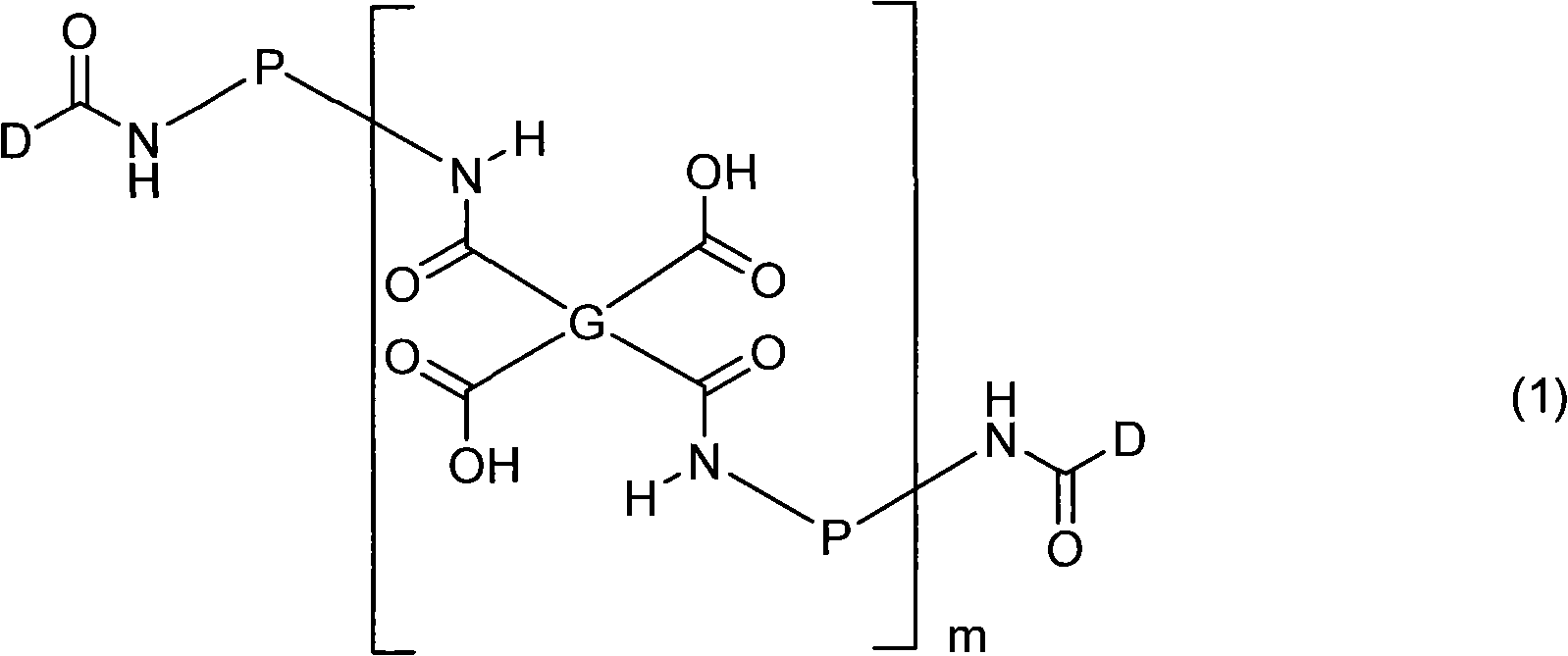

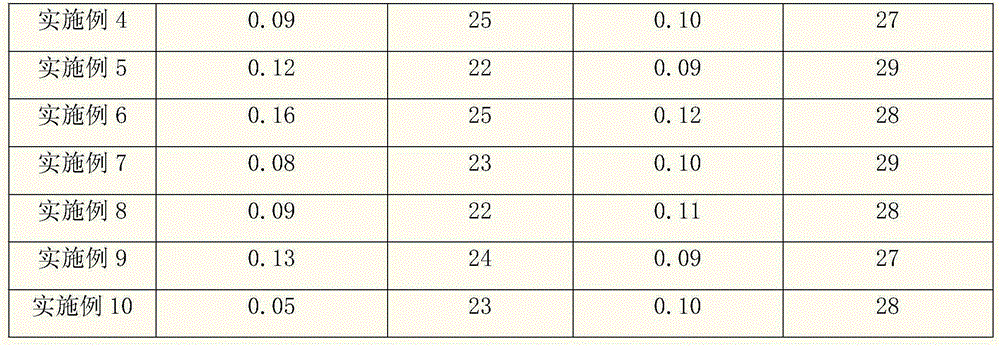

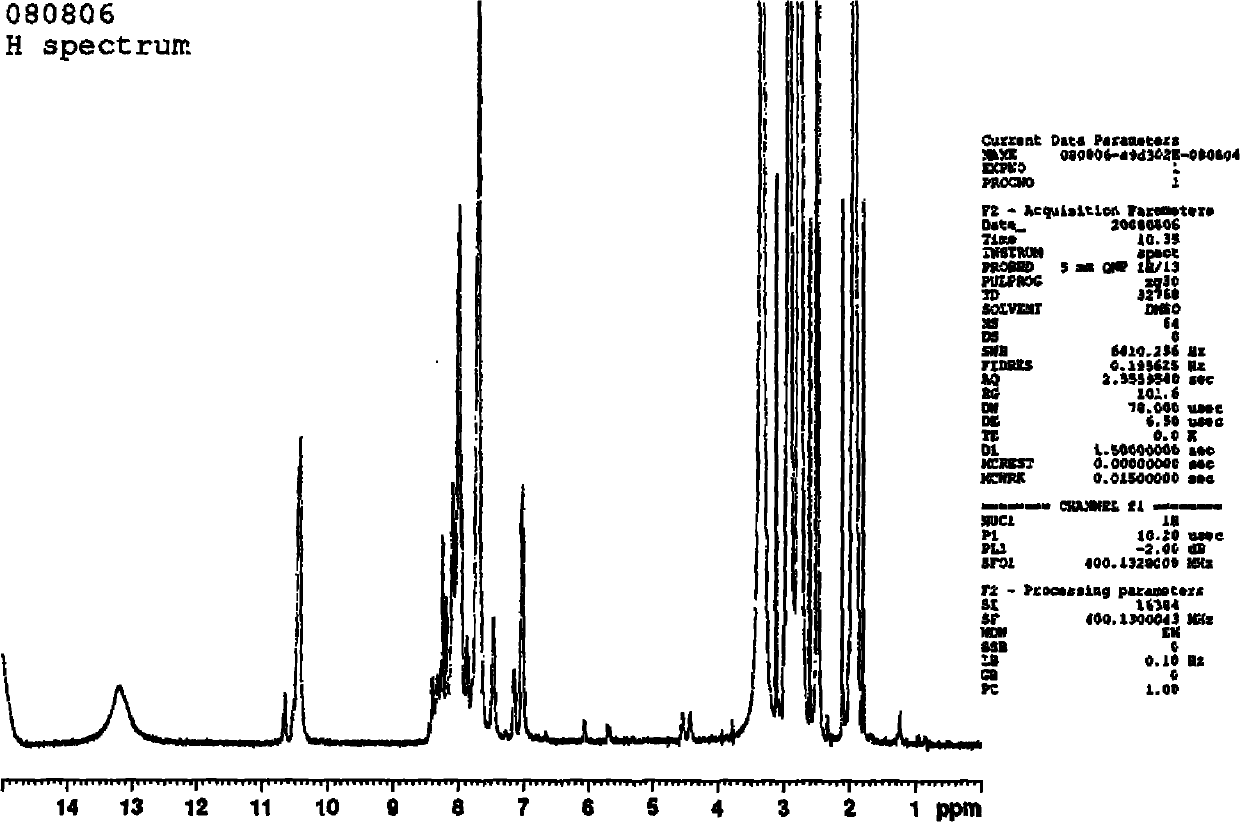

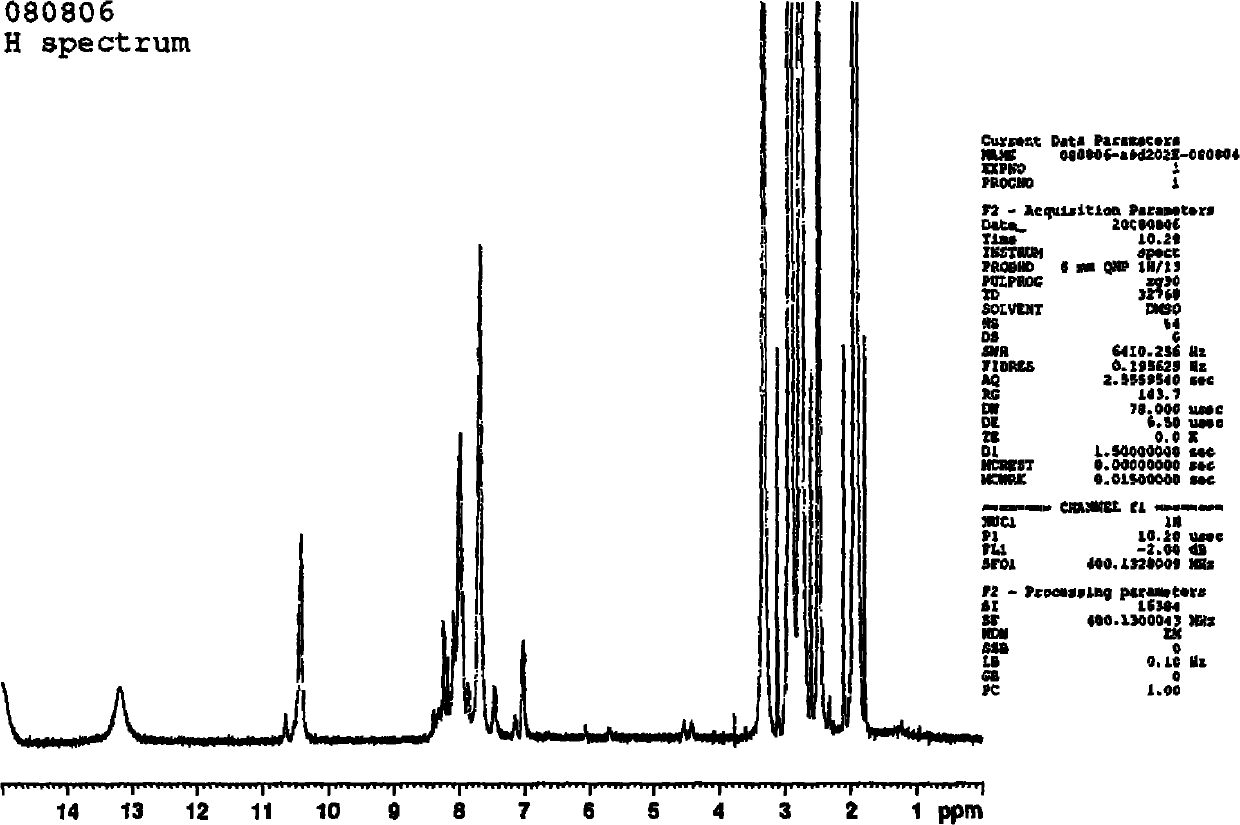

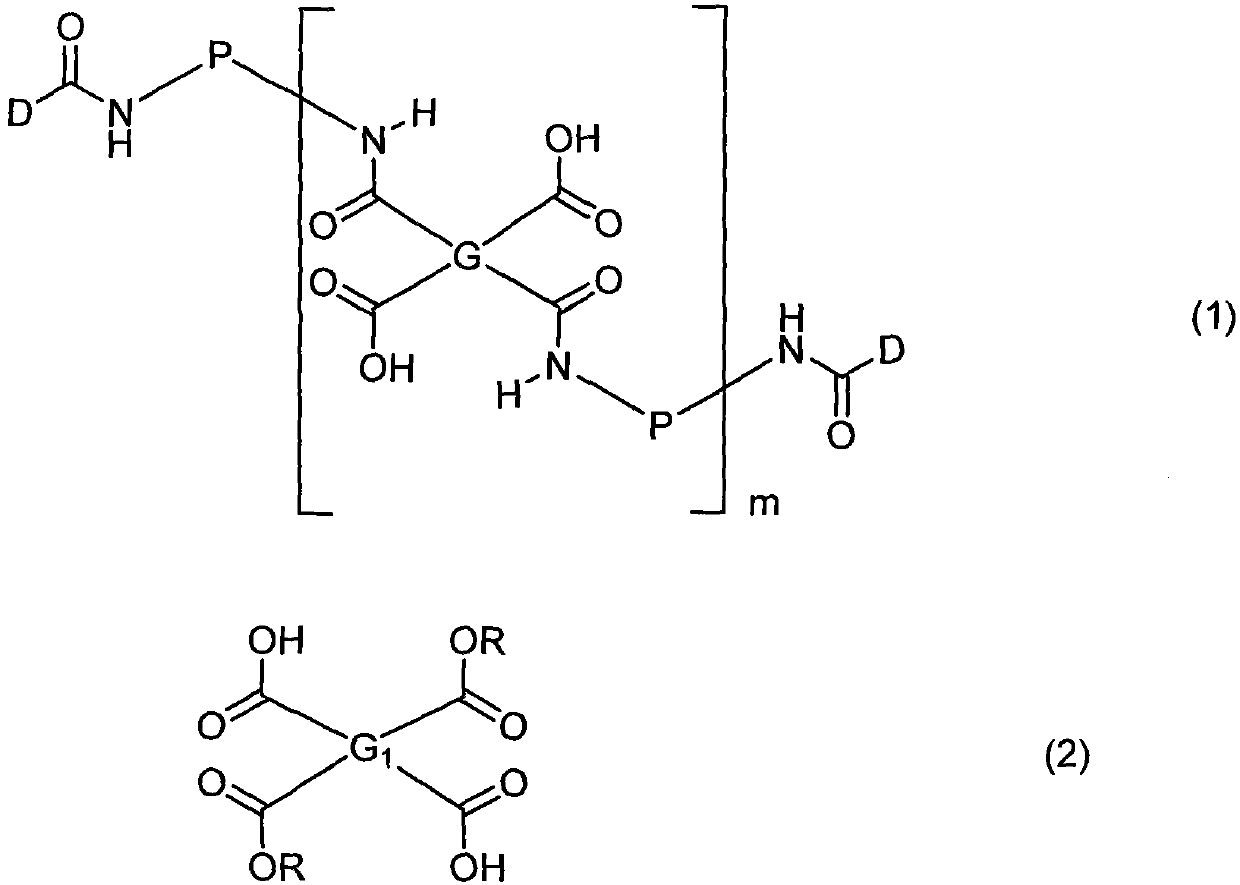

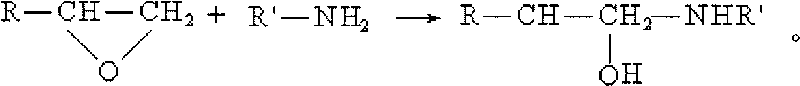

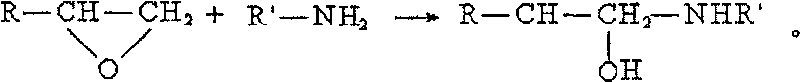

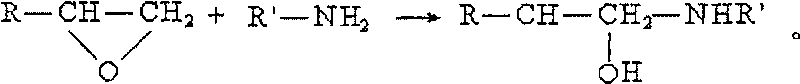

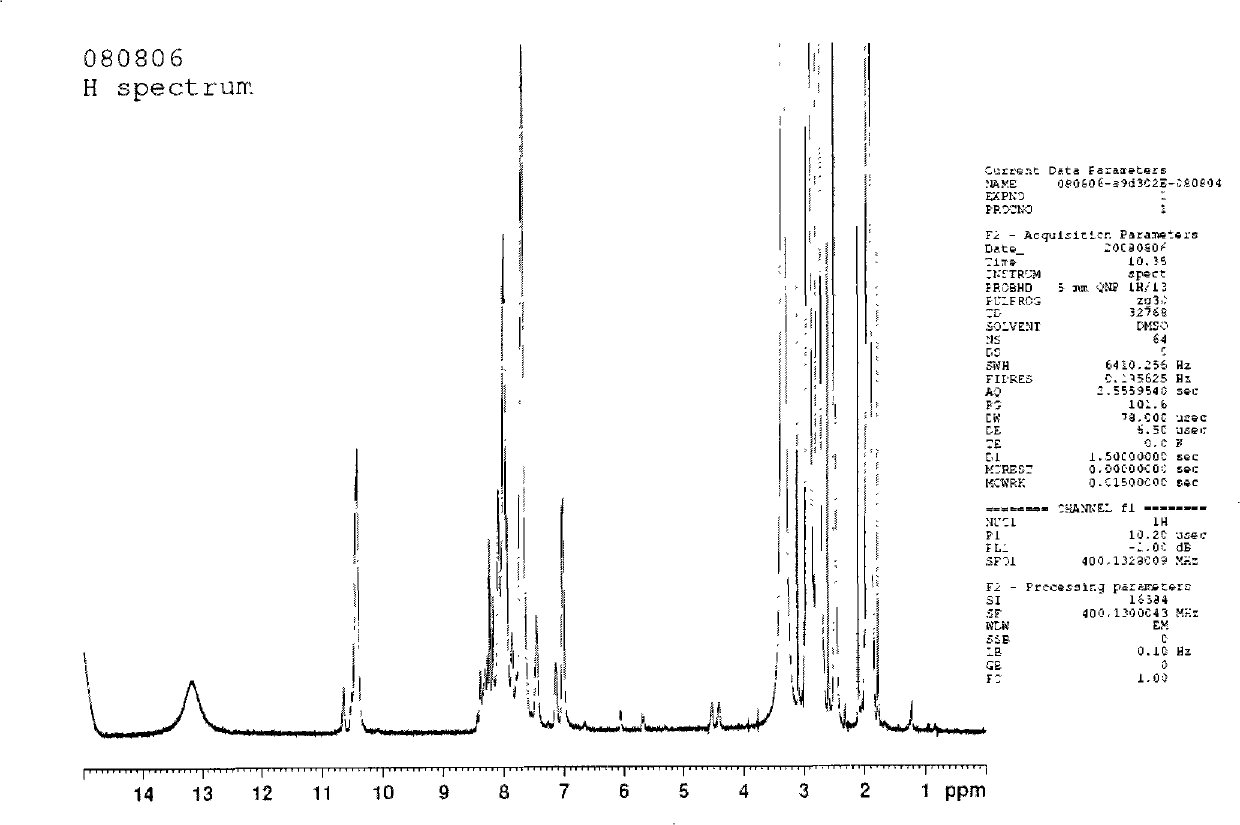

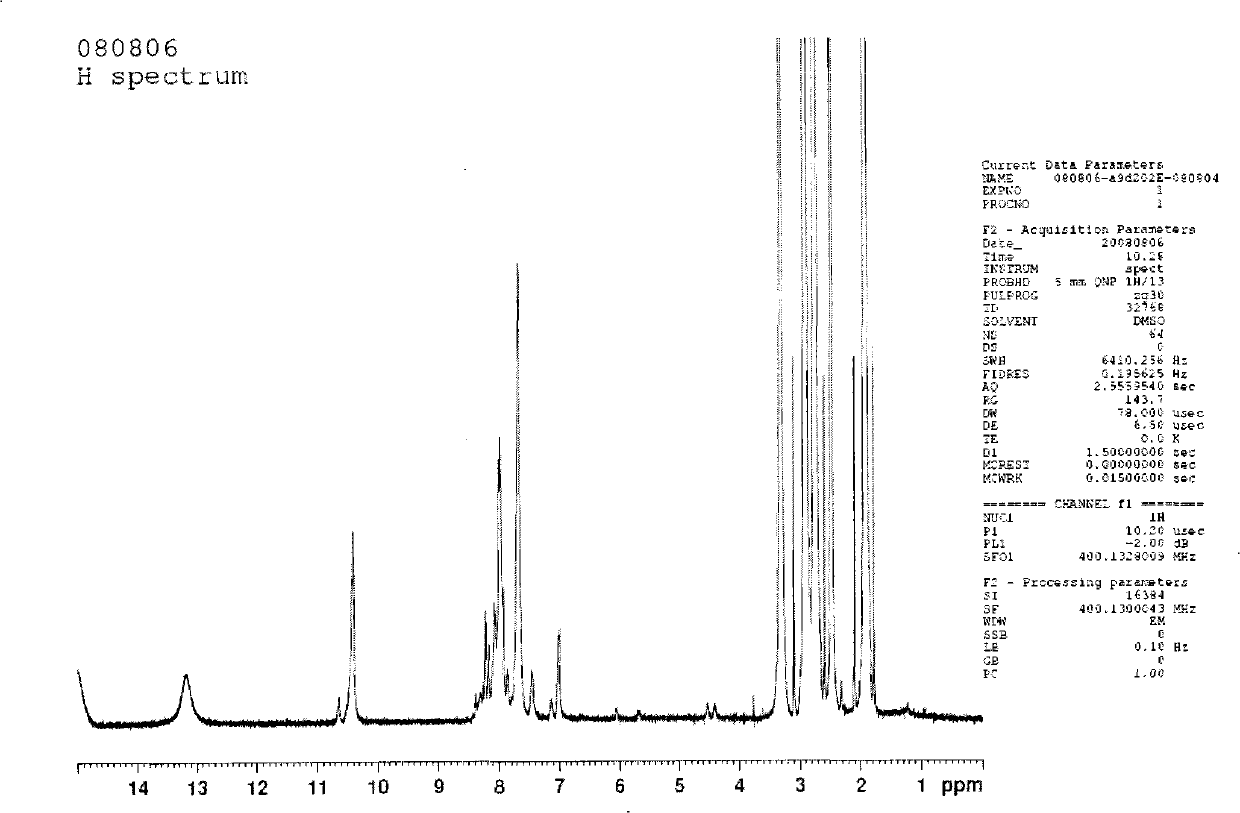

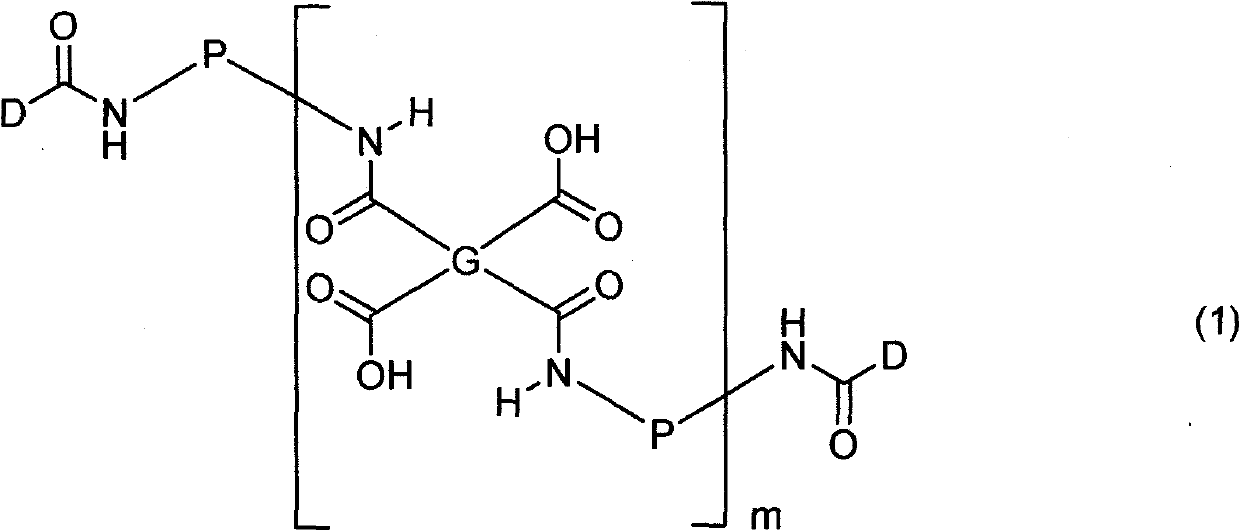

Forerunner composition of polyimide and method for preparing polyimide

The invention provides a precursor composition of polyimide and a method for preparing the polyimide. The precursor composition of polyimides contains amic acid low polymer of sentence type (I) and dicarboxylic anhydride derivative at the end with ester group (-C(O)OR) and carboxyl(-C(O)OH) of sentence type (II); wherein, R, G, G1, P, D and m are ones defined in the article. The invention also provides the polyimide synthesized by the precursor composition.

Owner:ETERNAL MATERIALS CO LTD

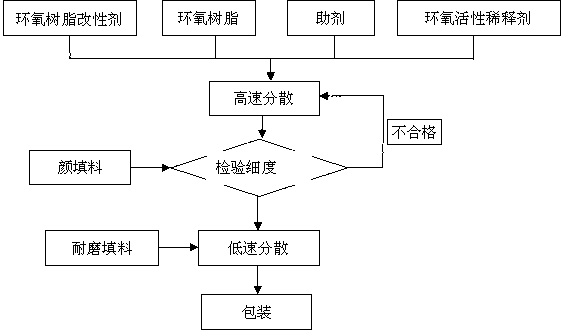

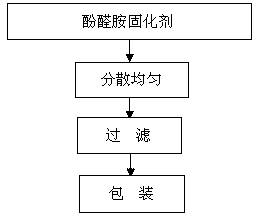

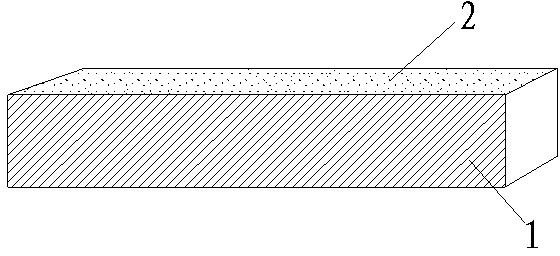

Two-component modified heavy-duty-anticorrosion epoxy mortar coating for super-thick membranization construction, and preparation method thereof

InactiveCN103275589AStrong adhesionOvercoming the complexity of the production processAnti-corrosive paintsEpoxy resin coatingsAlkaline waterPolymer science

A two-component modified heavy-duty-anticorrosion epoxy mortar coating for super-thick membranization is composed of a component A and a component B, and the component A is composed of 8-13mass% of an epoxy resin, 2-7mass% of an epoxy active diluent, 5-19mass% of an epoxy resin modifier, 0.1-0.5mass% of a wetting dispersant BYK-110, 0.1-0.5mass% of an antifoaming agent BYK-A530, 4-5mass% of a multifunctional thixotropic agent, 5-10mass% of an alkaline water absorbing agent, 10-20mass% of a wear-resistant filler, 5-15mass% of an antirust pigment filler, and 10-25mass% of a pigment filler; and the component B is a phenolic aldehyde amine curing agent. The adoption of the optimized combination of the liquid epoxy resin, the epoxy active diluent and the epoxy resin modifier in the invention realizes the compactness, strong adhesion, excellent chemical resistance and strong anticorrosion property of a coat; and the production technology of the coating is simple, so the coating can be used for the super-thick membranization construction.

Owner:XIAMEN SUNRUI SHIP COATING

Solvent-free anticorrosive coating material and preparation method thereof

ActiveCN111303729AImprove mechanical propertiesImprove water resistanceAnti-corrosive paintsPolyamide coatingsPolymer scienceWeather resistance

The invention relates to a solvent-free anticorrosive coating material and a preparation method thereof. The solvent-free anticorrosive coating material comprises a first component and a second component, wherein the first component comprises 40-60 parts of a silane coupling agent modified epoxy resin, 20-30 parts of a polyamide resin, 5-10 parts of an alkyd resin, 2-18 parts of a functional aid and 40-60 parts of a filler, and the second component comprises a curing agent. According to the invention, a resin is modified with a silane coupling agent, and the silane coupling agent and the epoxyresin are subjected to a cross-linking effect, so that the molecular weight is increased, and the mechanical property, the water resistance, the weather resistance and the like of the resin are improved; and the silane coupling agent can improve the bonding performance of the resin, and the advantages of the epoxy resin, the polyamide resin and the alkyd resin are combined, so that the characteristics of good film-forming property and high adhesive force of the epoxy resin are achieved, and the characteristics of high viscosity and good gloss retention of the alkyd resin and the characteristics of good flexibility, wear resistance, oil resistance, water resistance and chemical corrosion resistance of the polyamide resin are also achieved.

Owner:FOSHAN GREEN INTELLIGENT MFG RES INST OF XIANGTAN UNIV +2

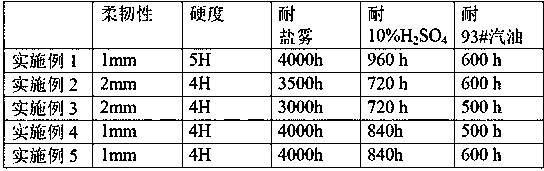

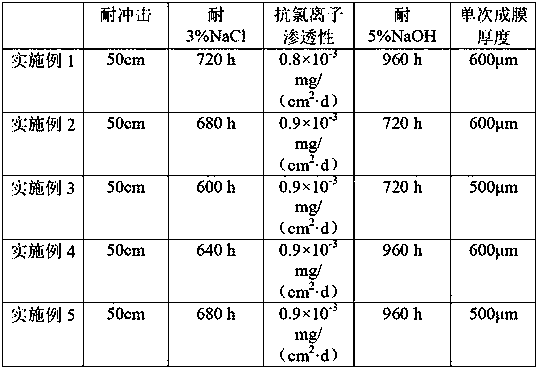

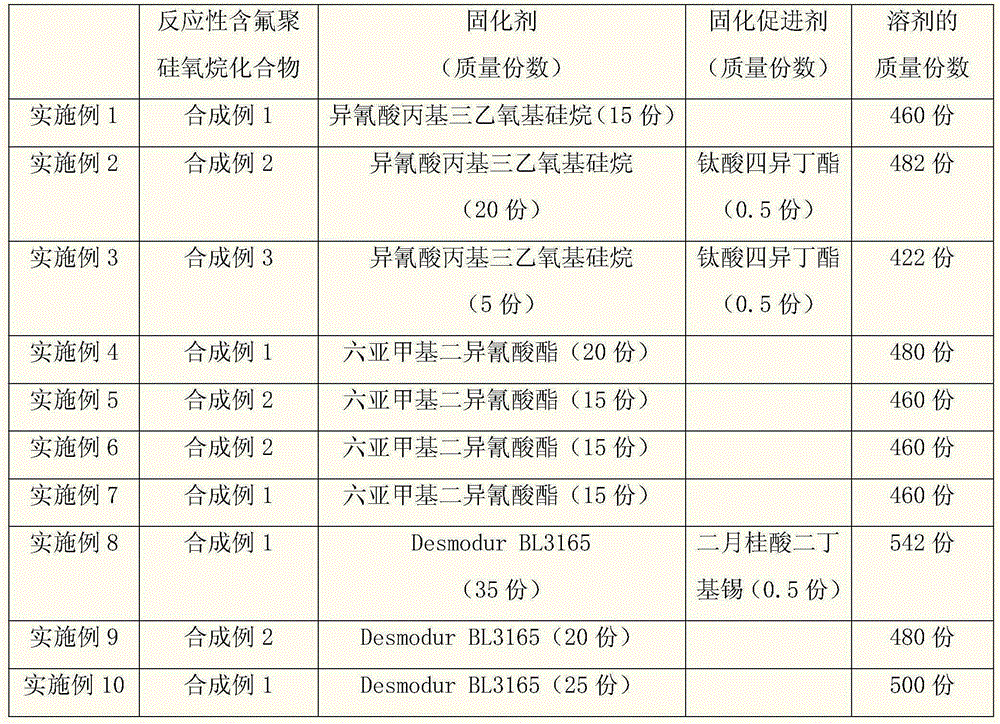

Curing-type coating composition and application thereof

ActiveCN105295723AStrong adhesionAvoid lostPolyurea/polyurethane coatingsOrganic groupFluorine containing

The invention discloses a curing-type coating composition and application thereof. The curing-type coating composition comprises a reactive fluorine-containing polysiloxane compound and a curing agent, wherein the reactive fluorine-containing polysiloxane compound is represented by a formula of R1[Si(CH3)2O]a[Si(CH3)(R)O]b[Si(CH3)(RF)O]cSi(CH3)2R2; in the formula, R is a monovalent organic group containing hydroxyl or alkoxyl silicon, RF is a monovalent organic group containing polyfluoroalkyl, R1 and R2 are CH3, R or RF respectively, and a, b and c are all positive integers from 1 to 300; the curing agent is a compound containing an isocyanate group or blocked isocyanate; the content of the curing agent relative to 100 parts by mass of the reactive fluorine-containing polysiloxane compound is 5-35 parts by mass; a curing film of the curing-type coating composition can be used as an easy-to-demould coating. The curing-type coating composition provided by the invention has the advantages that a mesh structure is formed on the substrate surface of a mould, the adhesive force is strong, the demoulding force is small, demoulding can be repeated, and the demoulding property is excellent.

Owner:宁波摩华科技有限公司

Surface coating technique of powder metallurgical parts

InactiveCN102861915AIncrease stiffnessReduce the number of coatsPretreated surfacesSolid state diffusion coatingMetallurgyCorrosion prevention

The invention provides a surface coating technique of powder metallurgical parts, wherein the method comprises the following steps of: (1) performing gas nitriding, sulfurizing and chromizing treatment on the powder metallurgical parts; (2) polishing the powder metallurgical parts treated in step (1); (3) oxidizing the powder metallurgical parts treated in the step (2); and (4) coating dopes on the powder metallurgical parts treated in the step (3). The surface coating technique provided by the invention reduces the coating times of Dacromet dopes, and the dopes are coated once to achieve a corrosion prevention effect, so that the cost is reduced, and meanwhile, the powder metallurgical parts have excellent rigidity.

Owner:WUXI HUAYUE OPTICAL MIRROR BOX CO LTD

Precursor composition of polyimide and method for preparing polyimide

The invention provides a precursor composition of polyimide and a method for preparing polyimide. The precursor composition of the polyimide comprises an acid amide oligomer which is shown as a formula (1) and a dicarboxylic anhydride derivative which is shown as a formula (2) and of which the tail end is provided with an ester group, namely (-C(O)OR) and a carboxyl group, namely (-C(O)OH), wherein R, G, G1, P, D and m are defined in the specifications. The invention also provides polyimide synthesized from the precursor composition.

Owner:ETERNAL MATERIALS CO LTD

AlMylar adhesive tape and preparation method thereof

InactiveCN107384233ASimple processMeet shading needsFilm/foil adhesivesElectrically-conducting adhesivesPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides an AlMylar adhesive tape and a preparation method thereof. The AlMylar adhesive tape comprises a surface layer, an ink layer, a black PET (polyethylene terephthalate) layer, an acrylic adhesive layer, an aluminum foil layer, a conductive adhering layer and an isolation layer from top to bottom, wherein the ink layer is prepared from the following components in parts by weight: 80 to 120 parts of ink, 30 to 80 parts of solvent, 2 to 5 parts of isocyanate type curing agent, and 0.5 to 2 parts of aids. The AlMylar adhesive tape has the advantages that the light shielding requirements of electronic products are met, and the thinning effect of the product is favorably realized; the technology is simple, and the coating amount and the coating frequency of the ink are reduced; the ink layer is firmly bonded with the black PET layer, the easiness in falling of the ink layer is avoided, and the problem of poor bonding force between the ink layer and the black PET layer in the existing multi-time coating technology is solved.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Environment-friendly epoxy glass squama antiseptic paint for steel construction protection

ActiveCN101314695BReduce harmImprove performanceLiquid surface applicatorsAnti-corrosive paintsFirming agentSolvent

The invention relates to an environment-friendly epoxy glass scale anticorrosive paint for steel structure protection, which comprises epoxy resin 22.85 to 24.65 percent, amine adduct curing agent 26.27 to 28.35 percent, modifier 1.36 to 1.85 percent, glass scales 6.20 to 8.20 percent, anti-rust pigment 8.82 to 10.80 percent, color filler 15.89 to 16.33 percent, additive and mixed solvent. The preparation method comprises the following steps: preparing a component: dispersing epoxy resin, the additive, modifier and the mixed solvent uniformly, adding color filler and glass scales, dispersing at high speed to regular fineness and mixing color; and preparing a component B: preparing amine adduct, adding anti-settlement agent and the color filter, and uniformly dispersing at high speed. During construction, the paint and the curing agent are respectively stirred uniformly, then mixed uniformly at a volume ratio, diluted by the diluting agent to adjust to the construction viscosity, and then applied for construction. The anticorrosive paint can improve the performance of heavy-duty anticorrosive coating and can better protect metal substrate.

Owner:SHANGHAI ZHENHUA HEAVY IND CHANGZHOU COATINGS CO LTD

Solvent-free epoxy heavy anti-corrosion coating as well as preparation method and application thereof

InactiveCN113025165AImprove adhesionHigh hardnessAnti-corrosive paintsPolyamide coatingsPolymer scienceSolvent free

The invention provides a solvent-free epoxy heavy anti-corrosion coating as well as a preparation method and application thereof, and belongs to the technical field of coatings. The solvent-free epoxy heavy anti-corrosion coating comprises the following components in parts by weight: 30-60 parts of epoxy resin, 20-30 parts of polyamide resin, 5-10 parts of alkyd resin, 0.5-2 parts of a dispersing agent, 0.5-2 parts of a defoaming agent, 1-3 parts of a flatting agent, 1-3 parts of an anti-settling agent, 30-70 parts of a filler, 1-2 parts of a rheological additive and 10-20 parts of a curing agent. The solvent-free epoxy heavy anti-corrosion coating disclosed by the invention combines the advantages of the epoxy resin, the polyamide resin and the alkyd resin, not only has the characteristics of good film-forming property and high adhesive force of the epoxy resin, but also has the characteristics of high viscosity and good gloss retention of the alkyd resin and the characteristics of good flexibility, wear resistance, oil resistance, water resistance and good chemical corrosion resistance of the polyamide resin.

Owner:SUN YAT SEN UNIV

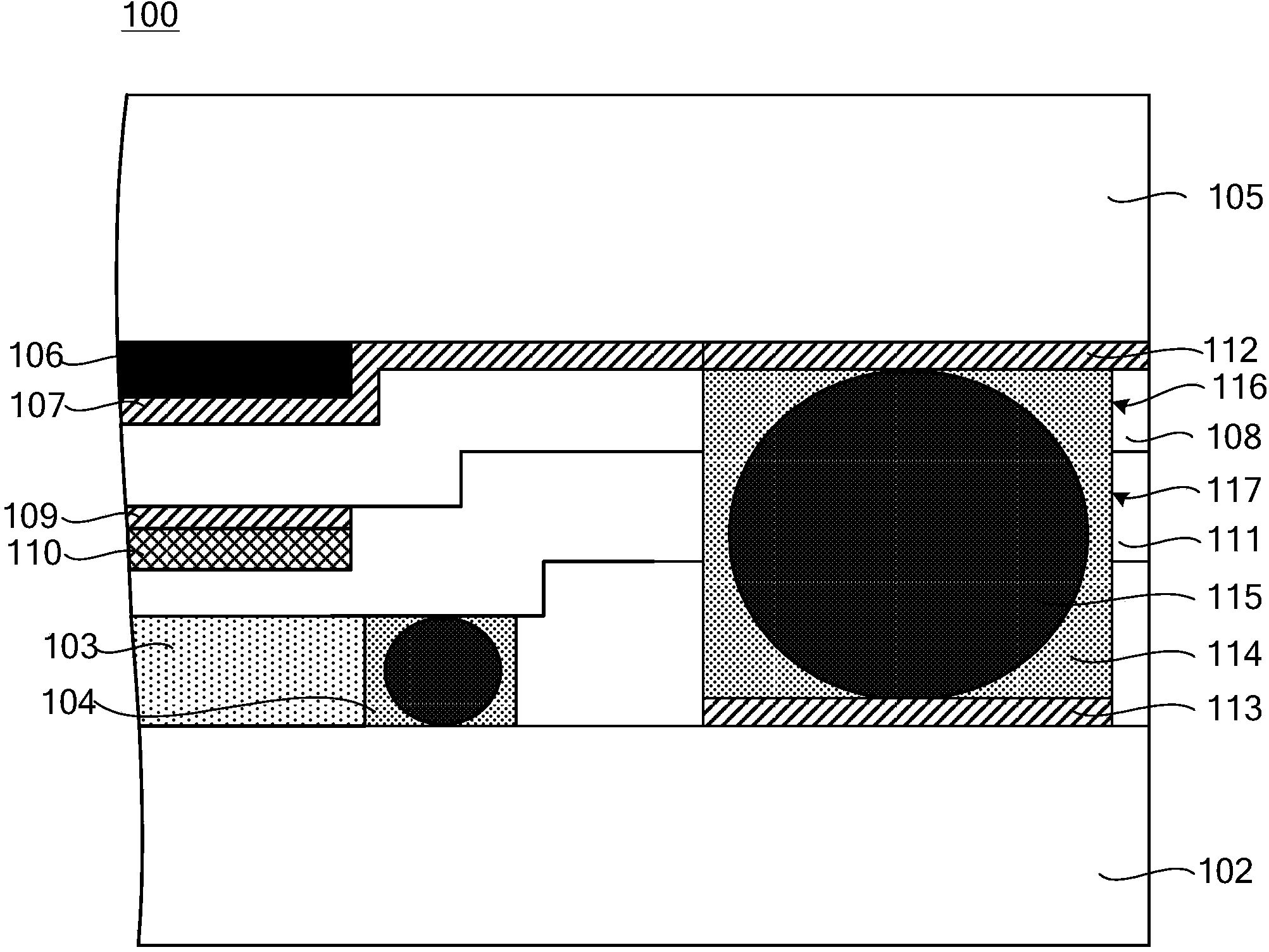

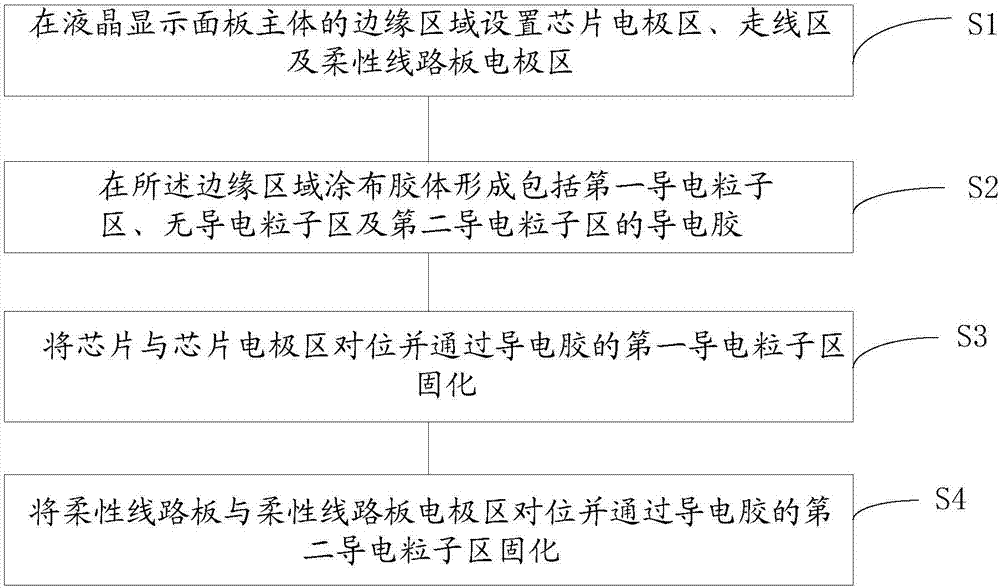

Liquid crystal display panel, press fit method thereof, and liquid crystal display

InactiveCN107015391AMeet the needs of electrical connectionsReduce the number of coatsNon-linear opticsLiquid-crystal displayFlexible circuits

The invention provides a liquid crystal display panel. The liquid crystal panel comprises a liquid crystal panel body, a flexible circuit board and a chip device, the liquid crystal panel body comprises a display area and an edge area, and further comprises a conducting gum, the edge area comprises a chip binding electrode area, a routing area and a flexible circuit board binding electrode area, the chip binding electrode area, the routing area and the flexible circuit board binding electrode area are arranged at intervals, the conducting gum comprises a first conducting particle area, an area free of conducting particles and a second conducting particle area, the particle concentration of the first conducting particle area is larger than that of the second conducting particle area, the conducting gum covers the edge area, the first conducting particle area covers the chip binding electrode area, the area free of the conducting particles covers the routing area, the second conducting particle area covers the flexible circuit board binding electrode area, the flexible circuit board is connected with the flexible circuit board binding electrode area through the second conducting particle area, and the chip device is fixedly connected with the chip binding electrode area through the first conducting particle area.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Resin composition

InactiveCN103436059AReduce construction difficultyReduce the number of coatsInksCoatingsPrinting inkChlorinated polyethylene

The invention discloses a resin composition. The resin composition comprises the following components in percentage by mass: 20%-40% of methyl styrene, 10%-20% of dicarboxylic anhydride radical, 12%-18% of isocaprylin acrylate, 11%-13% of zinc sulfide and 3%-5% of high-chlorinated polyethylene resin. Compared with the prior art, the resin composition can be used for preparing printing ink and paint, so that the construction difficulty is reduced, the time is saved, the labor is saved, the price is low, the film-forming performances and the adhesion are good, and the glossiness is good.

Owner:JIANGSU ZHONGWEI HEAVY IND MACHINERY

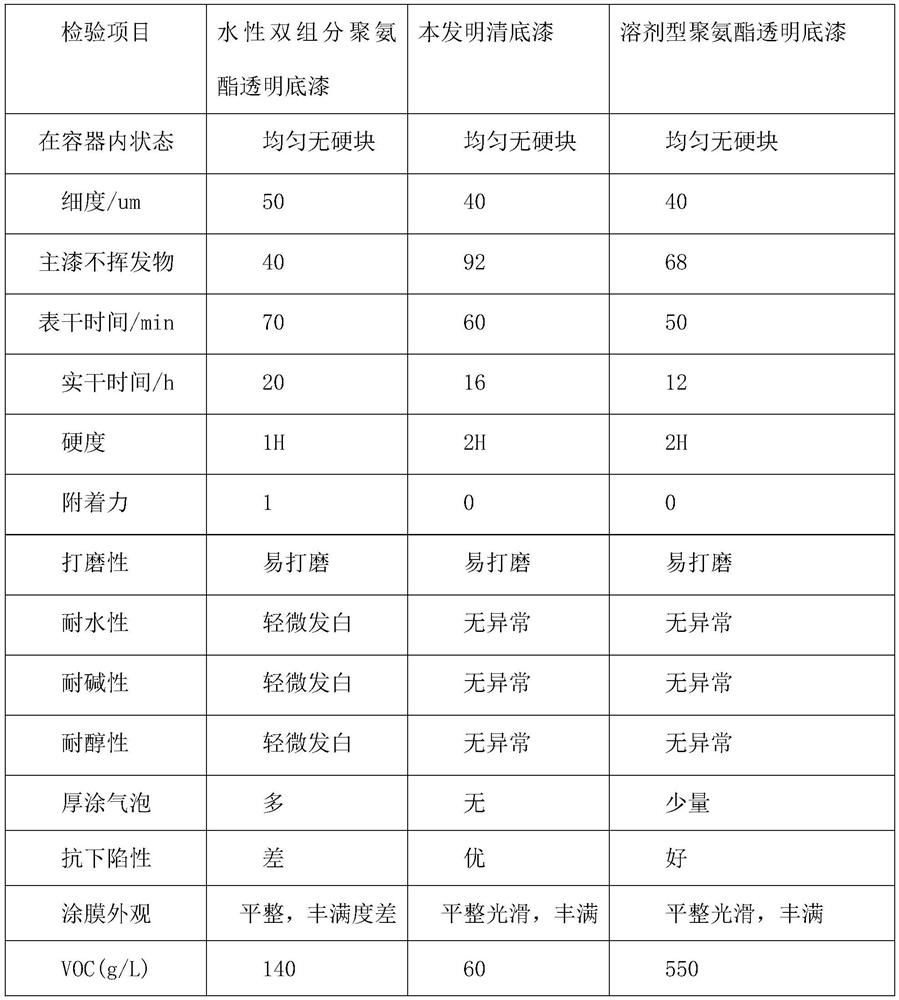

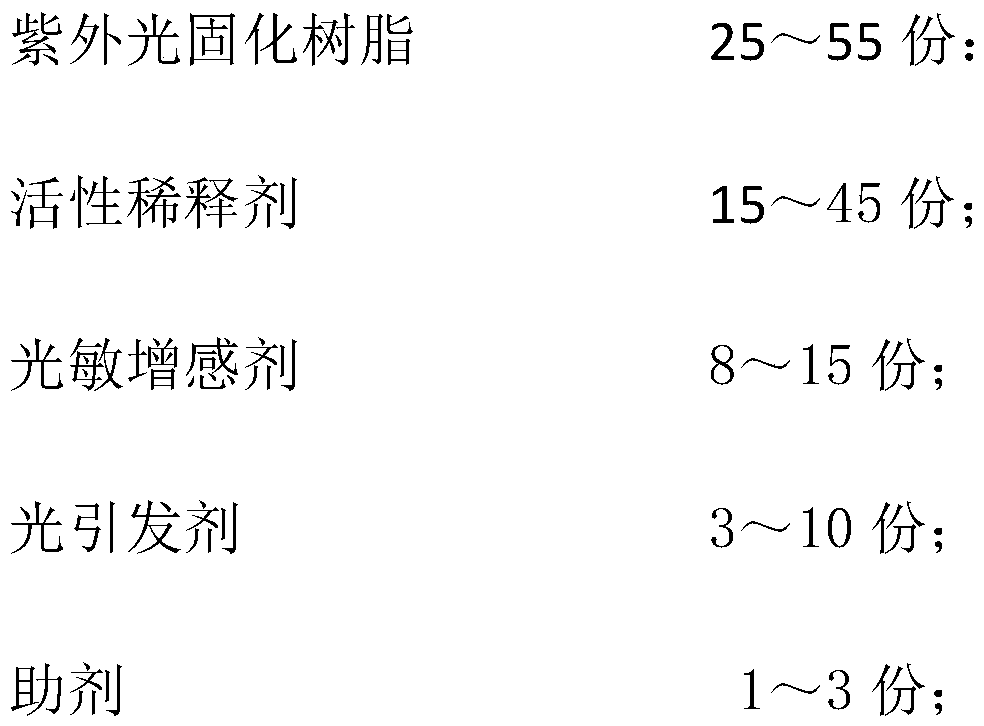

Water-based double-component thick-coating ultralow-VOC high-solid clear primer and preparation method thereof

InactiveCN113150648AGood anti-sag performanceImprove closureEpoxy resin coatingsPriming paintsFirming agentReactive diluent

The invention discloses a water-based double-component thick-coating ultra-low VOC high-solid clear primer capable and a preparation method thereof, the water-based double-component thick-coating ultra-low VOC high-solid clear primer comprises main paint and a curing agent, the main paint comprises the following components in percentage by mass: 55-70% of liquid epoxy resin, 0.2-0.4% of a dispersing agent, 0.5-1% of an anti-settling agent, 0.2-0.4% of a defoaming agent, 0.2-0.4% of a wetting leveling agent, 15-25% of filler, 8-12% of a reactive diluent and 3-8% of a cosolvent; the high-solid clear primer is high in solid content, very high in crosslinking density, relatively compact and smooth in formed film, high in hardness, excellent in transparency and filling property and excellent in sinking resistance, particularly has the advantage of no blistering in thick coating, can reduce the coating times of the primer, obviously reduces VOC emission in the coating process, and saves the coating labor cost, and thus the working efficiency of furniture enterprises is greatly improved.

Owner:安徽名士达新材料有限公司

Sand shell for casting and preparation method of sand shell

InactiveCN109746386AEasy to makeIncrease stickinessFoundry mouldsFoundry coresUltimate tensile strengthViscosity

The invention relates to a sand shell for casting and a preparation method of the sand shell. The sand shell for casting is prepared by mixing the raw materials of ammonium zirconium carbonate, zirconium dioxide and a penetrating agent, coating and other technologies. The sand shell has the beneficial effects that the sand shell for casting is simple in preparation, gas permeability is good, performance is stable, viscosity is good, and the cost is low; and a sand component is bound by metal wires and then coating is conducted, and therefore strength of the sand shell can be improved, coatingtimes of the sand shell are reduced, and the preparation cycle of the sand shell is shortened.

Owner:温州恒得晟钛制品有限公司

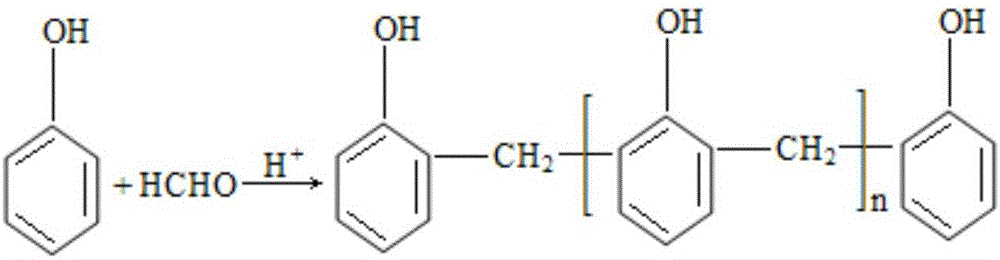

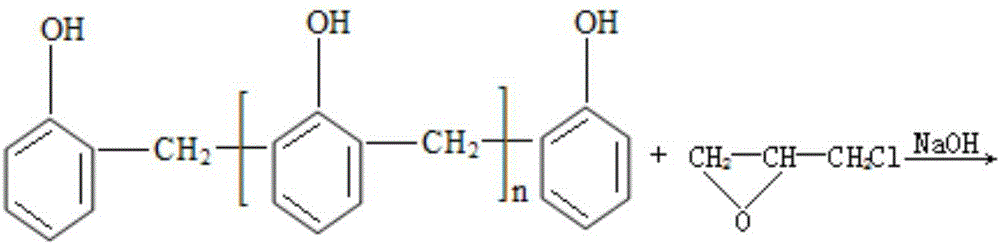

Damp-heat-resistant acid-resistant paint by using isocyanate for curing novolac epoxy resin

InactiveCN106010139AMake up for hard and brittle weaknessesImprove heat and humidity resistance and acid resistanceFireproof paintsAnti-corrosive paintsEpoxyToluene diisocyanate

The invention discloses a heat-resistant and acid-resistant paint using isocyanate to cure Novolac epoxy resin, which is composed of component A and component B; the component A is composed of the following components by weight: 30-40 parts of NOVOLAC EPOXY resin, 10-20 parts of xylene, 4-6 parts of butyl acetate, 0.2-0.4 parts of dispersant, 10-18 parts of coloring pigment, 8-10 parts of superfine barium sulfate, 5-6 parts of sericite 6 parts, 10-12 parts of mica iron oxide, 1-3 parts of chromium oxide green, 1-2 parts of cobalt blue, 0.4-0.7 parts of anti-settling agent, 0.3-0.6 parts of catalyst, 0.2-0.7 parts of leveling agent, defoaming 0.2-0.5 part of agent; said component B is TMP-TDI adduct or HDI trimer; the weight ratio of component A and component B is 2-3:1. The moisture-heat-resistant and acid-resistant paint prepared by the invention has excellent performance and can meet the anticorrosion requirements of automatic production equipment for silica gel.

Owner:青岛乐化科技有限公司

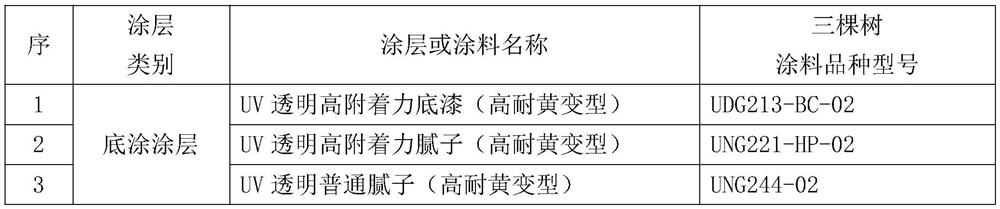

Preparation method of simulation wood grain three-dimensional decorative household board

ActiveCN114434998AIncrease production costGood value for moneyDuplicating/marking methodsPattern printingSurface coatingWood grain

The invention relates to a preparation method of a simulation wood grain three-dimensional decorative household board. The preparation method comprises the following steps: preparing a simulation wood grain digital color pattern standard image and a simulation wood grain digital black and white pattern standard image; standardizing the decorative surface of the base material; coating a base coating on the decorative surface; coating a color coating on the prime coating by using the simulation wood grain digital color pattern standard image; coating a floating coating on the pattern coating; the floating coating is coated with a reaction type UV transparent 3D primer coating; and a reaction type 3D ink coating is jet-printed on the position required by the liquid and uncured reaction type UV transparent 3D primer coating by using the simulated wood grain digital black and white pattern standard image, so that the reaction type UV transparent 3D primer and the reaction type 3D ink react to finally form a concave-convex effect layer, and the surface coating is coated on the obtained coating. The artificial wood grain three-dimensional decorative plate has a better artificial wood grain three-dimensional decorative effect, and the production process is simple, easy to implement, high in production efficiency and low in production cost.

Owner:小森新材料科技有限公司

Anticorrosive and antibacterial organosilicone resin coating and preparation method thereof

InactiveCN108610717AShorten construction timeReduce oversprayAntifouling/underwater paintsPaints with biocidesEpoxyFiber

The invention discloses anticorrosive and antibacterial organosilicone resin coating. The anticorrosive and antibacterial organosilicone resin coating is prepared from the following raw materials in parts by weight: 20-30 parts of epoxy modified organosilicone resin, 15-18 parts of a graphene / polypyrrole complex, 5-7 parts of silver-loaded silicon dioxide, 2-7 parts of nanometer titanium dioxide,6-10 parts of montmorillonite, 8-12 parts of carbon fiber, 8-12 parts of nanometer calcium carbonate, 10-15 parts of wet sericite, 3-8 parts of a bactericide, 25-35 parts of softened water, 2-5 partsof a thickener, 2-7 parts of a dispersant, 2-6 parts of a lubricant and 1-3 parts of a film-forming aid. The organosilicone resin coating is non-toxic and tasteless, does not produce irritating odor on the surface of a coating film during construction and after construction, has no impact on a human body, and is environment-friendly and safe; the construction time can be shortened, over-spraying is reduced, and a maintenance technology is greatly simplified; in addition, the preparation method is simple; the organosilicone resin coating has good sterilization, anticorrosion, elasticity, flexibility, water resistance and water-proof performance.

Owner:TONGCHENG HUIQI IND & TRADE

Disposable PP paint

The invention discloses a disposable PP (Propene Polymer) paint which comprises the following components: 25%-35% of chlorine modified thermoplastic acrylic resin, 5%-15% of hydroxy acrylic resin, 0.5%-1% of polymeric dispersant, 18%-25% of titanium dioxide, 3%-5% of xylene, 10%-20% of talcum powder, 1%-3% of modified polyester containing a special functional group, 5%-8% of methylbenzene, 5%-8% of methyl isobutyl ketone, 0.5%-1% of acrylic acid modified chlorinated polyolefine, 2%-4% of chlorinated copolyalkenamer, 1%-5% of propylene glycol monomethyl ether acetate (PMA), and 3%-6% of CAB cellulose. The disposable PP paint is excellent in water resistance, levelling property and adhesive force, can be directly coated on a PP material, and is safe and environmentally friendly, the performance is excellent, and the range of application is wide.

Owner:SHENZHEN YONGSHENGHUI IND

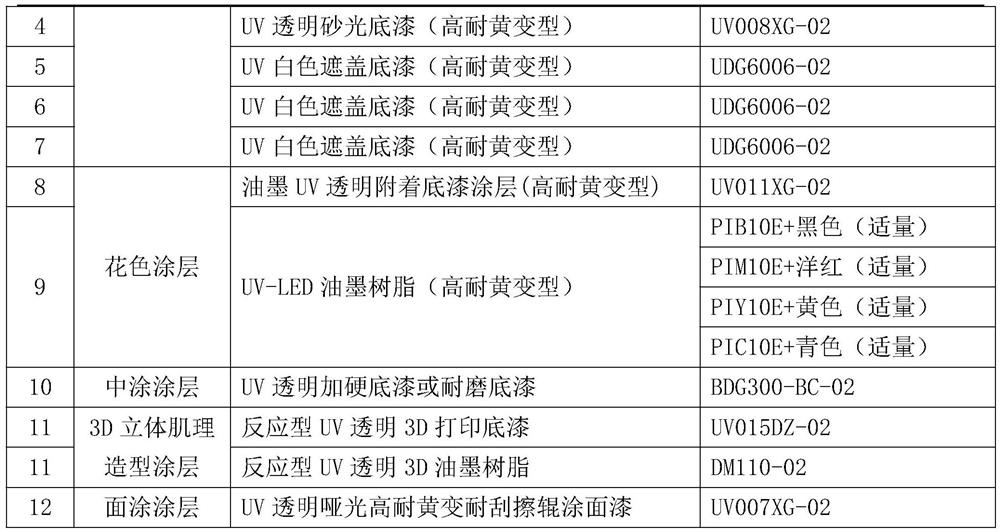

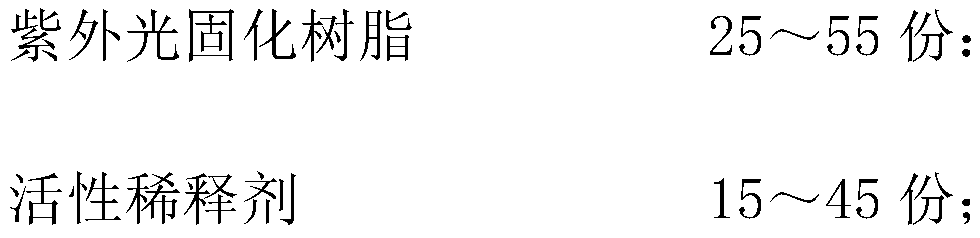

UV special release coating for PET or BOPP film and preparation method thereof

InactiveCN111440466AIncrease the degree of cross-linkingGood flexibilityCoatingsAcrylic resinPaperboard

The invention discloses a UV special release coating for a PET or BOPP film and a preparation method thereof. The release coating is prepared from the following components in parts by weight: ultraviolet curing resin is prepared by mixing modified epoxy organic silicon acrylic resin and pure acrylic resin. Through polymerization reaction among the components, a coating substrate is formed to adhere to a film; the reactive diluent enhances the crosslinking degree of the release coating so as to improve the flexibility and adhesive force of the coating, and the assistant improves the leveling property of the coating, so that the coating matrix has a flat surface, and the aluminum layer is completely stripped from the film. The durable frequency of the coating on the film is increased by 2-3times, the coating frequency is reduced, the production efficiency is improved, and the problem of low production efficiency of the vacuum aluminized paperboard due to the fact that the performance ofthe existing release coating is not suitable is solved.

Owner:广东博海化工科技有限公司

An embedded touch screen color film substrate and manufacturing method thereof

ActiveCN103984145BReduce the number of coatsShorten coating timeNon-linear opticsInput/output processes for data processingOrganic filmOptoelectronics

The invention discloses an embedded touch color filter substrate and a manufacturing method thereof. The embedded touch color filter substrate includes: a substrate including a plurality of display areas and a plurality of non-display areas surrounding the display areas; a first metal layer, a first organic A film layer, a second metal layer and a second organic film layer, the second metal layer includes a plurality of conductive pads arranged in the non-display area; wherein, the first organic film layer in the non-display area is formed There are a plurality of through holes or through grooves through which the conductive pad is electrically connected to the first metal layer, and the conductive pad is exposed outside the second organic film layer. The use of the embedded touch color filter substrate of the present invention can effectively shorten the coating time of the frame sealant, thus greatly improving the production efficiency.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

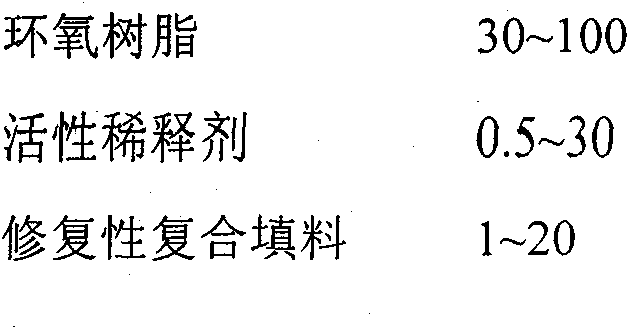

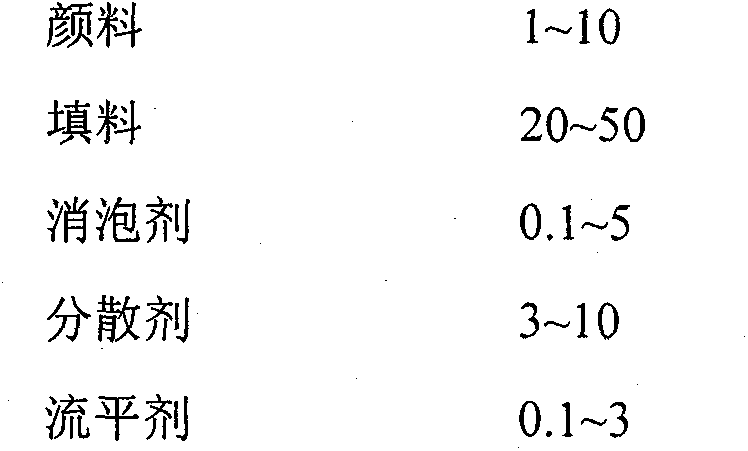

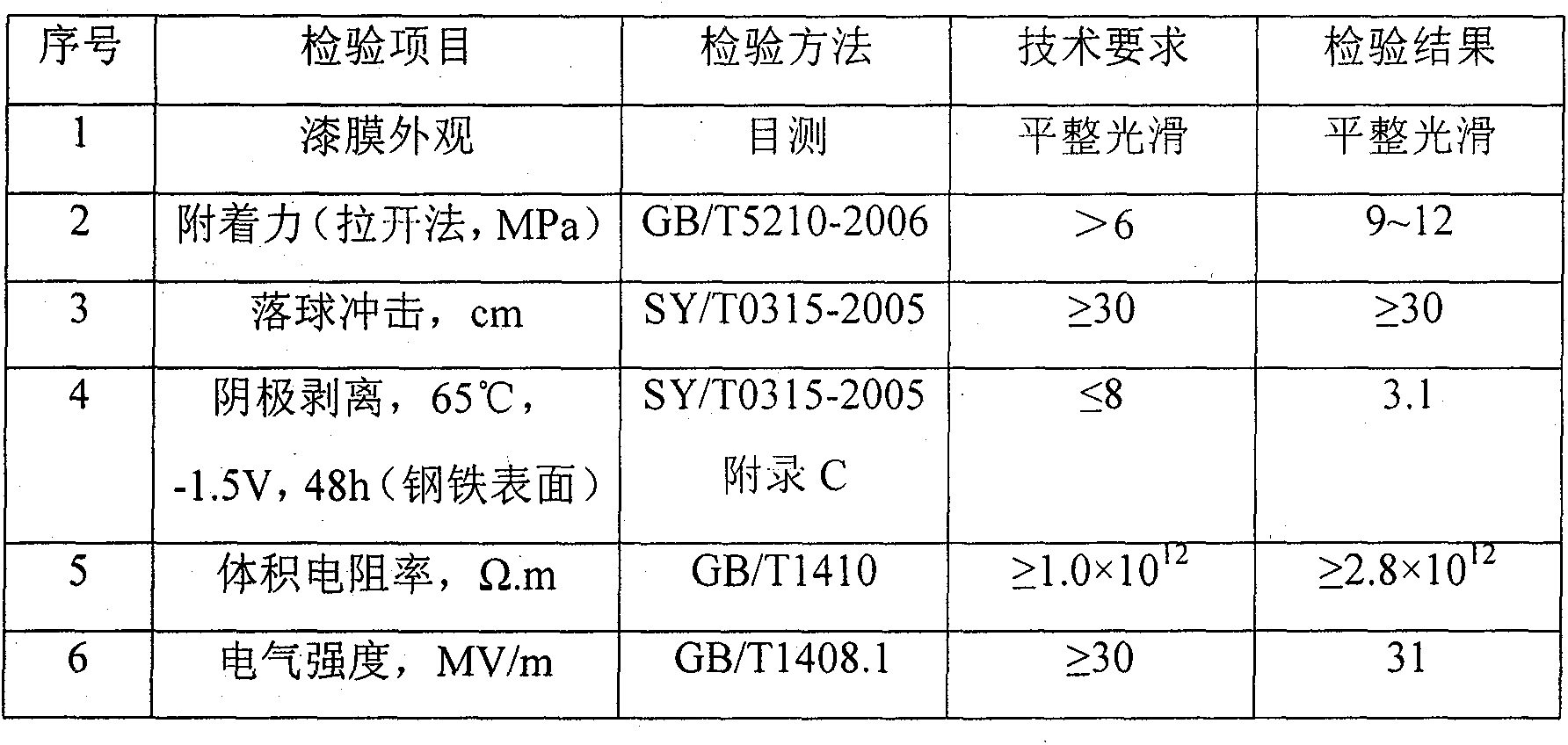

Solvent-free epoxy anticorrosion paint with corrosion restoration function and preparation method thereof

ActiveCN102382550BStrong adhesionImprove compactnessAnti-corrosive paintsEpoxy resin coatingsSolvent freeFirming agent

The invention provides a solvent-free epoxy anticorrosion paint with the corrosion restoration function and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises, by weight, 30-100 parts of an epoxy resin, 0-30 parts of an active diluent, 1-20 parts of a restoration composite filler, 1-10 parts of a pigment, 20-50 parts of a filler, 0.1-5 parts of an antifoaming agent, 3-10 parts of a dispersant and 0.1-3 parts of a leveling agent; and the component B comprises, by weight, 0.5-100 parts of an amine curing agent and 0.5-20 parts of the active diluent. The solvent-free epoxy anticorrosion paint with the corrosion restoration function of the invention, which can be applied to facilities and parts of water conveying pipelines, steel and aluminum ships, bridges, offshore petroleum platforms, wharf facilities, airplane sheathes and the like, has a strong anticorrosion performance and a solution penetration resistance, has a restoration effect on defect parts of scores, scratches and the like, and can restore anticorrosion-deteriorated coatings and metals under the coatings when the coatings are used.

Owner:哈尔滨工程大学船舶装备科技有限公司

Forerunner composition of polyimide and method for preparing polyimide

The invention provides a precursor composition of polyimide and a method for preparing the polyimide. The precursor composition of polyimides contains amic acid low polymer of sentence type (I) and dicarboxylic anhydride derivative at the end with ester group (-C(O)OR) and carboxyl(-C(O)OH) of sentence type (II); wherein, R, G, G1, P, D and m are ones defined in the article. The invention also provides the polyimide synthesized by the precursor composition.

Owner:ETERNAL MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com